Download Sears OVERLOCK 385. 564180 Owner`s manual

Transcript

OWNER'S

MANUAL

OVERLOCK

MODEL 385.

3j4

564180

Dear Customer:

You

have just

instructions

invested

Specific

instructions

expense

tor conditions

Advtce

in a very

on how to operate

on tile

or need parts

Safety

fine

overtock.

and care for your

are gLven on threading,

beyond

operation

using

your

new

Kenmore

machine,

please pause for a moment

and carefully

read this

booklet

which

tension

adjustments,

cleaning,

oiling,

etc.

This will

help you

obtain

the best sewing

results

and avoid

unnecessary

always

mention

machine

is always

the model

number

available

at your

nearest

and serial number

when

Sears Retail

you

Store.

Please remember,

if you have questions

about

your

inquire.

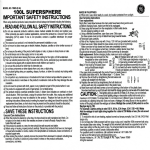

Cautions:

e

Be sure that

e

Disconnect

the electrical

the power

This efiminates

e

All covers

e

Do not pull

e

Before

e

e

voltage

supply

must be closed

the fabric

cleaning

your

machine,

Do not

attempt

to adjust

Handle

the foot

control

e

Closely

watch

e

Use only

disconnect

by accidentally

as this may deflect

the power

belt.

Contact

care and avoid

the area being sewn to avoid

to lift

is the same as the rated

changing

needles,

pressing

presser foot

the foot

voltage

of the motor.

or needle plate,

or when

control.

the machine.

are stitching

the motor

with

when

the machine

operating

you

(wall receptacle)

from the wall outlet

of sta_ing

when

while

of the wall outlet

plug

the possibility

the handle

contains

service

our control.

and care of your

and service,

Before

machine.

your

dropping

injuries

supply

the needle,

plug from

nearest

Service

it on the floor.

from

needles

causing

it to break.

the walt outlet.

Center should

any adjustment

Be sure not to place anything

be required.

on top of it.

and knives.

and move the machine,

Kenmore Overiock

Record in space provided below the model number and serial

number of this appliance. The model number and serial number

are located on the nomenclature plate, as identified on Page 3 of

this booklet.

Model No, 385,

Serial No.

Retain these numbers for future reference.

leaving

the machine

unattended.

machine

TABLE

SECTION

1.

KNOW YOUR MACHINE

Locate and Identify the Parts ...............

Identify the Accessories .....................

SECT! ON

2.

OFCONTENTS

PREPARE YOUR MACHINE

Attaching

the Presser Foot ....................

Changing Needle ...........................

To Disengage the Upper Knife ..................

To Engage the Upper Knife

......................

Types of Needle Plates .......................

Changing the Needle Plate

.....................

Thread and Needle Chart

...................

3_4

4

FOR SEWING

Plug in the Machine and Switch on the Power

Foot Control Use ....

......................

How to Turn Hand Wheel .......................

....

Opemng and Closing the Side Cover ................

Opening and Closing the Looper Cover .............

The Position of Thread Guide Bar

...............

6

6

7

Attaching

the Spool Cap

Raising or Lowering

the

Threading

the Machine

e Threading

the Lower

e Threading

the Upper

e Threading

the Needle

e Threading

the Needle

7

8

and Net ...............

Presser Foot

...............

.....................

Looper

...............

Looper .............

on the Right ...........

on the Left

............

Rolled Hemming,

Picot Edging and

Narrow Hemming

........................

Decorative

Overedging

..................

Pin Tucking

..............................

5

5

6

SECTION

4.

SECTION

SECTION

3.

LEARN

THE

32_34

35

36

CARE FOR YOUR MACHINE

Cleaning Upper Knife Area ..................

Cleaning the Feed Dog .....................

Replacing the Light Bulb ....................

Oiling the Machine

..........................

Replacing the Upper Knife ...................

9_17

t0_11

12"13

14_15

t6_17

5.

27

28

29

29

30

30

31

PERFORMANCE

PROBLEMS

37

37

38

39

40

CHART

STITCHES

What to Do When

Starting Sewing ........................

Finishing Sewing ...........................

Sewing Continuously ........................

Securing Ends ...........................

Thread Tension (4 threads) ...................

Threading the Machine (3 threads) ................

Thread Tension (3 threads) ...................

Adjustment of Stitch Length ...................

Adjustment of Foot Pressure ...................

Removing the Presser Foot .....................

18

!8

18

19_20

21"_23

24

24_25

26

26

27

PARTS

LIST

INDEX

Specification

........................

........................................

4t

42

............................................

43

of the Machine

44

..............................

Thread guide bar

Carrying handle

Face plate

\

Right needle

thread tension dial

-Stitch tength

dial

Thread guide

Spool pin

Thread

thread

take-up

Spool holder

lever

gude

Let[ needle

thread tension

Spool stand

dia!

Need le

thread guide

Rigilt needle

tllread guide

NomencLature

Side cover

Upper looper

thread guide (t)

Upper looper thread

tension dial

Plug

connector

Lower looper

thread gude (1)

Power switch

Lower looper thread

tension dial

Looper cover

Hand wheel

Looper thread

guide

Foot control

plate

Needle

clamp

Upper

knife

Needle

ptate

screws

Needle bar thread guide

Needle clamp

Presser foot

Needle plate

/

Foot holder

Upper looper

set screw

Upper looper thread guide

Knife

holder

Screwdr _vers

Lower looper

QQ

QQ

Upper looper

thread guide (2)

knife

Lower

thread

"!_

Lower looper

thread guide (2)

Spool

/

Tweezers

Looper

threader

caps

looper

guide 14)

Lower

thread

looper

guide (3}

Set of

need les

Thread

cutter

Rolled hemming

needle plate

Needle bar

0

Presser foot

lifter

Presser bar

Foot holder

set screw

Nets

Lint

Lower looper

thread gutde (5}

Upper

knife knob

Accessory

box

brush

supply

_

_

_

J_w_

_

_t_

_

_

h

Swit_

_d

_a

chrin_

a

_M

i_

_

_

i_

_

_IU_

_r

Power

plug

supply

Power

/

switch

Foot control

J

4.

conneCtOr

Your

inserting

machine,

be

the

sure

plug

the

into

power

your

switch

is

OFF,

Check

Volt

2,

insert

plug

your

outlet

to be sure it is a 110to

120

machine

connector,

|nsert

outlet.

the

power

will

light/power

switch

interrupted

or

light/power

switch

not

Is turned

stop

sewing,

to

regulates

To increase

speed,

ball

foot.

of your

plug

as shown,

into

the

_t wilt

supply

plug

gently

unless

the

To "decrease speed,

If you

are

stightty.

on,

turn

prevent

control

the

speed at which

you sew,

light.

operate

The foot

off

the

injury

to

NOTE:

The

foot

wilt

press down

release

your

control

increase

or

foot

with

is sensitive

decrease

speed immediately.

Practice

three-prong

sewing

your

only

needs.

fit one

_nto

the

wall

to

and

your

to reguiate

speed

the

pressure

on a scrap of fabric

way.

3.

to turn

sewing

AC out_et.

the

and sewing

switch

FEATURE:

machine

children.

1,

and power

plug

SAFETY

Before

light

on the power

Machine

Power

switch

NOTE:

Push the

taste

your

and

¸¸,

Side

_eel

Looper cover

Always

turnhandwheeltowardyou.

To open:

To open:

Push the side cover to the left.

While

pushing

with

it will

go, pull

looper

the thumb

to the right

cover toward

as far as

you.

To close:

Push the side cover to the right and slightly toward

the mach}ne body,

For Your

Safety:

Always

close both

machine

is in use.

side and looper

covers

when

the

To close:

Lift looper cover and push against the machine.

The looper cover snaps into the position automatically,

• v ":: :: ! =i::_:L•¸": •:i/>;: ?i:¸ :! • ••i_•LI/h :¸" _'_•i':'_ ,:i::•j!:j ii:¸ >!:i::

The Position 0fThread

:-:•7_:••:• :•_ _" :

•/:=::-•

GuideBar

e bar

Spool cap

|Thread

gutde

|

i

I I1"_ _!

1

,

lJ?l

]

i

, 11_-I_s,o_4,,

i

_

|

1

|

!

=

I H----J

Jl II

,

_II fi

o

V

Spool

!

pin

u

N

LOI

®

__.

,o

(_

Pull the thread

guide bar up as far as it will

go.

(_

When you use a small thread

with

Turn

the

thread

gutdes are right

guide

bar so that

above the spool

pins.

the

spool,

its slit side up, and put spool

remove

the spool

holder

from

the spool

pin.

sewing,

put

Then

place the spool

cap on top.

thread

2_

If the

thread

illustrated

slips

down

from

for preventing)ammlng.

the spool

during

threading

The nets are supplied

and/or

with

the machine.

a net on the spool

as

,; Raising.

"_ ;'=_,_:

o_

T:_,:_"_

L;,._o

_=_,,:werin=

, _,.g

_ =thePresser

_'=

_=.,:_.._ Foot,

=,

_feSSer

_oOt Iifter

By raising

or lowering

the presser foot

While in operation,

lowered

threading

weight

NOTE:

except

the

the

presser

foot

lifter,

goes up and down.

keep the

for

machine

presser

testing

or

sewing

foot

stitches,

heavy

fabrics.

Thread tension will not be released

if the presser foot is raised.

::iIT

: h _ead inglthe Mach ine I

For

I. Green

|

3.Blu e_------___,::2_]

IJ

p.Orano -

convenience,

of threads,

Connect

,_'k

I\

your

choice

your

follow

Kenmore

ovedock

these simple

the power

has been pre-threaded.

To prepare

to sew with

your

instructions:

supply

plug to

the wall

outlet

bar to

highest

pos+tion;

and turn

on the power

switch

(Page 5in owner's

cover

(Page 6 in owner's

manual).

--

Raise

thread

guide

open

side cover

and Looper

manual).

---

Untie knot holding threads together.

Place a thread cone on far right spool

farthest

on right

--

Pull thread,

-

Place

guiding

a second

cone to thread

-

Pull thread,

--

Place a third

guiding

Pull

thread,

presser

of

right

from

right

located

through

on

knot

tension

the

second

tie

end of thread

from

from

cone to

thread

Knife

may

disc, thread

from

tension

right.

guides

left

spool

through

and upper

end of thread

from

tie end of thread

from

looper.

Securely

give

guides,

on

needle.

to

tie

guide bar (BLUE)+

Clip thread

lowered

looper.

Securely

holder.

disc and thread

manual).

be

from

bar (RED).

left on thread

new thread

guides and lower

holder

guide

second

through

and thread

easier.

Securely

disc, thread

spool

on thread

(Page 27 +n owner's

needle

threading

f

tension

on second

cone

guiding

foot

through

cone

knot

thread

holder+

guide bar (GREEN).

knot

thread

second

cone to thread

-

of thread

both

Before

Use looper

you

more

reaching

sides of knot.

room

needle,

threader

or tweezers

to

(Page 29

work

remove

Pull old thread

out

to make

in owner's

manual).

-

Place a fourth

thread

-

Pull

cone of thread

on far left of thread

thread,

thread

guiding

on both

on spool

holder

at far left.

Securely

tie end of thread

from

cone to

guide bar (O RANGE),

knot

through

sides of knot.

tension

Pull

disc

old thread

and

out

thread

of left

guides.

needle

Before

reaching

and thread

new

needle,

thread

clip

through

needle.

+

Pull

both

sides

of

thread

firmly

between

each

tension

disc

(Pages 11,

13,

15,

17

in owner's

manual),

-

Refer to threading

-

Gently

-

behind

tooper cover)

Replace

manual).

Threading Chart

(Located

pull

chart

behind

all four thread

presser foot

Turn

-

Place fabric

hand wheel

NOW READY

toward

under

cover to check

back

(Page 27 in owner's

Close side cover

-

looper

ends towards

the

and looper

you

toe

TO BEGIN

to chain

of

the

manual).

cover

off

presser

threading

paths.

of machine.

Return

knife

(Page 6 in owner's

three

foot;

or four

to up position

(Page 29 in owner's

manual).

stitches.

it is not

necessary

to raise the

foot,

YOU

ARE

SERGING!

9

e Threading the Lower Looper

®

Thread guide

\

Looper thread gutde

4

1

Thread guide

plate

(9

_

(_)

.......................

Draw

J

the

thread

through

the right side thread

from back to front.

®

(_

guide

®

Pass

the

holes

on

thread

thread

the

guide

through

right

side

of

plate

as iliu-

strated,

How to Thread the Lower

(_)

Pass the

right

thread

side

sliding

the

10

*

[

Points

to thread

in green.

for

lower

looper

are marked

thread

to right.

as shown

in the figure

and remove

Thread the lower looper and then re-thread the needles.

i

through

thread

Looper

Cut the both needle threads

them from the needles.

Open the looper and side covers.

Loosen screw and remove presser foot assembly.

Place the spool of thread on the right side spool pin.

of

from

the

guide

left

._-

looperIk-k

%._-___

I

g_,de

I_l 31_ EL;xT..Looper

I

"

/

|

,..oooo,

_

(_)

Insert

the thread

discs

from

the

between

right

tension

Then

both

sides of the thread

between tension discs,

pull

(_)

Pass the thread

_)

Pass the

firmly

take-up

(_)

(_)

Pass

the

looper

thread

thread

guide

through

threader

//

0 ,deI41

I\IIhl

I\ /,

Lower looper

Looper li_read

Lower

!

looper thread I

_

lower

thread

through

through

the thread

the

gutde

looper

(2}.

(_

thread

lever (lower).

Pass the

thread

through

__

Turn

the

hand

wheel

toward

you

until

the

Iower

looper

comes

to the

threader

through

the

thread

guides

tooperthread

f3) and I4).

Hook

(1),

the

__

I

w

(_

Putt

left,

pass the

hole on lower

guide

on the

threader,

Woolly

NylonlPolyester

pass

the

hote

of

and

draw

the

thread

through

the

hole

on

lower

looper

to Thread

to

the

threader,

with

How

threader

through

lower looper thread guide (5}.

Remove

the thread

from

the

(5).

end of thread

the

thread

10

cm

(4"')

or

more

a pair of tweezers.

Thread

d

Thread _

Lower looper

[

*

Make sure that

the tenston

the thread

is between

discs.

Ordinary

thread

/

Tension discs

*

To

pass

WoolIy nyion/pio!yester

the woolly

easiest ways

*

nylon/polyester

thread

thread

shown

above is one of the

to do so.

Use the same method

for the upper

looper,

11

e Threading the Upper Looper

i./

thread

guide

Thread

guide

&

p_ate

C)

Draw

the

thread

the

thread

from

the

guide

right

from

through

Pass the thread

through

the

second

(_)

holes

in

second

row

back to

from

the

front,

guide plate

How to Thread

the Upper

the

right

Place

from

I

12

*

the

spool

of

thread

on

the spool

pm

second

the right.

Points

marked

to red,

thread

in

for

upper

Iooper

are

Pass the

left

thread

thread

side

sliding

as illustrated,

of

through

thread

the thread

from

to left,

Looper

Turn

Lower looper

threa#

of

(_

upper

Upper looper

the

hand

looper

wheel

comes

travel,

and

looper

from

unhook

Thread

the upper

the upper

toward

to the

the

thread

looper.

looper.

you

middle

until

point

of

the

the

of its

lower

the

guide

right

Loope_

threader_

/Uppe_

-,_

_(_

fooper

toope_

thread

_

lhread

,ens,on dia,

J

Insert

_)

the

thread

between

the right,

Then

pufl both

Pass the

thread

through

guide

(1).

tension

discs

from

(_

sides of thread.

upper

looper

Pass the

thread

through

upper

looper

thread

guJde (2).

thread

(_

Pass the thread

up lever (upper).

(_

Pass the

thread

through

upper

looper

thread

through

the hole on the upper

gu _de.

through

the looper

thread

take-

Pass the threader

looper,

Then

threader.

thread

from

Pull

through

threader,

hook

the end

out

the

the

hole.

and draw

of

thread

threader

Remove

the

to

on the

pass

the

the

thread

free end of thread

10 cm (4"} or more.

13

e

Threading

the Needle

on the

Right

_

Thread

gu+de

®

(_

Draw

the thread

through

the thread

second from the left from back to front.

guide

(_)

Pass

second

the

as illustrated.

©

Place the

from

14

spool

of thread

on the spool

pin second

the left.

+ Points to thread

for

are marked in blue.

needle

on

the right

]

/

thread

row from

through

the

holes

the left of thread

+n

the

guide plate

Needie thread

Thread take-up

lever thread guide

_

guide

_

Needte bar

t

thread guide

Right needle

thread guide

tension

Right needle

dial

threat

(_

Insert the thread between tension discs from

the right. Then pull both sides of thread.

®®

Turn

the

need{e

the

hand

wheet

toward

bar to its highest

thread

through

guide and thread

you

position,

right

take-up

..............

to

bring

then

needle

leverthread

®

Pass the thread through

the thread

the thread from teft to right.

(_

Pass through

pass

gwde

sliding

thread

guide.

needle

bar thread

guide

from

left

to right.

(_

Thread

the

back

and

from

the

right

pull

needle

the

eye of the

from

thread

needle

the front

about

to the

10

to the

cm

back

(4")

under

the foot.

NOTE;

Needle may be easier to thread if you

remove presser foot (See page 27) and

tower knife (See page 29).

15

e

Threading

the Needle

on the Left

®

Thread

guide

Thread

plate

(_)

0

Place the spool

*

Points

marked

16

of thread

to thread

in orange.

on the left side spool

pin.

for needle on the teft are

Draw the thread through

the thread

the le/t from back to front,

guide

on

(_)

Pass the

thread

of thread

guide plate

through

the

gutde

holes on

as illustrated,

the left

-

Gently

pull

all four

thread

ends towards

back of

machine.

_=

Needle

guide

I

needle thread

[ension dial

-

Replace

-

Return

--

Close side and looper

-- Turn

or four

_-_

-Needle bar

thread 0

presser foot

knife

hand

wheel

(See page 29).

covers.

toward

you

to chain

off

three

stitches.

Place fabric

is not

(See page 27}.

to up position

under

necessary

the toe of the

presser

foot;

it

to raise the foot,

\

lever thread

Thread

take-up

guide

[_

2®

(_

(_

......J

Insert the thread between

tension

discs

the right.

Then pull both sides of thread.

from

Turn

bring

needle

thread

gu ide.

the

hand

wheel

bar to its highest

through

thread

toward

you

to

®

Pass the

thread

the thread

position,

then pass the

take-up

lever

®

through

from

Pass through

right

needle

the thread

guide sliding

to left.

bar thread

guide

from

left

to right.

thread

_)

Thread

the

back

and

from

the

left

pull

needle

the

eye ot

from

thread

the

needle

the

front

about

10

to the

to

cm

back

the

(4")

under

the foot,

NOTE:

Needle

may

remove

presser

lower

knife

be easier

toot

to

(See

thread

page

if

you

27)

and

(See page 29}.

17

!iiii!ii

t

Thread

culler

3rio

J

(_,

(_)

(_)

Insert the

the foot.

(It

fabric

under

the

toe

ot

is not

Turn

you

the

necessary

hand

a couple

thread

chain.

slowly.

The

maticatly

fed,

the direction

18

stitching

continue

to

raise

the

fooL)

(_

When

wheel

of turns

Then

fabric

Guide

desired.

gently

toward

and check

start

will

the

the

sewing

be

auto-

fabric

in

Js

to produce

a thread

12 cm (5")

while

chain

completed,

to run the machine

slightly

chain

pulling

(_

Cut

the

threads

slowly

cutter

as illustrated,

for about

5 cm

(2"}

the thread

end of fabric.

thread

with

the

leaving

chain

thread

Insert

about

foot,

from

the

next

fabric

then

necessary

start

to

ordinary

under

the

sewing.

toe

It

raise the presser

of

is not

foot

for

fabric.

to the back,

For

heavy

presser

toot

weight

fabric,

and insert

front

of the knife.

Then

lower

the foot

raise the

the fabric

and sew,

m

Securing Ends

To avokd unravelling,

_t Is necessary

one of the lotlowmg

to leave a thread

chain

about

5 cm (2")

long at the beginning

and end of seam,

To secure the beginning

and end of a seam choose

methods.

At the Begmn|ng

A.

Separate

the end of threads

B.

Thread

C,

Cut the chain

D.

Backstitchmg

tile chain

t.

Before

2,

Put your

through

and knot,

a large eyed needle,

at the edge of fabric,

putting

your

fabnc

fabric

3,

Raise the presser foot

Place the

5,

After

thread

sewing

chain

about

apply

in the machine,

in the machine.

4,

Then

and bring

between

2.5 cm (t"},

Then

and weave that

a small

amount

sew a thread

the thread

chain

the chain

through

the overlock

of seam sealant

chain

serge a few stitches

the presser foot

move

chain

about

(Fray

5 cm (2")

stitches

Check

on the fabric.

TM or Fray-No-More

tong behind

TM)

on the end of the threads.

the needle.

and stop.

to the left around

and upper

to the right

knife,

and under

holding

and under

the presser foot.

it in position

the upper

knife,

as you lower

cutting

the presser foot

the chain

as you sew.

to sew,

t9

At the End

You can use the same methods

as at the beginning

to secure the end of seam except

"Backstttching",

or the methods

shown

below.

®®

(_

Serge one stitch

off

the end of seam.

(_)

®

20

Rinse

the needle

gently

pull

and presser

the threads

foot,

and

off the prong.

Turn the fabric over so that the under

sIde is up.

(_

Serge about

and angle off

2.5 cm (1")

the fabric.

over stitching

:Thread Tension (4 threads)

Thread

Tension

Dial

Correct

Thread Tension

Tension

f

Need Ie thread

tension (L)

Setting

Needle thread

tension (R)

mark

looper

Upper looper

thread tension

Loosen

L

_

Lower looper

thread tension

Tighten

Needle thread

on the rtght

J

The line

below

dials indicates

the

3 threads

sergmg,

ment

the

of

depending

on

setting

normal

however,

thread

the

of 3 on each of the

tension

tension

type

for 4 threads

an aiternate

of

may

fabric

or

adjust-

be required

and

thread

being used,

Refer to pages 22 and 23 for the adjustment.

21

Thread

*

Tension

Set all four

Wrong

Adjustment

thread

tension

dials at "3"

Then

sew, and check

Tension

the thread

tensions.

Wrong Tension

Correct

on the left ts loose.

)n the

Tension

is loose.

! upp

looper

thread

looper

thread

looper

thread

Cower

!:_:?::?

:::,'::i7; :of fab_tc':!?,_::_

looper

_thread

thread

Tighten

needle

thread

tenston

on

Tighten

the left.

Needle lhread

_enston tR)

Needle thread

tens}on (L}

O) Q

Upper looper

thread tenslotl

22

thread

tension

the right.

Needle thread

tension (L)

*

needle

It is easier to adjust

Lower

lhreed

looper

tenslon

by using 4 different

Upper

thread

colors

of thread.

Needle

tension

looper

tension

thread

(R)

Lower

thread

looper

tensior_

on

'):3::;:"i:'

:::;;71Needle thread

;_:;:{<;';;;::Jon the right

Wrong Tension

Wrong

Tension

thread

_er thread is tight and/or

read is loose.

is tlght

and/or

is loose.

looper

thread

Loosen

and!or

looper

thread

fewer

looper

thread

tension

Loosen

upper

looper

thread

tension

tighten

upper

looper

thread

and/or

ttghten

lower

looper

thread

tension.

tension.

Needle tt_read

tens_o_ ILl

Needle tl_tead

_enslon (R)

Needle thread

Ieos_on {L}

@@

Uppe[ looper

Lower

looper

the*cad

lt_read

tension

tenSlO_*_

Needle thread

_ens_on (RI

Upper leaper

thE'ead leas|on

Lower looper

lhrearJ tension

23

Using the Needle

(for narrow

on the Right

three-thread

Only

Using the Needle on the Left Only

(for wide three-thread sergtng)

sergmg)

Correct

Tension

_per looper

thread

Adjusting

the

depending

on the type

thread

tension

may

of fabric

used.

Refer to page 25 for the adjustment.

Disconnect

Remove

Then

tighten

slightly

Loosen

24

the

and

needle

from

the

the

thread

clamp

power

screw

on

suppiy.

the

Remove

left,

on the

Then

left

the

tighten

slightly

needle

the

and

needle

to avoid losing

the

thread

clamp

screw

on

the

right,

on the

right

the screw.

tosing the screw.

to the other

both

screw for

machine

needle

to avoid

To change

clamp

the

the

needle

the needle

needle

ciamp

in three-thread

screws

and remove

to be used while

screw on the other

serging

side slightIy

pushing

to prevent

the needle.

the

needle

Insert

the needle

up as far as it will

the screw from

dropping.

and tighten

go.

Then

the needle clamp

tighten

the

needle

be

required

and thread

being

Thread

"

Tension

Set alt three

Adjustment

thread

tension dials at "3"

Then

sew. and check

Wrong

Wrong Tension

the thread

tensions.

Tenston

Wrong Tension

_read is loose.

thread

!ep_!gqp_j_bread

is tight

::

; :i

: ::::::

Tighten

needle thread

tension.

Needle thread

tension {R }

Upper IDoper

thread tension

It Is easier to adjust

_

thread

:: ::of fabric :::::::::

Loosen

lower

looper

thread

tension

Loosen

upper

looper

thread

tension

and/or

t_ghten upper

looper

thread

andlor

tighten

lower

looper

thread

tension.

Needle thread

t_nsion (L!

NeedIe

Needle threed

tension (R)

tension

Lbread

IL)

Needte

tension

thread

(R)

@@

Lower looper

thread tens{o_

by using 3 different

tooper

1hread

looper

tension.

Needte thread

tet_ston (L)

is t_ght and/or

read is loose.

Upper

_

i::ii

)er thread

and!or

ts loose.

colors

Upper

looper

Lower

looper

thread

tension

lhread

tens{On

Upper

thread

looper

tension

Lower

thread

looper

lension

ot thread,

25

< Standard

Setting

Position

>

Top of the machine

\

decrease

\

To increase

scrsw

L

To select stitch

The larger

The stitch

5/! 28"

Posit_on

26

length,

the number,

length

View trom '*A"\

turn the dial.

It iS not necessary

the longer

When you

can be adjusted

the stitch.

from

1 to 5 mm,

(approx.

to adjust

the pressure

sew heavy or lightweight

-

clockwise

for heavyweight

-

counter-clockwise

for normal

fabrics,

sewing.

turn the adjusting

screw to:

fabric.

for lightweight

fabric.

to 25/128"').

"R"

is for rolled

and narrow

hemmings.

*

For normal

sewing,

the machine

as illustrated.

leave the

adjusting

screw even with

the top surface

of

"i:i:_

Removing the Presse_:Foot

f

iool

_if ter

\

__

zFoo!

holder

_foove

Lever _

Pin

D

11_ Ratse the needle

and presser

toot.

(_

Press

holder,

the

lever

located

The presser foot

on

will

the

drop

back

off.

of

foot

Place the presser foot

ties just under

Lower

the

the foot

foot

check

so that

the

pin

the groove

of the foot

holder

and push the

in place.

Raise the presser

that the presser foot

on the foot

holder.

lever to lock

foot

lifter

to

is secure.

27

Needle clamp

screws

-..

I

I

Needle slopper

/ r]l o

,o

Ed0o

o,

_

Needle clamp

[he Iett

needle bar

screw

"_\

Needle

Needte.

Fiat stale

to lhe back

I

f

1" Correct

®

(_

needle

2_

Disconnect

the

machine

from

the power

its

highest

position.

needle

clamp

supply.

the

Then

needle

loosen

the

to

screw

flat

for

the needle you are going to remove,

Refer

To Attach

Insert

Raise

to page 24 for changing

for three-thread

serging.

touches

needle

to

into the needle clamp

the

back

the stopper

until

the

pro, then

top

with

of

tighten

the

needle

the needle

screw on the right.

To attach

Insert

fiat

J

the needle on the right

new

side

clamp

the needle

setting)

......

the needle on the left

new needle

side

touches

to

the

into the needle clamp

back

until

the edge of needle

needle clamp

the

top

bar, then

with

of

the

needle

tighten

the

screw on the left.

* When the needles are set correctly,

needle is higher than the right one,

the left

NOTE:

Your

sewing

overlock

needles

No speciai

Do not use any needle which

or blunt.

28

Is bent

uses standard

(HA-1

needles

SP, #!1,

are required,

Kenmore

#14).

_To Disengage the Upper: Knife:

f

\

I

Upper

--b.-'--..b,>_<d_tt!

,

IlO__f'C""no

knife

Upper

_

_

knob

_

f_

topper

!It

v

p_n

Upper

knite

_'_Upper,

Slopper

i

pin

J

J

...........................J

1_) Disconnect

the machine

from

the powersupply.

(_)

Open the looper

and side covers.

_)

Turn

knife

the

pushing

on

knife

upper

upper

it m to

knife

m down

the

to

knob

right,

the

pin

to

Disconnect

Ctose the looper

the

machine

from

the

power

supply.

toward

then

(_)

you

guide

lock

the

the

while

hole

(_

Open the looper

_

Turn

the

while

pushing

upper

groove

position.

upper

_

'%

knob

_

I

on

knife

and side covers.

upper

knife

It to

upper

the

knife

knob

away

right,

to

then

the

pin

from

you

guide the

to

lock

m the up positron.

and side covers.

(_)

Close the looper

and side covers.

29

=:

::[::

,::::{:: ': ::::

:::::'::}:

: ::::::,:::::"

Tighten

®

®

N eedIe

Be[

Regular

Rolled

(ior normal

(for rolled hemming

p_cot

edging

and

narrow

hemming)

Sewing}

Stamp on the reverse

stde ol the plate

"

Select

*

Your

the needle plate for your

overlock

For your

When

nected

is shipped

with

"S ....

sewing

R"

need.

the regular

needle

(_) Turn

plate in place,

Safety:

you

from

change

(_

the needle

the power

supply.

plate or adjust

Screw

her'nm_ng

the seam width,

make

sure that

the machine

the

®

above

toward

remove

the presser foot.

the

until

plate.

the

Then

covers.

to page 6.)

Set the upper

Remove

you

needle

Open the side and looper

(Refer

@

wheel

comes

(Refer

is discon*

hand

needle

knife

to down

posrtion.

plate

set screw,

to page 29.)

the

needle

and

lift

the needle plate.

@

Attach

needle

(_)

needle

Bring the upper

(Refer

30

the

plate

you

require

plate set screw,

knife

to up position.

to page 29.)

(_

Close the looper

(_)

Attach

and side covers,

the presser foot.

with

the

Type

Needle

of Thread

Stitch

Length

Type of Fabric

L_ght

wetght

Organdy,

Lawn,

Georgette,

Crepe de chine,

Limng.

Medium

weight

Heavy

weight

Knits

Cotton,

Ordinary

Tweed,

Doeskin,

Kmtted

Linen,

Satin,

tabrlc.

Coating,

Thick

Demm,

fabric.

fabrfc

Cotton

No. 80 "_ 100

Silk

No. 80

Synthetic

No. 80

Cotton

No. 60

HA-t

Silk

No. 50

No. 1 t _ !4

Synthetic

100

100

No. 60 _- 100

Cotton

No, 50

Silk

No. 50

Synthetic

No. 50

Cotton

No. 60

Synthetic

No. 60

Woolly

ny{on

{For

looper

Woolly

(For

Refer to page 26 for adjusting

NOTE:Your

overtock

the stitch

uses standard

lO0

10o

HA-t

No.

60

6O

60

HA-t

8O

9O

HA-t

SP

2,0 _ 3,0

SP

2.5 _ 3.5

1t

3.0 _ 4.0

SP

No. t4

2.5 _ 3.5

SP

No. 1t _

14

thread)

polyester

looper

thread)

length.

Kenmore

sewing

needles

(HA-1

SP, #11,

#,'14).

31

Machine

f

Setting

Roiled

< Application

Hemming

Picot Edging

Narrow

Hemming

>

Stitch

Length

{a)

Needle

Remove

(R)

the left needle.

Needle

Plate

Rolled hemming

needle plate.

(Marked R on reverse side.)

.....

Refer to page 30 tot changing

32

the needle plate.

J

Thread,

Fabric

Tension

dial settings

and Range of the Tension

may vary depending

Dial

(3 Threads)

on the type and thickness

Fabric

Rolled

of fabric

and thread

being used.

Hemmtng

Picot Edging

Needle

thread

Long

fiber

polyester

Narrow

thread

No. 80 _

Hemming

100

Upper

and lower

looper

threads

Woolly

Woolly

nylon,

polyester

SynthetEc

Sitk

Needle

HA-1

Needle thread

tension (R)

Lfghtwetgh

t

fabric such as

organdy,

crepe

de chine, lawn

and georgette

setting

of

tenslon

dials

Upper looper

thread [ens_on

SP No.

Woolly

Woolly

Lower looper

thread tension

Upper looper

thread tension

nylon,

polyester

11

Need le thread

tension (R}

@

Standard

60 _ _00,

No. 50 _ 100

Needle thread

tension (R)

@

Lower looper

thread [ens_on

Upper looper

thread tension

Lower fooper

thread tension

i

....

jLowe

_!: _!_i,_[de2_f

.:_

_r_

'......................

looper

Correct

thread

tension

:

:

: Rigt_t

side

of fabric ;

r'_-- Upper

L_'-Upper

,_.._-_

looper

N:::ie_

_

Thread

_i:i

,breed

:/_;..-::

:

'::: threadll

:

;"

_'

lhread

'

33

Adjusting

1.

Thread

Tension

Set the tension

dials

as shown

on

page 33,

2.

the Thread

e

Hemming

For Rolled

Wrong

Sew and check

-- For better

f

How to Adjust

the tensions,

,%_.,._

Tension

and Picot

Edging

Tension

Wrong Tension

Needle thread

=s loose.

_Upper

result -

Wrong Tension

looper

thread

is loose.

:}_i_)we, r looper

thread

Is loose and/or

_!_:B_g£

thread

is tight,

i:!_[_,!i{AlO,s, kl:lilgi_:_._:,,!;4t.;i_iisliI i.......

!_"_-14::-_IQi:.,,l%>d_ _:=='Y_ll='l

i_;!_,t_

t eai:t+:÷,,

t ::::::=, .__@x,,,

. :_.:,.

Upper

_,_,_j_,,>,!_!i_>ii_!_!_

ii_,

ii!_i

!ii!)i!i!!i!iii'i

!!i!!ii

iii!

_i

iiil!i!i:i_i

i:ii_

Rolled

Pull

back

end

lightly

of

!i: i:ii!:i iii:ilildi:i_

:-:::, : _htead::::_ : :,:'::

Hemming

the

Upper

:::: :: :::: :t_fead:

thread

chain

in the beginning

to

and end

Tighten

needle

thread

tension.

Tighten

upper

looper

thread

tension.

of sewing,

Tighten

lower

looper

thread

and/or

loosen

upper

looper

tension

thread

tension.

4"

Needle

tension

Upper looper

thread tension

thread

(R}

Lower

thread

"_

Pull

the

while

sewing.

fabric

lightly

to

the

back

•

For Narrow

Needie thread

tension I R}

Needle tt'_r cad

tension {R)

@

looper

tension

Picot Edging

Hemming

Refer to page 25 for the adiustment.

34

:::::_

the

Upper

thread

looper

tension

Lower looper

thread tens=on

"_

@

Upp_r

thread

looper

lension

Lower

thread

looper

tension

Thread,

Fabric,

Range of the Tension

Fabric

< Application

and Machine

Setting

Thread

Standard

>

"

/Overedgmg

Medium

to

Needle

Synthetic

:

No. 60_

thread

Silk

:

No. 50_80

Upper

looper

Heavy

thread

Buttonhole

twist

Lightweight

woof

'I

80

..... i

Lower

thread

Synthetic

.

No. 60_

Silk

:

No. 50_80

....

LO

J

looper

,

_,%%,oo_,_o

t%%'°%o

yarn

Fabric

..................

Setting

80

r

Stitch

3_4

tength

Machine

Needle

Settmg

plate

Regular

(Marked

needle plate

S on reverse side)

HA-1 SP No,

Needle

Refer to page 21 for the correct

14

tension,

To adjust the thread tension balance, set the tension dials as shown above first, then refer to pages

22 _ 23.

*

For the best result,

*

Remove

either

pull

the thread

needle for three

chain

thread

to the back

decorative

lightly

at the beginning

and end of sewing.

overedging.

35

Fabric,

< App|ication

Thread

and Machine

Fabric

>

Sewing

Setting

Thread

Light

to

Medium

Fabric

Needle

thread

Synthetic

No. 60 _ 80

on the rtght

Silk

No. 50 _ 80

and lower

Synthetic

No, 60 "* 100

looper

Silk

No. 50 "_ 100

)!i:i} ::

Upper

threads

Folded edge

fStitch

2_3

length

,

Machine

........................

Remove

J

the needle on the left.

J

Setting

Needle

Regular

plate

(Marked

needle pfate

Disengage

S on reverse side)

Sew the

Needle

HA-1

Standard

SP No. 11 or 14

the

upper

knife.

(Refer

to page

29.)

right

folded

edge while

side edge of lower

guiding

along the

knife.

Setting

Needle lhread

_ens_on (R)

Q

Upper looper

thread tenslon

Lower looper

thread tension

J

Press the pin tucks

*

Refer

ment.

36

to

pages

24 _ 25 for thread

tension

balance

adjust-

Engage the

29.)

to one side,

upper

knife,

(Refer

to page

Disconnect

the machine

from

the power

supply

before

cleaning.

Needle pla

$8_

SCreW

J

®®

Open the looper

Remove

cover,

the waste

(_

materials

with

a lint

Open the looper

and side covers,

(_

brush,

Push

the

lint

by using iint

(_)

Remove

the needles and presser foot.

Remove

the

_)

needle

ptate

set screw

and needle

around

the feed dog

to the

front

brush.

Replace needle plate, presser foot and needles.

Close the looper and side covers,

plate.

*

You may use vacuum

cleaner

to clean

the upper

knife

area or teed dog.

37

Face

plate

plale

bulb

Set screw

Disconnect

the

machtne

face

plate

from

the

power

@

supply.

Remove

the

set screw,

and remove

the face plate.

CAUTION!

For your

"

38

(_

Put

the

turning

The

light

bulb will

Protect

your

fingers

handle it,

new

be HOT.

when you

safety:

The mach{ne

is designed

to use a 15 WATT

MAXIMUM

LIGHT

bulb

it clockwise.

BULB.

in

by

pushing

it

up

and

Attach the face plate,

set screw.

and tighten

the face plate

Disconnect

the machine

from

the power

supply

before

oiling.

Open the

looper cover.

end apply

,:,:::::,:::::

....

J

Apply

a few drops

of fine quality

Oiling

is recommended

once

sewing

a week

machine

in normal

oil to the parts indicated

use, once in ten hours

with

m continuous

arrows.

use.

39

\

\

0.5 _tmm

{]/32"'}

/_Jpper

Lower

knife

To Remove:

To Attach:

(_)

Disconnect

the machine

(_

Open the looper

trom

the power

supply.

insert

holder

and side covers.

hexagon

1_

Disengage

(Refer

the upper

(_)

Turn

(_)

Turn

upper

new upper knife into the groove of knife

and

stopper

pro,

then

tighten

the

bolt

slightly.

knife.

knife

Loosen

the

upper

of

knife

hexagon

upper

the

hexagon

bolt,

and

remove

the

Then

knife.

(_}

"

The lower

knife

at the same time.

4O

wilt

last over one year

in normal

use.

However,

if you

run over a pin or a hard object,

overlaps

tighten

to replace

and adjust

so that

the

0.5 to 1 mm

knife

as shown

the hexagon

Close the looper

it may be required

to cutting

bolt,

knife

the edge of lower

(_) Remove

holder

position.

the hand wheel

toward

you until

knife comes to its lowest position.

tion

upper

to page 29.)

the upper

the

the posi-

edge

(1/32"}

of

the

from

above.

bolt firmly.

and side covers,

both

upper

and lower

kmves

; _Y:T'_:_ _;=i_?::? :_'

:_':::_:::::_:_=:

:_

:

What to: DO When :_

Condition

The fabric is not

being

fed smoothly.

The needle breaks.

The thread

breaks.

Skipped stitches

t.

The feed dog is packed

2.

The presser foot

with

1.

The needle

is incorrectly

2.

The needle

is bent

3.

The fabric

is forcefully

1.

The machine

2.

The needle or looper

3.

The needle

Js Incorrectly

4.

The needle

_sbent

threaded.

thread

tension

_snot

1.

The needle and/or

sewn neatty,

2.

The machine

inserted.

3,

The needle

and/or

4,

The thread

is not between

threaded.

thread

The machine

3.

The needle plate

1,

The machnne

2.

The power

thread

is not correctly

tensions

are not

tension

off.

for the fabric

discs.

is too tight.

threaded.

for the use,

been plugged

asturned

are not correctly

suitable

the tension

is not suitable

has not

switch

See page 9 _ 17.

adiusted.

threaded,

the thread

The needle or looper

17.

See page 28.

Js not correctly

1.

See pages 9 _

See page 28,

correctly

2.

lightly.

See page 28.

or blunt.

looper

Pull the fabric

See pages 2t .v 25 and 33 "- 36.

is too tight.

or blunt.

The seam is not

not operate,

See page 28,

pulled.

The needle

the presser foot,

See page 28.

as not correctly

ts bent

Lower

inserted.

The machine

does

See page 37.

or blunt.

1.

Seam puckering.

lint.

has been raised,

2.

The machine

Reference

Cause

in firmly.

being sewn.

See pages 21 _ 25 and 33 "-_36.

See pages 9 _ 17.

See pages 31, 33, 35 and 36,

See pages 11, 13, 15 and 17.

See pages 21 "_ 25 and 33 _ 36.

See pages 9 _

17,

See page 30.

See page 5.

See page 5.

J

4t

PARTS LIST

All parts listed herein

3

4

WHEN ORDERING

INFORMATION:

may be ordered

REPAIR

from

PARTS,

1. PART NUMBER

3. MODEL NUMBER

any Sears store or service center.

ALWAYS

GIVE THE

FOLLOWING

2. PART DESCRIPTION

4. NAME OF ITEM

If the parts you need are not stocked localty, your order wilt be electronically

transmitted to a Sears Repair Parts Distribution Center for expedited handling.

Ref. No.

6

7

8

9

1

2

3

4

5

6

10

@

7

8

9

10

1!

11

12

13

14

15

12

13

14

15

*

42

Part No.

Description

762402009

366413003

624801001

822020307

784806005

784860OO7

Screw driver

Screw driver

Tweezers

784157004

784157015

784626009

785609009

Needle, HA-1 SP, No. tl

Needle, HA-1 SP, No. 14

Rolled hemming needle piate

Needle plate

Net

Lint brush

Spool cap

Looper threader

Needle set

624806006

802424004

0000098O3

Light bulb

784045019

*784809008

784223002

*6890

These items

are not

instructions

above.

furnished

(large)

(small)

Upper knife

Spanner

Spool holder

Oil

with

the machine,

but may be ordered

per

INDEX

A

Accessory box

..................

4

C

Carrying handle ...................

Changing needle ..................

Changing the needle plate ............

3

28

30

D

Decorative overedglng

.............

35

F

Face

Foot

Foot

Foot

plate ......................

holder ....................

holder set screw ...............

control ....................

3, 38

4, 27

4

3, 5

N

S

Narrow hemming .................

32

Needle .................

27, 28, 31, 42

Needle bar .......................

4

Needle bar thread guide .......

4, 15, 17

Needle clamp

...........

4, 28

Needle clamp screw ...........

4, 28

Needle plate .............

4, 30, 42

Needle plate set screw .........

4, 30, 37

Needle stopper pin .................

28

Needle threads ......

t4_16, 21_25, 33_36

Needle thread guide ..........

3, 15, 17

Needle thread tenston dial ..............

............

3, 15, 17, 21_25, 33_36

Net .......................

4, 7, 42

Screwdrivers

.................

Side cover ...................

Set screw ....................

Specification of the machine .........

Spool cap ................

Spook holder ...........

Spool pin .....................

Spool stand ......................

Stitch length dial ...............

Stoppers ......................

Stopper pin ....................

O

Oiling ..........................

39

H

Hand wheel ......................

3, 6

K

Knife holder

...................

4

L

Light bulb ..................

38, 42

Lint brush ..................

4, 37, 42

Looper thread take-up lever ......

4, 11, 13

Looper threader ..............

4, 11, 13

Looper cover ......................

3, 6

Lower knife .....................

4

Lower looper ...............

4, 10_1 t

Lowertooperthread

. , 10, 12, 21_25, 33_36

Lower looper thread guide .........

3, 1t

Lower looper thread tension dial ......

3, 1 t

Performance

problems chart

Picot edging ..................

Pin tucking

..................

Plug connector

...................

Power switch

....................

.........

Pressure adjusting

screw ............

Presser bar ......................

Presser foot

.................

Presser foot lifter

...............

41

32_34

36

3, 5

3, 5

3, 26

4

4, 8, 27

4, 8, 27

4, 42

3, 6

38

44

4, 7, 42

3, 7, 9, 42

3, 7

3

3, 26

7

29

T

Thread chain ....................

Thread cutter ...................

Thread guide bar .................

Thread guide plate .......

3, 10, 12,

Thread take-up lever thread guide. , , 3,

Tweezers ...................

4,

Upper

Upper

Upper

Upper

Upper

Upper

18

4, 18

3, 7

14, 16

15, 17

11, 42

knife .................

4, 29, 42

knife knob

................

4, 29

looper

.................

4, 12_13

looper thread

.....

12, 21_25,

33"36

looper thread guide

.........

4, 13

looper thread tension dial .....

3, 13

R

Right needle thread guide ...........

Rolled hemming .................

Rolled hemming needle plate .....

3, 15

32

4, 32, 42

43

Specification of the Machine

Item

Specification

WARRANTY

Sewing speed

t,300

Stitch length (feed amount)

1 _ 5 mm (Ordinary

Overedge stitch width

3.5 mm or 5.7 mm

5.7 mm (4 threads)

Needle bar stroke

26 mm

Presser foot rise

5 mm

r.p.m,

maximum

average 3)

(3 threads)

1)

-_

4t

-_

Needle

HA-1

Number of threads

3or4

Machine dimensions

width

SP #11

53 '° x depth

10_-_-

x height

Weight

or #14

I0-_'

10 _2"

0

#

15.5 lb.

FULL FIVE YEAR WARRANTY

ON MECHANICAL

COYPONENTS OF OVERLOCK MACHINE

For five years from the date of purchase, Sears will, free of

charge, repair defects in materiat and workmanship which

appear in the mechanical components of the overtock machine

head.

FULL TWO YEAR WARRANTY

ON ELECTRICAL

MENT OF OVERLOCK MACHINE

EQUIP-

For two years from the date of purchase, Sears will, free of

charge, repair defects in material or workmanship

which

appear in the electrical equipment of the overlock machine,

including electronic components,

motor, wiring, switch and

speed control.

FULL

90-DAY

WARRANTY

MECHANICAL

ADJUSTMENTS

ON

ALL

For 90 days from the date of purchase,

charge, replace any parts and provide

necessary for proper operation

except for normal maintenance.

{)

WARRANTY

SERVICE

_1

OVERLOCK

MACHINE

CENTER/DEPARTMENT

IS AVAILABLE

PARTS

44

SEARS, ROEBUCK

_)

._

-="

AND

Sears will, free of

mechanical service

of the overtock

machine,

BY RETURNING

TO THE NEAREST SEARS

IN THE UNITED STATES.

THE

SERVICE

If this overlock machine is used for commercial or rental purposes,

the above warrant-/coverage

applies for only 90 days from the date

of purchase.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

//

_1

AND CO., D/817 WA, Hoffman

Estates, IL 60179

{t

OVERLOCK

Now

that

service,

you

simply

have

purchased

contact

your

Kenmore

any Sears Service

Overlocko

Center.

should

a need

Be sure to provide

ever

exist

all pertinent

for

facts

repair

when

parts

or

you call or

v|sit,

The model number of your Overlock will be shown on your nomenclature

Over!ock. See page 3 for location,

WHEN ORDERING

*

MODEL NUMBER

REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

* NAME OF ITEM

plate on the back of your

INFORMATION:

* PART DESCRIPTION

If the parts you need are not stocked locally, your order will be electronically

Repair Parts Distribution Center for handling.

transmitted

to a Sears

SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S,A.

E

S-385

Printed in Taiwan

Part No. 785800909

i