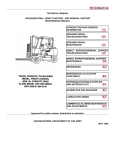

Download Yard Machines Y60 Operating instructions

Transcript