Download Monogram ZISS480N Owner`s manual

Transcript

Installation

Instructions

Side by Side Refrigerators

ZlS360N,ZlSB360D,ZlSW360D

ZlSS360N,ZlSS360D

ZlS420N,ZlSB420D,ZlSW420D

ZlSS420N,ZlSS420D

ZIS480N,ZISB480D,ZISW480D

ZISS480N,ZISS480D

Design 6uide

With Installation Instructions

Monogram:

Safety Information

BEFORE YOU BEGIN

Read

these

instructions

completely

• IMPORTANTfin" local inspector's

and ordinances.

• Note

• Note

with

with

Observe

- Be sure

the

to

• These

instructions

reference.

refl-igerators

be secured

fin'ward.

page

Anti-Tip

• Use

This

• hmnediately

"(;rounding

must

the

be properly

Refrigerator,"

grounded.

page

See

that

10.

this

Cet

appareil

Consulter

dolt

_tre

<_ Mise

correctement

fl la terre

If xou receixed

a damaged

immediatelx

contact

xour

du

toI>heavy

the

and

possibility

protection

appliance

become

• Uni)lug

AVERTISSEMENT

are

to prevent

is required.

See

the

only

for

repair

or

replace

fl'ayed

or

damaged.

refl'igerator

its intended

Imrpose.

electric

before

service

cleaning

cords

or making

repairs.

mis

• Repairs

should

technician.

a la terre.

r(_ffig(_rateur

>>,page

refrigerator,

)ou

dealer

or builder.

be

made

bv a qualified

service

10.

AVERTISSEMENT

should

• Ces r0fl'ig(_rateurs

sont lourds en haut et il flint les

arrimer

pour 0viter leur basculement.

I1 taut avoir

un syst0me de protection

contre le renve_ement.

Voir les d_tails page 12.

• 11 ne flint utiliser cet appareil

que pour l'utilisation

aI)I)ropri0e.

• R(_parer ou remplacer

imm0diatement

tout cordon

01ectrique efliloch(_ ou endommag(_.

• ll flint d(_brancher

le r0fl'ig0ratem"

awmt le

nettoyage

ou route intervention.

• i,es r0parations

doivent &tre taites par tm

technicien

qualifi0.

CAUTION:

Due to the weight and size of this refl'igerat(n,

and

to reduce the risk of personal

iqjm y or damage

to

the product

- THREE PEOPI,E ARE REQUIRED

FOR PROPER ]NSTAI,I,ATION

OF A 36" WIDE

UNIT. FOUR PEOPI,E ARE REQUIRED

FOR

]NSTAI,I,ATION

OF A 42" OR 48" WIDE MODEI,.

PRUDENCE

_k cause du poids et de la taille de ce r(_flJg0rator

et

pour r0duire le risque de blessure et de dommages,

]I, FAUT TROIS PERSONNES

POUR INSTAI,I,ER

For Monogram

1.800.444.1845.

local

For Monogram

1.888.880.3030

service

CORRECTEMENT

D'UN APPARE]I, DE 91 cm (36 po)

DE I,ARGE. 1i, FAUT QUATRE PERSONNES

POUR

I?INSTAI,IATION

D'UN MOD1_I,E DE 107 OU 122 cm

For Monogram

1.800.626.2002.

Parts mad Accessories,

(42 OU 48 po)

must

of tipping

12 fin" details.

WARNING:

appliance

of this refl'igerator

carl)entry

and l)lmnbing

is the responsibility

of the

due to improper

installation

GE Appliance

Warranty.

ti)r warranty inli)rmation.

WARNING:

leave these

- Kee I) these

Manual

for flmue

Owner's

codes

(:onsumer.

to Consumer

vour

carefully.

all governing

-Installation

requires

basic mechanical,

skills. Proper installation

installer.

Product

tailm'e

is not covered under the

See the Owner's

Manual

S.,'etheseinsnuctions

use.

to Installer

instructions

and

Skill Level

service

in your

in Canada,

area,

call

call

call

WWW. lnonograln.coln

DE lARGE.

CONTENTS

Planning Guide

Installation

The Installation Space .................................... 3

Dimensions and Clearances .......................... 3

Tools, Hardware,

Materials

........................ 10

Grounding the Refrigerator

.......................... 10

130° Door Swing .............................................. 4

Step 1, Remove Packaging

.......................... 11

90° Door Swing ................................................ 5

Customization Basics ...................................... 6

Step 2, Install Water Line ............................ 11

1/4" Framed Panel Dimensions

Step 3, Install Side Panels

...................... 7

Instructions

Step 2A, RO Water Line ................................ 12

.......................... 12

3/4" Overlay Panel Dimensions ...................... 8

Step 4, Install Anti-lip

Raised Overlay Panel Design ........................ 9

Side Panels ...................................................... 10

Step 5, Level Refrigerator

............................ 13

Step 6, Alternate

Procedure

Brackets

Anti-lip

Step 7, Secure Refrigerator

................ 12

........13

to Cabinetry

..14

Step

Step

Step

Step

Step

Step

Step

Step

Step

8, Adjust Door Swing ..........................

14

9, Install Grille Panel ............................

14

10, Install Framed Panels ....................

15

1OA,Install Overlay Panels ..........16-17

11, Install Dispenser Trim ....................

18

12, Connect Water Supply ..................

18

13, Connect Power ..............................

19

14, Start Icemaker ................................

19

15, Install Toekick ................................

19

Design Guide

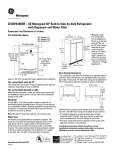

THE INSTALLATION

SPACE

DIMENSIONS

AND CLEARANCES

25-3/8" FramedModels

25-3/4" StainlessSteelModels

36" Models12"

42" Models18"

48" Models20"

_

_Finished

84 1/2" max,

,

^

Width_

J

J

L'"

831/2,,

min

II AreaElectdc X15 l

Finished ][

Opening ] [

75"FromFloor

24"

*The

I)

finished

35-1/2"

41-1/2"

47-1/2"

Water

_83-1/

at

Real

ff Electrical

Area

to Bottom

[_5

/

.36", 42", or 48"

Frameto Frame

WaterSupply_ 5%

3i/2"

cutout

width

must

DepthIncludingHandles:

26-7/8" FramedModels

27-3/4" StainlessSteelModels

be:

fin" 36" models

for 42" models

fin" 48" models

And Electrical

Product

Locations

The opening must be prepared with the electrical

and water supply located as shown.

beneath

beneath

exceed the 24" installation

trim overlaps the bottom

a soffit:

a soffit, the soffit

depth shown.

of the soffit.

130° DoorSwing

T

cannot

The

required.

An individual

properly

grounded

circuit or circuit breaker

is recommended.

i

top case

_'-4...... /

fault

interrupter)

bran(h

is not

,...

Models

36"

42"

48"

Install

a propedy

grom_ded

3-prong electrical

receptacle

recessed into the back wall. Electrical

must be

located on rear wall as shown.

(grotmd

90° DoorSwing

23-7/8"

Behind

Frame

Additional

Specifications

• A 115 volt 60Hz., 15 or 20 amp power suI}ply is

NOTE: OF]

Clearances

These refi'igerators

are equipi)ed

with a 2 position

door stop. The thctorv set 130 ° door swing can be

ac!justed to 90 ° if clearance

to ac!jacent cabinets or

walls is restricted.

The cutout

depth must be 24"

The refrigerator

will project fin'ward, slightly beyond

ac!jacent cabinetry;

depending

on wmr installation.

Cutout

depth

When installed

Shippingheight.The

refrigeratorcan be

adjustedto fit into a

cutoutthat is 83-1/2"

min. to 84-1/2"max.

_84" From height. Note that the

Floorto

top casetrim at the

TopFrame front is 1/2" higher

andwill overlap

uppercabinetryor

soffit. Useleveling

legs andwheels for a

maximum1" height

adjustment.

Allow

minimmn

(Dimension

.)_

A

13"

13"

15"

B

15"

19"

20"

fin" fl'eezer

clearances

A) and

C

20-5/8"

26-5/8"

28-5/8"

fl'esh

fi_od

swing

and

door

4" Min.

to Wall

door

(Dimension

B)

recoi/lillended.

• _&_ter line can enter the opening

through

the floor

or back wall. The water line should be 1/4" O.D.

copper

tubing

the cold water

long enough

refrigerator.

shut

or GE SmartConnect'"

kit between

line and water connection

location,

to extend

Installation

to the front of the

of an easily accessible

off wflve in the water

fl)r a flfll

YeIlloval.

130 ° door

to allow

fl_r pan

4" minimmn

clearance

is required

when door swing

is ac!justed to 90 °. If the 90 ° door stop position

is

used, pan access is maintained,

but pan remowfl is

restricted.

line is required.

See illustrations

door

swing

COtlntertol)

pages

interaction

s.

4 and

with

5 to determine

ac!jacent

cabinets

or

Design Guide

FramelessCabinets:The case trim overlaps

cabinets atthe top and sides. Therefore,

frameless cabinets may require filler strips to

prevent interfeence with cabinet door swing.

The opening must allow for filler strips.

Refrigerator

23-7/8"From

Rearof

Refrigerator

.

Case

Trim

"

3/4"

3"

1-3/4"

1/2"

2-3/4"

1-1/2"

1/4"

2-1/2"

1-1/4"

,,

2-1/4"

;

i

i

i

_1

"

L

",

i

i

I|11,|

I ----L

T

I

Door

(factory setting)

Scale 1:1

IMPORTANTNOTEFORDISPENSERMODELS:

Dispensermodels are supplied with two

dispenser trims, one to fit framed panels

and one for overlay panels. Dispenser trim

fit to the custompanel dependson correct

panel thickness. Framed panels must be

1/4"nominal. Overlay panelsshould be

constructed as shown to accomplish a total

1.100"thickness. See pages 7 and 8 for details.

4

|

i

i

i

i

i

i

|

|

|

|

L

I

I

,

I

I

L

I

I

•

|

|

|

I

4 ....

i

i

I

i....

i

i

I

4 ....

i

i

|

_ ......

|

|

....

L...;L...:L...:

....

....

Top View

130 ° DOOR SWING

.

i

|

|

1

ii

,,

1/9"

//L

..........

3/4"

1"

Design Guide

FramelessCabinets:

The case trim overlaps

cabinets at the top

and sides. Therefore,

frameless cabinets may

require filler strips to

prevent interference

with cabinet door swing.

The opening must allow

for filler strips.

Refrigerator

CaseTrim

23-7/8"

FromRearof

Refri(erator

,

i

i

b

i

i

,

i

i

'i

'i

'i

1/4"

1/2"

3/4"

I "

1-1/4"

1-1/2"

Top View

90 ° DOOR SWING

(optional setting)

Scale 1:1

IMPORTANTNOTEFORDISPENSERMODELS:

Dispensermodels are supplied

with two dispenser trims, one to fit

framed panels and one for overlay

panels. Dispensertrim fit to the

custompanel dependson correct

panel thickness. Framedpanels

must be 1/4"nominal. Overlay panels

should be constructed as shown to

accomplish a total 1.100"thickness.

See pages 7 and 8 for details.

Door

i

I

l

l

I I ,

ll_

3/4" Overlay

Panel

(NominalSize)

Design Guide

CUSTOMIZATION

Framed

BASICS:

Or Overlay

Panels,

Custom

Handles

Stainless Steel Wrapped

Models

36" wide models - ZISS360N,

ZISS360D

42" wide models - ZISS420N,

ZISS420D

48" wide models - ZISS480N,

ZISS480D

Trimmed

- ZIS360N,

- ZIS420N,

- ZIS480N,

ZISB360D,

ZISB420D,

ZISB480D,

ZISW360D

ZISW420D

ZISW480D

r

These

models

//

i

Stainless Steel Wrapped

Refrigerators

Stainless Steel wrapped

refrigerators

have wrapped

doors and grille panel, beveled edges, and tubular

stainless steel handles that coordinate

with other

Monogram

appliances.

readv for installation.

Kits

Overlay panels

You may also choose to install custom overlay panels

fl'om wmr cabinet mantdhcturer.

This design provides

a seamless appearance

which integrates

smoothly

with

surrotmding

cabinetry.

Models

36" wide models

42" wide models

48" wide models

and Accessory

//

qr

/

_'

_\\\\\\\\\\\\\\\\\\\\

are shii)ped

3/4" OverlayPanel_

J

_

i104";_i:kkSBPa:;:r

r Pp:::l

StandardDoorHandles

Trimmed

Refrigerators

Trimmed

refrigeratm_

are designed

to be customized

with decorative

panels. [qeld installed

custom door

and grille panels are required.

Standard supplied handles shown in 3/4" overlay panel position.

Door Handles

The standard

supplied

handles can be a(!iusted

to

accommodate

both fl'amed or overlay panels. Custom

handles

of your choice, SUl)plied by your cabinet maker

can also be installed

on 3/4" overlay panels. If desired,

you may order ZKHSS2 Monogram

stainless steel

tubular

handle kit Ira" 3/4" overlay panels.

Side Panels

Side panels

refrigerator

must be used whene_er

will be exposed.

the sides

of the

Standard supplied handles shown in 1/4" panel position.

Optional

ZKHSS2:

designed

Accessory

Accessory Kits

Monogram

Tubular Stainless

to nt./_

oxerlay panels.

Steel

handles

ZISW480D

ZPW480D

ZIS480N

ZPW480N

ZPS480D

ZPB480N

ZPS480N

ZPB420D

ZPS420B

Panels

ZISB420D

White, black and stainless steel accessory panels are

available fl'om yore" Monogram

dealer. Panels are

cut to size and ready to install.

6

ZISW360D

ZPW360D

ZIS360N

ZPW360N

ZPS360D

ZPB360N

ZPS360N

Design Guide

1/4" FRAMED PANEL DIMENSIONS

1_5/18"

L

If _ou

choose

cut

to the

into

the

to install

dimensions

fraine

on

Non-Dispenser

If the

fl'amed

panels,

shown.

the

The

door

and

they

panels

must

Door

be

Trim

Reveal

will slide

grille.

Models

custom

panel

loosely

in the

door

a piece

the fit,

of filler

is less

fl'ame

material

than

1/4"

it can

be

or

finm_

thick

and

backed

up

tape

it fits

\

with

to improve

IMPORTANTNOTE:Maximum total panel weight:

• Fresh food door panel-75 Ibs.

• Freezer door panel -53 Ibs.

• Grille Panel - 18 Ibs.

NOTE-

IMPORTANT

The

reli'igerator

one

fi)r

• If the

gap

fl'amed

panel

may

panels

is less

be

Foam

tape

the fit.

DISPENSER

is sui_plied

created

may

be

and

than

one

0,250"

around

applied

MODELS

with

two

fi)r

thick

the

on

dispenser

overlay

door

panel

dispenser

a noticeable

dispenser

the

• If the

trims,

panels.

See

Dispenser

is more

trim

than

cannot

Trim

0,250"

thick,

be secured

Fit Example,

page

trim.

to improve

Dispenser Cutout

The framed panel must be 1/4" nominal thickness

to fit the dispenser trim.

Grille Panel

15-3/8"

t

F

Cutout

Dispenser

_,

I_

94/8"

C

Side-by-Side(in inches)

Freezer

Panel

m

I_D_I

Fresh Food

Panel

m

I_E_

36"Models

42"Models

48"Models

33-7/8

39-7/8

45-7/8

9

9-1/2

9-1/2

68-3/8

68-3/8

68-3/8

14-9/16 18-9/16

14-9/16 24-9/16

18-9/16 26-9/16

the

to the

9.

door.

Design Guide

3/4" OVERLAY PANEL DIMENSIONS

OverlayPanel

Door

For a more custom appearance,

overlay panels may be

installed on trimmed

models. The overlay panel i/ltlst

be secured

to a 1/4" thick backer panel which slides

into the trim. A spacer panel 0.] 0" thick must be

placed between

the overlay and backer panel.

Assemble

the panels with glue and screws.

• Center the spacer panel on the backer panel, left to

right and top to bottom.

Secure the panels with glue.

• (:enter the spacer and backer panel on the overlay

panel and secure with glue and screws. Screws must

be countersunk

into the backer panel.

NOTE-

IMPORTANT

The

refi'igerator

one

fl)r

The

overlay

panel

be

fl'amed

panels

dispenser

thickness

• If the

is less

around

See Dispenser

Trim

two

and

one

trim

is designed

dispenser

fin" overlay

Backer_Panel_Spacer

trims,

• The

to fit a total

] .100"

the

dispenser

a noticeable

gap

may

panel

the

dispenser

trim

panel

will

Ht Example,

page

9.

a 3/4"

Another

on

not

When

a raised

middle

rail

constructed

to achieve

const_

uction

15-3/8"

F

methods

cannot

in the

panel

is required,

be

used.

required

C

correct

such

design

See

These

1.100"

is to be

page

94/8" _'_

36"Side-by-Side(in inches)

FreshFood

Panel

1/4"Backer Panel

.10"SpacerPanel

3/4"OverlayPanel

m

m

42" Side-by-Side(in inches)

_D_]

_E_

1/4"Backer Panel

.10"SpacerPanel

3/4"OverlayPanel

33-7/8

33

34-1/8

39-7/8

39

40-1/8

9

8-3/8

9-1/4

68-3/8

67

68-5/8

14-9/16 18-9/16

13-1/4

17-1/4

14-13/16 18-13/16

9-1/2

8-5/8

9-3/4

68-3/8

67

68-5/8

14-9/16 24-9/16

13-1/4

23-1/4

14-13/16 24-13/16

9-1/2

8-5/8

9-3/4

68-3/8

67

68-5/8

18-9/16 26-9/16

17-1/4

25-1/4

18-13/16 26-13/16

48" Side-by-Side(in inches)

1/4"Backer Panel

.10"SpacerPanel

3/4"OverlayPanel

45-7/8

45

46-1/8

8

to

total

as

used,

9 for

methods

panel

thickness.

a custom

details,

IMPORTANT NOTE:Maximum total weight for the assembled

panels:

• Fresh food door panel-75 Ibs.

• Freezer door panel -53 Ibs.

• Grille Panel - 18 Ibs.

I_

according

the

panel

to a 1/4" backer

panel

cannot

method,

routing

a 3/4" thick

all sides

result

be

*Cut the dispenser opening after the backer, spacer and overlay

panels have been assembled.

]_

m

must

shown

panel

secm'ing

be used.

trim.

1.100"

door.

Cutout

Dispensel

Freezer

Panel

overlay

the specifications

thickness.

• Alternative

than

top-to-bottom offset.

.250" + .10" + .750" = 1.100"Total Panel Thickness

panels.

Dispenser Cutout

GrillePanel

NOTE:Left-to-rightoffset

is not always equal to

',

1/4"

MODELS

with

panel

is more

than

be secured

to the

m

t

of 1.100".

panel

created

• If the

cannot

DISPENSER

is sui)plied

BackerPanel

\

Design Guide

DISPENSER MODELS:

RAISED OVERLAY PANEL DESIGN

1/4" Backer

When

a raised

custom

the

wide

panel

middle

dispenser

• The

rail

is to be

is required

used,

.10" SF

a

3/4" OverlayPanel

to accept

trim.

middle

rail

for the dispenser

• The middle

rail

to accept

design

the

must

be wide

trim

must

to overlap

be 1.100"

dispenser

enough

to allow

the

total

opening.

thickness

trim.

J

Dispenser

Trim

Wide

Middle

Railis

Required

16-3/4"

10-5/8%___,.

DISPENSER TRIM FIT EXAMPLES:

(NOT TO SCALE)

1/4" FRAMED

• The

dispenser

custom

freezer

• The

the

clips

• If the

trim

panel

door.

will

panel

panel

not

engage

gap

the

over

snaps

into

than

is less

a noticeable

fits

and

is more

around

PANEL

than

may

the

the

door

0.250"

thick.

0.250"

thick,

1/4" Dispenser Trim

be created

dispenser

dispenser

custom

freezer

trim.

• The

the

clips

will

panel

• If the

panel

the

fits

over

and

snaps

not

engage

is more

a noticeable

around

trim

panel

door.

gap

into

than

is less

than

mav

dispenser

0.250"

Thick

if

3/4" OVERLAY PANEL

• The

FREEZERDOOR

1/4"

Framed

the

be

1/4"Backer

Panel

FREEZERDOOR

1.100"

Total Thickness

the

.lO"Spacer

Panel

the

the

door

1.100"

thick.

1.100"

thick,

if

created

trim.

3/4" Overlay Dispenser Trim

Design Guide

SIDE PANELS

FLOORING

Side panels must be used

whenever

the sides of the

For

placed

on

refrigerator

will be

exposed.

The 1/4" side

panels will slip into the

side case trim. Secure the

at the

same

panels to the refrigerator

with stick-on hook and

_84"

a notch

fl'Oil[

coi'ilei"

,

3?

•

•

•

•

Tinsnips

to cut banding

Stepladder

Bucket

I,evel

•

•

•

•

•

•

Appliance

Hand THick

Tubing cutter

7/16" open-end

wrench

#2 Phillips screwdriver

Drill and ai)i)ropriate

bits

5/16", 7/16" socket

be

as the

strong

of the

enough

the

section

cardboard

finish

where

carton

w)u

are

a flfllv

1,500

and

lbs.

Cut

place

is

This

to support

flooring.

of the

be

that

flooring.

or approximately

NOTE: Protect

of the

rest

must

material

a large

trader

the

working.

THE REFRIGERATOR

on installation

HARDWARE

carefully)

MUST

The power cord of this appliance

is equipped

with

a 3-prong

(grotmding)

plug which mates with a

standard

3-prong

(grotmding)

wall receptacle

to

minimize

the possibility

of electric shock hazard

from this appliance.

Have

the wall outlet

qualified

properly

electrician

grounded.

and circuit

to make

checked

bv a

sure the outlet

is

Where a standard

2-prong wall outlet is encotmtered,

it is yore" personal

responsibility

and obligation

to

have it replaced

with a properly

grounded

3-prong

wall outlet,

DO NOT, UNDER ANY

CIR(:UMSTANCES,

CUT

OR REMOVE THE THIRD

(GROUND)

FROM THE

PRONG

POX_ ER CORD.

screwdriver

f--,a

_-)

y<

DO NOT USE AN ADAPTER

PLUG TO CONNECT

THE REFIIIGERATOII

TO A 2-PRONG

OUTLET.

SUPPLIED

• _hter

filter bypass I)lug

• Anti-Tip brackets

• l/4" Iltlt alld teritlle

DO NOT USE AN EXTENSION

APPI,IANCE.

• Dispenser

trims for 1/4" and 3/4" overlay panels

• A1tli/liiltlill cover tiiil/ tor 3/4" overlay panels with

custom handles.

]nchldes

22 fiat head screws and

4 endcaps.

MATERIALS

read

heiflht.

wrench

Phillips

- (Please

FOR PERSONAI,

SAFETY, THIS APPI,IANCE

BE PROPERI,Y

GROUNDED.

2-g/16"

glasses

open end wrench

• #2 Stubby

refl'igerator,

IMPORTANT

_3" to 4"

TOOLS REQUIRED

ratchet

should

loaded

refl'igerator

of hard

_lS showil

Dependin0

• 1/4"

height

sm'lace

this

sm'tace

GROUNDING

in the top

to allow clearance

fin.

corner

keys in the ti'ont

side trim,

• Safety

• l-I/4"

• Pliers

installation,

a level

refl'igerator

loop fastener

strips. Order

the side panels from the

cabinet manufi_cturer.

• ()it

proper

REQUIRED

• 35" long 2x4 fl>r Anti-Tip suI)port

• 1/4" copper

water line tubing or GE

Si//artCoililect

TM Refl'igerator

Tubing kits

• _4"_ter shut-offwflve

(optional

but recommended)

• Custom panels for doo_

and grille panel

• Screws to secm'e refl'igerator

to cabinett T

• Stick-on hook and loop fastener

strips tor

1/4" side panels

10

CORD

WITH

THIS

Installation

Instructions

• Remoxe

ISTEP 11REMOVE PACKAGING

CAUTI0N: Relrigerator

is much

hea, ier at the

PRUDENCE:i,e

• Careflflly cut banding

reulove

otffer carton.

ATTEMPT

TO ROI,I,

UNIT OFF SKID.

be...,.p

Remove

PRUDENCE:n,NE

lots

TieDowns FAUT PAS ESSAYER DE

• Support

blocks on the bottom

of the refl'igeration

case must be removed

befi)re the refl'igerator

is

taken off the skid or damage

will occm'. Careflflly;

tilt refl'igerator

and slide blocks out from beneath.

• Remove toekick, set aside fin" final installation.

NOTE: IT IS NOT NE(:ESSARY TO lAY CABINET

DOWN IN ORDER TO REMOVE SKID!

unit is secured

EMRE ROUI,ER

I,E

I_d_FRIGt_RATEUI _. POUR

I,'ENI,EVER

DE lAY

PA1,ETTE.

--,"

%

at the top and bottom,

• Slide out back corner posts (2).

• Slide carton off top of cabinet.

• The

the straps

CAUTION:DoNOS

top than at the botton/

- be careflll when moxing

X4hen usim* a hand track, handle fl'om side onE.

plus hmrd en haut qu'en bas. ll taut 6tre prudent

des d_placements.

Si tm diable est utilis_, il taut

soulexer le r_frig&'atetu

_sur le c'6t_ seulement.

the fore" 7/16"

bolts secm'ing

to the skid.

J

to the skid with 4 slotted

tie-down straps. Remove the timr 5/16" bolts

fl'om the base channels

in the tie-downs.

• I.ifl the refl{gerator

dolly. Handle fl'om

off the skid with an appliance

the sides.

[STEP 2] INSTALL WATER LINE

• A cold water SUl_ply is required

fin" automatic

icemaker

operation.

The water pressure

must be

between

40 and 190 p.s.i.

• Route l/4" OD COl)per or GE SmartConnect

'_

plastic tubing between

house cold water line and

the water connection

location.

Copper Tubing A'

Shut off the main water supply.

Turn on the nearest taucet long enough

to clear the

line of water.

• Install a shut-off valve between

the icelnaker

water

• Tubing should be long enough

to extend to the

fl'ont of the refl'igeratm:

Allow enough

tubing to

accommodate

bend leading

into the water line

valve and cold water pipe

The shut-off wflve should

be easily accessible.

connection.

NOTE:The only GE approved

plastic tubing is

sui)plied in the GE SmartConnect

TM Refl'igerator

Tubing kits. Do not use any other plastic water sui)ply

line because

the line is trader pressure

at all times.

Other types of plastic Inav crack or IUI)ture with age

_lll(1

Catlse

water dalnage to VO/lI" houle.

GE SmartConnect

"_Refl'igerator

Tubing

available in the fi_llowing lengths:

2' (.6 m)

WXO8XIO002

6' (1.8 m)

WXO8XIO006

15' (4.6 m) X,_3XO8XIO015

25' (7.6 m) X,_3XO8XlO025

• Turn

on the main

water

in a basement

or cabinet.

be located where it will

SUl)ply and flush

debris.

Run about a quart of water through

the tubing into

a bucket. Shut off water sui)ply at the shut-off wflve.

NOTE: Saddle tyi)e shut-off wflves are included

in

many water sui)ply kits. Befln'e pro'chasing,

make

stu'e a saddle type wflve complies

plmnbing

codes.

Kits are

with yore" local

NOTE: Commonwealth

of Massachusetts

Plmnbing

Codes 948CMR shall be adhered

to. Saddle valves

are illegal and use is not permitted

Consult with wmr licensed phunber.

11

in Massachusetts.

Installation

Instructions

ISTEP 2AI INSTALLATION WITH

HOUSEHOLD WATER

FILTRATION SYSTEM

I STEP 41 INSTALL ANTI-TIP BRACKETS

WARNING:Am,-T,p

PRECAUT,ONS

The

Skip this step if you do not have a household

water filtration system

If the

water

household

should

be

supply

water filtration

removed.

For

periin'mance,

bypass

to the

remove

refrigerator

is fl'om

filter

and

install

the

the

is top-hea_y

possibility

and

must

of tipping

be secured

to

forward.

ATTENTION:PRECAUTIONS

COmRE

,ES

any

BASCULEMENTS

system,

the filter

cartridge

better

ice and water

the

refl'igerator

prexent

I,e r(_frig_rateur

flint

filter

son

plug.

est beaucoup

le maintenir

en

basctlleillent

• Cut

place

_,ers

. :)

long

brackets

2 x4Cut_,

lom'd

&iter

haut

et il

la possibilit_

en

de

l'_l_,_lil[.

a 2" x 4" block,

to the mortaring

wood screws.

plus

pore"

and

secure

proxided

the

using

block

# 12 or # 14

-

35" Length ;

,_

Installation

Height

FromFloor

Mounting

Bracket

ISTEP 31 INSTALL SIDE PANELS

ScrewsMountedintoJ"

Vertical Wall Studs

Skip this step when not using side panels,

If you

are

inserted

using

into

refl_igerator

strips

beiin'e

1/4"

the

with

case

side

trim.

stick-on

setting

panels,

Fasten

hook

refl'igerator

and

they

should

be

the

panels

to the

loop

• Secure

the

bracket

with

wood

block

so that it is 84" (or yore" installation

the finished

floor.

Use #12 or #14

fastener

in place.

See

to the

back

wall

height)

fl'om

wood

screws.

illustration.

Brackets

Required

-__

Height

From

Floor

to

Bottom

of Wood

Block

Brackets

Not Required

Beneath a

Soffit

SideView

• Screws must

wall studs.

penetrate

at least one inch

into vertical

• Befi)re pushing

the refrigerator

into the opening,

plug the power cord into the receptacle.

Open the

grille panel and reach into the opening

at the back

to grasp the power cord. Pull the power cord into

the opening

as you push the refl'igerator

back.

• Gently push refl'igerator

into the opening

with

hands against fl'ont corners.

IMPORTANT NOTE:When the refrigeratoris installed undera soffit or

if there is not enoughheightfor this methodof security,bracketscannot

be used.Proceedto step 5 to levelthe refrigeratorandthen to step 7

to securerefrigeratorto cabinets.Seestep 6 if you havemetalwall

studs.The refrigeratormustbe securedto preventtipping.

12

Installation

Instructions

ISTEP 51 LEVEL REFRIGERATOR

I STEP 61 ALTERNATE ANTI-TIP

PROCEDURE

All models have 4-point leveling. The thmt is

supported

by leveling

a_!justable

wheels.

of the

legs,

Both

the

are

rear

is supported

by

fl'om

the

fl'ont

turn

the

accessible

The

7/16"

the

back

hex

clockwise

nut

of the

located

to raise

refligerator,

above

or

the

fl'ont

wheels.

com_terclockwise

be

secured

refrigerator

against

tip-over

are encountered

mad there

Turn

to lower

must

to prevent

tipping.

The mlti-tip

brackets

cmmot

be used on metal

studs.

Use this Alternate

Procedure

to secure

refligerator.

• To level

refrigerator

the

whenever

is no soffit.

metal

wall

the

wall

studs

refl'igerator.

• For

fl'ont

• A(!just

leveling,

height

use a ]-1/4"

open-end

of refl'igerator

cutout

opening

83-1/2"

should

be

and

level

wrench.

to match

The refligerator

to 84-1/2".

phunb

with

installation

cabinetry.

Side View

Top CaseTrim

/[

i

i

!

I

=

!

!

Hex Nut Adjusts_]

Install Four

1-1/2" DrywallScrews

ThroughTrimand IntoSoffit

or 3/4" Min. Wood Brace

Rear Whei__eg

• Raise

• Use a

holes

• Use a

metal

holes

CAUTION:

The

rear

limited

leveling

installation

should

of pl}_vood

added

across

elew_te

the

If you

thm_

and

more

leveling

top

84-1/2"

opening

to raise

will

rear

leveling

on

trim

the

wood brace. The brace spanning

be secm'elv tastened

to cabinets

the

a sheet

could

also

to shorten

the

dmnage

are

of 1". If the

height,

refl'igerator

of the

attempt

legs

ac!justment

Cabinetry

1", you

the

fl'ont

than

the

or rtmners.

opening.

legs

and

height

requires

installer

more

wheels

to a maximum

• Install

be

the

refrigerator

front

leveling

wheels.

PRUDENCE

I.es

roues

de nivellement

nivellement

de

avant

25 mm

a tree

(l po).

hauteur

de

doit

finition

et les

des

de

des

le haut

le r_fi'ig_ratem"

les

_fivellement

po),

sur

de

l'ouverture

de

pattes

une

ll est

baguettes

de

de

maximal

(84-1/2

glissi&res,

le r&frig&rateur

endommage

roues

m

le r_li'ig_ratem"

ou

sur

Lever

25 Inln (1 po)

pore"

_'l 2,15

d'ajouter

placards

de la r_duire.

avant

_lever

possible

des

r_glage

Si l'ouverture

contre-plaqu6

_galement

et les pattes

un

sup_rieure

l'installatem"

feuille

artiste

permettent

plus

the grille panel to access case trim.

3/16" bit to drill tour evenly spaced clearance

through

the metal top case trim.

1/16" bit to drill to pilot holes through

the

clearance

holes and into the wood sottit, The

should be centered

in the sottit or a 3/4" rain.

afin

de

de nivellement

arri&re.

13

flmr,

1-1/2"

drywall

screws

the enclosm'e

on both sides.

into

the pilot

must

holes.

Installation

Instructions

ISTEP71SECURE REFRIGERATOR

[STEP 9] INSTALL GRILLE PANEL

TO CABINETRY

_'_ henexer

security

The

i)erfiwm

or when

anti-tip

refrigerator

• Raise

the

• Drill

into

possible,

hole

grille

panel

in trim

ac!jacent

• Follow

must

the

and

be

this

step

brackets

cannot

secured

to prevent

to access

drive

case

screw

To insert fl'amed

• Raise the grille

for anti-tip

be

or o_erla) panel into the grille:

panel to stop position.

used,

tipping.

trim.

through

the

trim

cabinet.

same

procedure

on

the

opposite

side.

L00_

Side

Trim

Screw

Side

Trim

Screw

ThroughCaseTrimInto

AdjacentCabinets

Adjust Nut Below

Spring to Accommodate

Panel Weight

• I,oosen

ISTEP 81 ADJUST

DOOR SWING

bottom

on side trim

CAUTION:

NOTE: This refrigerator

has a 2-position

door stop.

When space does not allow the door to swing open

fldlv to 130 °, you may change

the door

opening.

Skip this step if door opening

for your installation

situation.

screws

behind

frame.

Remoxe

trim.

p.,.e,

,.,...

,.e

slippery.

Grip metal panel firmly; so the panel does

not slip out of the fl'ame and cause personal

i_wry

or damage

to the fl'ame.

swing to a 90 °

is satisfactory

PRUDENCE •• I,e

panneau

en m_tal

peut b&tre glissant. Tenir fermement

le panneau

en

m_tal, de mani&re _'lce que le panneau

ne glisse pas

en dehors du cadre en provoquant

des blessm'es

corporelles

ou des dolnlnages

au cadre.

• Slide panel over the metal backer panel and into

the trim.

130°

• If necessary, tap with a wood block until panel slips

under the top trim piece.

• Reassemble

bottom

trim. Tighten

screws.

• A(!just the hinge spring to accommodate

the panel

weight, if necessary.

Door

Hinge

• Open the door to view the bottom

hinge. Note the

door stop pin locations.

The pin is thcto_ T installed

in the 130 ° position.

• (:lose the door. From belo_, use pliers to tlIISCI'ew

the door stop and reinstall into the 90 ° position.

14

Installation

ISTEP 101 INSTALL

Instructions

1/4" FRAMED PANELS

Go to Step9Afor OverlayPanels

Handle

j

DoorTrim

Trim

Refrigerator

Door

Supplied

Handle Shown

in I/4" Panel

Position

-Install door panels:

• Open door to 90 °. l_.elnove the 6 Phillips

fl'om the door handle.

• Relnove handle.

Retain all screws.

• Remove

screws.

6 screws

• Slide fl'amed

panel

holding

into

trim,

head

lilt otI trim.

the door

screws

Retain

trim.

Dispenser

Models Only:

• The dispenser

controls

prottude

bevond the lace of

the fl'eezer door. To avoid damage

to the dispenser,

the trim at the top of the door should be removed.

• Renlove the screws holding

the top trim in place.

• Place the fl'eezer panel into the bottom channel

and

slide into the hinge side trim.

• Reinstall

the top trim piece with screws.

• There

are two sets of holes

in the handle

Replace handle side trim by installing

screws in the FRONT screw holes.

• Secure

holes.

the handle

to the door

/

side trim.

the original

using the

REAR screw

• Follow the same procedures

to install the opposite

panel.

• Check to be sure handles are evenly aligned with each

other at the top. To a_)iust, loosen handle screws and

slide up or down. Tighten

screws.

\Use RearHoles

to SecureHandle

NOTE: Aluminum

cover trim is supplied fl)r use with

custom handles

on overlay panels. It is not intended

for

use with 1/4" panels. Discard the cover trim when using

1 / 4" ti'amed panels.

15

Installation

Instructions

[STEP 10A] INSTALL OVERLAY PANELS

DoorTrim

Handle

Trim

Refrigerator

Door

Move

Forward

For3/4"

Panel

Supplied Handle

Shown in Overlay

Panel Position

Install

•

door

Open

panels:

door

to 90 °. Relnove

tile door

handle.

fl'om

tile

all

• Remove

handle.

Retain

• Remove

6 screws

holding

6

Phillips

head

screws

screws.

trim,

lift off trim.

Retain

scFews.

• Slide

overlay

Dispenser

• Tile

panel

Models

fl'eezer

the

trim

• Place

at the

the

the

channel

top

of the

are

into

top

trim

sets

• Secure

holes.

the

handle

• Follow

tile

same

into

side

with

removed.

in place.

the

bottom

trim.

handle

by installing

holes.

procedures

of

screws.

its tile

door

lace

dispenser,

be

trim

panel

of holes

to the

top

hinge

piece

tile

to the

should

the

the

Replace

handle

side trim

screws

in the REAR screw

bewmd

door

fl'eezer

slide

two

trim.

damage

holding

assembled

the

door

protHide

To avoid

screws

and

• Reinstall

• There

controls

door.

• Remove

tile

Only:

dispenser

the

into

side

the

using

to install

the

trim.

original

FRONT

tile

screw

opposite

Use Front Holes

to Secure Handle

panel.

• Check

other

slide

to be sm'e

at tile

up

top.

or down.

handles

To

are

a_!iust,

Tighten

evenly

loosen

aligned

handle

with

screws

each

UseRoarHoles

to SecureTrim

and

screws.

16

Installation

Instructions

ISTEP IOA] (continued)

Custom

ISTEP IOA] (continued)

Handles

• Carefully place the aluminum

cover trim into top

end cap so that the recess is aligned with the cap.

Use the top to bottom grooves ahmg the handle side

to align the cover trim accurately:

Pull tape a tew

inches at a time while pressing

the trim against the

door. Press and hold approximately

10 seconds

befl)re continuing

ahmg the length of the door.

• Install another end cap at the bottom of the door

to secure the cover trim. Use a stubby Phillips head

screwdriver

and 2 screws provided.

NOTE: Make sure there are no gaps in the installation.

• Follow the same procedure

on the opposite

door.

• If )'ou are using custom handles,

the handle must be

properly

secured to the overlay panel before sliding

the panel into the trim.

• The cabinet manufacturer

will supply the custom

handle and hardware.

• Discard

the supplied

handle.

Reinstall all original screws.

• Reinstall

the handle

side trim

using

all 12 supplied

flat-head

screws, plus the 12 flat-head screws

originally

installed in the handle

trim.

• Install a supplied

end cap onto the top of the door

using a Phillips head screwdriver

and 9 screws

provided.

Hmld-tighten

screws into end caps. Do not

overtighten;

damage

will occur.

• Clean the aluminum

do not use alcohols

prevent

adhesion

trim with _ubbing alcohol with oil or lanolin that will

of double-sided

tape.

• Slip ahuninuln

cover trim behind

the top end cap to

check fit. The aluminum

cover trim has a recess on

each

end which

fits the end

cap.

Cover Trim

Insert

Aluminum

Trim Int0

End Cap.

+

• Remove

the trim.

Peel away a ti_w inches

adhesive

backing.

IMPORTANT: Tape is very stick}' and strong.

adheres

to a surthce, it cannot be removed

of the

Once it

without

damaging

both surlaces. Do not install the trim before

the final wood panels are in place. Be sure to align the

t_im careflfllv befl)re removing the paper backing.

17

Installation

Instructions

[STEP 111 INSTALL DISPENSER

TRIM

[STEP 12] CONNECT WATER SUPPLY

1[

Skip this step is you are installing a stainless

steel wrapped or a non-dispenser refrigerator.

There

are

two

refrigerator,

dispenser

Select

trims

the

shii_ped

ai)i)ropriate

with

tFim

E

)our

fin" _our

application,

Framed

Panel

Trim

Overlay

Panel

Trim

>

WaterSupply_

• i,ocate and bring tubing to the fl'ont of the cabinet.

• Turn the water on to flush debris fl'om line. Run

about a quart of water

then shut-ott water.

Compare the dispenser trims. Note that the inside

depth of the frames are different. Choosethe trim

with less depth for framed panels, choose the

deeper one for overlay panels.

Dispenser

trim fit o_er the custom

correct panel thickness.

See pages

consti

tlction

infoY/ll

through

tubing

into

a bucket,

Copper Tubing:

• Slip a 1/4" nut and tbHule

(provided)

over both

ends of the COl)per tubing. Insert tube into the

union fitting on the unit and tighten nut to union.

• Turn on the water to check fin" leaks.

panel depends

on

7 and 8 for panel

ation,

GE SmaactCom_ecf'"

Tubing:

• Insert the molded

end of the tubing into the

refl'igerator

connection.

Tighten

the compression

nut until it is just hand tight.

• Tighten

one additional

turn with a wrench.

Overtightening

can cause leaks!

• Turn on the water to check fin" leaks.

NOTE:Make sure excess tubing

interfere

• Press

and

dispenser

If an

excessive

or if the

tape

the

snap

may

trim

around

the

recess

panel

the

the

gap

exists

fits

loosely

be applied

and

dispenser

on

panel

dispenser

trim

refrigerator

around

in the

apply

and

the

dispenser

door

fl'ame,

fi>am

the

Remove

loam

in the

the

door,

to hel I) improve

and

into

tape

fit.

t_im

to the

door

corners,

18

with toekick

installation.

length

does

not

Installation

Instructions

ISTEP 15] INSTALL TOEKICK

ISTEP 131 CHECK POWER, CLOSE

GRILLE PANEL

• Check

the

to be

sure

the

power

cord

is I)lugged,,

• I,ocate

the

into

the

side

provided,

receptacle,

suI)plied

of the

toekick

(shii)ped

refrigerator).

a(!just

taped

Install

to desired

with

height

and

to

2 screws

tighten

scFews.

• A custom

--I ri,,e l

-

-

-

Raise

r 7---

[

sui)plied

PaneIT_-_Lr

'\

]'_]

Master Light

toekick

complement

can

the

toekick

be installed

to match

surrom_ding

cabinetry.

as a template

to cut

or

Use

the

the

shape.

Supplied T0ekick

Ele!trical

I]

/

Outlet

-%

%

Sw tch

• Check

to make

opening

sure

refl'igerator

]I

power

door

1/4" or Thicker Toekick

to refl'igerator

to see

is on

if interior

by

lights

",%

,%

are on.

• The telni)erature

the fl'esh tood

• Allow

24

a (!j tlStI//e

horn's

controls

section

and

to stabilize

are preset

at 37°F it)i"

0°F tot the fl'eezer.

betore

INSPECT FINAL INSTALLATION

making

n is.

Check

door

aligmnent

Stand

back awav

final installation.

• Check

ISTEP 141START ICEMAKER

each

screws

• Dm'ing

panels

PowerSwitch

out

to be

other

and

fl'om

sure

at the

slide

shiI)ping

may

of aligmn

have

the

refl'igerator

handles

are

top.

a@lst,

up

To

to inspect

evenly

or down.

aligned

loosen

addition

caused

the

screws.

of heavy

doors

with

handle

Tighten

or the

the

door

to move

slightly

ent.

"Door Outof

Alignment

GreenPowerLight

• Flip

the

switch

operation

to ] (ON).

The

icemaker

will

//

begin

automaticallv.

• Be sm'e nothing

feeler

arm.

interferes

• Discard

the

first

fidl

• To turn

the

icemaker

with

bucket

off; set

the

sweep

of the

of ice cubes,

the

switch

to O (OFF),

• If necessary,

up

or

• Use

S h own.

19

down

a 5/16"

the

fl'esh

rood

door

to align

with

the

wrench

to a(!just

may

fl'eezer

the

be a(!justed

door,

hinge

pin

as

NOTE:While performing installations described in this book,

safety glasses or goggles should be worn.

o

6)

/_r 3/_0)zog'r.m

Iocnl s(o-vice i)z ._(mr (m_., c(dl

l.(500.444, l,_4).

NOTE:})ro(|ti(:l

(;(:n(:r_d

sl)(_tifl(:aliolls

Pub.No. 49-60314

h_ll)l-()'_(m(

El(_(tri(:.

Th(:r(:fLr¢_,

m'(_ sulzje(t

ill

i'_ a (:olHilitlillg

mal(_rials,

to (ll_lllg(

(_n(l(avor

_/i)l)(ai-an(

W]lhotll

_lt

¢ a11(1

lloli(:(.

Monogram:

Dwg.No. 197D5947PO01

GE Consumer & Industrial

01-04 JR

Louisvifle, KY40225

26054-0

(#)2004GE Company