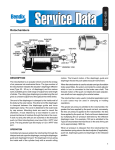

Download BENDIX MC-12 MODULATOR CONTROLLER ASSY Troubleshooting guide

Transcript