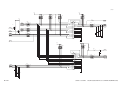

Download Canon CanoScan FB 630U Service manual

Transcript