Download Mitsubishi PEN-2.5 Service manual

Transcript

OC129A-1.qxp

01.10.1 7:33 PM

Page 1

1997

SPLIT-TYPE,AIR CONDITIONERS

No. OC129

REVISED EDITION-A

TECHNICAL & SERVICE MANUAL

Series PK Wall Mounted

Indoor unit

[ Model names ]

[ Service Ref. ]

1997, 1999, 2001

PK-2.5FLA

1997

1999

PK-1.6FLA3

PK-2FLA3

PK-2.5FLA2

PK-3FLA

PK-3FLA2

PK-4FLSA

PK-4FLSA2

PK-1.6FLA

PK-2FLA

PK-3FLA3

2001

PK-2.5FLA3

PK-2.5FLA4

PK-3FLA4

PK-3FLA5

PK-4FLSA3

PK-4FLSA4

CONTENTS

Indoor unit

˚C

AM

PM

AM

PM

NOT AVAILABLE

ON / OFF

TEMP

PK-1.6FLA3

PK-2.5FLA4

PK-2FLA3

PK-3FLA5

PK-2.5FLA2/3

PK-4FLSA4

PK-3FLA2/3/4

PK-4FLSA2/3

REMOTE CONTROLLER

• PK-2.5FLA3, PK-2.5FLA4, PK-3FLA3, PK-3FLA4, PK-3FLA5,

PK-4FLA3 and PK-4FLA4 are added in REVISED EDITION-A.

• Please void OC129 and OC200.

• This manual does not cover outdoor units. When servicing

them, please refer to the service manual No.OC127 REVISED

EDITION-A, OC187, OC217 REVISED EDITION-A and this

manual in a set.

1. TECHNICAL CHANGES ·······························3

2. COMBINATION OF INDOOR

AND OUTDOOR UNITS ··············3

3. PART NAMES AND FUNCTIONS ················3

4. SPECIFICATIONS ·········································6

5. DATA ···························································13

6. OUTLINES AND DIMENSIONS ··················16

7. WIRING DIAGRAM ·····································20

8. REFRIGERANT SYSTEM DIAGRAM···············22

9. OPERATION FLOW-CHART ······················24

10. MICROPROCESSOR CONTROL ···············27

11. TROUBLESHOOTING·································36

12. DISASSEMBLY PROCEDURE ···················39

13. PARTS LIST ················································42

14. OPTIONAL PARTS ·····································54

OC129A-1.qxp

01.10.1 7:33 PM

Page 2

OC129A-1.qxp

01.10.1 7:33 PM

1

Page 3

TECHNICAL CHANGES

PK-3FLA2 ➔ PK-3FLA3

PK-2.5FLA3 ➔ PK-2.5FLA4

PK-3FLA4 ➔ PK-3FLA5

PK-4FLSA3 ➔ PK-4FLSA4

● Outdoor units has changed.

● The parts No. of REMOTE CONTROLLER has changed.

(The following parts numbers are interchangeable.)

PK-2.5FLA2 ➔ PK-2.5FLA3

PK-3FLA3 ➔ PK-3FLA4

PK-4FLSA2 ➔ PK-4FLSA3

●

●

●

●

NOSE has changed by changing its shape.

UNDER PLATE has changed.

BOX ASSEMBLY has changed by changing its shape.

DRAIN PAN has changed by changing its shape.

˚C

AM

PM

AM

PM

NOT AVAILABLE

ON / OFF

TEMP

[ T7W 570 200 ]

2

COMBINATION OF INDOOR AND OUTDOOR UNITS

Indoor unit

PU-1.6

PU-2

PU-2.5

PU-3

PU-4

PU-3

PU-3

VLJSA2 VJA2 NJA1 VJA2 NJA1 VJA2 YJA2 YJA3 NJA1 VLJSA2 YJSA2 YJSA3 TJSA2 VJC YJC VJB YJB

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

PK-2FLA3

—

PK-2.5FLA2

PK-2.5FLA3

PK-2.5FLA4

—

—

—

PK-3FLA2

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

PK-3FLA3

PK-3FLA4

PK-3FLA5

PK-4FLSA2

PK-4FLSA3

PK-4FLSA4

Outdoor unit Outdoor unit

(OC187) (OC217

REVISED EDITION-A)

Outdoor unit

(OC127 REVISED EDITION-A)

PK-1.6FLA3

3

[ T7W E06 714 ]

—

PART NAMES AND FUNCTIONS

● Indoor Unit

Air intake

Room air is suctioned

in here.

Filter

Air intake grille

(Removes dust and dirt from the intake air.)

Guide vane

Swing louvers

Air flow can be changed to horizontally

by moving the Guide vane to the left or

right.

Disperses airflow up and

down as well as adjusts the

angle of air flow direction.

Air outlet

Air outlet

3

OC129A-1.qxp

01.10.1 7:33 PM

Page 4

●Remote controller

● When cover is closed.

display

PK-1.6FLA3

PK-2FLA3

PK-2.5FLA2, PK-2.5FLA3

PK-3FLA2, PK-3FLA3, PK-3FLA4

PK-4FLSA2, PK-4FLSA3

Part No.

[ T7W 570 200 ]

display

SET TEMP. display indicates desired temperature set.

OPERATION MODE display

Operation mode display indicates which operation mode is in effect.

• CHECK • TEST RUN display

CHECK&TEST RUN display indicates that the

unit is being checked or test-run.

CLOCK display

˚C

display

DIsplays the current time.

AM

PM

“

AM

PM

Displays when batteries are dead.

”display

NOT AVAILABLE

Flashes when the current time is displayed.

display

ON / OFF

TIMER display

Displays when setting timer.

Displays when in timer operation or when setting timer.

display

➡

” display

Displays the order of timer operation.

TEMP

display

“

The vertical direction of airflow is indicated in

marks.

”“

” display

“

FAN SPEED display indicates which fan speed

has been selected.

▼

”“

▼

▼

Displays whether timer is on or off.

display

” display

Displays when the current time and the timer

time can be changed.

button

button

SET TEMPERATURE button sets any desired

room temperature.

Push to start operation. Push again to stop

operation.

SET CLOCK button

● When cover is open.

Button used to set the current time.

MODE SELECT button

MODE SELECT button is used to change

cooling. dry (dehumidify) and fan (ventilation)

operation modes.

”“

➡

“

Lights when signal is sent from the remote

controller to the indoor unit.

ON / OFF

TIMER CONTROL buttons

MODE

CLOCK

FAN

FAN SPEED SELECT button

VANE

STOP

START

HR

MIN.

FAN SPEED SELECT button selects low or

high fan speed.

STOP (OFF timer): when this switch is set,

the air conditioner will be automatically

stopped at the preset time.

START (ON timer): when this switch is set, the

air conditioner will be automatically started at

the preset time.

VANE CONTROL button

HR. and MIN.buttons

VANE CONTROL button regulates the vertical

distribution of airflow.

Buttons used to set the “hour and minute” of

the current time and timer time.

4

OC129A-1.qxp

01.10.1 7:33 PM

Page 5

●Wireless remote controller

● When cover is open.

PK-2.5FLA4

PK-3FLA5

PK-4FLSA4

Part No.

[ T7W E06 714 ]

CHECK TEST RUN display

CHECK&TEST RUN display indicates that

the unit is being checked or test-run.

MODEL SELECT display

display

Blinks when model is selected.

Lights up while transmission to the indoor

unit is mode using switches.

display

SET TEMP. display indicates desired temperature set.

CLOCK display

display

Displays the current time.

OPERATION MODE display

Operation mode display indicates which operation mode is in effect.

TIMER display

CHECK TEST RUN

MODEL SELECT

˚C

AMPM

Displays when in timer operation or when

setting timer.

“

AMPM

NOT AVAILABLE

display

The vertical direction of air flow is indicated.

ON/OFF

“

TEMP

”“

” display

Displays the order of timer operation.

”“

” display

Displays whether timer is on or off.

display

button

FAN SPEED display indicates which fan

speed has been selected.

FAN

AUTO STOP

VANE

AUTO START

SET TEMPERATURE button sets any desired

room temperature.

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

MODE

CHECK LOUVER

h

FAN SPEED SELECT button

Used to change the fan speed.

MODE SELECT button

TEST RUN

SET

min

RESET

Used to switch the operation mode between

cooling, drying, fan.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch

is set, the air conditioner will be automatically stopped at the preset time.

AUTO START (ON timer): when this switch

is set, the air conditioner will be automatically started at the preset time.

CLOCK

h and min buttons

Buttons used to set the “hour and minute” of

the current time and timer settings.

LOUVER button

CHECK-TEST RUN button

This switch the horizontal fan motion ON

and OFF.

Only press this button to perform an inspection check or test operation.

Do not use it for normal operation.

(Not available for this model.)

CLOCK button

VANE CONTROL button

RESET button

Used to change the air flow direction.

SET button

5

OC129A-1.qxp

01.10.1 7:33 PM

4

Page 6

SPECIFICATIONS

1. STANDARD SPECIFICATION

Service Ref.

Item

Indoor, Outdoor D.B./W.B.°C

Condition

Capacity w1

Btu/h

W

kW

REFRIGERANT PIPING

OUTDOOR UNIT

INDOOR UNIT

Total input w1

Service Ref.

Power supply(phase, cycle,voltage)

Input

kW

Running current (Power factor)

A (%)

Starting current

A

External finish

Heat exchanger

Fan(drive) o No.

Fan motor output

kW

Airflow (Low-High)

m3/min(CFM)

Pa(mmAq)

External static pressure

kW

Booster heater

Operation control & Thermostat

dB

Noise level (Low-High) w2

mm(in.)

Cond. drain conn. O.D.

W

mm(in.)

D

mm(in.)

Dimensions

H

mm(in.)

kg(lbs)

Weight

Service Ref.

Power supply (phase, cycle, voltage)

kW

Input

A(%)

Running current (Power factor)

A

Starting current

External finish

Refrigerant control

Compressor

Model

kW

Motor output

Starter type

Protection devices

Heat exchanger

Fan(drive) o No.

kW

Fan motor output

m3/min(CFM)

Airflow

Defrost method

dB

Noise level w2

mm(in.)

W

mm(in.)

Dimensions

D

mm(in.)

H

kg(lbs)

Weight

W

Crankcase heater

kg(lbs)

Refrigerant Charge

mm(in.)

Liquid

Pipe size O.D.

mm(in.)

Gas

Indoor side

Connection method

Outdoor side

Between the indoor &

Height difference

outdoor units

Piping length

w1

w2

w3

w4

w5

w6

w7

PK-1.6FLA3

PK-2FLA3

27/19.0°C, 35/24°C

w6

27/19.0°C, 35/24°C

Cooling (JIS B8616)

w7

Cooling (JIS B8616)

19,000

19,100

16,000

13,300

5,450

5,600

4,600

3,900

2.54

2.52/2.56

3.06

1.49/1.59

PK-2FLA3

PK-1.6FLA3

Single, 50Hz, 220/240V

Single, 50Hz, 220/240V Single, 60Hz, 220V

0.07

0.08

0.09

0.32(99/91)

0.37(98/90)

0.42(97)

0.5

0.5

0.4

0.4

Munsell 3.4Y 7.7/0.8(White)

Munsell 3.4Y 7.7/0.8(White)

Plate fin coil

Plate fin coil

Line flow (direct) o 1

Line flow (direct) o 1

0.030

0.030

10-13 (353-459)

10-14 (353-459)

0 (direct blow)

0 (direct blow)

—

—

Wireless remote controller & Built-in

Wireless remote controller & Built-in

36 - 43

38 - 45

20 (13/16)

20 (13/16)

1,250 (49-3/16)

1,250 (49-3/16)

200 (7-7/8)

200 (7-7/8)

300 (11-13/16)

300 (11-13/16)

17 (37)

17 (37)

PU-1.6VLJA2

PU-2VJA2

PU-2NJA1

Single, 50Hz, 220/240V

Single, 50Hz, 220/240V Single, 60Hz, 220V

2.45

2.97

1.42 / 1.52

2.44 / 2.48

11.4(98) 13.6(99)

6.7 / 6.9 (97/92)

11.3 / 10.8(98/96)

54

54

30 /33

48 / 52

Munsell 5Y 7/1

Munsell 5Y 7/1

Capillary tube

Capillary tube

Hermetic

Hermetic

RH247VFC

NHJ41VMD

NHJ33NBD

1.2

2.0

1.5

Line start

Line start

w4

Inner thermostat, HP/LP switch

Plate fin coil

Plate fin coil

Propeller (direct ) o 1

Propeller (direct) o 1

0.065

0.065

45 (1588)

45 (1588)

—

—

49

49

50

870 (34-1/4)

870 (34-1/4)

295 (11-5/8)

295 (11-5/8)

650 (25-5/8)

650 (25-5/8)

45 (99)

60 (132)

—

32 / 38

—

R-22 1.78 (3.9)

R-22 1.9 (4.2)

R-22 1.3 (2.9)

9.52 (3/8)

9.52 (3/8)

15.88 (5/8)

15.88 (5/8)

Flared

Flared

Flared

Flared

w3 Max. 15m

w3 Max. 20m

w3 Max. 20m

w3 Max. 30m

Refrigerant piping length (one way) : 5m (16ft)

Noise level is measured in an unacoustic room based on JIS conditions.

Up to 20m it is unnecessary to charge additional refrigerant.

Inner thermostat, HP/LP switch.

Motor protector, Thermal switch, HP/LP switch.

Indoor, Outdoor D.B./W.B. : 29/19°C, 46/24°C

Cooling SSA385, 386

6

OC129A-1.qxp

01.10.1 7:33 PM

Page 7

Service Ref.

PK-2.5FLA2 PK-2.5FLA3 PK-2.5FLA4

Item

27/19.0°C, 35/24°C

Cooling (JIS B8616)

Indoor, Outdoor D.B./W.B.°C

Condition

Capacity w1

Btu/h

W

kW

OUTDOOR UNIT

INDOOR UNIT

Total input w1

Service Ref.

Power supply(phase, cycle,voltage)

Input

kW

Running current (Power factor)

A(%)

Starting current

A

External finish

Heat exchanger

Fan(drive) o No.

kW

Fan motor output

m3/min(CFM)

Airflow (Low-High)

Pa(mmAq)

External static pressure

kW

Booster heater

Operation control & Thermostat

dB

Noise level (Low-High) w2

mm(in.)

Cond. drain conn. O.D.

W

mm(in.)

D

mm(in.)

Dimensions

H

mm(in.)

kg(lbs)

Weight

Service Ref.

Power supply (phase, cycle, voltage)

kW

Input

A(%)

Running current (Power factor)

A

Starting current

External finish

Refrigerant control

Compressor

Model

kW

Motor output

Starter type

Protection devices

Heat exchanger

Fan(drive) o No.

kW

Fan motor output

m3/min(CFM)

Airflow

Defrost method

dB

Noise level w2

mm(in.)

W

mm(in.)

Dimensions

D

mm(in.)

H

kg(lbs)

Weight

W

Crankcase heater

kg(lbs)

Refrigerant Charge

mm(in.)

Liquid

Pipe size O.D.

mm(in.)

Gas

Indoor side

Connection method

Outdoor side

Between the indoor &

Height difference

outdoor units

Piping length

24,400

23,900

7,150

7,000

3.01

2.56 / 2.62

PK-2.5FLA2 PK-2.5FLA3 PK-2.5FLA4

Single, 60Hz, 220V

Single, 50Hz, 220/240V

0.095

0.095 / 0.095

0.44 (98)

0.44 / 0.44 (98/90)

0.7

0.7 / 0.8

Munsell 3.4Y 7.7/0.8(White)

Plate fin coil

Line flow (direct) o 2

0.04

15 - 20(530-706)

0 (direct blow)

—

Wireless remote controller & Built-in

39 - 45

20 (13/16)

1,400 (55-1/8)

235 (9-1/4)

340 (13-3/8)

24 (53)

PU-2.5NJA1

PU-2.5VJA2

Single, 60Hz, 220V

Single, 50Hz, 220/240V

2.91

2.46 / 2.52

13.4 (99)

11.4 / 10.7 (98/98)

58

45 / 49

Munsell 5Y 7/1

Capillary tube

Hermetic

NHJ41VMD

2.0

Line start

Inner thermostat, HP/LP switch

Plate fin coil

Propeller (direct) o 1

0.085

50 (1765)

—

52

53

870 (34-1/4)

295 (+24) (11-5/8 (add 1))

850 (33-7/16)

71 (157)

32 / 38

R-22 2.4 (5.3)

REFRIGERANT PIPING

w1

w2

w3

w4

w5

NHJ38NBD

1.7

—

R-22 2.4 (5.3)

9.52 (3/8)

15.88 (5/8)

Flared

Flared

w3 Max. 20m

w3 Max. 30m

Refrigerant piping length (one way) : 5m (16ft)

Noise level is measured in an unacoustic room based on JIS conditions.

Up to 20m it is unnecessary to charge additional refrigerant.

Indoor, Outdoor D.B./W.B. : 29/19°C, 46/24°C.

Cooling SSA385, 386

7

w4

w5

22,700

6,650

3.54

3.44

15.8(99)

58

OC129A-1.qxp

01.10.1 7:33 PM

Page 8

Service Ref.

PK-3FLA2

Item

Indoor, Outdoor D.B./W.B.°C

27/19.0°C, 35/24°C

Cooling (JIS B8616)

Condition

Capacity w1

Btu/h

W

kW

24,600

7,200

27,300

8,000

3.54

REFRIGERANT PIPING

OUTDOOR UNIT

INDOOR UNIT

3.28 / 3.30

3.28 / 3.30

Total input w1

PK-3FLA2

Service Ref.

Single, 50Hz, 220/240V

Single, 60Hz, 220V

Power supply(phase, cycle,voltage)

0.095 / 0.095

0.095

kW

Input

0.44 / 0.44 (98/90)

0.44 (98)

A(%)

Running current (Power factor)

0.7 / 0.8

0.7

A

Starting current

External finish

Munsell 3.4Y 7.7/0.8(White)

Heat exchanger

Plate fin coil

Fan(drive) o No.

Line flow (direct) o 2

kW

Fan motor output

0.04

m3/min(CFM)

Airflow (Low-High)

15 - 20 (530-706)

Pa(mmAq)

External static pressure

0 (direct blow)

kW

Booster heater

—

Operation control & Thermostat

Wireless remote controller & Built-in

dB

Noise level (Low-High) w2

39 - 45

mm(in.)

Cond. drain conn. O.D.

20 (13/16)

W

mm(in.)

1,400 (55-1/8)

D

mm(in.)

Dimensions

235 (9-1/4)

H

mm(in.)

340 (13-3/8)

kg(lbs)

Weight

24 (53)

PU-3YJA2 PU-3YJA3

PU-3NJA1

PU-3VJA2

Service Ref.

Single, 60Hz, 220V

Single, 50Hz, 220/240V Three, 50Hz, 380/415V

Power supply (phase, cycle, voltage)

3.44

3.18 / 3.20

3.18 / 3.20

kW

Input

17.6(89)

15.1/13.9(96/96)

5.7/5.3(85/84)

A(%)

Running current (Power factor)

80

68 / 68

36 / 36

A

Starting current

Munsell 5Y 7/1

External finish

Capillary tube

Refrigerant control

Hermetic

Compressor

Model

NHJ52YDA NHJ52YDE

NHJ47NAD

NHJ52VND

kW

Motor output

2.2

2.2

2.2

Line start

Starter type

w6

w7

w6

Protection devices

Plate fin coil

Heat exchanger

Propeller (direct) o 1

Fan(drive) o No.

0.085

kW

Fan motor output

50 (1765)

m3/min(CFM)

Airflow

—

Defrost method

53

53

dB

Noise level w2

870 (34-1/4)

mm(in.)

W

295 (+24) (11-5/8 (add 1))

mm(in.)

Dimensions

D

850 (33-7/16)

mm(in.)

H

73 (161)

kg(lbs)

Weight

W

Crankcase heater

32 / 38

32 / 38

38

kg(lbs)

Refrigerant Charge

R-22 3.08 (6.8)

R-22 2.88 (6.3)

R-22 3.5 (7.7)

mm(in.)

Liquid

9.52 (3/8)

Pipe size O.D.

mm(in.)

Gas

15.88 (5/8)

Indoor side

Flared

Connection method

Outdoor side

Flared

Between the indoor &

Height difference

w3 Max. 20m

outdoor units

Piping length

w3 Max. 30m

w4

w5

23,500

6,900

4.19

w1 Refrigerant piping length (one way) : 5m (16ft)

w2 Noise level is measured in an unacoustic room based on JIS conditions.

w3 Up to 20m it is unnecessary to charge additional refrigerant.

w4 Indoor, Outdoor D.B./W.B. : 29/19°C, 46/24°C

w5 Cooling SSA385, 386

w6 Inner thermostat, HP switch, LP switch.

w7 Thermal switch, Reversed-phase protector, HP switch, LP switch, Thermal relay.

8

4.09

20.9(89)

80

OC129A-1.qxp

01.10.1 7:33 PM

Page 9

Service Ref.

PK-3FLA3 PK-3FLA4 PK-3FLA5

Item

Indoor, Outdoor D.B./W.B.°C

27/19°C , 35/24°C

Cooling (JIS B8616)

Condition

27,300

8,000

3.28 / 3.30

3.28 / 3.30

3.54

Total input w1

PK-3FLA3 PK-3FLA4 PK-3FLA5

Service Ref.

Single, 50Hz, 220/240V

Single, 60Hz, 220V

Power supply(phase, cycle,voltage)

0.095 / 0.095

0.095

Input

kW

0.44 / 0.44 (98/90)

0.44 (98)

Running current (Power factor)

A(%)

0.7 / 0.8

0.7

Starting current

A

External finish

Munsell 3.4Y 7.7/0.8(White)

Heat exchanger

Plate fin coil

Fan(drive) o No.

Line flow (direct) o 2

Fan motor output

kW

0.04

Airflow (Low-High)

m3/min(CFM)

15 - 20 (530-706)

Pa,mmAq

External static pressure

0 (direct blow)

kW

Booster heater

—

Operation control & Thermostat

Wireless remote controller & Built-in

dB

Noise level (Low-High) w2

39 - 45

mm(in.)

Unit drain pipe O.D.

20 (13/16)

W

mm(in.)

1,400 (55-1/8)

D

mm(in.)

Dimensions

235 (9-1/4)

H

mm(in.)

340 (13-3/8)

kg(lbs)

Weight

24 (53)

PU-3YJC

PU-3NJA1

PU-3VJC

Service Ref.

Single, 50Hz, 220/240V Three, 50Hz, 380/415V

Single, 60Hz, 220V

Power supply (phase, cycle, voltage)

3.44

3.18 / 3.20

3.18 / 3.20

kW

Input

17.6(89)

15.1/13.9(96/96)

5.7/5.3(85/84)

A(%)

Running current (Power factor)

80

54 / 58

34 / 37

A

Starting current

Munsell 5Y 7/1

External finish

Capillary tube

Refrigerant control

Hermetic

Compressor

Model

NHJ47NAD

NH52VND

NH52YDE

kW

Motor output

2.2

2.2

2.4

Line start

Starter type

w6

w7

w6

Protection devices

Plate fin coil

Heat exchanger

Propeller (direct) o 1

Fan(drive) o No.

0.085

kW

Fan motor output

50 (1765)

m3/min(CFM)

Airflow

—

Defrost method

52

53

dB

Noise level w2

870 (34-1/4)

mm(in.)

W

295 (+24) (11-5/8 (add 1))

mm(in.)

Dimensions

D

850 (33-7/16)

mm(in.)

H

73 (161)

kg(lbs)

Weight

W

Crankcase heater

32 / 38

32 / 38

38

R-22 2.8(6.2)

kg(lbs)

Refrigerant Charge

R-22 3.5 (7.7)

mm(in.)

Liquid

9.52 (3/8)

Pipe size O.D.

mm(in.)

Gas

15.88 (5/8)

Indoor side

Flared

Connection method

Outdoor side

Flared

Between the indoor &

Height difference

w3 Max. 20m

outdoor units

Piping length

w3 Max. 30m

27,000

7,900

Btu/h

W

kW

REFRIGERANT PIPING

OUTDOOR UNIT

INDOOR UNIT

Capacity w1

w4

w5

23,500

6,900

4.19

w1 Refrigerant piping length (one way) : 5m (16ft)

w2 Noise level is measured in an unacoustic room based on JIS conditions.

w3 Up to 20m it is unnecessary to charge additional refrigerant.

w4 Indoor, Outdoor D.B./W.B. : 29/19°C, 46/24°C

w5 Cooling SSA385, 386

w6 Inner thermostat, HP switch, LP switch.

w7 Thermal switch, Reversed-phase protector, HP switch, LP switch, Thermal relay.

9

4.09

20.9(89)

80

OC129A-1.qxp

01.10.1 7:33 PM

Page 10

Service Ref.

Item

Indoor, Outdoor D.B./W.B.°C

Condition

Capacity w1

Btu/h

W

kW

27/19°C , 35/24°C

Cooling (JIS B8616)

25,600

7,500

2.75

PK-3FLA2 PK-3FLA3 PK-3FLA4 PK-3FLA5

Single, 50Hz, 220V

0.095

0.44 (98)

0.7

Munsell 3.4Y 7.7/0.8(White)

Plate fin coil

Line flow (direct) o 2

0.04

15 - 20 (530-706)

0 (direct blow)

—

Wireless remote controller & Built-in

39 - 45

20 (13/16)

1,400 (55-1/8)

235 (9-1/4)

340 (13-3/8)

24 (53)

PU-3YJB

PU-3VJB

Single, 50Hz, 220V

Three, 50Hz, 380V

2.65

2.65

12.4(97)

4.2(97)

54

34

Munsell 5Y 7/1

Capillary tube

Hermetic

NH47VNHT

NH47YDNT

2.2

2.2

Line start

w6

w7

Plate fin coil

Propeller (direct) o 1

0.085

50 (1765)

—

52

870 (34-1/4)

295 (+24) (11-5/8 (add 1))

850 (33-7/16)

73 (161)

32

32

R-22 3.0(6.6)

9.52 (3/8)

15.88 (5/8)

Flared

Flared

w3 Max. 20m

w3 Max. 30m

REFRIGERANT PIPING

OUTDOOR UNIT

INDOOR UNIT

Total input w1

Service Ref.

Power supply(phase, cycle,voltage)

Input

kW

Running current (Power factor)

A(%)

Starting current

A

External finish

Heat exchanger

Fan(drive) o No.

kW

Fan motor output

m3/min(CFM)

Airflow (Low-High)

Pa,mmAq

External static pressure

kW

Booster heater

Operation control & Thermostat

dB

Noise level (Low-High) w2

mm(in.)

Unit drain pipe O.D.

W

mm(in.)

D

mm(in.)

Dimensions

H

mm(in.)

kg(lbs)

Weight

Service Ref.

Power supply (phase, cycle, voltage)

kW

Input

A(%)

Running current /Power factor

A

Starting current

External finish

Refrigerant control

Compressor

Model

kW

Motor output

Starter type

Protection devices

Heat exchanger

Fan(drive) o No.

kW

Fan motor output

m3/min(CFM)

Airflow

Defrost method

dB

Noise level w2

mm(in.)

W

mm(in.)

Dimensions

D

mm(in.)

H

kg(lbs)

Weight

W

Crankcase heater

kg(lbs)

Refrigerant Charge

mm(in.)

Liquid

Pipe size O.D.

mm(in.)

Gas

Indoor side

Connection method

Outdoor side

Between the indoor &

Height difference

outdoor units

Piping length

PK-3FLA2 PK-3FLA3 PK-3FLA4 PK-3FLA5

w1 Refrigerant piping length (one way) : 5m (16ft)

w2 Noise level is measured in an unacoustic room based on JIS conditions.

w3 Up to 20m it is unnecessary to charge additional refrigerant.

w4 Indoor, Outdoor D.B./W.B. : 29/19°C, 46/24°C

w5 Cooling SSA385, 386

w6 Inner thermostat, HP switch, LP switch.

w7 Thermal switch, Reversed-phase protector, HP switch, LP switch, Thermal relay.

10

OC129A-1.qxp

01.10.1 7:33 PM

Page 11

Service Ref.

PK-4FLSA2 PK-4FLSA3 PK-4FLSA4

Item

27/19.0°C, 35/24°C

Cooling (JIS B8616)

Indoor, Outdoor DB/WB°C

Condition

37,500

11,000

3.46 / 3.63

3.40 / 3.47

4.38

Total input w1

PK-4FLSA2 PK-4FLSA3 PK-4FLSA4

Service Ref.

Single, 50Hz, 220/240V

Single, 60Hz, 220V

Power supply(phase, cycle,voltage)

0.114 / 0.114

0.114

kW

Input

0.53 / 0.53 (98/90)

0.53 (98)

A(%)

Running current (Power factor)

0.8 / 0.9

0.8

A

Starting current

Munsell 3.4Y 7.7/0.8(White)

External finish

Plate fin coil

Heat exchanger

Line flow (direct) o 2

Fan(drive) o No.

0.07

kW

Fan motor output

22 - 28 (777 - 989)

m3/min(CFM)

Airflow (Low-High)

0 (direct blow)

Pa(mmAq)

External static pressure

—

kW

Booster heater

Wireless remote controller & Built-in

Operation control & Thermostat

41 - 46

dB

Noise level (Low-High) w2

20 (13/16)

mm(in.)

Cond. drain conn. O.D.

1,680 (66-1/8)

W

mm(in.)

235 (9-1/4)

D

mm(in.)

Dimensions

340 (13-3/8)

H

mm(in.)

28 (62)

kg(lbs)

Weight

PU-4YJSA2 PU-4YJSA3

PU-4VLJSA2

PU-4TJSA2

Service Ref.

Single, 50Hz, 220/240V Three, 50Hz, 380/415V

3, 60Hz, 220V

Power supply (phase, cycle, voltage)

4.27

3.35 / 3.52

3.29 / 3.36

kW

Input

12.2 (92)

16.9 / 16.3 (90/90) 5.7 / 5.5 (87/85)

A(%)

Running current (Power factor)

69

79 / 79

38 / 38

A

Starting current

Munsell 5Y 7/1

External finish

Capillary tube

Refrigerant control

Hermetic

Compressor

NH56VND

NHJ56YDA NHJ56YDE

NHJ56TKA

Model

2.7

2.7

2.7

kW

Motor output

Line start

Starter type

w6

w7

w7

Protection devices

Plate fin coil

Heat exchanger

Propeller (direct) o 2

Fan(drive) o No.

0.065 + 0.065

kW

Fan motor output

95 (3352)

m3/min(CFM)

Airflow

—

Defrost method

54

55

55

dB

Noise level w2

mm(in.)

W

870 (34-1/4)

mm(in.)

Dimensions

D

295 (+24) (11-5/8 (add 1))

mm(in.)

H

1258 (49-1/2)

kg(lbs)

Weight

94 (207)

W

Crankcase heater

32 / 38

38

32 / 38

kg(lbs)

Refrigerant Charge

R-22 3.8 (8.4)

R-22 4.6 (10.1)

R-22 4.6 (10.1)

9.52 (3/8)

mm(in.)

Liquid

Pipe size O.D.

19.05 (4/3)

mm(in.)

Gas

Flared

Indoor side

Connection method

Flared

Outdoor side

w3 Max. 30m

Between the indoor &

Height difference

w3 Max. 40m

outdoor units

Piping length

33,400

9,800

Btu/h

W

kW

REFRIGERANT PIPING

OUTDOOR UNIT

INDOOR UNIT

Capacity w1

w4

w5

33,800

9,900

5.08

w1 Refrigerant piping length (one way) : 5m (16ft)

w2 Noise level is measured in an unacoustic room based on JIS conditions.

w3 Up to 20m it is unnecessary to charge additional refrigerant.

w4 Indoor, Outdoor D.B./W.B. : 29/19°C, 46/24°C

w5 Cooling SSA385, 386

w6 Inner thermostat, HP switch, LP switch.

w7 Thermal switch, Reversed-phase protector, HP switch, LP switch, Thermal relay.

11

4.97

14.0(93)

69

OC129A-1.qxp

01.10.1 7:33 PM

Page 12

2. POWER SUPPLY & MODEL NAMES

Power supply

1ph

50Hz

60Hz

Service Ref. (Outdoor unit)

Service Ref. (Indoor unit) PK-1.6FLA3 PK-2FLA3 PK-2.5FLA2 PK-3FLA2 PK-3FLA3

PK-2.5FLA3

PK-3FLA4

PK-2.5FLA4

PK-3FLA5

PU-3VJA2 PU-3VJC

PU-1.6VLJA2 PU-2VJA2 PU-2.5VJA2

220,230,240V

PU-3VJB

PU-3VJB

3ph

380/220,400/230,415/240V

—

—

1ph

220V

—

PU-2NJA1

3ph

220V

—

—

—

(1) Rating conditions

JIS B8615, 8616

Series PK Indoor Unit (Single Phase)

PU-3YJC

PU-3YJB

PU-3YJB

PU-2.5NJA1 PU-3NJA1

—

Notes : 1. Power supply key N …… 1ph, 220V, 60Hz

V(L) … 1ph, 220, 230 240V, 50Hz

T …… 3ph, 220V, 60Hz

2. Primary power supplies for all indoor units are single-phase.

3. ELECTRICAL SPECIFICATION

PU-3YJA3

—

PK-4FLSA2

PK-4FLSA3

PK-4FLSA4

PU-4VLJSA2

PU-4YJSA3

PU-3NJA1

—

—

PU-4TJSA2

Y … 3ph, 380/220, 400/230,

415/240V, 50Hz, 4 wires

Indoor : D.B. 27°C (80°F), W.B. 19°C(66°F)

Outdoor : D.B. 35°C (95°F)

Power supply (1 Phase)

Service Ref.

Current

Input

V : 220V 50Hz

V : 230V 50Hz

PK-1.6FLA3 PK-2FLA3 PK-2.5FLA2 PK-3FLA2 PK-3FLA3 PK-4FLSA2 PK-1.6FLA3 PK-2FLA3 PK-2.5FLA2 PK-3FLA2 PK-3FLA3 PK-4FLSA2

PK-2.5FLA3

PK-2.5FLA3

PK-3FLA4 PK-4FLSA3

PK-3FLA4 PK-4FLSA3

PK-2.5FLA4

PK-2.5FLA4

PK-3FLA5 PK-4FLSA4

PK-3FLA5 PK-4FLSA4

A

0.32

0.37

0.44

0.44

0.44

0.53

0.32

0.37

0.44

0.44

0.44

0.53

kW

Starting current A

Outdoor unit

0.07

0.08

0.095

0.095

0.095

0.114

0.07

0.08

0.095

0.095

0.095

0.114

0.4

0.4

0.7

0.7

0.7

0.8

0.4

0.4

0.8

0.8

0.8

0.8

PU-1.6

PU-2

PU-2.5

PU-3

PU-3

PU-4

PU-1.6

PU-2

PU-2.5

PU-3

PU-3

PU-4

Power supply (1 Phase)

Service Ref.

Current

Input

V : 240V 50Hz

N : 220V 50Hz

PK-1.6FLA3 PK-2FLA3 PK-2.5FLA2 PK-3FLA2 PK-3FLA3 PK-4FLSA2 PK-2FLA3 PK-2.5FLA2 PK-3FLA2 PK-3FLA3 PK-4FLSA2

PK-2.5FLA3

PK-2.5FLA3

PK-3FLA4 PK-4FLSA3

PK-3FLA4 PK-4FLSA3

PK-2.5FLA4

PK-2.5FLA4

PK-3FLA5 PK-4FLSA4

PK-3FLA5 PK-4FLSA4

A

0.32

0.37

0.44

0.44

0.44

0.53

0.43

0.44

0.44

0.44

0.53

kW

Starting current A

Outdoor unit

0.07

0.08

0.095

0.095

0.095

0.114

0.09

0.095

0.095

0.095

0.114

0.4

0.4

0.8

0.8

0.8

0.8

0.5

0.7

0.7

0.7

0.8

PU-1.6

PU-2

PU-2.5

PU-3

PU-3

PU-4

PU-2

PU-2.5

PU-3

PU-3

PU-4

12

OC129A-1.qxp

01.10.1 7:33 PM

5

Page 13

DATA

1. PERFORMANS DATA

W Outdoor unit

PU-3JB

COOLING CAPACITY 50Hz

Service Ref.

Temperature

Outdoor D.B.

Indoor W.B.

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

21˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(69.8˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

25˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(77˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

30˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(86˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

32.2˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(90˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

35˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(95˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

40˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(104˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

40.6˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(105˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

45˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(113˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

46˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(115˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

50˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(69.8˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

52˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(125.5˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

Evaporator airflow (CMM)

Bypass factors

S.H.F. at rating conditions

PK-2FLA3

T.C.

C.F.

(T.I.)

5.6

0.81

6.0

0.82

6.2

0.83

6.2

0.83

6.4

0.84

6.7

0.86

5.5

0.84

5.9

0.85

6.0

0.86

6.1

0.86

6.2

0.87

6.6

0.89

5.3

0.90

5.6

0.92

5.8

0.93

5.9

0.93

6.0

0.94

6.4

0.96

5.2

0.93

5.5

0.95

5.7

0.96

5.8

0.97

5.9

0.97

6.3

0.99

5.1

0.96

5.4

0.99

5.6

1.00

5.7

1.00

5.8

1.01

6.2

1.04

4.9

1.03

5.2

1.06

5.4

1.07

5.4

1.08

5.5

1.08

5.9

1.11

4.8

1.04

5.2

1.06

5.3

1.08

5.4

1.08

5.5

1.09

5.9

1.12

4.6

1.10

4.9

1.12

5.1

1.14

5.2

1.15

5.3

1.16

5.7

1.20

4.6

1.11

4.9

1.14

5.1

1.15

5.1

1.16

5.2

1.17

5.6

1.21

4.4

1.16

4.7

1.19

4.9

1.21

4.9

1.22

5.0

1.23

5.4

1.28

4.3

1.19

4.6

1.22

4.7

1.24

4.8

1.25

4.9

1.26

5.3

1.31

14

0.16

0.73

PK-1.6FLA3

C.F.

T.C.

(T.I.)

3.9

0.81

4.2

0.82

4.3

0.83

4.4

0.83

4.4

0.84

4.7

0.86

3.8

0.84

4.1

0.85

4.2

0.86

4.3

0.86

4.3

0.87

4.6

0.89

3.7

0.90

3.9

0.92

4.1

0.93

4.1

0.93

4.2

0.94

4.5

0.96

3.6

0.93

3.9

0.95

4.0

0.96

4.0

0.97

4.1

0.97

4.4

0.99

3.5

0.96

3.8

0.99

3.9

1.00

4.0

1.00

4.0

1.01

4.3

1.04

3.4

1.03

3.6

1.06

3.7

1.07

3.8

1.08

3.9

1.08

4.1

1.11

3.4

1.04

3.6

1.06

3.7

1.08

3.8

1.08

3.8

1.09

4.1

1.12

3.2

1.10

3.4

1.12

3.6

1.14

3.6

1.15

3.7

1.16

3.9

1.20

3.2

1.11

3.4

1.14

3.5

1.15

3.6

1.16

3.6

1.17

3.9

1.21

13

0.18

0.81

PK-2.5FLA3/4

T.C.

C.F.

(T.I.)

7.0

0.81

7.5

0.82

7.7

0.83

7.8

0.83

7.9

0.84

8.4

0.86

6.9

0.84

7.3

0.85

7.6

0.86

7.7

0.86

7.8

0.87

8.3

0.89

6.6

0.90

7.1

0.92

7.3

0.93

7.4

0.93

7.5

0.94

8.0

0.96

6.5

0.93

6.9

0.95

7.2

0.96

7.3

0.97

7.4

0.97

7.9

0.99

6.3

0.96

6.8

0.99

7.0

1.00

7.1

1.00

7.2

1.01

7.7

1.04

6.1

1.03

6.5

1.06

6.7

1.07

6.8

1.08

6.9

1.08

7.4

1.11

6.0

1.04

6.4

1.06

6.7

1.08

6.8

1.08

6.9

1.09

7.4

1.12

5.8

1.10

6.2

1.12

6.4

1.14

6.5

1.15

6.6

1.16

7.1

1.20

5.7

1.11

6.1

1.14

6.3

1.15

6.4

1.16

6.5

1.17

7.0

1.21

5.5

1.16

5.9

1.19

6.1

1.21

6.2

1.22

6.3

1.23

6.7

1.28

5.3

1.19

5.7

1.22

5.9

1.24

6.0

1.25

6.1

1.26

6.6

1.31

20

0.11

0.81

PK-3FLA2

T.C.

C.F.

(T.I.)

7.2

0.81

7.7

0.82

7.9

0.83

8.0

0.83

8.2

0.84

8.7

0.86

7.1

0.84

7.5

0.85

7.8

0.86

7.9

0.86

8.0

0.87

8.5

0.89

6.8

0.90

7.3

0.92

7.5

0.93

7.6

0.93

7.7

0.94

8.2

0.96

6.7

0.93

7.1

0.95

7.4

0.96

7.5

0.97

7.6

0.97

8.1

0.99

6.5

0.96

7.0

0.99

7.2

1.00

7.3

1.00

7.4

1.01

7.9

1.04

6.2

1.03

6.7

1.06

6.9

1.07

7.0

1.08

7.1

1.08

7.6

1.11

6.2

1.04

6.6

1.06

6.9

1.08

6.9

1.08

7.1

1.09

7.6

1.12

5.9

1.10

6.4

1.12

6.6

1.14

6.7

1.15

6.8

1.16

7.3

1.20

5.9

1.11

6.3

1.14

6.5

1.15

6.6

1.16

6.7

1.17

7.2

1.21

5.6

1.16

6.0

1.19

6.2

1.21

6.3

1.22

6.5

1.23

6.9

1.28

5.5

1.19

5.9

1.22

6.1

1.24

6.2

1.25

6.3

1.26

6.8

1.31

20

0.12

0.76

PK-3FLA3/4/5

T.C.

C.F.

(T.I.)

0.81

7.9

0.82

8.4

0.83

8.7

0.83

8.8

0.84

9.0

0.86

9.5

0.84

7.8

0.85

8.3

0.86

8.5

0.86

8.6

0.87

8.8

0.89

9.4

0.90

7.5

0.92

8.0

0.93

8.2

0.93

8.3

0.94

8.5

0.96

9.0

0.93

7.3

0.95

7.8

0.96

8.1

0.97

8.2

0.97

8.3

0.99

8.9

0.96

7.2

0.99

7.6

1.00

7.9

1.00

8.0

1.01

8.2

1.04

8.7

1.03

6.8

1.06

7.3

1.07

7.6

1.08

7.7

1.08

7.8

1.11

8.3

1.04

6.8

1.06

7.3

1.08

7.5

1.08

7.6

1.09

7.8

1.12

8.3

1.10

6.5

1.12

7.0

1.14

7.2

1.15

7.3

1.16

7.5

1.20

8.0

1.11

6.4

1.14

6.9

1.15

7.1

1.16

7.2

1.17

7.4

1.21

7.9

1.16

6.2

1.19

6.6

1.21

6.9

1.22

6.9

1.23

7.1

1.28

7.6

1.19

6.0

1.22

6.5

1.24

6.7

1.25

6.8

1.26

6.9

1.31

7.4

20

0.12

0.73

PK-3FLA2/3/4/5 W

T.C.

C.F.

(T.I.)

0.81

7.5

0.82

8.0

0.83

8.3

0.83

8.4

0.84

8.5

0.86

9.0

0.84

7.4

0.85

7.8

0.86

8.1

0.86

8.2

0.87

8.4

0.89

8.9

0.90

7.1

0.92

7.6

0.93

7.8

0.93

7.9

0.94

8.1

0.96

8.6

0.93

7.0

0.95

7.4

0.96

7.7

0.97

7.8

0.97

7.9

0.99

8.4

0.96

6.8

0.99

7.3

1.00

7.5

1.00

7.6

1.01

7.7

1.04

8.3

1.03

6.5

1.06

6.9

1.07

7.2

1.08

7.3

1.08

7.4

1.11

7.9

1.04

6.5

1.06

6.9

1.08

7.1

1.08

7.2

1.09

7.4

1.12

7.9

1.10

6.2

1.12

6.6

1.14

6.8

1.15

6.9

1.16

7.1

1.20

7.6

1.11

6.1

1.14

6.5

1.15

6.8

1.16

6.9

1.17

7.0

1.21

7.5

20

0.12

0.75

PK-4FLSA2/3/4

T.C.

C.F.

(T.I.)

0.81

9.8

0.82

10.5

0.83

10.8

0.83

10.9

0.84

11.1

0.86

11.8

0.84

9.6

0.85

10.2

0.86

10.6

0.86

10.7

0.87

10.9

0.89

11.6

0.90

9.3

0.92

9.9

0.93

10.2

0.93

10.3

0.94

10.5

0.96

11.2

0.93

9.1

0.95

9.7

0.96

10.0

0.97

10.2

0.97

10.3

0.99

11.0

0.96

8.9

0.99

9.5

1.00

9.8

1.00

9.9

1.01

10.1

1.04

10.8

1.03

8.5

1.06

9.1

1.07

9.4

1.08

9.5

1.08

9.7

1.11

10.3

1.04

8.4

1.06

9.0

1.08

9.3

1.08

9.5

1.09

9.6

1.12

10.3

1.10

8.1

1.12

8.6

1.14

8.9

1.15

9.1

1.16

9.3

1.20

9.9

1.11

8.0

1.14

8.6

1.15

8.9

1.16

9.0

1.17

9.2

1.21

9.8

1.16

7.6

1.19

8.2

1.21

8.5

1.22

8.6

1.23

8.8

1.28

9.4

1.19

7.4

1.22

8.0

1.24

8.3

1.25

8.4

1.26

8.6

1.31

9.2

28

0.12

0.73

Notes: 1. T.C.: Total capacity (kW) … (kcal/h)=(kW)x860, (Btu/h)=4x(kW)x860

C.F.(T.I.) : Correction factors of Total input(Indoor unit input + Outdoor unit input)

2. (°F)=32+9/5(°C)

Lower limit … Indoor : D.B. 21°C(70°F), W.B. 15.5°C(60°F), Outdoor : D.B. 21°C(70°F).

3. Guaranteed operating range(cooling)

Upper limit … Indoor : D.B. 35°C(95°F), W.B. 22.5°C(72.5°F), Outdoor : D.B. 46°C(115°F)…VLJ, VJB, YJB. W

W Outdoor : D.B. 52°C(125.5°F)…VJA, YJA.

{

COOLING CAPACITY correction factors 50Hz

Service Ref.

PK-1.6FLA3

PK-2FLA3

PK-2.5FLA2/3/4

PK-3FLA2/3/4/5

PK-4FLSA2/3/4

Refrigerant piping length (one way)

5m (16ft)

1.0

1.0

1.0

1.0

1.0

10m (33ft)

0.992

0.985

0.983

0.978

0.984

15m (49ft)

0.987

0.975

0.972

0.962

0.974

20m (66ft)

0.982

0.964

0.961

0.948

0.964

13

25m (82ft)

—

0.954

0.951

0.934

0.954

30m (98ft)

—

0.944

0.940

0.921

0.944

35m (115ft)

—

—

—

—

0.914

40m (13ft)

—

—

—

—

0.902

OC129A-1.qxp

01.10.1 7:33 PM

Page 14

COOLING CAPACITY 60Hz

Service Ref.

Temperature

Outdoor D.B.

PK-2.5FLA3/4

T.C.

C.F.

(T.I.)

7.2

0.81

7.6

0.82

7.9

0.83

8.0

0.83

8.1

0.84

8.6

0.86

7.0

0.84

7.5

0.85

7.7

0.86

7.8

0.86

8.0

0.87

8.5

0.89

6.8

0.90

7.2

0.92

7.4

0.93

7.5

0.93

7.7

0.94

8.2

0.96

6.6

0.93

7.1

0.95

7.3

0.96

7.4

0.97

7.5

0.97

8.0

0.99

6.5

0.96

6.9

0.99

7.2

1.00

7.2

1.00

7.4

1.01

7.9

1.04

6.2

1.03

6.6

1.06

6.8

1.07

6.9

1.08

7.1

1.08

7.5

1.11

6.2

1.04

6.6

1.06

6.8

1.08

6.9

1.08

7.0

1.09

7.5

1.12

5.9

1.10

6.3

1.12

6.5

1.14

6.6

1.15

6.8

1.16

7.2

1.20

5.8

1.11

6.2

1.14

6.5

1.15

6.6

1.16

6.7

1.17

7.2

1.21

5.6

1.16

6.0

1.19

6.2

1.21

6.3

1.22

6.4

1.23

6.9

1.28

5.4

1.19

5.8

1.22

6.1

1.24

6.2

1.25

6.3

1.26

6.7

1.31

20

0.12

0.78

PK-2FLA3

T.C.

Indoor W.B.

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

21˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(69.8˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

25˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(77˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

30˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(86˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

32.2˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(90˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

35˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(95˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

40˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(104˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

40.6˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(105˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

45˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(113˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

46˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(115˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

50˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(69.8˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

16˚C

(60.8˚ F)

18˚C

(64.4˚ F)

52˚C

19˚C

(66.2˚ F)

19.4˚C

(67˚ F)

(125.5˚ F)

20˚C

(68˚ F)

22˚C

(71.6˚ F)

Evaporator airflow (CMM)

Bypass factors

S.H.F. at rating conditions

C.F.

(T.I.)

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

5.5

5.8

6.0

6.1

6.2

6.6

5.3

5.7

5.9

6.0

6.1

6.5

5.2

5.5

5.7

5.7

5.9

6.2

5.1

5.4

5.6

5.6

5.8

6.1

4.9

5.3

5.5

5.5

5.6

6.0

4.7

5.0

5.2

5.3

5.4

5.8

4.7

5.0

5.2

5.3

5.4

5.7

4.5

4.8

5.0

5.0

5.1

5.5

4.4

4.8

4.9

5.0

5.1

5.5

4.2

4.6

4.7

4.8

4.9

5.2

4.1

4.5

4.6

4.7

4.8

5.1

14

0.16

0.73

PK-3FLA2/3/4/5

T.C.

C.F.

(T.I.)

8.0

0.81

8.6

0.82

8.8

0.83

8.9

0.83

9.1

0.84

9.6

0.86

7.8

0.84

8.4

0.85

8.6

0.86

8.7

0.86

8.9

0.87

9.5

0.89

7.6

0.90

8.1

0.92

8.3

0.93

8.4

0.93

8.6

0.94

9.1

0.96

7.4

0.93

7.9

0.95

8.2

0.96

8.3

0.97

8.4

0.97

9.0

0.99

7.3

0.96

7.7

0.99

8.0

1.00

8.1

1.00

8.3

1.01

8.8

1.04

6.9

1.03

7.4

1.06

7.7

1.07

7.8

1.08

7.9

1.08

8.4

1.11

6.9

1.04

7.4

1.06

7.6

1.08

7.7

1.08

7.9

1.09

8.4

1.12

6.6

1.10

7.1

1.12

7.3

1.14

7.4

1.15

7.6

1.16

8.1

1.20

6.5

1.11

7.0

1.14

7.2

1.15

7.3

1.16

7.5

1.17

8.0

1.21

6.2

1.16

6.7

1.19

6.9

1.21

7.0

1.22

7.2

1.23

7.7

1.28

6.1

1.19

6.5

1.22

6.8

1.24

6.9

1.25

7.0

1.26

7.5

1.31

20

0.13

0.78

PK-4FLSA2/3/4

T.C.

C.F.

(T.I.)

11.0

0.81

11.8

0.82

12.1

0.83

12.3

0.83

12.5

0.84

13.2

0.86

10.8

0.84

11.5

0.85

11.9

0.86

12.0

0.86

12.2

0.87

13.0

0.89

10.4

0.90

11.1

0.92

11.4

0.93

11.6

0.93

11.8

0.94

12.6

0.96

10.2

0.93

10.9

0.95

11.3

0.96

11.4

0.97

11.6

0.97

12.4

0.99

10.0

0.96

10.6

0.99

11.0

1.00

11.1

1.00

11.4

1.01

12.1

1.04

9.5

1.03

10.2

1.06

10.5

1.07

10.7

1.08

10.9

1.08

11.6

1.11

9.5

1.04

10.1

1.06

10.5

1.08

10.6

1.08

10.8

1.09

11.6

1.12

9.1

1.10

9.7

1.12

10.0

1.14

10.2

1.15

10.4

1.16

11.1

1.20

9.0

1.11

9.6

1.14

9.9

1.15

10.1

1.16

10.3

1.17

11.0

1.21

8.6

1.16

9.2

1.19

9.5

1.21

9.7

1.22

9.9

1.23

10.6

1.28

8.4

1.19

9.0

1.22

9.3

1.24

9.5

1.25

9.7

1.26

10.4

1.31

28

0.14

0.73

Notes: 1. T.C.: Total capacity (kW) … (kcal/h)=(kW)x860, (Btu/h)=4x(kW)x860

C.F.(T.I.) : Correction factors of Total input(Indoor unit input + Outdoor unit input)

2. (°F)=32+9/5(°C)

Lower limit … Indoor : D.B. 21°C(70°F), W.B. 15.5°C(60°F), Outdoor : D.B. 21°C(70°F).

3. Guaranteed operating range(cooling)

Upper limit … Indoor : D.B. 35°C(95°F), W.B. 22.5°C(72.5°F), Outdoor : D.B. 52°C(125.5°F).

{

COOLING CAPACITY correction factors 60Hz

Service Ref.

PK-2FLA3

PK-2.5FLA2/3/4

PK-3FLA2/3/4/5

PK-4FLSA2/3/4

Refrigerant piping length (one way)

5m (16ft)

1.0

1.0

1.0

1.0

10m (33ft)

0.985

0.978

0.971

0.980

15m (49ft)

0.975

0.963

0.950

0.966

20m (66ft)

0.964

0.948

0.931

0.952

14

25m (82ft)

0.954

0.934

0.913

0.939

30m (98ft)

0.944

0.921

0.896

0.926

35m (115ft)

—

—

—

0.941

40m (131ft)

—

—

—

0.902

OC129A-1.qxp

01.10.1 7:33 PM

Page 15

2. STANDARD OPERATION DATA

PK-1.6

FLA3

Service Ref.

Outdoor Indoor

side side

Refrigerant circuit

Electrical circuit

Total

MODE

Capacity

Input

Indoor unit

Service Ref.

Cooling Cooling Cooling

3900

5600

4600

1.49

2.52

2.60

PK-1.6 PK-2FLA3

FLA3

W

kW

Phase , Hz

Volts

Amperes

Outdoor unit

Service Ref.

Phase , Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Refrigerant pipe length

Intake air

temperature

Discharge air temperature

Intake air

temperature

PK-2FLA3

Mpa

(o/f)

Mpa

(o/f)

˚C

˚C

˚C

m

D.B.˚C

W.B.˚C

D.B.˚C

D.B.˚C

W.B.˚C

1 , 50

220

0.32

PU-1.6

VLJA2

1 , 50

220

6.7

1.89

(19.3)

0.5

(5.1)

84

50

9

5

27

19

15.4

35

24

1 , 50

220

0.37

PU-2

VJA2

1 , 50

220

11.3

1.98

(20.2)

0.46

(4.69)

66

52

3

5

27

19

13.4

35

24

1 , 60

220

0.42

PU-2

NJA1

1 , 60

220

13.6

1.96

(20.0)

0.47

(4.79)

66

52

5

5

29

19

13.5

46

24

PK-2.5FLA2

PK-2.5FLA3

PK-2.5FLA4

Cooling Cooling

7000

6650

2.56

3.54

PK-2.5FLA2

PK-2.5FLA3

PK-2.5FLA4

1 , 50 1 , 60

220

220

0.44

0.44

PU-2.5 PU-2.5

VJA2 NJA1

1 , 50 1 , 60

220

220

11.4

15.8

2.05

2.13

(20.9) (21.7)

0.47

0.44

(4.79) (4.49)

74.3

87

52

54

10.3

10

5

5

27

29

19

19

14.1

14.1

35

46

24

24

PK-3FLA2

Cooling Cooling

7200

6900

3.28

4.19

PK-3FLA2

1 , 50

220

0.44

PU-3

VJA2

1 , 50

220

15.1

1.99

(20.3)

0.47

(4.79)

62

51

6

5

27

19

13.7

35

24

1 , 60

220

0.44

PU-3

NJA1

1 , 60

220

20.9

2.07

(21.1)

0.44

(4.49)

70

53

4

5

29

19

13.2

46

24

PK-3FLA3

PK-3FLA4

PK-3FLA5

Cooling Cooling

7900

6900

3.28

4.19

PK-3FLA3

PK-3FLA4

PK-3FLA5

1 , 50 1 , 60

220

220

0.44

0.44

PU-3 PU-3

VJC

NJA1

1 , 50 1 , 60

220

220

15.1

20.9

1.99

2.07

(20.3) (21.1)

0.47

0.44

(4.79) (4.49)

86

70

51

53

6

4

5

5

27

29

19

19

13.0

13.2

35

46

24

24

PK-3FLA2 PK-4FLSA2

PK-3FLA3 PK-4FLSA3

PK-3FLA4

PK-3FLA5 PK-4FLSA4

Cooling Cooling Cooling

7500

9800

9900

3.28

3.46

5.08

PK-3FLA2 PK-4FLSA2

PK-3FLA3 PK-4FLSA3

PK-3FLA4

PK-3FLA5 PK-4FLSA4

1 , 50

1 , 60

1 , 50

220

220

220

0.53

0.53

0.44

PU-4 PU-4

PU-3

YJSA3 TJSA3

VJB

1 , 50

3 , 50 3 , 60

220

220

220

12.4

5.7

14.0

1.94

1.80

1.93

(19.8)

(18.4) (19.7)

0.48

0.48

0.45

(4.85)

(4.89) (4.59)

76

65

74

51.4

49

52

5

6

5

5

5

5

27

27

29

19

19

19

13.4

13.9

13.2

35

35

46

24

24

24

Total Electrical circuit Refrigerant circuit Indoor side Outdoor side

The unit of pressure has been changed to Mpa on the international system of unit(SI unit system).

The converted score against the traditional unit system can be gotten according to the formula below.

1(Mpa)=10.2(O/F·G)

3. ADDITIONAL REFRIGERANT CHARGE (R-22…kg(lbs))

Service Ref.

PK-1.6FLA3

PK-2FLA3

PK-2.5FLA2/3/4

PK-3FLA2

PK-3FLA3/4/5

PK-4FLSA2/3/4

Outdoor unit precharged (kg)

(up to 20m)

VL---1.3,

V---1.79, N---1.9

V---2.4, N---2.4

V---3.08, Y---2.88, N---3.5

V---2.8, Y---2.8, N---3.5

VL---3.8, Y---4.6, T---4.6

20m (66ft)

0

0

0

0

0

0

Refrigerant

25m (82ft)

—

0.06(0.13)

0.06(0.13)

0.06(0.13)

0.06(0.13)

0.15(0.33)

piping length (one way)

30m (98ft)

35m (115ft)

—

—

0.12(0.26)

—

0.12(0.26)

—

0.12(0.26)

—

0.12(0.26)

—

0.30(0.66)

0.45(0.99)

40m (131ft)

—

—

—

—

—

0.6(1.32)

60Hz

50Hz

Frequency

4. OUTLET AIR SPEED AND COVERAGE RANGE

Configuration

Wall mounted

Model

Airflow

Air speed

Coverage rangew

Airflow

Air speed

Coverage rangew

m /min

m/sec.

m(ft)

m3/min

m/sec.

m(ft)

3

PK-1.6FLA

PK-2FLA

PK-2.5FLA

PK-3FLA

PK-4FLSA

13

4.0

9.1(30)

—

—

—

14

4.3

9.8(32)

14

4.3

9.8(32)

20

4.9

12.4(41)

20

4.9

12.4(41)

20

4.9

12.4(41)

20

4.9

12.4(41)

28

5.4

15.3(50)

28

5.4

15.3(50)

w The air coverage range is the value up to the position where the air speed is 0.25m/sec. when air is blown out horizontally

from the unit at the Hi notch position/

The coverage range should be used only as a general guideline since it varies according to the size of the room and furniture inside the room.

15

OC129A-1.qxp

6

01.10.1 7:33 PM

Page 16

OUTLINES AND DIMENSIONS

Unit : mm

1. REMOTE CONTROLLER

57

18

3

58

19

CHECK TEST RUN

MODEL SELECT

˚C

AMPM

˚C

AM

PM

AMPM

NOT AVAILABLE

AM

PM

ON/OFF

NOT AVAILABLE

TEMP

162

153

ON / OFF

TEMP

55

PK-1.6FLA3

PK-2FLA3

PK-2.5FLA2, PK-2.5FLA3

PK-3FLA2, PK-3FLA3, PK-3FLA4

PK-4FLSA2, PK-4FLSA3

PK-2.5FLA4

PK-3FLA5

PK-4FLSA4

16

Front

(Height ut unit)

68- 5

hole

53

491

476

450

405

Gas pipe position

Liquid pipe position

2 X5 - 2.9 hole

for tapping screw

Knock out hole for

left-rear piping

Tapping screw

277

300

0

45

85

80

5

2.

323

276

229

R5

179

150

330

1250

60

24

0

190

Knock out hole for

left-rear piping

447

(375)

(178)

300

286X 2

227

2

Bass pipe

1 Liquid pipe

Drainage

50

2 tapping screws

for installation plate

0

35

53

80

130

177

Rear piping hole

13- 14

hole

(Necessary clearance for

Unit installation)

130 or less

Right side

Left side

60

(100 for left-hand

side piping)

150 or more

70

73

(Width of unit)

.5

35

Ref.pipes & drain pipe

Knock out hole for

left-hand side piping

150

174

224

Sleeve Through hole

90

90~ 100

Details of installation plate

w 1 Sleeves are available on

the market.

w 2 This size shows the lower

end of through hole.

2-unit hangers Unit cennter

50 or more

Service space required

around indoor unit

Gas pipe

Drain pipe

Lequid pipe

70

R5

2

215

80

271

47

70

25

318

3/8F

5/8F

2

1

976

479 Air outlet

Knock out hole

for piping

1100

Drainage(Flexible hole: length 1200)

685

635

Terminal block & pipe position

Lower side

500

(manual)

236

227

553

A

26

200

190

60

Installation bolt position

Right side

15 or less

bolt

A

B

Knock out hole

for piping

70

20

8

Knock out hole for under-piping

(2:1)

60

8

Knock-out hole for

night-hand side piping

(2:1)

Knock out hole for right piping

B

Knock out hole for piping

Terminal block for control

170

200

Right side

Terminal block

Air intake

Terminal block for

power supply

222

143

173

223

Service panel for

power supply connection

449 Air intake

Auto vanes

Lower side

48

16 -louvers

479 Air outlet

449 Air intake

168

1250

91

968 Air intake

213

4

Front

8

Pipe position

Left side

625

30 or more

180 or more

374

405

450

476

486

9

17

8

65

2. INDOOR UNIT

PK-1.6FLA3

PK-2FLA3

20

01.10.1 7:33 PM

70

OC129A-1.qxp

Page 17

Unit : mm

37

74

A

30

32-ø12 hole for bolt

66-ø6 hole for

tapping screw

Wall fixture

100

4 39

225

18

39

990

180

12-ø6 hole for

tapping screw

240

on left-hand side

C

30

455

39

610

91

314

285

19

245

90

25

Drain hose for

left-hand side piping

Knock out hole for

left piping

Left side

Range for left rear piping opening

280

Drainage range

on right-hand side

37

74

Unit center

10 91=(910)

900

18 Drainage range

98 32

B

37

65

Knock out hole for piping

A

100

4

340

30

10

184

30

30

80

29

280

18

45

45

Front

235

552 Air outlet

Liquid pipe

235

Refrigerant pipe. Drain pipe

Change vane (manual)

Under panel

Removable at left-hand

side piping

Knock out hole for under-piping

1120

Auto vane

Lower side

1110

Drain hose

45

62.5

13

Top

1400

1090 Air intake

235

552 Air outlet

235

Rear piping opening

60

183

240

235

Right side

Terminal block for control

197

B

Terminal block for power supply

Gas pipe

Drain hose

Bolt

15

C

Knock out hole for right piping

Refrigerant pipe. Drain pipe

Liquid pipe 9.52(3/8F)

Gas pipe 15.88(5/8F)

(Liquid pipe)

55 (Gas pipe) 107

120

111

42

01.10.1 7:33 PM

58

OC129A-1.qxp

Page 18

PK-2.5FLA2, PK-2.5FLA3, PK-2.5FLA4

PK-3FLA2, PK-3FLA3, PK-3FLA4, PK-3FLA5

Unit : mm

19

295

225

39

180

314

285

19

245

90

Range for left rear piping opening

280

750

Drainage range

91

on right-hand side

595

12-ø6 hole for tapping screw

240

25

Knock out hole for left piping

340

Drain hose for left-hand side piping

37

74

C

30

13 91=(1183)

900

Drainage range

on left-hand side

18

Range for left rear piping opening

41-ø12 hole for bolt

18

1270

Unit center

98 32

Wall fixture

39

B

37

65

Knock out hole for wiring

Unit out line

37

74

A

30

84-ø6 hole for

tapping screw

100

4 39

A

100

4

Left side

235

10

184

30

30

80

29

280

30

Rear piping opening

Auto vane

45

1680

Front

235

Drain hose

235

694 Air outlet

183

Under panel

(Removable at left-hand side piping)

Refrigerant pipe. Drain pipe

Knock out hole for under-piping

235

Right side

240

(Liquid pipe)

B

55 (Gas pipe) 102

120

111

Terminal block for power supply

Gas pipe

C

Gas pipe 19.05(3/4F)

Liquid pipe 9.52(3/8F)

Bolt

Terminal block for control 15

Change vane (manual)

Lower side

1400

45

Knock out hole for right piping

235

Liquid pipe

1370 Air intake

45

1110 Drain hose

235

694 Air outlet

45

62.5

13

Top

42

PK-4FLSA2, PK-4FLSA3, PK-4FLSA4

58

01.10.1 7:33 PM

60

197

OC129A-1.qxp

Page 19

Unit : mm

OC129A-1.qxp

01.10.1 7:33 PM

7

Page 20

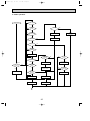

WIRING DIAGRAM

L

N

PK-1.6FLA3

PK-2FLA3

POWER SUPPLY

~(1 PHASE)

AC220-240V 50Hz

AC220V 60Hz

GRN/YLW

10.6VAC

220V

TB2

YLW

RED

240V

14.5VAC

T

MV

7

W.B

SW1

LS

ORN

230V

7

MF

LD1

CNB

W.R

1 3 5

FAN

CNV

VANE

POWER

12345678 12345

CN28

1 2 3 4 5 6

WHT

2 1

ON

OFF

L.TEST

CN70

WIRELESS

TO OUTDOOR UNIT

CONNECTING WIRES

DC12V

RT1

VANE

TWIN.1

SW2

CN2

TWIN.2

SW1

JR

TIMER

CN2A

INTAKE

2

1

RT2

CN23

123

CN2B

1

3 2 1

7

ON

OFF

YLW

2 1

CN20

SW3

TB4

ORN

2 1

PIPE

CN30

CN21

ZNR

OUTDOOR

CN51

MULTIPLE

F1

X4

X4

BRN

BRN

WHT

RED

RED

4 3 2 1 CN4T

TRANS

1 3 CNT

TRANS

1 3

F2

YLW

RED

CND

1 3

BLU

BLK

1 3 5

BLK

BLK

WHT

RED

I.B

Ru

C

REMORT

CONTROLLER

RED

PK-1.6FLA3

PK-2FLA3

SW1

ON

OFF

1 2 3 4 5 6 7 8

SYMBOL

C

CN2<I.B>

CN2A<I.B>

CN2B<I.B>

CN23<I.B>

CN28<I.B>

CN51<I.B>

F1,2<I.B>

I.B

JR

NAME

SYMBOL

NAME

FAN MOTOR CAPACITOR

LD1<W.B> RUN INDICATOR LED

TIMER ADAPTOR CONNECTOR

MF

FAN MOTOR

TRANSMISSION WIRES No.1 CONNECTOR

MV

VANE MOTOR

TRANSMISSION WIRES No.2 CONNECTOR

ROOM TEMPERATURE THERMISTOR

RT1

VANE POSITION CONNECTOR

(0%/15k",25°C/5.4k" DETECT)

TIME SHORTENING CONNECTOR

PIPE TEMPERATURE THERMISTOR

RT2

MULTIPLE CONNECTOR

(0%/15k". 25°C/5.4k" DETECT

FUSE(6.3A 250V)

Ru<W.B> RECEIVING UNIT

INDOOR CONTROLLER BOARD

SW1<I.B> FUNCTION SWITCH

FUNCTION SELECTOR JUMPER RESISTORS

SW2<I.B> UNIT SELECTOR SWITCH

SYMBOL

SW3<I.B>

SW1<W.B>

T

TB2

TB4

X4<I.B>

ZNR

W.B

W.R

SW1

ON

OFF

1 2 3 4 5 6 7 8

NAME

EMERGENCY OPERATION SWITCH

ON/OFF SWITCH

TRANSFORMER

POWER SUPPLY TERMINAL BLOCK

INDOOR/OUTDOOR CONNECTING WIRE

TERMINAL BLOCK

FAN MOTOR RELAY

VARISTOR

WIRELESS REMOTE CONTROLLER BOARD

WIRELESS REMOTE CONTROLLER

NOTES:

1. Since the indoor fan motor (MF) is connected with 220V power, using 230, 240V power will require a setting change of the dip switch (SW1<I.B>) on the

indoor controller board as shown is fig:w1.

SW1

SW1

fig

w1

Indoor fan motor (MF) for 230,240V.

ON

OFF

ON

OFF

12345678

12345678

2. Since the outdoor side electric wiring may change be sure to check the outdoor unit electric wiring for servicing.

3. Since the indoor transformer (T) is connected with 220V power, if 230,240V power is used. Change the wiring connection showing fig * : 2.

fig

w2

When power supply is

230V

220V

220V YELLOW

230V ORANGE

240V RED

4. Symbols used in wiring diagram above are,

: Connector,