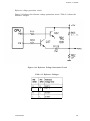

Download Epson ActionPrinter 3000 - ActionPrinter-3000 Impact Printer Service manual

Transcript