Download Craftsman 113.213090 Owner`s manual

Transcript

f

Save ThisManual

"_

I

For FutureReference

MODEL NO.

113.213090

DRILL PRESS WITH

MAXIMUM

DEVELOPED

1/2 HP MOTOR

Serial

Number

Model and

serial number

may be found at the rear of

the head.

You should record both

model and serial number in

a safe place for future use.

10-INCH

BENCH MODEL DRILL PRESS

• assembly

• operating

e repair parts

CAUTION:

READ ALL

iNSTRUCTIONS

CAREFULLY

",...

MOTORIZED

.j

Sold by SEARS, ROEBUCK AND CO., Chicago,

Part No. SP5t85

../

IL 60684

U.S.A.

Printed

in Taiwan

GENERAL SAFETY INSTRUCTIONS

1, KNOW YOUR POWER TOOL

Read and understand the owner's manual and

labels affixed to the tool Learn its application and

limitations as well as the specific potential hazards

peculiar to this tool.

2. GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor

cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle. The green conductor in the cord is the grounding w_re. Never

connect the green w_reto a live terminal.

3. KEEP GUARDS IN PLACE

In working order, and in proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form a habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning It on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6, AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted,

Provide adequate surrounding work space.

7. KEEP CHILDREN AWAY

All visitors should be kep_ a safe distance from

work area

8. MAKE WORKSHOP CHILD-PROOF

With padlocks, master switches, by removing starter keys. or storing tools where children can't get

them.

13.

15.

16.

17.

18.

19.

FOR POWER TOOLS

Z87.1) at al! times. Everyday eyeglasses are not

safety glasses. They only have impact resistant

lenses Also. use face or dust mask if cutting operatior is dusty, and ear protectors (plugs or muffs)

during extended oeriods of operation.

SECURE WORK

Use c_arnps or a vise [o hold work when practical.

It frees both hands to operate tool.

DON'T OVERREACH

Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories.

DISCONNECT TOOLS

Before servicing; when changing accessories such

as blaoes bits, cutters, etc.

AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before olugglng _n

USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended accessor es Fo ow the

the accessories. The instructions that accompany

use of improper accessories

may cause hazard s,

NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted. Do not

store materials above or near the tool such that _t

is necessary to stand on the tool or _ts stand to

reach them

9. DON'T FORCE TOOL

It will do the job better and safer at the rate for

which it was designed.

10. USE RIGHT TOOL

Don't force tools or attachment to do a job it was

not designed for.

11. WEAR PROPER APPAREL

Do not wear loose cothing goves necktes, or

jewelry (rings wristwatchesito get c_Lught n moving p_trts. NONSLIP f0otwear S re ;ornmended

Wear protective ha r cover ng to conla n ong hair.

20. CHECK DAMAGED PARTS

Before further use of the tool. a guard or other part

that =s damaged should be carefully checked to

ensure that it will operate properly and perform its

=ntended functJon Check for alignment of moving

parts, b_nding or moving parts, breakage of parts.

mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged

should be proper_y repaired or replaced.

21. DIRECTION OF FEED

Feed work nto a b ade or cutter aga nst the d rect on of rotation of the bade or cutter on y

Roll t(_ngsleeves above the elbow.

12. USESAFETYGOGGLES(HEADPR

:)TECTION)

Wear safety goggles (must _om'rp wth ANSi

22 NEVER LEAVETOOL RUNNING UNATTENDED

Turn power off Dont eave too unt t comes to a

compete stop.

2

additional safety instructions for drilm presses

2

WARNING: FOR YOUR OWN SAFETY, DO NOT

ATTEMPT TO OPERATE YOUR DRILL PRESS

UNTIL iT iS COMPLETELY ASSEMBLED AND INSTALLED ACCORDING TO THE iNSTRUCTIONS...

AND UNTIL YOU HAVE READ AND UNDERSTAND

THE FOLLOWING:

1. General Safety instructions for Power Tools.

--

2

2. Getting to Know Your Drill Press ........

3. Basic Drill Press Operation .............

17

22

4. Adjustments ..........................

5. Maintenance ..........................

24

25

6. Stability of Drill Press

If there is any tendency of the drill press to tilt or

move during any use, bolt it to the floor or a flat

piece of 1/2" exterior plywood large enough to

stabilize the drill press. Bolt the plywood to the

underside of the Base. so it extends at least to

both sides. Make sure the plywood won't trip the

operator, Do not use pressed wood panels-they can break unexpectedly.

If the workpiece is too large to easily support with

one hand, provide an auxiliary support.

7. Location

Use the drill press in a well lit area and on a level

surface clean and smooth enough to reduce the

risk of trips, slips, or falls. Use it where neither the

operator nor a casual observer is forced to stand

in line with a potential kickback.

8. Kickback

A kickback occurs when the workpiece is suddenly

thrown in the OPPOSITE direction to the DIRECTION OF FEED: THIS CAN CAUSE SERIOUS INJURY. Kickbacks are most commonly caused by

use of accessories NOT recommended for this tool.

9. Protection: Eyes, Hands, Face, Ears and Body

WARNING: TO AVOID BEING PULLED INTO

THE SPINNING TOOL -1. Do NOT wear:

-- gloves

-- necktie

-- loose clothing

-- jewelry

2. Do tie back long hair

a. If any part of your drillpress is missing, malfunctioning, has been damaged or broken..,

such

as the motor switch, or other operating control,

a safety device or the power cord . . . cease

operating immediately until the particular part

is properly repaired or replaced.

b. Never place your fingers in a position where

they could contact the drilI or other cutting tool

if the workpiece should unexpectedly shift or

your hand should slip.

c. To avoid injury from parts thrown by the spring,

follow instructions exactly as given and shown

in adjusting spring tension of quill.

--

---

--

---

-

-

--

d: To prevent the workpiece from being

torn from your hands, spinning of the

toot. shattering the tool or being thrown,

always properly support your work so

it won't shift or bind on the tool:

Always position BACKUP MATERIAL (use

beneath the workpiece) to contact the left

side of the column.

Whenever possible, position the WORKPIECE to contact the left side of the column-if it is too short or the table is tilted,

clamp solidly to the table. Use table slots

or clamping ledge around the outside edge

of the table.

When using a drill press VICE, always fasten it to a table.

Never do any work "FREEHAND" (handholding workpiece rather than supporting it

on the table), except when polishing.

Securely lock Head and Support to Column,

and table to support before operating drill

press.

Never move the Head or Table while the

tool is running.

Before starting the operation, jog the motor

switch to make sure the drill or other cutting

tool does not wobble or cause vibration.

If a workpiece overhangs the table such

that it will fall or tip if not held, clamp it to

the table or provide auxiliary support.

Use fixtures for unusual operations to

adequately hold, guide and position workpiece.

Use the SPINDLE SPEED recommended

for the specific operation and workpiece

material--check

the inside of the Belt

Guard for drilling information; for accessories, refer to the instructions provided

with the accesso[ies.

f. Never climb on the drill press Table, it

could break or pull the entire drill press

down on you.

g. Turn the motor Switch Qff and put away

the Switch Key when leaving the drill

press.

h. To avoid injury from thrown work or tool

contact, do NOT perform layout, assembly, or setup work on the table while

the cutting tooI is rotating,

10. Use only accessories designed for this

drill press to avoid serious injury from

thrown broken parts or work pieces.

a. Holesaws must NEVER be operated on

this drill press at a speed greater than

400 RPM

.E

_

_"

"_

t,_

:_

-D

"._

13 Think Safety, Safety is a combination of operator

common sense and alertness at all times when the

drill press is being used.

WARNING: DO NOT ALLOW FAMILIARITY (GAINED

FROM FREQUENT USE OF YOUR DRILL PRESS)

TO BECOME COMMONPLACE.

ALWAYS REMEMBER THAT A CARELESS FRACTION OF A

SECOND iS SUFFICIENT TO iNFLICT SEVERE

INJURY,

b. DrumsandersmustNI

_ER be operated on

the drill press at a sp_ d greater than 1800

RPM.

o. Do not insta I or use an_

length or extends 6' b#lc

Cad suddenly bend out_

d Do not use wire whee s,

ters circle (fly) cutters €

drill press.

rill that exceeds 7" in

the chuck jaws. They

rd or break.

)uter bits, shaper cutrotary planers on this

11. Note and Follow the Safety Warnings and Instructions that Appear on the Panel on the

Right Side of the Head:

o

o

I DANGER

J FOR YOUR

The operation of any power toot can result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles comply with ANSl Z87.1 (shown on Package) before comrnenc_ng 0ower tool operation. Safety Goggles are

available at Sears retail or catalog stores.

OWN SAFETY:

Know This Tool! Read and Understand

Owner's Manual before Using th=s

Machine, Use Recommended

Drill S_eedSee Chart inside Pulley Cover,

m Always

wear safety goggles

that comply

with

m Donotweargloves.necktieorlooseclothing

long hair.

m Securelyclampworktotableifitistooshort

the column

when in operatmg

position.

O

•

Securely lock head and support to Column.

to support, before operating drill press,

a

Use

only

recommended

accessories.

ANSI

Tieback

Z87.1

WEAR

SP=NO_E

YOUR

_N

tocontact

and table

_" ('U_

E82443

O

12. This Drill Press has 4 speeds as listed below:

48O RPM

930 RPM

1750 RPM

3000 RPM

i

See inside of guard for specific placement of belt

on pulleys.

4

glossary

1. Workpiece

The item on which the cutting operations

is being

performed.

2. Drill

The cutting toot used in the dril_ press to make holes

in a workpiece.

of terms

4. Revolution

Per Minute

(R.P.M.)

The number of turns completed

by a spinning

in one minufe,

object

_=

O

5. Spindle Speed

The RPM of the spindle.

_"

3. Backup

Material

A piece of wood placed between the workpiece and

table ....

it prevents wood in the workpiece from

splintering

when the drill passes through the backside of the workpiece ....

also prevents drilling into

the table top.

table of contents

Page

17

.

19

20

2O

Page

General Safety Instructions

for Power Tools ......

Additional Safety Instructions

for Drill Presses

....

Glossary of Terms .......................

Table of Contents ..........................

Motor Specifications

and Electrical

Requirements

..........................

Unpacking and Checking Contents

.............

Table of Loose Parts ........................

Location and Function of Controls

.............

Assembly

................................

Assembly of Base/Column

...............

Installation of TabletSupport

..............

Installing the Head .....................

Installing Feed Handles

.................

Installing the Chuck .....................

Installing Belt Guard Knob

...............

Tensioning

Belt ........................

Adjusting the Table Square to Head

.......

Bevel Scale ...........................

2

3

5

5

6

7

8

9

10

10

10

13

14

14

15

15

I6

16

Getting

to Know You_

On-Off

Switch

Remownq

Dnlhng

Drdl

Press

..

The Chuck

Io Depth

......

Depth Sca_e

...........

Bas=c Drill Press Operation

Installing Drills

...........

Pos*honmg Table and VVorko_ece

T_thng Table

Hole hocatlon

Feeding

Adlus[rnenls

............

Qudl Relurn Sprtng.

.

Maintenance

............

Lubncat_on

......................

Recommended

Accessories

Trouble Shoot_ng

................

Repair Parts

..

...

.....

21

. 22

22 "_

23€_

23 "_

24

24 "_

24

24

25

25

25

26

27

i_i !i_i_i_i

_

motor spec Tca ons and electrica

ifi

requ

_ m

MOTOR SPECiFICATiONS

TNs dril! press is designed to use a 1725 RPM motor

only. Do not use any motor that runs faster than 1725

RPM It is wired for operation on 110-120 volts. 60 Hz.

alternating current,

WARNING: TO AVOID INJURY

FROM UNEXPECTED STARTUP, DO NOT USE BLOWER OR

WASHING MACHINE MOTORS OR ANY MOTOR

WITH AN AUTOMATIC RESET OVERLOAD PROTECTOR.

CONNECTING TO POWER

SOURCE OUTLET

This machine must begrounded while _nuse to protect

the operator from electric shock.

Plug power cord Into a 110-!20V properly grounded

type outlet protectea by a 15-amo dual element time

delay or Circuit breaker.

NOT ALL OUTLETS ARE PROPERLY GROUNDED.

IF YOU ARE NOT SURE THAT YOUR OUTLET, AS

PICTURED BELOW. iS PROPERLY GROUNDED,

HAVE IT CHECKED BY A QUALIFIED ELECTRiCiAN.

WARNING: TO AVOID ELECTRIC SHOCK. DO NOT

TOUCH THE METAL PRONGS ON THE PLUG,

WHEN INSTALLING OR REMOVING THE PLUG TO

OR FROM THE OUTLET.

°reme

t s i¸

This power tool is equipped with a 3-conductor

and grouna_ng type plug, approved by Underwriters'

Laooratories and the Canadian Standards Association:

The grouna conductor has a green jacket and is at_

tached to the tool housing at one end and to the grour]d

prong in the attachment plug at the other end.

This plug requires a mat ng 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this power tool

s of the two prong type, DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use

an adapter as shown and always connect the grounding

tug to known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE orong outlet.

An adaoter as shown below is available for connecting

plugs to 2-pror_g receptacles.

WARNING: THE GREEN GROUNDING LUG EXTENDING FROM THE ADAPTER MUST BE CONNECTED TO A PERMANENT GROUND SUCH AS

TO A PROPERLY GROUNDED OUTLET BOX.

GROUNDING

SCREW

LUG

\

WARNING: FAILURETO PROPERLY GROUNDTHIS

POWER TOOL CAN CAUSE ELECTRICUTION OR

SERIOUSSHOCK, PARTICULARLY WHEN USED IN

DAMP LOCATIONS. OR NEAR METAL PLUMBING.

IF SHOCKED, YOUR REACTION COULD CAUSE

YOUR HANDS TO HIT THE CUTTING TOOL

IF POWER CORD IS WORN OR CUT, OR DAMAGED

IN ANY WAY, HAVE IT REPLACED IMMEDIATELY

TO AVOID SHOCK OR FIRE HAZARD.

ADAPTER

3-PRONG

PLUG

NOTE: The adapter illustrated is for use only if you

alreaoy nave a properly grounded 2-prong receptacle,

Adapter is not allowed in Canada by the Canadian Electrical Code.

\

GROUNDING

PRONG

The use of any extension cord will cause some loss of

0ower. To Keep this to a minimum and to prevent overneatmcj and motor bum-out, use the table below to

determine the minimum wire size (A W.G) extension

cord Use only 3 wire extension cords which have 3prong grounding type plugs and 3-pote receptacles

which accept the tools ptug.

Extension Cord Length

0-25Feet

26-50Feet

51-100 Feet

has a plug that looks

Wire Size A.W.G.

16

!4

12

unpacking

and checking

WARNING:

TO AVOID

iNJURY

FROM

UNEXPECTED STARTING

OR ELECTRICAL

SHOCK, DO

NOT PLUG THE POWER CORD iNTO A SOURCE

OF POWER. THIS CORD MUST REMAIN

UNPLUGGED WHENEVER

YOU ARE WORKING

ON THE

DRILL PRESS.

Model 113.213090

one box.

1. Unpacking

Drill Press

and Checking

a. Separate ali "loose

rials and check each

Parts" to make sure

before discarding any

is shipped

compiete

n

Contents

parts" from packaging mateitem with "Table of Loose

ali items are accounted

for

packing material

WARNING:

IF ANY PARTS ARE MISSING,

DO NOT

ATTEMPT TO ASSEMBLE

DRILL PRESS, PLUG IN

THE POWER CORD, OR TURN THE SWITCH ON

UNTIL THE MISSING PARTS ARE OBTAINED

AND

ARE INSTALLED

CORRECTLY.

2

3

Remove the protective oil that is apoliec to the

table and column. Use any ordinary hoLJsehold type

grease and spot remover.

WARNING:

TO AVOID FIRE OR TOXIC REACTION, NEVER

USE GASOLINE,

NAPTHA

OR

SIMILAR HIGHLY VOLATILE

SOLVENTS.

Apply a coat of paste wax to the tab!e and co!umn

to prevent rust. Wipe all parts thoroughly

with a clean

dry cloth.

G

E

TABLE

Item

contents

OF LOOSE

pARTS

Description

Qty.

A

_::

C

D

E

F

"

r, ,_,t Asrlr_....

Tae

e "Su_..pL

.............

Column

SL_pport As,q"_ ..................

Owners MamJa

...................

Box of Loose Parts

.................

Base .........

•

•

..............

Head A.....

,_

................

I_

_

"1

G

Bag of Loose Parts

i

...........

'

_

1

"_

_ "_

.E o

o c

t*_

=

L_

_,.,c _'

o

List of Loose Parts in Box 507884

item

Description

Chuck Key . ......................

Chuck ..............................

B

A

/

Qty.

1

1

List of Loose Parts in Bag 507885

item

C

D

E

*F

*G

H

I

*J

*K

Description

Feed Handle ........................

Wrench Hex "L" 3mm

................

Wrench Hex "L" 4mm ................

Knob .............................

Screw Pan Hd, M5 x 0.8-12

..........

Table Crank ........................

Support LOCKHandle .................

Switch Key ........................

Screw Hex Hd M8 x 1.25-20 ..........

Qty.

3

1

1

1

1

1

1

1

4

C

fD

7

F

These Parts Shown =ull Size

E

#

J

qJ

G....G ]'llltlrl,l,l'l'lt!'l'l'g (_

H

J

K

/

/

/

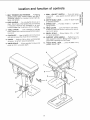

location and function

1, BELT TENSION LOCK HANDLES...

Tightening

handles locks motor bracket support and BELT

TENSION HANDLE to maintain correct belt distance and tension,

7. DRILL "ON-OFF"

SWITCH . . . Turns drift press

on and off . . , also used to lock drill press in off

position,

8. DEPTH SCALE LOCK

at selected position.

2. FEED HANDLE...

For moving the chuck up or

down, One or two of the handles may be removed

if necessary whenever

the workpiece

is of such

unusual shape that it interferes with the handles,

"5

scale

Provides

_

means tc ; ,_just quill

10. HEAD LOCKS...

Locks the head to the columr

ALWAYS have them locked in place while operazing the drill press.

11. BEVEL SCALE . •

for bevel operations.

4. CHUCK KEY...

Used to tighten drill in the chuck

and also to loosen the chuck for drill removal.

,

Shows

degree

tab_

s ÷_

,_ted

12. SUPPORT

LOCK HANDLE...

Tightening

locks

table support to column, Always" have it Iocke(_ tn

place while operating the Drill Press.

Holds drill bit or other recomrpended

to perform desired operations.

6. DEPTH SCALE...

Allows operator

press to drill to a desired depth.

Locks the depth

_

,_ o

.-J

9. SPRING CAP

spring tension,

3. TABLE

CRANK

. . . Turn clockwise

to elevate

table. Support lock must be released before operating crank,

5. CHUCK...

accessory

of controls

to adjust drill

13. TABLE

position

5

4

11

12

13

£

BEVEL LOCK...

from 0'_'-45 °.

Locks the table

in any

o

to

"

u,.

FRAMING SQUARE MUST BE TRUE,

-Check its accuracy

....

TOOLS

NEEDED

..............

as il;ustrated below,

DRAW LIGHT

LINE ON BOARD

STRAIGHT EDGE OF

BOARD 3/4" THICK-THIS EDGE MUST BE

ALONG THE EDGE ,_

PERFECTLY

SCREWDRIVER

STRAIGHT

_m

SQUARE

_J"

fl

_J

8-INCH ADJUSTABLE

WRENCH

SHOULD

SQUARE

BE NO GAP OR OVERLAP

WHEN

IF FLIPPED

OVER IN DOTTED

POSITION

JflllJltli!li JIl tlltllltlll

8mm DIA. x 20turn LONG BOLT

ASSEMBLY

OF BASE/COLUMN

COLUMN

ASSEMBLY

1 Position base on floor. Remove protect_vecoverlng

and discard

2, Remove protective sleeve from column tube and

discard. Place column assembly on base, and align

holes in column support with holes in base.

RACK

3. Locate four (4) 8ram Dia. x 20ram long bolts among

oose parts bag,

4, Install a bolt _n each hole through column support

and base and tighten with adjustable wrench.

1, L_sen set screw n Column collar with 3ram HEX

wrenchand remove co ar and rack from co umn

COLUMN

COLLAR

10

SPECIAL

NOTE: Make sure the elevation worm gear

shaft is extending through the opening in the table support as far as possible -- See Illustration.

2. With long smooth end of rack pointing upward, slide

rack down through large round opening in table

support.

Engage rack in gear mechanism

found

inside opening of table support.

RACK

GEAR

MECHANISM

TABLE

SUPPORT

ELEVATION

WORM GEAR

SHAFT

TABLE

RACK

COLt.

3. While hotding rack and table support in an engaged

position slide both down over column. Slide rack

down column until rack is positioned against lower

column support.

TABLE

ELEVATION

WORM GEAR

SHAFT

!

TABLE

11

LOWER

COLUMN

SUPPORT

COLUMN

COLLAR

4. Replace column collar and position it bevel side

down over rack. Tighten set screw in collar with

3ram HEX "E' wrench. To let the rack slide when

the table is swung to the left or right around the

column, the collar must s_t loosely over rack aria

should not be angled on the column- Only tighten

set screw enough to keep collar _n ulace, otherwise

the collar may De broken due to excess pressure

CAUTION: To avoid co lumn tube or collar damage, do not over tighten set screw.

RACK

TABLE

5. Locate support

lock handle in loose 3arts bag.

SUPPORT_

6. Install support lock from left side into table support

and tighten by hand.

SUPPORT

LOCK HANDLE

TABLE

SUPPORT

7. Locate table crank in loose parts bag.

8. Install table crank assemb y and tighten set screw

with a 3turn HEX "E' wrench.

TABLE

CRANK

12

INSTALLING

THE HEAD

CAUTIONi

The head assembly

pounds. Carefully li_ head.

1. Remove

protective

covering

weighs

about

45

from head.

2. Carefully lift head above column tube and slide it

down on the column as far as it will go. Align head

with table and base.

i

HEAD

COLUMN

3.

Using a 4mm Hex 'L" wrench tighten the head lock

set screws on the right side of the head

..J

HEAD

HEAD

LOCK

SET SCREWS

13

FEED

HANDLE

HUB

!NSTALL{NG

FEED

HANDLES

!

Lecate th_-ee _3i feed handl_-s amor; 9 io0se pa,*ls.

2

S(_w

_ie feed ha:nd_es tight!y i_to 1he threaded

_ht hub

INSTALUNG

2

THE

CHUCK

_ocale the chuck among loose parts

CIear: out the TAPERED HOLE in the chuck: clean

the spindle nose with a clean cloth. Make sure

the_e are no foreign partic}es sticking to the surfaces The slightest piece of dirt on the spindle

nose or _n the chuck wi_ prevent the chuck from

seating

proper!y

THis w;_ cause the drill to

X,vobbte '

NOTE:

tremeIy

do_h

\

_f TAPERED HOLE in the chuck iS exdirty, use a c_eamng so_vent on the clean

CHUCK

•:_ Push the cr]_Jc:Kup on lhe spindle

,t w_t go

clockwise

nose ;As fa

and open

jaws

as

4

]urn cm_ck sleeve

chuck Cornpietely

_n

5

L_gntb! lap the nose of the chuck w_th a _ece of

woeo _o _nsure r_roper seating of the d]uck on the

spindle.

SPINDLE

J

NOSE

CHUCK

14.

BELT

5rr_m DiA

x !2ram

PAN

LONG

GUARD

KNOB

NO. SCREW

SCREW

BELT

GUARD

INSTALUNG

KNOB

BELT

GUARD

KNOB

1

To attach belt guard k:ob !ocate knob ar'd 5ram

Oa × 12ram ong par] hd screw _ loose parts

bag _nstalJ sc_ew n hoe ocated _n guarc and ab

taCh knob t_rnmg ;_;1_ l/ghl

WARNING:

TO AVOID

POSSIBLE

INJURY

KEEP

GUARD

1N PLACE

AND _N PROPER

WORKtNG

ORDER WHILE OPERATING.

TENSIONING

BEt.T

TENSION

LOCK

HANDLE

BELT

NOTE: T,__ Dr_ll P,ess s :m_pped w_ff: th(? bet _r_St,:_Jied

but _t shoud be pro;beriy t_.'m,oq_-,'dbefor÷, Js(,_

!

2

i.lfl (juard f[orn qghl s,;xe apt! e:-_v(' Op!}nei on

hinge

Looser

Be!t Te,%on

Lock Hand!es !ocaled on

BOTH SIDES of 0_1t P_es;head

P}il the motor

toward flont of @! pzess to r{:,_eve tens;o _on t}elt

BELT

TENSION

HANDLE

3

Choose speed for drii!ing operation, and move belt

to correct position for desired speed

NOTE: Refer to chart _nside belt guard

mended Drilfing Speeds

for Recom-

!5

4 _._ove

the_d.1orrearwarotoaop_yte_ls_on

tothe

5. TightenBeetTensionLOCk

Handles

NOTE:Be_,t

SHOULDdeflectapprox_matew

I/2'_ by

thuntb pressure

at mid-point

of be_t between

pulleys.

6 C_ose De_1[guard.

7

_ be_t s_[_£ ,*rhine drfihng, readjust

belt tension.

BELT

LOCK HANDLE

ADJUSTING

HEAD

THE

TABLE

SQUARE

TO

NOTE: The comb_nahon square rT1USt[3_ "_"Uf_

Unpack_n_

and Checking

Contents

section

mettled

See

to_

•

b_sert orec_s_on round steel

_ong rote chuck and tighten

rod approxlnqatel',i

2

With table raised to working height aria locked on

CO_LJrT'_n.

p_ace combmatlon square flat on table Deside rod

3

_f an adjustment _snecessary _oesen tl_e set screw

under bevetIock w_th 3ram "L wrench then loosen

the table bevel IoCk bolt with an adj LJstan_ewrench

(Th_s adjustmen,, _s located unaer the tablel

4

Ahgn the table square to the rod by relating table

unt_] the square arid rod are n I_ne

5

Ret_ghten table beve

6

Retighten

PRECISION

ROD

3

TABLE

BEVEL

LOCK

lock

set screw

SCREW

BEVEL

TABLE

SCALE

NOTE: The beve! scale t_as been included to Drowae

a qu_ck method for bevehng the table to approximate

angIes, tt precise accuracy ts necessary, a square, or

o_hef prec|s}on measuring tool should be used to posehen the table

1 To use {he bevel scale do the loltow ng

a. Loosen set screw and table beve! lock,see

3 above_

POINTER

steo

b

Move table so desired angle on beve sea e s

straigh_ across from zero line on table

c

Ret_g_en

SCALE

TABLE

table beve_ tock ana se_ screw

16

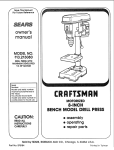

getting

knOW

to

your

driSl press

O

o3

o_

0

.F5

1

BELT

GUARD

22

FEED

HANDLE

2

BELT

TENSION

HANDLE

21

DEPTH

SCALE

LOCK

3

2O

COLUMN

DEPTH

SCALE

COLLAR

19

4

DEPTH

iNDiCATOR

FEED SPRING

ADJ USTME NT

rABLE

SUPPORT

18

TABLE

FEED

SPRING

5

TABLE

CRANK

6

17

RACK

COLUMN

7

COLUMN

8

16

15

HEAD LOCK

SCREWS

ON-OFF

SET

BASE

SWITCH

{_ ,,,/

14

SPRING

SPLINES

(GROOVES)

CAP

fJ_L,_-"'-_ SP,NDL

E

11

TABLE

13

SUPPORT

LOCK

HANDLE

BEVEL

LOCK

_

U

!2

BEVEL

(TEETH)

SCALE

CHUCK

10

CHUCK

KEY

QUILL AND SPINDLE

iNSiDE OF DRILL

17

ASSEMBLY

PRESS

SUPPORT

LOCK

SPINDLE[

This Drill Press has 4 speeds as listed below:

480 RPM

930RPM

1750 RPM

3000 RPM

See inside of belt guard for soecific placement of belts

on pulleys.

SPEEDS

IN

R.P.M.

480

930

1750

3OOO

and belt dunng

13

2. BELT TENSION LOCK HANDLE...

Tightening

handle locks motor bracket support to maintain c0rrect belt dtstance and tension

SUPPORT LOCK . . . T ghtentng locks tabe support to column. Always have _tlocked _nplace whde

operating the Unll Press

14

SPRING CAP

spring tension

15

HEAD LOCK SET SCREWS...

Locks the head

to the column ALWAYS have them locked tn place

wh_le operating tne drill press,

16

ON-OFF

SWITCH ... Has locking feature THIS

FEATURE

IS INTENDED

TO PREVENT

UNAUTHORIZED

AND POSSIBLE

HAZARDOUS

USE

BY CHILDREN

AND OTHERS

_7

COLUMN..

a one-piece

ment

18

TABLE .

workplece

!9

DEPTH SCALE iNDICATOR...

oepth selected on deoth scale.

!

BELT GUARD...

Covers

operation of drill press

pulleys

3. COLUMN COLLAR...

Holds tne rack lo the co_umn

Rack remains movable in collar to permit

table support movement.

4

TABLE

table

SUPPORT...

Rides on column

to support

5. TABLE

CRANK . _ . Turn ClOCKWiSe [O elevate

table. Support lock handle must be released before

operating crank

6. RACK...

Combines with gear mechanism to provide easy elevatton of table by hand operated table

Crank

7

COLUMN

SUPPORT...

Supports column

provides mounting holes for column to base

8

BASE...

Supports Drill Press. F:or addihonat stability: holes are provided in base to bolt Drill Press

to bench {See "Additional

Safety Instruchons for

Drill Presses.'h

9. CHUCK

accessory

,.,

1o perform

TABLE

position

...

Locks

the table m any

12. BEVEL

SCALE...

Shows degree table Js hlted

for bevel operations.

Scale _s moun_eo on table

suoport. It is to be used for qu_ck reference where

accuracy is not critical

18

means

working

to adjust qudt

surface

Locks

to support

Indicates

_ _ . Shows depth

and milhmeters

21, DEPTH SCALE LOCK...

to selected ae ptn

It is a self-electing

chuck key

out of the chuck when you let go

is designed to help prevent throwkey from the chuck wnen power

Do not use any other key as a

a new one d damaged or lost

BEVEL LOCK

from 0 -45.

. Prowaes

SCALE

drdled in mcnes

desired operations.

Provides

Coqnec[s head, table, and base on

tube for easy alignment

and move-

20 DEPTH

Holds anll bit or other recommended

10. CHUCK KEY...

which wtll "'pop"

of it. This action

mg of the chuck

_s turned "ON,

substitute, oraer

11

and

...

drilling

of hole being

the depth scale

22

FEED HANDLE

. . . For mov=ng the chuck up or

aown One or two of the handles may be removed

if necessary whenever

the workpiece Js of such

unusual shade that _t interferes with the handles

23

BELT TENSION

Bett "

24

DRILLING SPEED...

Can be changed by placing

the belt n any of the STEPS [grooves!

_n the pulleys See Spindle Speed chart _nside belt guard,

.

. Refer

to sechon

Tensioning

DRILL "ON-OFF" SWITCH . .. Has Iocmng feature

THIS FEATURE tS XITENDED TO HELP PREVENT

UNAUTHORIZED AND POSSIBLE HAZARDOUS USE

BY CHILDREN AND OTHERS

€.J

L, U . =::::

O

&

c_

Insert KEY into swftch

NOTE:

Key

_s made of yellow

plastic.

/

To turn drill ON . . .

Insert finger under switch

To turn drill OFF,

lever and pull.

. . Push lever in,

In an emergency;,

. . the drill bit BINDS.,

, STALLS

. . . STOPS . . . or tends to tear the workpiece loose

• .. you can QUICKLY turn the drill OFF by hitting the

switch with the palm of your hand.

To lock switch in OFF position , , . hold switch

one hand ... REMOVE key with other hand,

IN with

WARNING:

FOR YOUR OWN SAFETY,

ALWAYS

LOCK THE SWITCH "OFF" WHEN DRILL PRESS IS

NOT IN USE . .. REMOVE KEY AND KEEP IT IN A

SAFE PLACE ...

ALSO...

iN THE EVENT OF A

POWER FAILURE (ALL OF YOUR LIGHTS GO OUT)

OR

BLOWN

FUSE

OR

TRIPPED

CIRCUIT

BREAKER,

TURN SWITCH OFF . . . LOCK IT AND

REMOVE

THE KEY. THSS WILL PREVENT

THE

DRILL PRESS FROM STARTING

UP AGAIN WHEN

THE POWER COMES BACK ON.

19

REMOVING

1

THE CHUCK

Open jaws of chuck

turning chuck sleeve,

as wide

as they w_lt go by

2. Carefully tap chuck w_th mallet

holding other hand under chuck

_t falls. It may be necessary to

several different spots around the

n one hand while

to catch _t when

lap tlqe crluck at

top of the chuck.

SLEEVE_

CHUCK_

CHU(

BODY

DRILLING

TO A SPECIFIC

DEPTH

To drill a BLIND hole (not all the way through) to a

given depth, proceed as follows.

1. Mark the depth of the hoe on the s de of the workpiece.

•

2. Loosen the depth scale lock.

3. With the switch OFF bring the dri!l down until the

TIP or lids of the dril are even with the Mark

DEPTH SCALE"

LOCK

4. Turn the depth scale counterclockwise until it stops

moving.

DEPTH

SCALE

5. Tighten the depth scale lock.

6. The drill will now be stopped at this depth until the

deoth scale is readjusted,

2O

ANOTHER

WAY

--

DEPTH

SC/_LE

1. With the switch OFF, loosen the depth scale lock.

2. Turn the depth scale clOCkWiSe until the depth scale

indicator points to the desired drilling depth on the

depth scale.

3. Tighten

DEPTH SCALE

LOCK

DEPTH

SCALE

the depth scale lock.

4. The chuck or drill will now be stopped after travefing

downward

the distance

selected

on the depth

scale,

LOCKING

CHUCK

DESIRED

1. With the switch off--loosen

DEPTH SCALE

INDICATOR

DEPTH

the depth scale lock.

2. Turn the feed handles until the chuck is at the

desired depth, Hold feed handles at this position.

3. Turn the depth scale

4. Tighten

clockwise

DEPTH

SCALE LOCK

until it stops.

the depth scale lock.

5. The chuck will now be held at this depth when the

feed handles are released.

SCALE

21

has c dr=l| press operation

i

•

Follow the following instructions for operating your drill

-

tool is running.

Before starting the operation, log the motor

switch to make sure the drill or other cutting

tool 0oes not wobble or cause vibration.

-- If a workpiece overhangs the table such that

it will fall or tip if not held, clamp it to the

table or provide auxiliary support.

- Use fixtures

for unusual

operations

to

adequately

hold. guide and position workpiece.

Use the SPINDLE

SPEED recommended

for the specific operation and workpiece material-check

the panel inside the guard

cover for drilling

information:

for accessories, refer to the instructions provided with

the accessones.

f. Never climb on tlqe drill press Table, it could

break or pull the entire drill press down on you,

g, Turn the motor Switch Off and put away the

Switch Key when _eaving the dri_t press.

h To avoid injur_ from thrown work or tool contact,

do NOT perform

iayout, assembly,

or setup

work on the table while the cutting tool is rotating.

2. Use only accessories

designed

for this drill

press to avoid serious

injury from thrown broken parts or work pieces.

a. Holesaws must NEVER be operated on this drill

press at a speed greater than 400 RPM,

b Drum sanders must NEVER be operated on

this drill press at a speed greater than 1800

RPM,

WARNING: TO AVOID BEING PULLED iNTO

THE SPINNING TOOL --

--

1. Do NOT wear:

-- gloves

-- necktie

-- loose clothing

-- jewelry

2, Do tie back long hair

a. It any part of your drill press is mtssing,.maffunctioning, has Peon damaged or broken.,

such

as the motor switch, or other operating control,

a safety device or the power coro.,

cease

operating immediately until the oarticutar part

is properly repaired or replaced.

b. Never place your fingers in a position where

they could contact the drill or other cutting tool

if the workpiece should unexpectedly shift or

your hand should slip.

c. To avoid injury from oarts thrown by the spnng,

tollow instructionsexactly as g_ven and shown

in adjusting spring tension of ouitl.

d. To prevent the workp_ece from being torn from

your hands, spinning of the too!. shattering the

tool or being thrown always properly support

your work so it won't shift or bind on the tool:

-- Always position BACKUP MATERIAL (use

beneath the workpiece) to contact the left

side of the column.

-- Whenever possible, position the WORKPIECE to contact the left side of the column-if it is too short or the table is tilte_

clamp solidly to the table. Use table slots or

clamping ledge around the outside edge of

the table.

-- When using a drill press VICE. always fasten

it to a table.

INSTALLING

Never do any work "FREE HAND" (handholding workpiece rather than supporting it

on the table), except when polishing_

Securely lock Head and Support to Column,

and table to support before operating drill

press.

Never move the Head or Table while the

c. Do not install or use any drill that exceeds 7" in

length or extends 6" below the chuck jaws. They

can suddenly bend outward or break.

d. Do not use wire wheels, router bits, shaper cutters, circle (fly) cutters or rotary planers on the

drill press.

DRILLS

Insert dri{_ into chuck far enough to obtain

GRIPPING of the CHUCK JAWS

. . the

approx. 1" long. When using a small drill do

it so far that the jaws touch the flutes (spiral

of thedrilL

Make sure that the drill is CENTERED

maximum

jaws are

not insert

grooves)

CHUCK

,n the chuck

22

KEY

POSITIONING

TABLE

AND WORKPiECE

Lock the table to the column in a position so that the

tip of the drill is just a little above the top of the workpiece.

Always place a piece of BACK-UP MATERIAL (wood,

plywood . . .) on the table underneath

the workpiece.

This will prevent "splintering"

or making a heavy burr

on the underside on the workpiece as the drill breaks

through. To keep the backup material from spinning

out of control, it must contact the left side of the column,

as illustrated,

WORKPIECE

WARNING:

TO PREVENT

WORKPIECE

OR THE

BACKUP

MATERIAL

FROM BEING TORN FROM

YOUR HAND WHILE DRILLING,

POSITION

THEM

AGAINST THE LEFT SIDE OF THE COLUMN. IF THE

WORKPIECE

OR THE BACKUP

MATERIAL

ARE

NOT LONG ENOUGH

TO REACH THE COLUMN,

CLAMP THEM TO THE TABLE.

FAILURE

TO DO

THIS COULD RESULT IN PERSONAL

INJURY.

BAC K-U P..-"-_

MATERIAL

WORKPIECE.

DRILL PRESS X

For small pieces that cannot be clamped to the table,

use a drill press vise (Optional accessory),

VISE

WARNING:

THE VICE MUST BE CLAMPED

OR

BOLTED TO THE TABLE TO AVOID INJURY FROM

SPINNING WORK AND VISE OR TOOL BREAKAGE.

BOLT OR CLAMP

VICE SECURELY

BEVEL

LOCK

TILTING

TABLE

To use the table in a bevel (tilted) position, loosen the

set screw under table bevel lock with Hex 'L" wrench.

Loosen beret lock with an adjustable wrench.

Tilt table to desired angle by reading

tighten bevel lock and set screw.

bevel scale.

J_

BEVEL SCALE

Re-

I::

SET SCREW

23

p-

WARNING:TO AVOID

INJURY FROM SPINNING

WORK OR'TOOL BREAKAGE, ALWAYS CLAMP

WORKPIECE AND BACKUP MATERIAL SECURELY

TO TABLE BEFORE OPERATING DRILL PRESS

WITH THE TABL E TILTED.

Before urnmg the switch ON, bring the drill down to

the workpiece lining it up with the hole location.

HOLE

to allow the drill to cut.

Feeding TOO SLOWLY might cause the.drill to burn

Feeding TOO RAPIDLY might stop the motor. , .

cause the belt or drill to SLIP . , . tear the workp_ece

LOOSE or BREAK the drill bit.

FEEDING

Pull down on the feed handles with only enough effort

LOCATION

Make a DENT in the workp_ece where you want the

hole.., usingaCENTERPUNCHoraSHARPNAIL,

adjustments

BOSS

WARNING: FOR YOUR OWN SAFETY TURN

SWITCH "OFF" AND REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE MAKING ANY ADJUSTMENTS. TO AVOID INJURY FROM THROWN PA RTS

DUE TO SPRING RELEASE, FOLLOW INSTRUCTIONS CAREFULLY AND WEAR EYE GOGGLES,

QUILL

RETURN

SPRING

1. With the chuck at its highest possible position, turn

the depth scale clockwise until it stops and tighten

the depth scale lock, This wilt prevent the Quill dropping while tensioning the spring.

2. Lower table for additional clearance.

,NOTCH

STAND_

NUT

3, Work from left side of Ddtl Press,

(INNER)

4. Place screwdriver

ir lower front notch of spring

cap, ancl hold it in place while loose n ing and removfng jam [outer]

nut only.

CAP

JAM

(OUTER)

5. With screwdriver

remaining in notch. _oosen large

standard [inner] nut (approximately

1/8") until notch

disengages from boss on head. DO NOT REMOVE

THIS NUT

6. Carefully turn screwanver

counter clockwise and

engage next notch in boss. DO NOT REMOVE

SCREWDRIVER

7_ Tighten stanclarc nut with wrenci_ only enough to

engage boss. Do not overttghten as this will restrict

quill movement.

8. Move stop nuts and depth pointer to upper most

posit_on ant check tension while turmng feed handles.

11.

9. If there is not enough tenson

on spr ng repeat

steps 4-8 moving on y ONE notch each time and

checking tension after EACH repetition.

12. Check quill while feeding to have smooth and unrestricted

movement,

if movement

is too tight,

loosen jam nut and SLIGHTLY

loosen standard

nut until unrestricted,

Retighten jam nut.

t0.

Propertens on s ach eyed when quil returns gent y

to full up position when released from 3/4' depth.

24

When there is enough tension after checking,

replace .am nut and tighten to standard nut, BUT do

not overhghten against standard nut.

maintenance

)WARNING

FOR YOUR OWN SAFETY,

TURN

SWITCH "OFF" AND REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE MAiNTAINiNG OR LUBRICATING YOUR DRILL PRESS.

Frequently blow out any dust that may accumulate inside the motor.

A coat of furniture-type paste wax applied to the tab}e

and column wilt help to keep the surfaces clean.

WARNING: TO AVOID SHOCK OR F1RE HAZARD,

iF THE POWER CORD iS WORN OR CUT, OR DAMAGED iN ANY WAY, HAVE iT REPLACED IMMEDIATELY.

Wiri._g Diagram

=_

SPINDLE

ASSEMBLY

OF DRILL PRESS

lubrication

_1

SPINDLE

j 1[----._

RACK

All of the BALL BEARINGS are packed with grease at

the factory. They require no further lubrication.

(TEETH)

Periodically lubricate the SPLINES (grooves) in the

spindle, and the RACK (teeth of the quill).

.o_

.J

o"a

O

Sears Recommends

Drill Bits .........................

Hold-Down and Guide ..................

Drill Press Vises ...................

5 pc. Stop Collar Set ...............

Sanding Drums ................

the Following

See Catalog

9-2457

See Catalog

See Catalog

9-2497 -- 9-2498

Sears may recommend other accessories

o_

Accessories

15 Piece Drum Sanding Kit ..........

Clamping Kit ......................

Buffing Wheels up to 4" dia. max ......

Power Tool Know-How Handbook ........

See Catalog

See Catalog

See Catalog

9-29117

-g

E

E

o

not listed in the manual.

See your nearest Sears store or Catalog department for other accessories,

Do not use any accessory unless you have received and read complete instructions for its use.

25

trouble

WARNING:

SOURCE

shooting

FOR YOUR OWN SAFETY,

OUTLET

® CONSULT

BEFORE

TROUBLE

YOUR LOCAL SEARS

,

"OFF"

SERVICE

CENTER

IF FOR ANY REASON

CAUSE

1

tnc0rrect bett tension,

2

DrySpindte,

3

Loose spindle pulley,

!.

Incorrect speed•

2

Chips not coming out

of hole

Dul! Drill,

Feedingtoo slow,

Not lubricated

3

4

5

i

Drill leads off...

ho!e not round.

PLUG

FROM POWER

MOTOR

WILL

NOT RUN

1. Adjusttension.

See section

"ASSEMBLY --TENSIONING

BELT"

2. Lubricate spindle See "Lubrication"

section.

3. Checking tightness of retaining nut on

pulley, and bghten if necessary,

4, Tighten setscrews m pulleys.

4. Loose motor pulley

DrillBurns

REMOVE

REMEDY

I

=

NOisy Operation

AND ALWAYS

SHOOTING.

PROBABLE

TROUBLE

j_

TURN SWITCH

1. Change speed See section 'Getting

To Know Your Drill Press".

DRILLING SPEED•

2 Retract drill frquently to clear chips

3. Resharpen drilt.

4. Feed fast enough

allow drill to cut.

5. Lubricate drill• See "Basic Drill Press

Operation" section.

1. Resharpen

1, Hard grain_n woodor

lengths of cutting

lips and/or angtes

not equal.

2. Bentdrill bit.

drillcorrectly.

2. Replace drill bit.

1. Use"back-up

material"..

See Basic

Drill Press Operation" section.

Wood splinters on

underside,

t,

Workpiece

torn

toose from hand,

1. Not supported or

clamped properly,

I.

DriIi Binds in

1, workpiece pinchin_ri!i

or excessive feed pressure.

2 Improper belt tension.

t.

Excessive drill

runout or wobble,

I. Bent drill:

2. Worn spindle bearings,

3, Drill notproperly

installed in chuck.

4.. Chuck notproperly installed.

1, Use a straight drill.

2. Reptace bearings.

3. Install drill properly•..

See "Basic

Drill Press Operation" section.

4. Install chuck properly..,

refer to

"Unpacking and Assembly Instructions

... INSTALLING THE CHUCK."

Quill Returns

too slow or too

fast,

1. Spring has improper tension,

1. Adjust spring tension...

See section.

"Adjustments--Quill

Return Spring."

1. Dirty. grease, or oil on the

tapered inside surface of chuck*

or on the spindles tapered

surface.

1. Using a household detergent-clean

the

tapered surface of the chuck and spindle to

remove a!Idirt, grease and oit.

workpiece.

Chuck will not stay

attached to spindle

it falls off when

trying to install it,

NO "back-up material"

under workpiece.

Supportworkpiece

or clampit..

See

"Basic Drill Press Operation" section.

Supportworkpiece

orclamp it... See

"Basic Drill Press Operation" section.

2. Adjust tension..,

See section

"ASSEMBLY--TENSIONING

BELT."

t

26

repair parts

PARTS

UST

FOR CRAFTSMAN

10" DR_LL

MODEL

NO. 113,213090

I

PRESS

3

2

4

/

19

14

Always

order

by Part Number--Not

FIGURE

Description

i

No.

1

2

3

4

817325

816755G

817587

817391- !

5

6

7

8

8! 7779q

STD3152 t 5

817605

817340-1

81 73391

8t 7606

817413

8! 7453

11

12

" Standard

Hardware

,,

i

LIST

..-TT--q

Key i

No. I

Part

Key

No.

uJ

1 PARTS

by Key Number

Part

No,

Description

i

Knob

Screw-Pan Hd M5 x 0 8-12

PutIey Motor

Screw-Hex Soc Set

M6xl

0-!0

Guard-Pu_iey w/Labels

* Bearing-Ba!} t 2ram

S aft-Spindle

Chuck

Key-Chuck

Tube-Qu_

Gasket-Quilt

RmgoRetainmg

item

--

May

Be

Purr.::hased

Loca

_'

14

t5

!6

17

18

19

2O

21

22

23

y

27

817358-2

817451

817483_1

STD31523_

817408

817407

817586

817440

817428

802864

816755-1

1

Screw-Wash

Fd

M6× _0 _ 12

Bush_ngoRubber

Ring Reta_!ir_g

'_BearJng-Bal 17ram

Spacer

Ir_sert-Puiley

Pulley-Spindle

Nut-Pul ey

Be}t-W" 5,'16 × 30

Ciamp Cord

Screw-Par- Hd M5 x (i, 8-i0

PARTS

LIST FOR CRAFTSMAN 10" DRILL PRESS

MODEL NO. 113.213090

=O

;:3.

O')

37

38

33

\

35

4

36

12

31

\

29

_

2O

\

24

\

26

4O

8

30

27

7

4

3

25

\

21

1

19

27

17

28

FIGU_2

39

3

PARTS LIST FOR CRAFTSMAN

MODEL

NO.

10" DRILL PRESS

113.213090

O

Always order by Part Number--Not

FIGURE

2 PARTS

by Key Number

LIST

"O

fl#

_'_

Part

No.

I

2

1817610

I

I

I

I

1

4

5

6

7

8

t

!

I

t

I

Pa_

Description

Head w/Pointer & Trim

eMotor

*Nut-HexM8

* Washer 5/16 x 7/8 x 5/64

* NuFHex M!0

* Lockwasher- 7/16

Bracket-Motor

Screw-Hex Hd. M8x 1.25-2C

Support-Motor Bracket

Pin-Roll 6x 16

I 3 t ST0840812

STD5,51()37

STD841015

STD551143

817607

STD835025

t 9 1817596

f,o

I

t

I

I

10

11

!2

13

i15

] 16

t 17

I 18

t t9

j20

I 2t

t 22

123

[_

I 813249-152

I 817421

I 817391"2

{ 817343

1817439

I 817582

I 817485

I 8t3249-!28

I 817603

1817303

t STD375008

_ $7D852005

1816755-4

816755-3

Knob -Motor Adjusting

Screw-Hex Soc. Set

M8x 1,25-8

LOck-Depth Screw

Ring-Depth Stop w/Scale

Knob

Rod

Hub

Pin-Rolt5 x 16

Shaft-Pinion

Pin-Stop

*Connector-Wire

* Lockwasher-Ext.

5mm

Screw-Pan Hd. M5 x 0.8-8

Screw-Pan Hd. M5 x 08-12

25

26

27

816113

815863

817357

28

29

30

817585

817597

817594

31

817593

34

33

35

36

37

38

39

40

--

817595

STD541150

817415

817443

817329-1

71252

8133!7-6

8133!7-7

507885

507884

--

SP5185

® Any Attempt to Repair This Motor May Create a Hazard U{,,less Repair

Technician. Repair Service is Available at Your Nearest Sears Store

* SIandard

Hardware

Item -

May Be Purchased

L0cafiy

Description

Switch-Locking

Key-Switch

Screw-Self Tap, Parr Hd

M4x 16-8

Cover-Switch Piate

Box-Switch

Screw-Specia_ Set

M8x125x!8

Seat-Spring

*Nut-Hex 1/2-20

Cap-Spring

Spring-Torsion

Retainer-Spring

Cord-Power

i

Cord-Motor

I

Hex 'L'-Wrench

3ram

Hex "L '-Wrench 4ram

Bag of Loose Parts

(Not tflustrated)

Box of Loose ::ads

(Not l_tustrated)

I

Owners Manua_

(Not tiiustrated)

_s Done by QJa;,'ied

Service

¢e

PARTS

LIST FOR CRAFTSMAN

10" DRILL

MODEL NO, 113.213090

PRESS

1

10

\16

Always

order

by Part Number--Not

FIGURE

No.

i

u

817599

817601

817600

817609

5TD835020

6

817348

Tube-Column

Rack

Support*Column

Base

Screw-Hex Hd

M8 x 1,25-20

Crank

817590

Shaft-Gear

i

..

* Standard

Hardware

Part

No.

i

1

2

3

4

5

8

LIST

Key

No.

Description

No,

....

3 PARTS

by Key Number

,

9

10

11

12

13

14

15

16

,

Item -- May Be Purchased

Locally

3O

817447

817608

817772

817290

817589

817591

817592

817391-1

Description

i

Screw-Hex Hd 1/2-12 x 7/8

Table

Support-Table

w/Scale

Clamp-Table

Gear-Helical

Worm-Elevation

Collar-Rack

Screw-Hex Soc.

Set M6 x 1.0-10

NOTES

31

/-

MOTORIZED

SERVICE

Now that you have purchased

your 10-inch Drill Press, should

a need ever exist for repair parts or service, simply contact

any Sears Service Center and most Sears, Roebuck and Co.

stores. Be sure to provide all pertinent

facts when you call

or visit.

MODEL NO.

113.213090

The model

on a plate

number

attached

of your 10-inch Drill Press will be found

to the rear of the head.

DRILL PRESS WiTH

MAXIMUM

DEVELOPED

I/2 HP MOTOR

HOW TO ORDER

REPAIRPARTS

WHEN ORDERING REPAIRPARTS,ALWAYS GIVE THE FOLLOWING

INFORMATION:

PARTNUMBER

PARTDESCRIPTION

MODELNUMBER

113.213090

NAME OF ITEM

MOTORIZED 10-INCH

BENCH MODEL DRILL PRESS

All parts listed may be ordered from any Sears Service Center

and most Sears stores. If the parts you need are not stocked

locally, your order will be electronically

transmitted to a Sears

Repair Parts Distribution Center for handling.

j

J

Sold by SEARS, ROEBUCK AND CO., Chicago,

Part No. SP5t85

Form No. SP5185-4

IL 60684

U.SA.

Printed

in Taiwan

2/91