Download Craftsman 298.586190 Specifications

Transcript

MODEL NO.

298.586190::

Foi _ q_iick :service or repair, take your Outboard .....

Motor t o any: Sears Service Unit throughout

the

U.S. and Canada.,

Each Service Unit is staffed

by trained

technicians,

using Sears approved

.

parts and repair

procedures

to ensure that we .

meet our pledge to youJ'We

service what we

Sell." Refe_ to the Iocat telephone directory

for •

the Sears Unit nearest you,

.

FULL ONE YEARWARRANTYON

OUTBOARDMOTOR

For one year

this

tions

will

plete

mode!

replacement

identification

number

parts

for

Plate

for

when requesting

your

outboard

the'chin-

"

service or

motor,

mercial

WAY£

GIVE

REPAPR

THE

TION! :

::

the

parts

You

FOLLOWING

from.

applies

for

order

will

need

be

are

not

tronic

AL-

trollin

or

the

is used

only

oui_ -_:

for

com-

this

thirty

war-

days

from

9 motor

to the

in the

Warranty

by simply

Or etec-

motor

nearest

United

iS valid

Sears

States

in country

Or

of

purchase.

warranty

rights,

and

rights which

gives

yoLf

vary

you

may

specific

also

have

legal

other

from state to state.

SEARS,ROEBUCK

AND CO.,

DEPARTMENT

698/731A

locally,

transmitted

Center for:

is avail_able

out,board

center

Canada.

INFORMA,

stocked

in

purposes,

Service

returning the

3. Part Name

4, Quantity

electronically

to a Sears Repair Parts Distribution

expedited

handling,

your

motor

rental

Warranty

This

_:1, Model:Number

Part Number

If

PARTS,

material

appear

free of charge,

or

service

ORDERING

the

Sears

the first, day of use,

.....

WHEN.......

in

followed,

in

which

Sears

Tower. Chicago_ lL 60684

SEARSCANADAINC.

::

222

Jarvis

St.

Toronto,

:

all instruc-

detailed

are

defects

the outboard

ranty

motor.-

All parts ]isted herein may beordered

ahy Sears, Roebuck and Co.

,

when

procedures

Manual

repair

board

first day of use of

motor,

workmanship

If

the

and

Owner's

HOWTOOROER

.EPAmPARTS.....

Refer 'to

from the

outboard

Ontario.

canada

:

TABLE OF CONTENTS

SPECIFICATIONS

P se No.

..........................................

I

OWNER'S RESPONSIBILITY

...........

_ • , .............

:.......

2

MAINTENANCE

..........................................

4

"LUBRICATION

GEAR HOUSING

4

MUFFLER

INSPECTION

• .....................

4

PROLONGED

STORAGE

.................................

4

OPERATIONS

.............................................

4

NEW AUTOMATIC CLUTCH

• ..................

4

BOAT MOUNTING ..................................

.......

5

STEERING ADJUSTMENT

.....

...........................

5

2"CYCLE ENGINE FUEL MIXTURE

.........................

6

STARTING PROCEDURES_

. .................................

6

STOPPING PROCEDURES

............

. .........

.........

6

FLOODING

...........................................

7

CARBURETOR

ADJUSTMENTS

.............................

7

PROPELLER SHEAR PIN .................................

7

IGNITION SYSTEM

.............

, ..........................

8

REMOVING MOTOR FROM BOAT

• ........

8

SALT WATER OPERATIONS

..............................

8

TROUBLE SHOOTING CHECK LIST

..........................

9

REPLACEMENT PARTS ....................................

10

ORDERING PROCEDURES

......................

Outside Back Cover

PRODUCT WARRANTY

Outside Back Cover

SPECIFICATION:::,

Horsepower

...............

..i,:/_!_;,:/. o. , . , . Air Cooled 2-Cycle

'::"_:_;:_'-_,':?,_

:_i ; ::"' .... "..............

3.00

"

Propeller Via. and Pitch .....

; (!82mm x i30 mm) .. _7.177 x 5.127:

Lub. (Gear Hsg.) ...................

.... ::,:..

i;i_ : ,:_.....

. ..... _ ......

SAE 90!

Fuel Mixture , .,

50 to 1 ratio Of regula,_-gr_ad_gaso

ine t62-cycle outward

lubricant or its equivalent BIAcertified!TC_W:2_ycle outboard lubridanti

Steering ........................

,.,,

=.........

243

Pivot Steering

r

Type of Engine .................

...........

'

_i _

•_

•

:

IMPORTANT

• •

:

i

Owner's

.::.

:

BE SURE TO READ

OPERATING

SAFETY

Learn

2.

U,S. Coast Guard

3,

4:

5.

and

_!

:):

HH_

Check List

AND DO THE:FOLLOWING

BEFORE

YOUR OUTBOARD

MOTOR

:......_

the

t_oatingilawsof

reguMtions

an approved

II • ..................

:: • •

: i::H-:

req0i_:e the

life-Vest,

:

the

U.S, Coast

following:

tYPe 1,2

state.

Ic.:at:author:

"

or 3, Personal

:

:

Guard,

a,

Provide

b.

person in boat. (Encourage passengers to wear them,)

If the boat exceeds 16 feet, also carry a type 4, throwable

Device.

"

Flotation

7

::

Device for each

Personal

•

Flotation

Do not fill fuel tank with motor

running or near any flame or lighted smoking

material.

_ ,, ::

When loading boat distribute

the load evenly , keep the 10ad low; don't overload;

don't stand in a small boat. Take weather and water conditions

into account.

Do not permit

persons to ride on parts of the boat not designed

Standing, bow riding and seat back or gi_nWale riding can be especial|y

:i: OWNER'S

: 6.

• 7,

observe

:

i

and Operat_gSafety

CHECK,LIST

1.:

;:

: ;:

Responsibility

•

RESPONSIBILITY

for such use.

dangerous. "=

:

Read owner's manual before running your new outboard

motor,

Before starting, make sure your motor'

is!:seCurely mounted to boat

•

transom

:

with a

:i safew Chain: Tighten clamp stead handies_0:relyby

hand,

8. Be sure to have pliers, screwdriver,

spare'sp_tPk plugs, wrench, shear pins and cotter

_ins in boat whenever leaving shore,

9,

Be sure t_o have an adequate supply of fuel (carry only inan approved container) on

:_ board;

Use a good grade of regular gasoline with proper mixture,

as cited in the

Specifications.

10. Occasionally

check to be sure clamp stud handles on transom mounting

bracket are

11.

tight.

IN CASE

SING

12.

_:!!i 13,

14.

OF AN

THE

STOP

EMERGENCY,

BUTTON

THE

(IF

ENGINE

SO EQUIPPED)

CAN

BE STOPPED

OR

PLACING:CHOKE

BY DEPRES:

KNOB

::÷_

IN

Keep an alert i6ok0ut,

Serious accidents have resulted from failure to use eyes.

Keep

gh'tlngPOSITION

and lifesaving

equipment

in good €ondition

and readily accessible -FULL firef

CHOKE

........

at all times,

:

. :

Good housekeeping

is eveh more important

afloat than ashore: Cleanliness dimin;

ishes the probability

of fire and tripping

: TIPS FOR TRAILERING

hazards.

OR AUXILIARY

USE..... - ..... _

15.

When launching

or loading boat on a trailer, place your Outboard

motor

in tl_e

tilted

storage position,

Also when tra lering your boat and outboard

mot6r, keep

outboard

motor

inupright

(vertical)

position

on:the

boat transom.

Outboard

::motors,transp0rted,

across :rough roads in the "tilt"

position could cause trans0rn

...... iidam_;:br

::m0ul_tirig brackets to break off, losing your motor.

If motor_must

be:

iltra[i_b_i!!i_!_itiW!i:posJ:tli0n,

a Short

i_o_

ibrack"t

and the:mot0i::lag.

i•again:st :the, 2 x:4: to ,prevent

!:takbn: ifOSing

i: 'i

themoto

r asan

length of 2 x 4 should' be placed between the"

The motor leg shoiild then be firmly tied down

any possible

auxiliary

g motol_ as_an:auxiliary

power

motor:brackbt

is recommended.

damage.

power

source,

•

Similar

precautions

source for a sailboat

should

o(Powe¥

be

_oat, I

the use of an auxi[iaryadjustabie

:

•

-:

MAJOR PARTS

Fuel Filler Cap

a.d Air VentScrew

StarterHandle

ChokeLever

Power Head

Stop Bullon

Spark Plug

Fuel Shut-offValve

-Steering Handle

Fuel SedimentBow]

and Filler

Dual AutomaHc

Clutch

ClampStudHandles

/

ReverseDrivingLock

Brackel

Tilt Pin Adjustment

MufflerPipe

DriveShaft Pipe_

ExhaustOutlel

CavitalionPlale

Propeller---Fill and Drain Plug

CollerPin

Gear Housing

-

Figure

I

MAINTENANCE

1.

FEATURE

a.

This outboard

motor

has special design

features as shown in Figure 1,

Your selection of our Marine Products will

b.

INFORMATION

provide you with many hours of enjoyable

boating.

To assure your complete

satisfaction on the investment

you have just made,

we ask you to read this manual thoroughly

before going afloat.

Acquaint yourself with

the particular

areas of operation

on your

outboard

motor: as you read, the step-by-step

procedures.

Keep in mind maximum

Performance

is achieved only wher] the owner

or operator

is completely

familiar

with the

c,

operating instructions.

Periodic servicing

will

recommended

that you

: .....

be required,

consult your

Service Center when service

We will be happy to extend

and assure prompt service.

. Figure.2

it is

Sears=

is necessary,

our facilities

Figure 3

MAINTENANCE

2.

LUBRICATION

a.

The Gear Housing hasbeen pre-lubricated

at

the factory;

however, the grease level should

be checked as follows

using SAE 90 out-

_

GEAR

HOUSING

board motor grease, tSee Figure 2).

(1)

Prior to initial operation.

(2)

After first four {4) hours of use.

(3)

Recheck

after every fifty

(50)

b.

• _(3)

(4)

(5)

(6)

c.

3.

a.

For

with

(6)

Replace plug and washer. Be sure plug

is tightened securely.

To achieve complete

drainage of',lubricant. remove cotter pin, propeller

and

shear pin from propeller

shaft; also_

gear housing cover by Unscrewing

2

bolts,

c.

When lubricant

has completely

_ra_ned,

repJace parts and refill gear housing

using filling procedure above,

best results, lubricate

propeller

shaft

tithium grease every 30 to 60 days.

by uncarbon

build-up ins_i.de the muffler

inlet and outlet,

the

exhaust

port

andi:the

combustion

carbon

power

b_ Care: should

be exercised

while cleaning

.away

carbon

tO prevent:i scratches to the

surface of the engine components

and dropping carbon inside of crankcase.

4.

(5)

b.

"chamber

of the cylinder; ,:Excessive

will prevent drawing

the maximum

out of the engine. [see Figure 3).

PROLONGED

STORAGE

a. Tot store your= outboardlonged ,storage,

prepare

lows:

motor

for pro=

outboard

as fol-

(1) ' See paragraph on stopping

(Ref. 10)

' '

(2)

When removing outboard

boat,

unit.

a_tow all

water

to

(4)

mounted

on a stand vertically

power head up for storage.

Pull starter handle slowly until

hours

Remove

drain plug and washer, then

insert

nozzle

of gear lubricant

tube

into hole.

-Squeeze tube until

lubricant

is forced

out around tube.

MUFFLER

INSPECTION

Periodically

remove '_miJffler coverscrewing

screws and

inspect for

The

outboard

motor

should

be

with

resist-

ance iS felt due to compression

pressure, then stop. Release starter tension

slowiy to prevent

engine from revers-

running time.

(4)

Replace with new |ubdcant

at the end

of your outboard

motor season.

This

is important,

as it removes any water

from

the gear housing

and prevents

possible corrosion to internal parts.

To Check, Drain or Fill gear housing, follow

these steps:

(1)

Position outboard

motor upright,

(2)

(3)

procedures.

motor

from

drain

from

ing

rotation

due

to

compression

pressure,

This position will close both.

the

intake

and

exhaust

ports

.for

storage.

Drain and fill gear housing as outlined

under Lubrication

of Gear Housing.

|Ref. 2)

Wipe exterior

completely

with

fresh

water cloth and then apply light coat-

ing of oil,

When starting a new season, always use fresh

gasoline.

Last year's gasoline may

have

varnish deposits that will plug the carburetor jets. thus requiring a complete

overhaul.

To plan for the coming season, we recommend

you

contact

your

Sears

Service

Center before the new season for any service

repair work required,

OPERATION

NEW

New

AUTOMATIC

CLUTCH

automatic

clutch.

Based

on

a dual

centrifugal

clutch design, it allows the outboard

prop to turn at very sJow speeds or

even come to a complete

stop while the

engine continues

operating

efficiently.

It

eliminates

the need to shift gears by hand

and prevents the engine from

overheating

and stalling at slow speeds.

When engine starts, motor

is neutral.

As

throttle

increases, sub clutch engages.

At

approx.

6 MPH,

main clutch

ehgages to

provide direct drive for cruising.

OPERATION

6. BOAT

a. Mount

MOUNTING

the motor

transom

Hand

(stern).

tighten

on the center of the boat

(See Figure 4).

CAUTION

transom

bracket

and clamp

stud handles simultaneously.

Do not use a

wrench or any other device that would

Cause damage to brackets.

Occasionally

:check tO be sure lamp stud handles on

transom

mounting

bracket

are tight.

(See Figure 5).

!,

20,7""

b.

To obtain

the best performance

from your

outboard,

the following

boat transom speci_

fications

are recommended:

(See Figure 4).

Transom Angle {See View 3):

....

. . . ....

12 to 15degrees

Transom Height (See View 4):

20.7 inches

c. The angle of the motor

column

is easily

adjusted

changing

View 4

•

.

?

by removing

the Hitch Pin:and

the Tilt Lock Bracket

Pin in the

five

(5)

different

angle position

holes

_ located on either side of the right or left

Transom

Mounting

Brackets,

Each angle

position

elevates

five

(5) degrees.

Try

center hole position

d.

first.

(See Figure 6).

To find the correct angle

test run at full

throttle

positio n, make a

with your

usual

loading in the boat,

Always stop motor to

change the Tilt Lock Bracket pin_ The c0r,: rect angle position

will

have your

boat

traveling

the-stern,

with the bow

but should

H

Figure 5

slightly higher than

not porpoise (bow

_:

rises and falls rapidly and continuously).

Be

sure Tilt Lock Bracket Pin is always pushed

completely

through

both Transom

Mount-_

ing Brackets and Hitch Pin is secured,

----------------If the motor

WARNING

column is tilted

ward, the boat

cavitate

at full

is likely

throttle,

too far out*

to porpoise

which can

or

be

dangerous because a cross wind or a wave

could suddenly .deflect

the boat into a

dangerous -turn.

Ale00

if the

motor

column

of-the

is tilted too fa T inward, the bow

boat wilt dig in, which can: be

dangerous

When

crossing.a

rough _water,i '' Do

St0_age position,

FigiJre 4) _.

e.

Secure

motor

to boat

Chain not included

wak e or fin

not runmotor_

(See -View.:1

with

with motor.

in, the.

and 2,

_,

Safety

:Chain.

.

Figure 6

7.

STEERING

Tighten

ADJUSTMENT

steering tension

for desired

bolt

steering eff0rt.(See

using a spanner

:

Figure 6).

_

There

is a possibility

of losing

backed out too far,

CAUTION

bolt

'

if

I

OPERATION

8. 2-CYCLE

ENGINE

FUEL

MIXTURE

Use a good grade of regular gasoline. (See mixing table below.)

CAUTION

Always use BIA certified

TC-W oil in the

50,1 ratio.

Failure to do so may result in

excessive

spark

plug

fouling,,

piston

scoring, or bearing failure.

Oonot

unde[

any circumstances,

use multigrade,

such as

10W-30, or other automobile

oils; •

if BIA certified

oil is not available,'use

an SAE 30 or 40 2-cycle or outboardoil;We reserve the right to refuse warranty on

parts

which are

damaged

when. using

improper

fuels or lubricants.

....

Figure 7

.WARNING

Gasoline is highly f!amm;_ble.

Always mix

in well ventilated

area; : Do not fill tank

with motor

running,

n0r= near any flame

or while smoking.

Be sure vent screws

and filler

caps on tanks are finger tighte:

ned when

trunk of

transporting

gasoline in the

your

automobile

to prevent

explosion.

Figure 7A

U.S. Measure

-::i

;

E:

Regular

Gasoline

_.!':

:

to be added

In Gallons

In Pints

1

FUEL

MIXING

i: TABLE

I. : 50:1

3

5

6

i_.

....

: '

':

In Oz

0.16

2.6'

0.48

0.80-_::

''''_ .......r

.:. 7.7

.....

I: MIXTUR

E

: "

=

Regular

Gasoline

AmoUnlof!:oil:

!

In Liters

In Liters

.

1

0i02 ;: :::

Figure 8

e.

,

9,

a.

': :,20

'

:

retract

STARTING

PROCEDURE

(See Fig;7&

7A)

Open air vent screw located on fuel filler

f.

cap by turning counterclockwise,

b. Open fuel shut-off valve.

c. Open throttle- grip to hatf throttle.

do Move choke lever to "On'* position.

g.

WARNING

When

stetting

outboard,

the

boat

Pull starter handle slowly until you feet

starter

engage.

Then pull with rapid

motion

and allow the starter cord to

slowly.

(See Figure 8).

After engine has started,

gradually move

choke

laver to "Off"

position

while

warming up the engine.

Let engine

idle for

approximately

3

minutes before moving throtUe grip to

"Fast"

position.

wilt

move with a sudden burst of speed. Make

sure you are well seated so as not to lose

your balance with e fast start,

10.

STOPPING

PROCEDURE

To

stop engine,

move throttle

position

grip

and press stop button,{See

to

"Slow"

Figure

7A)

OPERATION

WARNING

In case of an Emergency, the engine can

be stopped by moving the Choke Lever to

Full Choke Position.

if the motor will not be operated

for a

period of time, if it is to be removed from

the boat, or if it is to be tilted up, we

recommend

the

following

practice

to

prevent

spitlage

from

the

carburetor

_

throat

and bow!

and to prevent

gum

formations

in

the

carburetor

during

storage:

1,

Close fuel

shut-off

valve

and air

vent screw at fuel filler cap.

Al!ow

motor

to run at idling speed

until

it stops of its own accord,

indicating

the

carburetor

has run

dry,

2.

1%

Figure 9

FLOODING

To clear engine of excess fuel, move choke lever

to "Off"

position

and throttle

grip to half

throttle

position.

Pull recoil starter

handle

until engine starts and continues to run.

12.

a.

CARBURETOR

Your

motor

Figure IO

ADJUSTMENTS

has a idle adjusting

screw and

the idle speed has been preset at the factory.

However,

you may need to adjust the idle

speed using Idle Adjusting

Screw. Turn the

Screw clockwise

to increase motor

speed .......

and counter clockwise

to decrease it. The

idle speed adjustment

must be done with

' throttle

grip at ful closed position and the

idle speed should be as low as possible while

-

: the engine runs steady.

b,

.'

Periodically

ing Sediment

i3,

Bowl.

PROPELLER

PIN

a.

The

(See Figure 9)

check filter for dirtby

unscrew*

(See Figure 12)

SHEAR

PIN

"

& COTTER

HOLDER

Shear

Pin is used for

the

purpose

of

protecting

the Drive Train and Gears.

The

Shear Pin wil! not prevent

the propeller

from

becoming

damaged when striking an

under water

object.

When shear I pin is

broken,

the engine will continue

to run,

however, the propeller will not be rotating.

Stop engine immediately

after

shearing

CAUTION

pin to avoid possible

damage to the engine.

b.

To replace

shear

remove cotter pin

propeller.

c.

7

pin,

with

(See Figures

shut

pliers

off

motor,

and slip off

10 & t 1).

Replace with new shear pin located in shear

pin and cotter pin holder.

(See Figure 12).

Figure 12

Fl_Adjlsti!g

_rew

OPERATION

14.

FLYWHEEL

¸

MAGNETO

SYSTEM

WITH

ELECTRONIC

The magneto

following

sisterized

IGNITOR

ignition

system consists of the

component

parts: Flywheel. Trar_Electronic

Ignitor and Ignition Coil.

Inspect the following

if

hard to start:

(1)

Spark plug as often

sure spark

tO.6mm).

C,

d.

15.

a.

IGNITION

.TRANSISTERIZED

plug

engine

fails or

is

CENTER

as necessary.

gap setting

supply and

be open.

is .025"

fuel

(2)

Gasoline

fuel

off valvesho01d

{3)

The

Carburetor being starved of fuel.

correct

spark plug for this motor

Figure 13

shut-

is

NGK 8MR-6A

or Campion RCJ-8,

To

test

ignition

system,

remove

spark

plug and pl_E',ce against bare spot on meta_

part of motor

away

from cylinder

spark,'

plug hole and then pull starter cord several

times.

If a spar k bridges the plug gap. the:

magneto

is in good operating

condition.

The high tension lead wire must be con-:

nected to the plug for this check.

If there

is no spark,= have the ignition

checked

at

your Sears Service Center.

REMOVING

Always

shroud.

MOTOR

tilt motor

DO NOT

FROM

Figure

If

BOAT

by lifting

on rear of

PUSH DOWN

ON THE

upward

direction

until the propeller

clears

the transom.

Hold the motor upright long

enough to allow alt_Water to drain from the

exhaust pipe, When yop find it difficult

to

hold the;motor

uprigllti tighten the Center

Bolt increasingly

for desired effort.

(See

Figure 13).

_,.

possibleto

WARNING

burn your

one

be necessary

side

before

.16.

To

.......

to rotate

the

transom

tO remove leg from

.... installed on boats with thick

the motor

motor

on

WARNING

will not be operated

it Stops of its own

caring the carburetor

for

a.. Always

tilt your

when not in use.

b. Never leave the

motor

to

lower

follow

"

.

out

unit

of

the

steps

water

in salt-water

overnight.

Wipe exterior completely

with fresh water

cloth and then apply light

coating of oil.

Lubricate

propeller

shaft occasionally

with

a waterproof

type of lubricant

(Lithium

Grease), thus enabling

the propeller

to be

the

c. Always

carry

outboard

with

the engine

above

the lower unit'to

prevent moisture

from

entering • the

engine

through

the

exhaust ports.

handle

indi-

the

removed easily.

the water when_i

e,' It is good practice

when opereting

transoms;

.

1

water to inspect your .motor daily

:d_ Steering handle serves as carrying

.... shown in Figure 14.

a

SALT

WATER

OPERATION

" .:

materially

increase the life of all exposed

finishes;

c.

accord,

has run dry.

parts and decorative

indicated

below.

hands on the engine:

tilting

motor

until

d.

It may

the

storage:

1.

Close fuel shut-off valve and air vent

screw at fuel filler cap.

2.

Allow motor

to run at idling speed

"

biock and upper portion

of the cotumn.

Although'

the engine is air cooled, it is

Do not touch.

b.

14

period

of time.

if it is to be removed

from the boat, or if it is to be tilted up_

we recommend

the following

practice

to

prevent

spil|age

from

the

carburetor

throat

and bowl

end to prevent

gum

formations

in

the

carburetor

during

STEERING

HANDLE.

When removing the

motor from the boat. raise the outboard

i;n

,_ ,;

BOLT

Be

as

_

_

: f.

apply

a

part or

rosion or

Always

tically,

before

in salt

and to

light

coating

of grease to

area that shows evidence

of

rust,

remove

motor

from

boat

allowing water to drain

tilting the motor.

any

cot-:

ver-

from column

TROUBLE SHOOTING CHECK LIST

*Take

Fuel Tank

your

outboard

motor into any one of over

2000 Searz Service Units.

X

X

X

X

X

X

Fue

L ne KZnked or Pin_;hed

X

X

X

Fuel

Filter

X

X

X

vent

Screw On Fue] Tank

X

X

X

X

X

X

X

X

X i' '

incorrect

X

X

X

X

X

Carburetor

X

X

X

X

X

X

X

X

X

X

"" X

X

X

'

'i"

X

X.

x

.x"

x

X

X

X

X

Fuel-Oil

X

" ' '

X

X

•

×

X

•

='

'

Cap Closed.'

*

Out of Adjustment

•

'

Spark

Defective

or Fouled

Magneto

•

'

'

Ptug

Spark

Plug

,,i,.

,

Does Not Jump, Spark

Out of Time

: o

Transisterized

Electronic

Weak' 'Ignition

Coil

Spark

"

Dirty

Mixture

• Defective

.... Engine

X

Fitter

Passages Clogged or

Type

Spark

"'

or Clogged

Flooded

Wrong

x

X

Dirty

Carburetor

Engine

X

"

'

Empty

Piug Lead Wire

PJug Gap

:_

.

...

_gnitor

'

,

'-

out of order

"

_ -

:

Not Secured

* •

:' ' "

*

'

'_

• *

X

,

.1

.

X

X

Propeller

:

IMPORTANT

MODEL

NUMBER:,

SERIAL

NUMBER

Bound

High Tension

by Foreign

Lead-Salt

Objects

Water

(Fishing

Build

INFORMATION

Line. Weeds.

Etc.)

Up

IDENTIFICATION

PLATE

298.586190

DATE OF PURCHASE

INSURE

Many

insurance

InsuraNce

boat

offer

and

own

etc.,

as well

ble.

agen t

protection

outboard

your

damage

YOUR

companies

as

and

for_

be wise

further

Allstate

to

for

information

theft,

property

others

to contact

your

covering

damage,

insurance

injury

for

Insurance

againstr

liability

pe_'sonal

It would

including

contracts

engine_

equipment

ENGINE

is availa-

your

insurance

about

adequate

protection.

OPERATING?:LOG

DATE

9

NO.

HRS.

USED

GALS.

FUeL

USED

DATE

NO: HRS.

USED

GALS;

FUEL

USED

REPLACEMENT PARTS _

FOR!,,,_._

MODEL No.298.586190

IO

FIG.I

ENGINE

_

79_

1

3O

65

75

66

74

48

80

5

86

299

8

-27

|'!

FIG.I

ENGINE

REENo,

_:o0i

P.P.No;

PARTS

NAME

o10-1o201-2oiCYLI'NHER:-SH2OUP_

1-002

157_04000-900

1 ";003

018-00546-200

1._004

002"10200"802

1-005

OI_-I0200:ZOZ

040-I0100-2_0

1-006

t°-007:

041_10100-201

t-OOE

039-02000-201

1-009

031-10100;210

037-10100;200

1-010

1-011

046-10242-800

1-012

068=02000-200

. _1-014

999-01020-300

1-015

996-66173-000

11017

" 999-62101-004

1-020

1:59-21401-871

1-024_

07!-02007-2]0

07.1.;02007-220

!-024

1 ;024

071_02007-230

1,_024

07I=02007-240

' _ 1-o25 999-61620_200

1-028

999-60153-000

1-027

o9o-lo2oo_202

,1-029

072-.I0242_900

:107-20751-801

:: 1-031_ :?:.198;01046_g00

.... 'I"032

155-21717-801

1-033112_10242-200

1-038

; 055:_02501-200

1-039.,

I 99I_00100_001

1-048

19U-11109-200

1-055

256-01046-200

1-065

g90_11050-102

1-006

1992-0!050-04!

1-067 :l 990-11060-302

1-068

: ] 992-10060-042

090_11040-162

•

_ 1-070.:

1_074

990-11040-182

, 1_075

992-10040-042

: 1-078

990-11060-252

1-079

_92-I0060-042

.!

1,080

992:10060-042

l:'OG 1

991-01060-021

:'_.

I "085

992-01050-041

l:-OGU

090-11050-102

1:1o3.... 992--ri0040--042

SPARE PLUG CAP ASS'Y

SPARS PLUG BHRSA

CYLINDEZiCONP.

"

CYLINDEI:_GASKET

PISTOH!.21B6

PISTOH R:IHO

PISTOH PIN CIRCLIF

_ISTOH

::

PISTORPIH

IOX35

.

CEAHK"SHAFT COHP.. " .

VOOD-_UFF KEY 3Xi3X5

5ALL BEARIHO e6203

OIL SEAL 17307

HEEDL2 BEARING FIOIOB

rIGHITOR TTI-IE

:CRANK SHAFT SHIK o;|o

CRAEK.SHAFT SHIX.O.15

CRA#ESUAFT SHIH0.20

CRAHS SHAFT S9IH 0.30

BALLBEARING

16202

_IL SEAL 15307

_RAHE.CASE GAS[ET

_RANI:CrASEASS'y

IGBITION:COIL

CORD"CLAHP

ASS COHP.

Y

MAGNETO ROTOE:'COHP._

FAH:CASE

:

FLYVBEEL VASUER

FLYVHEEL HUT 10

CO_D CLARP L

SPAR[ PLUG RUBBER COVER E

SCREH 5X10

VASHE_ 5

SC_EV 6X30

S.VASHEK 6

SCREV 4X16

SC_EU 4118

S,UASGER 4

SCR£9 6X25

S.HASHER 6

S,VAS_E2 6

NUT 0

..

VASHER 5SCREV 5X10

S.VAS_R

4

O'ty

1

!

1

I

1

1

1

1

t

1

1

1

1.

1

V

V

V

V

I

1

I

t

!

1

1

1

1

1

1

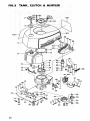

FIG.2

TANK,

CLUTCH

& MUFFLER

102

45

42

\

\

31

15

61

56

55

16

13

28

29

24

Z2

78

3O

13

FIG,2

TANKt

REENo.

2-002

2-003

2-004

2-005

2-006

2-007

2-008

2-009

2-010

2-0It

2-012

2-013

2-014

2-015

2-010

2-017

2-OIG

2-019

2-020

2-02I

2-022

2-023

2-024

2-025

2-026

2-027

2-028

2-029

2-030

2+031

2-033

2-034

2-035

2-038

2-037

2-038

2-030

2-040

2-041

2-042

2-043

2-044

2-04S

2-04H

2-04?

2-048

2-049

2-050

2-052

2-053

2-054

2-055

2-050

2-059

2-060

2-001

2-082

2-063

2-004

2-085

2-066

2-087

2-068

2-069

2"070

2-071

2-072

2-073

2-074

2-075

2-070

2-077

2-07E

2-100

2-101

2-102

2-103

2-104

CLUTCH

P.P.No.

595-35100-D02

630-35500-200

300-35505-200

305-35500-200

650-00801-200

82D-10201-20

790-1020t-210

788-10200-202

793-10200-201

401-35500-200

603-02101-803

653-10218-800

854-10201-201

965-34501-200

1655-10201-200

855-014tA-200

592-10201-900

594-00517-200

700-15008-!26

T00-14508-140

680-01004-200

021-35100-202

260-00503-203

170-I0218-800

180-02004-200

182-01004-200

403-02000-202

393-02500-201

U80-031t3-200

420-10201-900

347-01046-20!

210-35300-800

358-10212-200

290-10112-802

359-10212-203

357-10112-204

342-10205-220

085-02501-200

991-09100-00!

737-10100-200

716-10201-200

737-10201-200

727-10201-200

221-35500-200

228-35500-200

220-35300-200

1225-35500-200

i227-35500-200

i990-12050-452

i992-20050-042

992-00050-04_

i990-21080-222

i992-I0060-042

1991-01080-021

992-20060-012

990-21040-302

992-20040-042

990-11060-202

992-20060-042i

990-12040-122i

992-10040-042i

990-12050-122

992-10050-042i

990-12050-252i

992"I0060-042

990-22050-222

D92-10050-042i

992"02050-04|:

990-12060-121

992-00050-021

012-35500-200

011-35100-200

702_30200-200

330_35555-200

331-355550200

900_35555-200

338_35118-200

992-10050-012

& MUFFLER

PARTS

NAME

O't_

_TANK CAP AS$'Y

TANK CAP GASKET

ENGINE

COVED

CUSHION

RUBBER

COLLAR

STARTER

PAUL BASE

STARTER

PAWL SPRING

STARTER

PAUL

I

1

1

2

4

l

2

2

STEP BOLT

FUEL TAHK

FUEL TANK RAnD CORP.

FUEL TAHX BRACKET

COXP.

FBEL TAnK

BRACKET

9

TAXE SUPPORT

RUBBER

FOEL TANK CUSHION

RUBBER

FUEL TAHK CUSHIOE

RUBBER

PET-COCK

ASS'Y

PET-COCR

FIXIE9

NUT

FUEL PIPE

5X8XI1U

FUEL PIPE

4.SXBX240

CLIP

a

PI_

HOLDER

STOP BUTTON COVER

STOP

BUTTUX CORP,

STOP BgTTOX

FIXIRG

NUT

SPECIAL

S.UASNER

'IHLET

RAnIFOLD

GASKET

INLET

XAHIFOLO

CLIP

7,5

AIR CLEANER

ASS'Y

CLUTCH

FLANGE

CLUTCH SPRING

COXP,

CLUTCH

HASHER A

CLUTCH

ARE CORP.

CLUTCH

HASHER B

CLUTCH STEP

BOLT

CLOTCII

$PRIHG

FLYVHEEL

VASHEE

FLYWHEEL

NUT 10

HUFFLER

GASKET

HgFFLER

BODY A

XUFELEE

GASKET

XUFPLER

BODY H

HUFFLER

PIPE

GASKET

HUFFLEE

PIPE

STAY

A

RUFFLER

PIPE

HUFFLER

PIPE

BRACKET

RUFFLER

PIPE

BRACKET

SCREW 5X45

S.UASHER

5

WASHER 5

SCREW 5X22

S.VA_flEK

8

: '.,

HUT 6

S.VASHEE

O

SCREV 4X30

S.VASAER

4

SCREW BX20'

S.gASHER

8

SCREV

4X12

2

12

!2

,1

I

1

I

1

4

4

4

2

251

A

B

....

.........

+,

::

.

.

:

+

:

•

+

S.VASEEE4

SCEEV

5X22

S.VASEER

5

SCREW 0X25

S.VASHER

6

SCREW 5El2

1

.

.

S.WASHER

5 BASHER 5

SCREW HX12

SHALL HASHER 5

SHEAR

PIE

....

COTTER PIN

_

FUEL

PIPE

COIL

RIGHT

SIDE

HARK

LEFT SIDE

HARE

RAgE

PLATE

STARTER

S.VASEEK

2

2

2

1

I

I

2

2

I

I

1

1

3

Z

1

I

2

2

]

1

I

2

I

3

3

3

3

3

3

2

HARK

O

, "

'

,_

:

'

.'

'

,

2,

+ 2

2

2

2

+ 2

.7

:

+

7

2

.2

I

!:

-_

3

3

3

2

_:

i+

+

"

:'

'

2

2"

2

1

1

1

2

3

14

FIG'S

RECOIL

STARTER

13

t4

0--

•

• •

18

3•0

_;f.--26

REENo,

•5 •

!,.,

P.P,No,

3-000

3-001

750-10207-900

772-10207-200

3-002

3-003

774-10200-200

779-10200-203

3-000

3-01I

3L012

3_013

3-014

3-Q15

3-_17

3-018

3-019

3-020

3-021

3-022

3-023

3-024

783-01006-201

780-10201-200

785-10207-201

833-10207-200

992-01040-011

773-10200-200

990-11050-25!

778-10200-200

827-10200-20]

900-11050-122

992-10050-042

992-01050-041

902-10050-042

991-41050-022

3-026

3-030

788-10200-200

791-I0200-200

:•

PARTS

NAME

• !Q'ty

_ECOIL 3Tk_TEg ASS Y

RECOIL STARTEE BODY

STARTEg 20PE REEL

AECOIL SPEIEG

•

STA£TE_ _OPE ''

20PE GUIOE

STA_TEZ HAHDLE

STAETEE EAEDLE CAP.

VASEZA 4

_

"

=,t

11

:t

t

I

1

1

t

1,

1

1

PULLEyrsBAFT/OUT_I

SC_EV 5X25

££C0IL SPBIHG CASE

RECOIL SPRZNGHOLDEZ_

SCREV 5X12

S,VASHgR 5

VASHE= 5

S,VASEEE 5

CAP HOT 5

STARTER VASHER

STARTER BUSBIKG

,

].

2

2

1

!

!

,

]

1

IG.4

CARBURETOR

f

/""

/-

_38

0--

4o

12

17

30_

21

31_

......

:j%,,,

REENo.

4-000

4-002

4-003

4-004

4-005

4-000

4-007

4-008

4-010

4-011

4-012

4-018

4-017

4-OF!

4-024

4-026

4-027

4-028

4-029

4-030

4-031_

: 4-037

4-038

4 -039

4-040

P.P.No.

455-20217-900

597-20110-200

595-20200-200

594_20202-200

619-20202-200

593-20202-200

592-2002T-920

591-2005T-200

623-21700-200

622-20217-200

561-20202-900

6O7-EOHO_200

599-gOO]T-740

606-20202-200

994-34040-106

605-20202-200

603-20400-200

_2B-20202-EOO

604-20!t0-200

629-20202-2001

02?-20400-200

571-20200-200

802-20420-200i

598-20202-200

5_8-2005T-gSO

_

-

PARTS

•

NAME,

i O'ty

,4

CARBgRETOR ASS'Y

CABLE ADJUSTEE

BODYCAP

TIIEOTTLE VALVE $PR]_Q

TREOTTLE SPEING SEAT

I

.

i

..........

. 1

' _ 1

l

!

,i1

JET HEEOLE

NEEDLE ASS'Y

CLIP

JET

004

THROTTLE VALVE 0.5X1.5

ADJUST SPRIHG

ADJUST SCREV

:

.

OUTLET CLIP ASS'¥

FLOAT CHAHBER GASKET

HAIN JET fT4

FLOAT CHAXBER V/TNREAD

SCREV 4X10/S

CHOKE PIH

NEEDLE VALVE

FLOAT E_

FLOAT

DRAIN SCREV GASKET

DRAIN PLUG

HAN.IFOL_ SEAL

HEEDLE SEAT

CABLE ADJUSTER LOCK NUT

_EEDLH:JET

.2095

'

!

.

1

!

1

l

l

I

2

!

!

1

l

1

l

t

!

1

16

FIG.5

HANDLE

& BRACKET

0

52

47

7

]6 14 15

-54

|_

17

39

22'

23

41

20

4O

31

37

•I•,7

45

HANDLE

REF.No.

_,

& BRACKET,

P.P.No.

J

PARTS

NAME

O'ty

,,

5-000

570-35552-900

5-001

885-01058-800

5-005

200-35300-800

5-006

093-51042-002

5-BB?

999-61600-404

5-008

993-50020-002

5-009

185-35300-203

5-010

OBO-210UO-252

5-01!

992-10060-042

5-012

990-11050-202

5-013

992-10050-042

5-014

18t-35500-202

5-015

793-10200-201

5-016

992-O4080-B31

5-017

100-35552-800i

5-019

102-35500-200

5-020

, 990-21080-302

_5-021'

992-0'1080-041

5-022

991_010E0-021

5_023_ _ 992_1'0080-042;

5-024

134=r35500--201:

_5_025

"]'15--3530_'210

.-,_5-028.1

131-35308-200

5-027"

t35-35500-20I

":-5-028

990-21060-I02

5-029

990-11050-162

5_030,..

992-10050-042

5_031

13T-35500_20!

5_032

138-35500-201

5_033

992-10050-042

5-034

990-11050-122

5':035

139-35500-200

+5-038

t29_35100-200

'_5-037123-35500-201

5_038'_

107_35t18_801

5-039:

106_35119_'80!

5"040

990-2]0U0-752

5-04!

108:35501_:_200

5-042

991-41060-022

5-043 /

992-10060_042

5-044

g92-01060-041

5-045

871-35552-2U0

5-O45

8?2,_35552-290

5-047

873-35552-200

5-048

B74-35552:200

5-049

875-35552-'200

5-050

870-355527200

5-051,

879-35552-209

5-052

99BT11050-202

5-053

991-B1050-02|

5-054

877-355_2-200

5-055

578-35552-200

5-056

903-32201-200

TWIST 6RIP ASS'Y

THROTTLE WIRE COHP.

CLUTCH DRU# COEP.

STOP RtHG C42

BALL BEARING 160040D.

STOP RING C20

CLDTC_ CASE

HEX. BOLT 8X25

$.VASHER B

SCREW 5X20

S.VASHER 5

HAHDLB STOPPER

STEP BOLT

HAVE RASHER 8

5TEERIH6 HAHOLE COHP.

UAHDLE V_SBrE_

_OLT 8X30

WASHER 5

_UT 8

$,VASHER 8

THRUST VASBER

BRACKET

THRUST BRACKET

RETHRH CAH

BOLT BXIO

SCREW 5X10

S,VASHER 5

......

RETUXE CAH GUIDE

RETURK GUIDE PLATE

$.VASEER 5

SCREW 5XI2

.

RETURB SPRIHG

BRACKET PIH STOPPER A

5RAC£ET PIE S

CLAHP-BRACRET B COXP;

CLARP BRACKET A CBXP.

BOLT 6X75

CLAHP BRACKET BgSBIUG

CAP HUT 6

S.VAS'HER U

WASHER 6

!THROTTLE GRIP

ITHROTTLE I_HER .PIPE

THROTTLE HOLBER A

THROTTLE HOLDER H

THROTTLE HOLDER COVER

:WIRE GUIDE

:.

:TAPPIHG_;SCREV '

"

SCREW 5X20

;:

HUT 5

'

:

l

I

1

I

1

I

I

2

2

4

4

I

]

1

1

2

FIG,5

l

1

1

!

l

1

4

I

l

:

l

1

1

4

4

I

I

l

! .

1 .

1 _2

1

1

I

I

l

1

!

1

I

2

2

2

TttROTTLES_OPP'_R::

,t

THROTTLE STOPPERSPRIHG

VIRE CLAKPBA_P

'+

I

I

'

"

18

..... FIG.6

DRIVE SHAFT

PiPE'!I_::_GEAR:;¢ASE '_:

/

/

/

,/

/

•

24

T

18

27

28

22

21

23

30

29

19

/

/

PIPE & GEAR

PARTS

P,P.No.

_

!

I

3

2

2

I

2

2

1

!

1

'1

I

1

1

v

v

v

v

l

1

v

v

v

I

i

1

1

!

!

t

l

2

2

1

v,

v

1/

V

t

1

11

!

I

.!

2

?

.

'

L

" .J

,'"

+

+

,

:

.

:'

+

, :: .....

+

....

_

,

,

_

t

'

+

:

%

4

Q'ty

TH]_HST HEAEIH6 '1024

DRIVE SHAFT SHIH 0.50

DRIVE SE_FT S_tE O.tO _ +

DRIVE SHAFT S]flH 0,05 '+

DELVE SHAFT $EIH 0.20

PIHIOH COLLAE ,

P]IilOH

PlRIO]f FIN 4X16

GE/_R COLL_I_

GEAR PIE

DRAIN _ASRET O

BOLT _X8

THRUST VASHER 1024

i

t

;

t .......

NAME

DRIVE SHAFT PiPE A$S*Y

DRIVE SHAFT COHP.

BEARIHG BOLDER CLIP

HEEDLE 5EAHI'H6 10t5

BEAR IiiGHOLDEI_

OKlV_ SHAFT pIPE-GASKET

_OLT 6X18

S,VASHER 6

BOLT 8X40

S.VASBER 8

GEA_ CASE HOLD]_R

DRIVE SHAFT PIPE GASRET

9EAR CASE ASS'¥

BALL *BEA'R'IRG 16900

FLAIH BEAR.I]_G

.

OIL SEAL 10228 ..... :

PROPELLER SHAFT SAlt4 E 0,$0

PROPELLER SHAFT SHIH A 0.20

PKOPI';LLER SHAFT SHIH A 0.30

PROPELLER SHAFT SliIH A 1,0

STOP Ring C-ZO EX

GEAR

_EAA SHAFT Sllll_ 0,10

GEAR SHAFT SHIH 0.20

6EAR SHAET SHIN 0.30

GEAR CASE:,GASKET

BALL BEARING 10001

GEAR CASE COVER

OIL SEAL 12227

PROPELLER SHAFT

SHEA_ FIH

COTTER P l_

P20PELLEE

_BOLT 6X18"

.

8-OOl

090-35306-900

6-002

075-35300-800

9-003

OSB-S5_O0+200

8-004

999-82101-521

6-005

039-35500-200

0-000

091-35500-200

8-007

99o-21000-182

6-008

992-t1090-942

6-009

990-21080-402

6-010

992-10080-042

6-0t!

034-35500-201

6-012

091-35500-200

6-013

031-35500-900

8-014

999-81000-000

8-015

032-35500-210

6-016

999-00402-209

8-017

171-35500-201

6-017

173-35500-200

0-017

174-35500-200

8-017

I75-35500-200

6-018

993-50010-002

8-019

017-36120-201

6-020.

330-00200-2!0

0-020

330-00200-230

8-020

330-00206-24¢

6-021

048-35500-202

8-022

999-61600-100

6-023

046-35506-200

6-024

999-_5122-2BS

6-025

019-35500-201

6-026

012-35500-200

6-02T

011-35100-200

6-028

010-35555-200

8-029

990_21060-182

6-030

992-11060-042

8-031

999;62102_463

8-032

083:35500-200

6-032

064_35500-290

6-032

065-3550,0-200

8-032

066-35500-200

6-033

062-3550.0-200

8-034

080-35300-200

0-035

061-35500-20C

6-035026_35500-200

8-037

025-35500-200

8-038

31T-02000-200

6-039

_96-2_0_0-062

8-040

999-62102-464

+

RERNo: ....

SHAFT

r

DRIVE

I

FIG.6

"

r

. .

i

]

20.:i¸i

¸

TOOLS

FIG.7

o

REENo.

7ooo

PARTS

: P.P.No.

:

:

7-001

7"002

85_-20000-20|

808-20000-200

"

?-003

882-20000-200

SP^HHER lOX13

PLUS DRIVER 4

D48-32352-200'

TOOL

7-004

:

NAME

O'ty

Tool _T ....

gas-3s3o4:goo

sP^_KPLuG

_oxsP^,,E_

[

1

1

1

1

BAG

i

•

i

MODEL NO.

298.586190

t owner's

responsibilily

,o m_iintenance

i_

_*_operation

• Irouble

" shooling

• replacemen!

parls

Publication

967-45560-204

No,