Download A.O. Smith BTH 120 - 250 Instruction manual

Transcript

Instruction Manual

COMMERCIAL GAS WATER HEATERS

MODELS BTH-120/150/199/250

SERIES 100 & 101

!"#$%&

INSTALLATION - OPERATION - SERVICE

- MAINTENANCE - LIMITED WARRANTY

ANSI / NSF 5

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not

touch any electrical switch; do

not use any phone in your building.

Immediately

call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot

reach your gas supplier,

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED 1011

197727-002

TABLE OF CONTENTS

)V(C#)//C=#"J)(#+)(?5C!( $

Supply Gas Line Installation $'

W(#(?/)V(@C#V=?BC=# 4

( 41

4

)

!41

C#?=+J!C=# 6

(*+!

41

`

6

/! 42

!=BBk3^!!; 6

356+ 42

VC 6

TEMPERATURE REGULATION 8$

V(J?()#+!=B=#(#) 7

:;

/;!<(!=> 8$

^= 7

;! 8$

5 8

!=#?=/)@)(B=(?C=# 44

)5 10

!);#6 44

C#)//C=#!=#)C+(?C=#)11

+)44

Rough In Dimensions11

)

C45

?6! 12

J)3!);B

47

/: 12

Temperatures Menu47

!!;

B&$

Heater Status Menu48

)6!&$

Display Settings49

Insulation Blankets &$

Heater Information49

INSTALLATION REQUIREMENTS 14

!

V

50

Gas Pressure Requirements 14

V

:50

Supply Gas Line 14

V

=

50

Supply Gas Regulator 14

?V+

50

)6!C;51

)

14

START UP 52

Mixing Valves 15

Initial Start Up 52

+B 15

)

W

X

;54

!); 15

BW

X

;54

Thermal Expansion 15

!V? 55

Temperature-Pressure Relief Valve 16

:

C 55

!+ 17

LIGHTING THE WATER HEATER 56

Air Requirements 18

Lighting & Operation Labels 56

!;;B

21

TROUBLESHOOTING 58

VENTING INSTALLATION 22

C! 58

General Venting Information 22

!C522

)]

== 58

5!

22

)]

==V! 59

+5!

22

Operational Problems 60

W5C

22

?

)"?

=60

Venting Requirements 24

Momentary Ignition60

Maximum Equivalent Lengths24

Not Enough Or No Hot Water60

Minimum Equivalent Lengths24

VJ/#+/(?!=#+CC=#) 61

B};

;#

;=(24

V

!61

5C)]

25

!61

5C 25

?!);/=

61

+5C 25

+!61

5;C 27

V

B62

);C 29

BC#(##!( 64

B)

64

!;C $

B

!;!$~

DIAGRAMS 67

B

!;;$$

!!^_!!^/

67

Venting Arrangements $8

BTH 120 & 150 Wiring Diagram 68

;!)5 $

BTH 199 & 250 Wiring Diagram 69

;!)+5 $%

!

;+; 70

WATER HEATER INSTALLATION $

Water Piping Diagrams 71

!+C $

/CBC(+??#@ 78

2

SAFE INSTALLATION, USE AND SERVICE

"

6};;

B_;

66;

X

?;

;

C6;

;;

"

"6

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER

DANGER indicates an imminently

hazardous situation which, if not avoided,

will result in injury or death.

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in injury or death.

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result in

minor or moderate injury.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, could result in

property damage.

CAUTION

;

"

;"

6X

!)+}(;]

W6!

) ! " " 6 ;" ]

}

;)!

""

6;

6}

;

APPROVALS

ASME CRN

ANSI / NSF 5

NOTE: )B( 6;

$

GENERAL SAFETY INFORMATION

PRECAUTIONS

HYDROGEN GAS FLAMMABLE

+= #= J)( :C)/C#!( CV#@ ? :) ^((#

J#+(?(?C;;]

6

;;

}

C

}"

6 6 ; ]

6

Explosion Hazard

Flammable hydrogen gases

may be present.

& (}

Keep all ignition sources away

from faucet when turning on

hot water.

~ +;

$ V

GROUNDING INSTRUCTIONS

;

# ( ! * ;

V

;

;

: ; 6

;<;>:};

;;

X

"

;;

6

6 ;

; C THERE

):=J/+ ^( #= )B=

C#W =? =(# V/B( #(? :(

VJ!(:(CB(CC)=(#

;

;"

;;]

;

;

]

;

;

Verify the power to the water heater is turned off before performing any service procedures.

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Explosion Hazard

Overheated water can cause

water tank explosion.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

Properly sized temperature and

pressure relief valve must be

installed in the opening provided.

This manual must remain with the

water heater.

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

CAUTION

Improper installation, use and service may result

in property damage.

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

4

Do not operate water heater if flood damaged.

Inspect and anode rods regularly, replace if damaged.

Install in location with drainage.

Fill tank with water before operation.

Properly sized thermal expansion tanks are required on all

closed water systems.

Refer to this manual for installation and service.

GENERAL SAFETY INFORMATION

Fire or Explosion Hazard

Fire Hazard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

For continued protection against

risk of fire:

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Do not install water heater on

carpeted floor.

Do not operate water heater if

flood damaged.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Fire and Explosion Hazard

Read instruction manual before

installing, using or servicing

water heater.

Use joint compound or Teflon tape

compatible with propane gas.

Leak test before placing the

water heater in operation.

Disconnect gas piping and main

gas shutoff valve before leak

testing.

Install sediment trap in

accordance with NFPA 54.

Breathing Hazard - Carbon Monoxide Gas

Do not obstruct water heater air intake

with insulating blanket.

Gas and carbon monoxide detectors

are available.

Fire and Explosion Hazard

Install water heater in accordance with

the instruction manual.

Do not use water heater with any gas

other than the gas shown on the rating

label.

Excessive gas pressure to gas valve can

cause serious injury or death.

Turn off gas lines during installation.

Contact a qualified installer or service

agency for installation and service.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

CAUTION

Property Damage Hazard

All water heaters eventually leak.

Do not install without adequate drainage.

Jumping out control circuits or components can

result in property damage, personal injury or death.

Electrical Shock Hazard

Turn off power to the water heater

before performing any service.

Label all wires prior to disconnecting

when performing service. Wiring errors

can cause improper and dangerous

operation.

Verify proper operation after servicing.

Service should only be performed by a qualified service

agent using proper test equipment.

Altering the water heater controls and/or wiring in any way

could result in permanent damage to the controls or water

heater and is not covered under the limited warranty.

Altering the water heater controls and/or wiring in any way

could result in altering the ignition sequence allowing gas to

flow to the main burner before the hot surface igniter is at

ignition temperature causing delayed ignition which can

cause a fire or explosion.

Any bypass or alteration of the water

heater controls and/or wiring will result

in voiding the appliance warranty.

Failure to follow these instructions can

result in personal injury or death.

5

INTRODUCTION

@

;"

6

6

+;

;

; 6 6 C 6" " ABBREVIATIONS USED

6

C

B

6 ;; ;

#)C_;#)C

)B(_;)B(

WB_WB

#(!_#(!

#V_#V

J/_J/

!)_!)

;

V

!;%;

J

6

;

) C ! ^ ; ; ; X

;6

6:6"

6

;

`

)6

QUALIFICATIONS

QUALIFIED INSTALLER OR SERVICE AGENCY

C 6 ]

]

6 `

< #)C

>66C

;"

"6"

]

;6

NOTE: ! 6

;

~ ^ ;#6

;

ANSI Z223.1 2006 Sec. 3.3.83: `

_

6

";";

6<>

" ; <> """6

]

;}

;

]

;

]

;

6X

$ ;

;

;

6X

6 X

]

;

"

C " ;

;

#V

W

!"#)C~~$&*#V8#(

!" #V % !#*!)_^&8'&" #

W

C ! !) !~~&" ! ( ! ; 6

; ! ) " & (

5 ?" !6" =: 88&$& #V

; 6 ; # V

" & ^; " `

"

B~~'

C

]

<#)C6>

]

6 X

; 6 ; ; ;

C 6;

;;

;

ICOMM™ & BACNET COMPATIBLE

; !=BBk ;

; ; !=BBk ; ; 6 C ; " ;

8 C ;

6 ]

" ;6;

C}

]

"

6 B" ) ) ;

6 ;

!=BBk ; ; 6 ; * } ; ;

!

!=BBk;;^!;

6 ;; ; V

;;'~_$%~

!

; (};

;]

;

/ : &~ ?

C+;&&

PREPARING FOR THE INSTALLATION

& ?;

;

W)

C; 8 C ";C

;"X

*

V ! ;

6 ;6 ]

) C

;;!

= )" &&~ ` )" )

&"

);"!'&&

;

"

" ; C ;

;

% B

! ]

B

~8_!B?~

)

;!~8_!B?)!;;

B

~&

6

FEATURES AND COMPONENTS

BLOWER/BURNER ASSEMBLY DETAIL

BASIC OPERATION

INTAKE AIR

(combustion air)

CONNECTION

3 INCH PVC

6 ;

6 }

;

B ^

" ;

}

} }

}

*6;

)V

&V

~

BLOWER

BURNER

ASSEMBLY

COMBUSTION

BLOWER

BLOWER

FLANGE

FLAME

SENSOR

MAIN

BURNER

(radial design)

INTAKE AIR

(combustion air)

CONNECTION

3 INCH PVC

HOT SURFACE

IGNITER

120,000 & 150,000 Btu/hr MODELS

MAIN

BURNER

(radial design)

COMBUSTION

BLOWER ASSEMBLY

INTAKE AIR

(combustion air)

CONNECTION

3 INCH PVC

HEAT

EXCHANGER

BLOWER

FLANGE

HELICAL

COIL

HOT SURFACE

IGNITER

MAIN

BURNER

(radial design)

FLAME

SENSOR

199,000 & 250,000 Btu/hr MODELS

Figure 2

VENT (exhaust)

OUTLET

Hot Surface Igniter

; : )

C &~

5! ; "&V<'~!>"

B^

NOTE:!;

6

Flame Sensor

;;;;

;B^

C;6

<$_>;

;; _ ~8 5 W 56 ) )]

=V'

Figure 1

7

TOP VIEWS

120,000 & 150,000

Btu/hr MODELS

TOP VIEW

6

7

8

9

10

2

5

11

4

12

13

3

2

14

FRONT

15

16

1

17

Figure 3

BTH 120 & 150 COMPONENTS

&&!;

^

& :&~5!*

&~^(}

<6>#;

(}

<6> ; ; ~ 6 ;

]

< > <>^:&~";

66

;

;

6 ;6

<

>;

&$^6#;

!;

^;;

!;

^

;

))]

=

'

$ ! ! ^ <!!^> ; ; !!^

;

"!);=88

&8;

_

? 56 ) ;

_

?56&

8 C_$5!

&~ 5! X

} C; ;))

&8

&J;

"&~;

;;

;

~85W56

% )

) ]

; )

W/&8

J;

(!=<

> X

;

; (!= ; ;

):;

/;!<(!=>8$

/W

#;

6 ;;

; ]

; ;;

)8

W

?]

;&8

&

&&*~#

&%JCB <

;

> JCB " ; /!+ JX

6

6;)!);=

88

' ^ C #; <;

> ;;

&5<}

>_$5!

8

TOP VIEWS (CONT)

199,000 & 250,000

Btu/hr MODELS

TOP VIEW

7

2

8

10

9

6

5

11

4

12

13

3

2

14

FRONT

15

16

1

17

Figure 4

BTH 199 & 250 COMPONENTS

&5<}

>_$5!

& :&~5!*

&&C_$5!

~ 6 ;

]

<>

^:&~";

66

;

; 6 ;6

<

>;

&~^(}

<6>#;

(}

<6> ; ; &$^6#;

!;

^;;

!;

^

;

))]

=

on page 58

$ ! ! ^ <!!^> ; ; !!^

;

"!);=88

8 (^B !;

^; 5V+ <6

]

6>"W565

;

&8;

_

? 56 ) ;

_

?56&

&~ 5! X

} C; ;))

&8

&J;

"&~;

;;

;

~85W56

% ^ C #; <;

> ;;

J;

(!=<

> X

;

; (!= ; ;

):;

/;!<(!=>8$

)

) ]

; )

W/&8

&

&&*~#

&%JCB <

;

> JCB " ; /!+ JX

6

6;)!);=

88

' /W

#;

6 ;;

; ]

; ;;

)8

W

?]

;&8

9

4

5

5

6

4

13

3

14

2

3

7

8

2

9

15

10

11

1

12

16

LEFT SIDE

120,000 & 150,000 Btu/hr MODELS

RIGHT SIDE

199,000 & 250,000 Btu/hr MODELS

Figure 5

SIDE VIEWS

& !

" 6 56+?]

;&

$ C_$5!

&/;

"&~;

;;

;

8 ~85W56

&&_&&*~#

!;

^

&~66

_&&*~#

&$)

))

W/&8

% JCB <

;

> JCB " ; /!+ JX

6

6;)!);=

88

&8/W

"

)8W

?]

;

&8

~ !!^

_

;

_

? 56 ) ;

_

?56&

' ;

_

?56_3

10

&5<}

>_$5!

&! &*~ 5! )

V

' &% ! + C $

INSTALLATION CONSIDERATIONS

ROUGH IN DIMENSIONS

SUPPLY GAS

CONNECTION

INTAKE AIR CONNECTION

3 INCH PVC

WATER OUTLET

HEIGHT

FRONT

I

BACK

T & P VALVE

E

F

B

H

D

CLEANOUT

VENT CONNECTION

3 INCH PVC

(exhaust elbow)

3/4” NPT DRAIN

1 1/2” NPT

WATER INLET

CONDENSATE

DRAIN CONNECTION

1/2 INCH PVC

C

A

G

These designs comply with the current edition of the American National Standard for Gas Water Heaters, Volume III, ANSI Z21.10.3 / CSA 4.3

as an automatic circulating tank water heater, and automatic storage water heaters.

35°

35°

120,000 & 150,000

Btu/hr

MODELS

TOP VIEWS

22°

V

3 I ENT

N

PV CH

C

V

3 I ENT

N

PV CH

C

64°

GA

S

68°

199,000 & 250,000

Btu/hr

MODELS

SUPPLY GAS

CONNECTION

VERTICAL

INTAKE AIR

3 INCH PVC

INTAKE AIR

3 INCH PVC

E

LV

E

LV

N

O

UT

VA

A

FRONT

CL

EA

C

LE

P

V

N

O

U

T

&

P

VE

VAL

AIN

DR

&

VE

VAL

A IN

DR

FRONT

A

T

*1 1/2” NPT

WATER

OUTLET

T

*1 1/2” NPT

WATER

OUTLET

18°

18°

45°

45°

45°

45°

* Center line of water outlet on top of the water heaters is approximately 7 inches from the front edge of the water heater.

DIMENSIONS

MODEL

SHIP

SHIP

WEIGHT

WEIGHT

A

B

!

D

E

V

G

H

I

STD

ASME

C#!:()*!B

C#!:()*!B

C#!:()*!B

C#!:()*!B

C#!:()*!B

C#!:()*!B

C#!:()*!B

C#!:()*!B

C#!:()*!B

LBS/KG

LBS/KG

BTH 120

$*%~

~%%*%

$*&

$*'

*&8&

8*&~&'

&&*~%'

8~*&%

8%*&~

460/208

490/222

BTH 150

$*%~

~%%*%

$*&

*&8&

%*&'&

*&%8

&&*~%'

$*&

'*&%$

555/252

595/270

BTH 199

$*%~

~%%*%

$*&

*&8&

%*&'&

%*&'&

&&*~%'

$*&

'*&%$

555/252

595/270

BTH 250

$*%~

~%%*%

$*&

*&8&

%*&'&

%*&'&

&&*~%'

$*&

'*&%$

555/252

595/270

Figure 6

11

GAS LINE CONNECTION SIZE

STORAGE CAPACITIES

TABLE 1

TABLE 2

† MODEL

SERIES

NATURAL GAS

PROPANE GAS

MODEL

J)W//=#)

LITERS

BTH 120

100/101

$*8#

$*8#

BTH 120

60

227

BTH 150

100/101

$*8#

$*8#

BTH 150

100

$%'

BTH 199

100/101

$*8#

$*8#

BTH 199

100

$%'

BTH 250

100/101

$*8#

$*8#

BTH 250

100

$%'

+]

6"*

;

"

;6

;;

;]

_W/)$'

RECOVERY CAPACITIES

TABLE 3

U. S. GALLONS/HR & LITTERS/HR AT TEMPERATURE RISE INDICATED

V

$V

8V

V

V

%V

V

'V

&V

&&V

&~V

&$V

&8V

!

&%!

~~!

~!

$$!

$'!

88!

!

!

&!

%!

%~!

%!

GPH

461

$8

276

~$

197

&%$

154

&$

126

115

106

99

Propane

LPH

1744

&$

1046

872

747

654

581

~$

476

8$

402

$%8

Natural

GPH

576

8$~

$8

288

247

216

192

&%$

157

144

&$$

&~$

Propane

LPH

2179

&$

&$

1090

'$8

817

726

654

594

545

$

467

Natural

GPH

767

575

460

$8

$~'

288

256

~$

209

192

177

164

Propane

LPH

2904

2178

&%8$

1452

1245

1089

968

871

792

726

670

622

Natural

GPH

960

720

576

480

411

$

$~

288

262

240

221

206

LPH

$$~

2724

2179

1816

1557

&$~

1211

1090

991

908

$

778

Type of

Gas

B

Input

Btu/hr

kW

Natural

BTH 120

&~"

BTH 150

&"

BTH 199

&''"'

BTH 250

~"

$

44

58

%$

Propane

?6';

LOCATING THE WATER HEATER

!

;6;

;;

CAUTION

/]

;

6)

?]

;&

' /6"

" ; ;};

; ]

6

)5?]

;~8

&+ <

!;

^> ; XX

Property Damage Hazard

&&+ ]

6 <}

> ;

X ;<>

;

)5C~~

All water heaters eventually leak.

Do not install without adequate drainage.

}

6

Fire or Explosion Hazard

& ;

~ ;

X;

$ /

X

;;66

8 /6

/

; X

6";;

;"]

"

/;X

% / &~ 5! ))

&8]

;

12

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Read instruction manual before

installing, using or servicing

water heater.

;""

;; ]

6 ]

; 6 "V;;66

6;

B^

;

}

V;;;"

;

6X

CLEARANCE TO COMBUSTIBLE MATERIALS

6 ;

6 ;

;

;

; 66

NOTE:]

6

;

))6!

ALCOVE

CLEARANCES TO COMBUSTIBLE

AND NON COMBUSTIBLE

CONSTRUCTION MATERIALS

}" ; ;; "

""

]

;)B8;

;;6

CIRCULATION PUMPS

;

;]

X

)+;%&

;

)!

;+;%

;C

# ( !" #V % !

(!"!)!~~&

_

;;

;;

);

;;

]

); ;

;

? ; ;

]

;

TOP COVER

0

0

INSULATION BLANKETS

0

WATER

HARD WATER

HEATER

FRONT

FRONT

TOP VIEW

FRONT VIEW

Breathing Hazard - Carbon Monoxide Gas

Do not obstruct water heater air intake

with insulating blanket.

Figure 7

SERVICE CLEARANCE

6~8<&;>

;

; 6 3 66" ;

;"66"

"66"6

<}

>/6

;

; 6 }

)V

'&%

INTAKE AIR AND VENT PIPE CLEARANCES

;;

;;;

;6

<}

>5

;

;

<X>

EXTENDED VENT TERMINATIONS

6;

$*6

;};

;

]

6<&~;>*6

}

&~]

6<$;>

8)5?]

;~8

; <~> $ ; 8 5! 86"

8;;

!

;

;6;

8

;<>

OPTIONAL CONCENTRIC TERMINATIONS

6;

+5

;

)!;C$

&$

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

C

6

}

6;

;}(

]

;";

)

" ) V

!; ;

;;V

]

;

"

"}"

X

DO NOT

"

;

DO NOT6;/!+

DO NOT6;

_

?56

DO NOT6

;

DO

;

;

;6

}

DO

]

;

"

;

INSTALLATION REQUIREMENTS

GAS PRESSURE REQUIREMENTS

TABLE 4

MODEL

B#CV=/+?())J?(

NATURAL GAS

BC#CBJB)J/@?())J?(

B¡CBJB)J/@?())J?(

PROPANE GAS

NATURAL GAS

PROPANE GAS

NATURAL GAS

PROPANE GAS

BTH 120

8!<&>

&!<~8'>

8'!<&~~>

&&!<~%8>

&!<~~>

&8!<$8'>

BTH 150

8!<&>

&!<~8'>

8'!<&~~>

&&!<~%8>

&!<~~>

&8!<$8'>

BTH 199

!<>

!<>

8'!<&~~>

&&!<~%8>

&!<~~>

&8!<$8'>

BTH 250

!<>

!<>

8'!<&~~>

&&!<~%8>

&!<~~>

&8!<$8'>

B

?

¢$!6

&~"&"^

*;

;

%"%<~"$8%;>&''"~"^

*;

;

&"&<$"%;>):

C6

B;

;

<

>#+<;

>)

;

6

;;

;6

)

;

;;;

C

;&!

;<*

>;

))

W?

]

;))

W/C$')

W?

&8

B};

;

<

>#+<;

>)

;

6

};};

;6

SUPPLY GAS LINE

6;

]

]

6

;

6

;

"

C

DOES NOT

6

; ;

;

;};

;

8

;;

; ;

6

]

6

;

6DO NOT

}

)

6;;]

)W/)$'

MINIMUM SUPPLY GAS LINE SIZE

TABLE 5

† MODEL

NATURAL GAS

PROPANE GAS

BTH 120

$*8#

$*8#

BTH 150

$*8#

$*8#

BTH 199

$*8#

$*8#

BTH 250

$*8#

$*8#

8 ;

; ; ;; 6

6

_

POWER SUPPLY

6 ;

]

&~ 5!"

&<>":"&;

;

"

"#(!"#)C*

#V%!(!"!)!~~&

POWER FLUCTUATIONS AND ELECTRICAL NOISE

; ]

!

X

66

(BC<;>

?VC<]

>;

;;

]

*

/ ; )(/V*_& ) )!_/ ]

6 ;

6}!

;6;

;

;

+]

6"*

;

"

;6

;;

;]

_W/)$'

NOTE:B

6

;

SUPPLY GAS REGULATOR

;};

;

&!<~~>

&8

! <$8' > C 6 _

}

;

C6_

]

& 6_

;

6

^

*

~ 6_

<>

$<&;><~8

;>;

$ 6 _

<>

;

%!

;;

6);X

;

;]

;

14

DEDICATED POWER WIRING AND BREAKERS

+ " 6

POLARITY SENSITIVE

;6;

6 ; ]

; ;; ; ;

C:#

&~

5!

6";

V

"

;

!?6V

;/!+

)(8&

MIXING VALVES

HOT WATER

OUTLET

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

12” TO 15”

(30-38 cm)

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

TEMPERED WATER

OUTLET

Feel water before bathing or

showering.

CHECK

VALVE

COLD

WATER

INLET

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

CHECK

VALVE

MIXING

VALVE

TO TANK

INLET

;

"

" ; X

) ;

;

};

~V<&&!>

); ; ; X

" " ; *; }; ;__

; C 6 ]

;

"

;

C

;

;B}56

< V

> ;;

B} 66 6 ; !

`

C )6 V ;} 66

;

66

TABLE 6

;

~3$

+^

)

Water Temperature

&V<~!>

Nearly instantaneous

&%V<%%!>

Nearly instantaneous

&V<%&!>

&*~

&V<!>

&_&*~

&8V<!>

/

&$V<8!>

$

&~V<8'!>

More than 5 minutes

Figure 8

#)V

;;

&V<~!>"

6 X

6&V<~!>_

;

X

66 ;#6

;)+;

%&

NOTE:;#)V)]

;

;;

66

CLOSED WATER SYSTEMS

; ;" ]

;

" ; " 6

6 66" 66"6+6

;;

THERMAL EXPANSION

DISHWASHING MACHINES

; ; # )

V

]

;

&~

]

<&$

&%$>V

6~

]

<&%$>"&

]

<&$>"

;

"

66

&V <~!> ;

X

6

;

15

"}<;}>C

;6

;

6

; ;};}

;

<>

6 ; ; }

;;

_

? 56

; 66 }6

6

;

;

_

?56

;}

; } ;

; ;

;

} ! ; 6 6 ;}

)/!8~

+;%&

TEMPERATURE-PRESSURE RELIEF VALVE

CAUTION

Water Damage Hazard

Explosion Hazard

Temperature-Pressure Relief Valve discharge

pipe must terminate at adequate drain.

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

T&P Valve Discharge Pipe Requirements:

Properly sized temperaturepressure relief valve must be

installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

6 * ; ;

_

? 56 <3

66>;

66

;

]

; ; ; ]

; ? 56 : )

);"

#)C~&~~!)88"]

;)B(

C " 3 66 ;

; ]

;

" ; ;

_

? 56 * 6 66 ;

; ;};

; } ; <&£&"$>

^

*

;

NOTE:C;

_

?56";

;;

6 " 6;

_

? 56 ! ;6;

;

_

?

56;

V";

_

?56;

;6;

;

_

? 56 ;

66C}

<&~;>6]

"

} C ; ;;

;]

^

;6

;

;(}6"6$<'&8;>"

;

66

# 66 ;

_

?56+

<&~ ;>

6 6 X

" " ;"66;

]

]

; ; C

;";

;

16

Shall not be smaller in size than the outlet pipe size of the

66"6

)

)};

);

);

;

_

?56

B

;;};

;}6

}

C;"

;;;

]

)666

66

Burn hazard.

Hot water discharge.

Keep clear of TemperaturePressure Relief Valve

discharge outlet.

The Temperature-Pressure Relief Valve must be manually

!

<&>

;

_

? 56 " <~> ;

X

; ; }; C

;

66" ; ";;

" ;

";

_

?56

*

NOTE: The purpose of a Temperature-Pressure Relief Valve is

6}6;

3 66 ;};};

;;}"

!);;(}&

C

6]

;

_

?56

; 6 ;

CONDENSATE DRAIN

COMBUSTIBLE MATERIAL STORAGE

6 ;

]

};

!;}

; ;

6 6 " V

' C }

<6>

^

(}

;

; " ^ (}

)

; ^ (}

V

; ; /!+" V

!&

NOTE:C^(}

V

;6

;/!+"

EXHAUST (VENT)

ELBOW

CLEANOUT

PLUG IS

REMOVED

TO CLEAR

DRAIN

CONDENSATE DRAIN

LINE CONNECTION

Fire or Explosion Hazard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Read instruction manual before

installing, using or servicing

water heater.

;

;"

;;6]

CONDENSATE DRAIN

LINE - FIELD INSTALLED

CONTAMINATED AIR

Breathing Hazard - Carbon Monoxide Gas

FACTORY INSTALLED

CONDENSATE TRAP

Install water heater in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near water heater.

BUILDING

DRAIN

Figure 9

CONDENSATE DRAIN WATER TRAP

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

!

6;;

;

; 6 )

;

}

Breathing Hazard - Carbon Monoxide Gas

Ensure a functioning water trap is

installed in the condensate drain.

!;

; ; ;

" " ; ;

;

"6;

;

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

DO NOT ;6 " V

' 6 6 6

; ) ! +

C$

CONDENSATE PH LEVEL

; 6 ;

6 : 6 8$ C ;;6

]

NOTE:/:6+;

" " )

!+C$

17

+

;C"

;

;;

;

6 6

; <) ; ; ; >

C

""

;" _6 ]

;";6<>

+5

;

6;

;

)5C~~

UNUSUALLY TIGHT CONSTRUCTION

AIR REQUIREMENTS

C

";]

6 ;

" 6

:6"

<

};" " 6 " " 6

">;

6

;

!)

Breathing Hazard - Carbon Monoxide Gas

Install water heater in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near water heater.

CONFINED SPACE

!)6

;IS LESS THAN

&"^

*<8;>

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

V]

;

;

6;

6

=;

6;

"

6

]

;

6

AND the total Btu/hr input rating of all

DIRECT VENT APPLIANCES

;

; ; )

"

;

;"

;

;"

}

+5

6

;

;

;

^

*

;6

+ ]

;

6

; !

)

EXHAUST FANS

#6

6C

6

]

"

V

6

;

;

}

;"

X

UNCONFINED SPACE

J)6

;IS NOT LESS THAN

&"^

*<8

;>

?;

;;

"

" " B

]

; }

"

6 ;" ; ]

6;

"6

18

}

"6

}

}

; " 6 ;

6 ;; ]

;;}

J ;

6;

;

)"

;

};

C}

LOUVERS AND GRILLES

6"

]

;

" 6

6

" ]

6

6

"

;

66~;

6

6%#;

6

}

FRESH AIR OPENINGS FOR CONFINED SPACES

"

; ; 6 ;

" 6 ;

6 DO NOT refer to these illustrations for the purpose of vent

) 5 C ~~ ;

6

OUTDOOR AIR THROUGH TWO OPENINGS

6;";;&~

<$;;>

"6

) V

&& 6 &<~;;>;<

;;>;

;;

;;

6

;;

6;;

;

& &]

$^

*<%;;~>

"

~ #

;6

OUTDOOR AIR THROUGH TWO HORIZONTAL DUCTS

Figure 10

6 ;

";;&~<$;;>

;;&~<$;;>;

;;

)V

&

(6;;

;&]

8"^

*<;;~>

(

&]

<8;~>

Figure 12

6 ;

";;&~<$;;>

;;&~<$;;>

;

;;

)V

&~

(

6;;

;&]

~"^

*<&&;;~>

OUTDOOR AIR THROUGH ONE OPENING

";

;;

;;

$

Figure 11

19

OUTDOOR AIR THROUGH TWO VERTICAL DUCTS

AIR FROM OTHER INDOOR SPACES

;

6 DO NOT refer to these illustrations for the purpose of vent

) 5 C ~~ ;

6

Figure 14

6 ;

";;&~<$;;>

;;&~<$;;>;

)V

&8

Figure 13

6;6

";;&~<$;;>

;;&~<$;;>;

6

;;

)V

&$

(

6;;

;&]

8"^

*<;;~>

";

;;

;;

$

20

( ;;

;<>

6

;;6

;

;J)

(6;;

;&]

&" ^

* <&& ;;~ > (

&]

<8;~>

INSTALLATION REQUIREMENTS - COMMONWEALTH OF MASSACHUSETTS

COMMONWEALTH OF MASSACHUSETTS

INSPECTION

V;"66"

6"6

6"

"

!;;}

6;

6 <%> 6 6"

;"

]

;

6 ]

; 6 " " 6 ;}

6~8!B?<~><>&

8

INSTALLATION OF CARBON MONOXIDE DETECTORS

; 6

]

;" ; 6 ;} ;_

6

]

;C"

; 6 ;};

6 " 66

]

;

C

6]

;}

C 6 6 ]

;"

;};_

;

}X6

C 6 ]

; 6 ;;;"

6 <$> ; 6

]

;6

<$>"

;};

APPROVED CARBON MONOXIDE DETECTORS

(;}]

66;#V%~#)C*

J/~$8!)

SIGNAGE

; ;

;

} ;;

; <>6}

6

;6

]

;"_

<&*~>"“GAS VENT DIRECTLY BELOW. KEEP

CLEAR OF ALL OBSTRUCTIONS.”

21

EXEMPTIONS

]

; }; ; ~8 !B? <~><>&

8

& ]

;!&(]

;#

?]

^5;

#V

8^

~ 6 6 ]

;;

;

" " MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM PROVIDED

;

6 6 ]

; 6 6 ;

6 ; ; ]

;" 6;

]

;6;

& +

6;

6;;

~ ;6;6

;

MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED

;

6 6 ]

; 6 6

" 6

;" ]

; ;

& 6 ; ]

;

~ 6;

6

^"

;

6

6 ]

;" 6

" 6 " * 6 ; ]

;;

VENTING INSTALLATION

6]

;

+5

~ C "

" ;" ]

;;

;6 <> +

5 ;

6

;

;

Breathing Hazard - Carbon Monoxide Gas

, Install vent system in accordance with codes.

, Do not operate water heater if flood damaged.

, Special consideration must be taken with installations

above 10,000 feet (3,048 m) refer to high altitude

section of this manual.

$ 6;

;

, Do not operate if soot buildup.

, Do not obstruct water heater air intake with insulating

, Do not place chemical vapor emitting products near

8 ;;

;;;

;

6<}

>5

;

;

<X>

, Gas and carbon monoxide detectors are available.

, Never operate the heater unless it is vented to the

;

;

,

6<}

>;

;

6;;

jacket or blanket.

water heater.

outdoors and has adequate air supply to avoid risks

of improper operation, fire, explosion or asphyxiation.

Analyze the entire vent system to make sure that

condensate will not become trapped in a section of

vent pipe and therefore reduce the open cross

sectional area of the vent.

% ;

;

Breathing carbon monoxide can cause brain damage or death.

Always read and understand the instruction manual.

/6<}

>

;;};

;]

6

)5?]

;~8

#6

6

' +6;

;

;

6;

)

;

;"

}

GENERAL VENTING INFORMATION

6 ;

]

6 ! C5 ; 5+5

CATEGORY IV APPLIANCE

! C5 6 6 <}

>

6 ;

6

POWER VENT CONFIGURATION

5 6 ;

; ;

; 6 <}

> 6

66

;6

;)V

8V

8&$8

DIRECT VENT CONFIGURATION

+5

6;

;

;

; 6<}

>+5

6

" 6 + 5 ;

};)V

8~$8

V

8%$

GENERAL VENTING INSTRUCTIONS

;

& DO NOT 5

]

"

?]

;&C

22

&5;

;;

;&*8

<>

&&+6;

"

66;;

&~J66*;

)5?]

;~8

&$J 6 ;)5?]

;~8

&8+ 6 <}

> ;

X ;<>

;

&+6

"

;"

?

" ;

} ;

6 6

" ; ;

6;

&+6;6

6

&%(

;

66;

&)6*

; C ; ";6

";";

;;

}

C;;

&'(

^:&''*~;"~$

~!

5?]

;~8

5C)]

~

BTH 199 & BTH 250 INTAKE AIR CONNECTION

^: &'' ^: ~ ; ]

]

!;

^

$}$}&*~

&*~

^C

"V

&

FACTORY INSTALLED

INTAKE AIR TEE FITTING

&*~ };&$

6 ; " V

&

&*~ ;

< > " ' " 6 INSPECT/ADJUST INTAKE AIR TEE FITTING

COMBUSTION BLOWER

C &*~ 6;"V

&C

&*~

"X

;X

Adjustment Procedure:

& (

*

1/2 INCH

BRANCH

HOSE BARB FITTING FOR

BLOCKED INTAKE AIR

SWITCH SENSING TUBE

~ +^C

"

V

8'

FERNCO

COUPLING

$ / ; V !;

"V

&%

COMBUSTION BLOWER ASSEMBLY

199,000 & 250,000 Btu/hr MODELS

8 X

&*~

V

&

Figure 15

? ; !;

^

V

"

(

IS NOT

<&_>6

;

'

;&$V

&C

" ; ^ C ;

^C

;

?^C

;

LARGE HOSE

CLAMP

FERNCO

COUPLING

90° TO 130°

3 INCH PVC

INTAKE AIR

TEE FITTING

INTAKE AIR CONNECTION PIPE

199,000 & 250,000 Btu/hr MODELS

Figure 17

END VIEW

CORRECT ORIENTATION

INTAKE AIR TEE FITTING

Figure 16

~$

VENTING REQUIREMENTS

MINIMUM EQUIVALENT LENGTHS

APPROVED MATERIALS

Three Inch Pipe

66;;

J)

6 ;

;;

; $ 6 <}

> %

]

6 <~& ;> ;;

; ]

6 ]

;

5!)

8<)B+~~8&*!)^&&~")B+

&%*!)^&$%$

!5!)

8<)BV_8&&*!)^&$%>

^)<)B+_~&>

66;;

!

J/!)$5!*!5!

Four Inch Pipe

6 ;

;;

; 8 6 <}

> ]

6 <&~ ;> ;;

; ]

6 ]

;

MAXIMUM NUMBER OF ELBOWS

FIELD SUPPLIED FITTINGS

Three Inch Pipe

V

]

6;

V*

]

6

6

* ;

]

6

6;6;};

;

'

$ ; 6;};

;

'C(+5

6

'

'<

>]

6

<&~;>

8<

>]

6~

<%;>

PRIMER AND CEMENT

6;6;};

;}'

8 ; 6;};

;}'C(+5

6

}'

Four Inch Pipe

FACTORY SUPPLIED FITTINGS

<:V> ; 6C!5!^)

";;

X" X 6

; <5! ;> 5! B )B

+_~8W!;!5!B

)BV_8'$

W !; ^) B )B +_~~$

W!;

PIPE SIZE REQUIREMENTS

6;

$86<}

>

C]

66

<&~;>"$;

C

]

6;<&~;>"8

;

NOTE:C]

]

6

C(C

]

66;

]

6;

$

6;

8

MAXIMUM EQUIVALENT LENGTHS

Three Inch Pipe

6 ;

;};

; $ }

6

; ]

6 <&~ ;> ;};

; $ ]

6 <&~ ;> C( = + 5 ]

6<&~;>

Four Inch Pipe

6 ;

;};

; 8 }

6

; &~ ]

6 <$ ;> ;};

;8&~

]

6 <$ ;> C( = + 5 &~]

6<$;>

24

<~> $ ; <5! 8 > V

6 ; ; ;

V ; <}

> ]

66

TABLE 7

Number of

90° Elbows

Installed

=<&>

3 Inch Pipe

4 Inch Pipe

Maximum Feet (Meters)

Maximum Feet (Meters)

8<&$%;>

&&<$;>

<~>

8<&~~;>

&&<$$;>

<$>

$<&%;>

&<$~;>

V

<8>

$<'&;>

&<$;>

V6<>

N/A

'<~';>

)}<>

N/A

'<~%8;>

4 INCH EXTENDED VENT TERMINATIONS

86"

8

;;

!

;<

;6

;

>8;<>

OPTIONAL CONCENTRIC TERMINATIONS

6;

;

+5

8;

! ; ;

!

;

;

6;

Concentric Vent Termination Part Numbers:

8!;¤'$~

VENTING INSTALLATION SEQUENCE

& ? W 5 C

~~ 5?]

;~8

]

; ;

~ +; 5 + 5 6

;;

)

6

6;$8$

$

' 6<}

>;

;;

;&*8

<

>

&C $ 6 6 }

&&C8$}

V

&

$ }

8 }

$

&<8;>

DIRECT VENT INSTALLATION

5C~

+5C~

POWER VENT INSTALLATION

& ? W 5 C

~~ 5?]

;~8

]

; ;

5

~ +; 5 ; 6;)V

8V

8&$8

$ +;6"5

?]

;~8

8 6 ; ; /

6

;;

;

C;

C6;6"

"

5;C~%

C 6 ; " ");C~'

; ; 6

% 6;

6

;

;;

6

6<&~;>6

6$<'&;>

+6;

4” PIPE FIELD

SUPPLIED

& ? W 5 C

~~ 5?]

;~8

]

; ;

+ 5

~ +; + 5 ; } <> + 5 ;

)V

8~3V

8$$8V

88

V

8%$

$ +; 6 5?]

;~8

8 6

; ; /

6 ;;

; C;

C ; 6 ; 6" " 5;C~%

C;

6;"

"

);C~'

C ;<> !

;C$

;<> ; C

6

% 6 ;

6 ;

;;6

6<&~;>6

6$<'&;>

+6;

' ;6

;

} ; ]

;

)V

~&~

4” x 3” REDUCER

FIELD SUPPLIED

3” PIPE FIELD

SUPPLIED

NOTE:)

;}6;

;

;;;"

;

}6

;;;

EXHAUST ELBOW

VENT CONNECTION

FACTORY INSTALLED

VENT (EXHAUST) CONNECTION

&6<}

>;

;;

;&*8<

>

Figure 18

25

&&C $ 6 6 }

&8C$

&~C 8 6 $ }

V

&

~$}

8}$

&<8;>

&C8$

V

~$

8 } $ &

<8;>

&$(

C)C!

;6

)V

&'

4” PIPE FIELD

SUPPLIED

3” PIPE FIELD

SUPPLIED

3” PIPE FACTORY

INSTALLED

INTAKE AIR

Breathing Hazard - Carbon Monoxide Gas

Do not obstruct water heater air intake.

4” x 3” REDUCER

FIELD SUPPLIED

Gas and carbon monoxide detectors

are available.

INTAKE AIR CONNECTION

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

Figure 20

NOTE: + 6 C ! + 5 = ;6

;;6;

; ;

; ^ C

;

120,000 & 150,000

Btu/hr MODELS

COMBUSTION

BLOWER

3” COUPLING OR TEE

FACTORY INSTALLED

INTAKE AIR CONNECTION

INSTALL TEE FITTING AS CLOSE TO WATER HEATER

INTAKE AIR CONNECTION AS POSSIBLE

FACTORY

INTAKE AIR

CONNECTION

INTAKE

AIR

PIPING

FIELD SUPPLIED

3” x 3” x 1/2” TEE

WITH HOSE BARB

FITTING INSTALLED

199,000 & 250,000

Btu/hr MODELS

CONNECT FIELD

SUPPLIED FLEXIBLE

DRAIN HOSE TO BARB

FITTING AND FORM A

LOOP WATER TRAP IN

DRAIN HOSE

INTAKE AIR SCREEN

RUN DRAIN HOSE

TO SUITABLE FLOOR

DRAIN SEPARATELY

FROM OTHER

CONDENSATE DRAINS

3 INCH INTAKE AIR CONNECTIONS

FACTORY INSTALLED

INTAKE AIR SCREEN

INTAKE AIR CONDENSATE TEE INSTALLATION

(remove for Direct Vent)

Figure 19

Figure 21

26

6;;

6;;

;

~8<&;>;

V

~~C;

8<&~~;>

VERTICAL TERMINATION INSTALLATION

& +;;<>

NOTE:6;

"V

~~

~ C 6 <}

> 5

6 } 6 ]

; V

~$V

~8~;

;

;

NOTE:=6;;

;;

;~8<;>6"6

&<$;>)V

~8~

$ C 6 + 5

6 } 6 ]

; V

~$V

~8~;

;

;

NOTE: = 6

;;

;;

;~8<;>6

" 6 & <$ ;>

)V

~8~

8 C 6 5 6

;

6;;

V

~$V

~8~

;6;;

;;

;

&~<$;>"&<8;>!"6

6}6V

~$

~

C 6 + 5

6 ;

6;

;

V

~~

6;;

;V

~

~

; 6 ;

;

;;

;&~<$;>"&<8;>

!" 6 6 } 6 V

~$V

~~

* 6 ; ;

; ; 6

; }; *

C;

};*

6 ; ;

;;

; ~8 <& ;>

V

~ ~ C ; 8 <&~~

;>

% !

8<&;>;$

<&$;>;8<>

NOTE:^

)

<> ;]

6

;

V

~$~

' ) ]

6 6 ]

6 V

~$" V

~8 V

~~

&C

*6;<>

' V

~$~

'

;;

}6

} ; ~

<;>"V

~$~

&&?

5C~+5

C~;

* 6 ;<> INTAKE AIR TERMINATION

45° ELBOW WITH

DOME SHAPED DEBRIS

SCREEN

VENT TERMINATION

45° ELBOW WITH

RECESSED DEBRIS

SCREEN

STANDARD FACTORY SUPPLIED TERMINATIONS

Figure 22

27

2” (5 cm)

MAXIMUM

24 INCHES (61 cm) MINIMUM

48 INCHES (122 cm) IN COLDER CLIMATES

FACTORY SUPPLIED

STANDARD TERMINATION

POINTED DOWN TOWARDS

THE GROUND

FIELD

SUPPLIED

90° ELBOW

FIELD

SUPPLIED

90° ELBOW

NOTE: INTAKE AIR

TERMINATION

SHOWN HERE

FIELD SUPPLIED

PLUMBING

ROOF BOOT

OR FLASHING

INTAKE AIR

TERMINATION

VENT (EXHAUST)

TERMINATION

FACTORY SUPPLIED

STANDARD TERMINATIONS

POINTED DOWNWARD

MAINTAIN 12” (30 cm)

18” (45 cm) FOR CANADA

MINIMUM CLEARANCE

ABOVE HIGHEST

ANTICIPATED SNOW LEVEL.

MAINTAIN 12” (30 cm)

18” (45 cm) FOR CANADA

MINIMUM CLEARANCE

ABOVE HIGHEST ANTICIPATED

SNOW LEVEL.

FIELD SUPPLIED

PLUMBING

ROOF BOOTS

OR FLASHINGS

VERTICAL TERMINATION - DIRECT VENT

STANDARD TERMINATIONS

FIELD

SUPPLIED

STRAP/SUPPORT

Figure 25

VERTICAL TERMINATION(S) INSTALLATION

INTAKE AIR AND/OR VENT (EXHAUST)

Figure 23

IF LESS THAN

10 FEET (3 m)

24 INCHES (60 cm)

MINIMUM HEIGHT ABOVE

NOTE: VENT

TERMINATION

SHOWN HERE

INTAKE AIR AND/OR VENT

TERMINATION(S) MUST BE A

MINIMUM OF 24 INCES (60 cm)

ABOVE ANY PARAPET, VERTICAL

WALL OR STRUCTURE WITHIN

10 FEET (3 m) HORIZONTALLY.

VERTICAL TERMINATION(S) FLAT ROOF CLEARANCE

INTAKE AIR AND/OR VENT (EXHAUST)

Figure 24

28

% !

8<&;>;$

<&$;>;8<>

SIDEWALL TERMINATION INSTALLATION

& +;;<>

NOTE:6;

"V

~~~%

NOTE:^

~ C 6 <}

> 5

}

]

; ;"

V

8 $" ; ;

;

!

<> $ <' ;>

'<~8&;>

)V

~%

$ C 6 + 5

}

]

;;"

V

8'$%"6;

;

;

;

8 C 6 ; + 5 ;

;;

; ~8 <& ;> " ;

6 " 6

;"V

~

NOTE:C;

8 <&~~ ;> 6;6

;

_ 6 ; }

6;;;

!

C6;+

5 6 ; ;

; 6

;

_V

~

VENT (EXHAUST)

TERMINATION

INTAKE AIR

TERMINATION

NOTE: 5 ; ¥ }

&8VC;6

}

6

6}

6

} 6 ; 6 (}}6

;};

;<&~;>;6

; 6 ;"6;6

"5;C~%

' !;*6;<>

6)

&)

;<>6<>

* 6 ; ;

< > <>

&& ; " ;<>

;6

(

;<> )

V

~%

METAL PLATES

INSTALL INSIDE

AND/OR OUTSIDE

FROM

WATER

HEATER

ELEVATION

INSTALL ON

INCREASE EXPOSED VENT

PIPING UP TO A MAXIMUM

OF 6 INCHES (15.2 cm) FROM

WALL TO HELP PREVENT VAPOR

FROM DISCOLORING THE WALL

SURFACE IN COLDER CLIMATES

FACTORY SUPPLIED

STANDARD TERMINATION

POINTED DOWN

TOWARDS THE GROUND

COUPLING

CENTERLINE

INTERIOR WALL

KEEP INTAKE AND VENT

TERMINATION SCREENS

CLEAR OF DEBRIS

EXTERIOR WALL

SIDEWALL TERMINATION INSTALLATION

INTAKE AIR AND/OR VENT (EXHAUST)

24 INCHES (61 cm) MINIMUM

Figure 27

48 INCHES (122 cm) IN COLDER CLIMATES

&~

<

>

<>

<>

SIDEWALL TERMINATION - DIRECT VENT

STANDARD TERMINATIONS

&$

Figure 26

* 6 ; ;

;;

"

6 ; }; _ *

;

};_*

:6"6

; ;

;;

; ~8 <& ;>

C;

8<&~~;>)V

~

29

&8 ; <> 6<>

&C

<>

^ ; ; ;<> )V

~%

&?

5C~+5

C~;

* 6 ;<> CONCENTRIC TERMINATION INSTALLATION

& ! ; ;

^:

&~_~;;

8;

#

;'$~!

;

;6

;

;

~ +;;

NOTE:?;

;"

;

666

$ ;6

}6]

;

;"V

$$&

;

;

;

8 ;6

";6;

;;

;&

<$;>;"6

V

~

NOTE:C]

&<$;>"

6 ;" ; ;

) 5 ;

C~%

;

} ]

; ;" V

8' $%" ;

;

;

;

; 6

]

;

;

;;)$~$$

;;

% !

<&$;>;8

;;

NOTE:^

;

; 6

; ; ; ;

; ;

;

)B

!;

;$$

' +; ; ;; ]

6;

;

; 6 ;

CONCENTRIC TERMINATION(S)

MUST BE A MINIMUM OF 10 FEET

(3 m) AWAY FROM ANY PARAPET,

VERTICAL WALL OR

STRUCTURE.

) V

~' $& ;};

; ;;

;

8;

} ;

DO NOT ; ; ;

;

;6;

;;

};

J )+?_~ } 8 ;

; ;

< > !

;;

;<6>

4 INCH CONCENTRIC TERMINATION

FLAT ROOF CLEARANCE

& 8 C ! ; C $&

Figure 28

$

86_

;

8}

$ $ <&

>!;

4 INCH CONCENTRIC TERMINATION INSTALLATION

INTAKE AIR CONNECTION

3 INCH PVC

3” x 3” x 4”

Y FITTING

INTAKE AIR PIPE

VENT CONNECTION - 3 INCH PVC

VENT PIPE

' ?

+5C~;

6 ;

VENT

VENT CAP

VENT PIPE IS 2 1/2 INCH SDR-26 PIPE

SUPPLIED LENGTH 37 INCHES (94 cm)

MAXIMUM ALLOWABLE LENGTH 73 INCHES (185 cm)

MINIMUM ALLOWABLE LENGTH 25 INCHES (64 cm)

COMBUSTION

AIR

INTAKE AIR PIPE IS 4 INCH SDR-26 PIPE

SUPPLIED LENGTH 24 INCHES (60 cm)

MAXIMUM ALLOWABLE LENGTH 60 INCHES (152 cm)

MINIMUM ALLOWABLE LENGTH 12 INCHES (30 cm)

MAINTAIN 12” (30 cm)

18” (45 cm) FOR CANADA

MINIMUM CLEARANCE

ABOVE HIGHEST ANTICIPATED

SNOW LEVEL. MAXIMUM OF

24” (60 cm) ABOVE ROOF.

ROOF FLASHING

(field supplied)

INTAKE AIR PIPE

Y FITTING ASSEMBLY

STRAP

(field supplied)

NOTE: SECURING STRAP

MUST BE FIELD INSTALLED

TO PREVENT MOVEMENT

OF TERMINATION KIT

VENT CAP

VENT PIPE ASSEMBLY

VENT

PIPE

4 INCH CONCENTRIC TERMINATION KIT

FOUR PIECE KIT - FIELD ASSEMBLY REQUIRED

Figure 29

INTAKE

AIR PIPE

4 INCH CONCENTRIC TERMINATION

VERTICAL INSTALLATION

;8;?

V

~'"V

$V

$&

Figure 30

& !;@;

~ )@;;

; (

; ;

;

$ )

@;

;]

6

;

8 = ;6@

;

NOTE: SECURING STRAP MUST BE

FIELD INSTALLED TO PREVENT

MOVEMENT OF TERMINATION KIT

IN SIDEWALL.

VENT

PIPE

COMBUSTION

AIR

STRAP

(field supplied)

VENT

)

;

!;66_

;

~

; ; ;

6

;*6*6

% C6*6;@

;"(

;;6;

;@

$ 6 ; ;

$&

1 INCH

MAXIMUM

INTAKE

AIR PIPE

4 INCH CONCENTRIC TERMINATION

SIDEWALL INSTALLATION

Figure 31

MULTIPLE CONCENTRIC TERMINATION CLEARANCES

Four Concentric Terminations

;

;6

]

<> ; ;

(

;

; ]

& ;

};;

V

$8

V

$

NOTE: ;

; 6 6<}

>!

;

;

~ V

;};

;

;;

; ; };V

$8

A

;

; V

$~ ;

;

CONCENTRIC

TERMINATION

CAPS END VIEW

A

)B

!;;$$

Close Proximity & Standard Clearance

& ;

;;

<

>;};

;~<;>";

_V

$~";

};)V

$%$$

A = 0 - 2 INCHES (0 - 5 cm)

CLOSE PROXIMITY

FOUR CONCENTRIC TERMINATIONS

(THROUGH A ROOF OR SIDEWALL)

~ ;

; ;

;;

;~8<&;>";^_

V

$~"};<6>

A

CONCENTRIC

TERMINATION CAPS

END VIEW

A

V

$8

CONCENTRIC

TERMINATION

CAPS END VIEW

CLOSE PROXIMITY

STANDARD CLEARANCE

A = 0 - 2 INCHES (0 - 5 cm)

B = 24 INCHES (61 cm)

OR GREATER

A = 0 - 2 INCHES (0 - 5 cm)

CLOSE PROXIMITY

B = 24 INCHES (61 cm)

OR GREATER

FOUR CONCENTRIC TERMINATIONS

TWO CONCENTRIC TERMINATIONS

(THROUGH A ROOF OR SIDEWALL)

(THROUGH A ROOF OR SIDEWALL)

V

$

Figure 32

Groups Of Terminations

Three Concentric Terminations

& ;

;;

};;V

$$

~ C }; ; ;;

;^V

$$

A

A

B

OR

CONCENTRIC

TERMINATION

CAPS END VIEW

B

& ;

;

};

V

$/

V

$;

; 6 ; ;

6

A

B

B

CONCENTRIC

TERMINATION

CAPS END VIEW

A

A

THIRD

TERMINATION

A = 0 - 2 INCHES (0 - 5 cm)

CLOSE PROXIMITY

A = 0 - 2 INCHES (0 - 5 cm)

CLOSE PROXIMITY

B = 24 INCHES (61 cm)

OR GREATER

B = 24 INCHES (61 cm)

OR GREATER BETWEEN

GROUPS OF FOUR

THREE CONCENTRIC TERMINATIONS

EIGHT CONCENTRIC TERMINATIONS

(THROUGH A ROOF OR SIDEWALL)

(THROUGH A ROOF OR SIDEWALL)

V

$

V

$$

$~

MULTIPLE CONCENTRIC TERMINATION ARRANGEMENTS

Four Concentric Terminations

; ; ;

; V

;;};

V

$)V

$8V

$$~

; ;

)B

!;!$~

; ;

SIDEWALL

NOTE: ;

; ;;;

;;

;

Two Concentric Terminations

;;};

V

$% ;)V

$~$~

; ) V

$$ $~ ;

SIDEWALL

ROOF

Figure 38

Eight Concentric Terminations

ROOF

( ; ; " };" V

$' )

V

$$~;

/

V

$$~;

;6;;

6

SIDEWALL

Figure 37

ROOF

Figure 39

$$

VENTING ARRANGEMENTS

Power Vent Vertical

Figure 40

Power Vent Horizontal

Figure 41

Direct Vent Vertical

Figure 42

Direct Vent Horizontal

Figure 43

$8

VENTING ARRANGEMENTS

Direct Vent Vertical Vent Horizontal Intake

Figure 44

Direct Vent Horizontal Vent Vertical Intake

Figure 45

Direct Vent Vertical Concentric

Figure 46

Direct Vent Horizontal Concentric

Figure 47

$

TERMINATION CLEARANCES SIDEWALL POWER VENT

POWER VENT

(using room air for combustion)

EXTERIOR CLEARANCES FOR SIDEWALL VENT TERMINATION

G

V

D

H

A

v E

L

v

B

FI XE D

CLOSED

V

OPERABLE

F

B

B

C

V

OPERABLE

V

B

FI XE D

CLOSED

M

K

J

A

X

V

X

V

B

V

B

V

X

VENT TERMINAL

AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

Figure 48

CANADIAN INSTALLATIONS

A

!6"

6"" &~<$;>

B

!

;

1

<&;>

&"^

*<$>"&~<$

;>&"

^

*<$>&"^

*<$

>"$<'&;>

6&"^

*<$>

US INSTALLATIONS

2

&~<$;>

8<&~;>

&<$;>6

opening

CANADIAN INSTALLATIONS

H

I

1

US INSTALLATIONS

!

}

above meter/regulator

assembly

$<'&;>

$<'&;>&

&<8;>

<8;>6;*

above the meter/regulator

regulator assembly

assembly*

!6

regulator vent outlet

$<'&;>

<&;>

&"^

*<$>"&~

<$;>

&"^

*<$>&"

^

*<$>"$<'&;>

6&"^

*

<$>

<&$;>

C

!

;

&~<$;>

&~<$;>

J

!

;

;

D

5

6

above the terminal

&~<$;>

~<&

;>;

of the terminal

&~<$;>

K

!

;

inlet

E

!

6

&~<$;>

&~<$;>

L

!66

6

%<~&$;>

6

F

!

~<;>

~<;>

M

!

6""" &~<$;> G

!

&<8;>

&<8;>

$<'&;>

8<&~;>

&

<$;>6

$<'&;>6

&<$;>

%<~&$;>

&~<$;> &C

!)^&8'&"#

WC!

~C

#)C~~$&*#V8"#V

W!

6;666;6

;6"""

;;

;

!]

;

;

$

2

TERMINATION CLEARANCES SIDEWALL DIRECT VENT

DIRECT VENT

(using outdoor air for combustion)

EXTERIOR CLEARANCES FOR SIDEWALL VENT TERMINATION

G

V

D

H

A

v E

L

v

B

FI XE D

CLOSED

V

OPERABLE

F

B

B

C

V

OPERABLE

V

B

FI XE D

CLOSED

M

K

J

A

X

V

X

V

B

V

B

V

VENT TERMINAL

X

AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

Figure 49

CANADIAN INSTALLATIONS

1

A

!6"

6""

B

<&;>

&"^

*<$>"&~

<$;>

!

&"^

*<$>

;

&"^

*<$>"$

<'&;>

6&"^

*<$>

&~<$;>

US INSTALLATIONS

2

CANADIAN INSTALLATIONS

1

US INSTALLATIONS

!

$<'&;>&

}

<8;>6;*

above meter/regulator

regulator assembly

assembly

$<'&;>

&<8;>6

meter/regulator assembly*

I

!6

regulator vent outlet

$<'&;>

$<'&;>

<&;>

J

!

;

;

<&;>

&"^

*<$>"&~

<$;>

&"^

*<$>&"

^

*<$>"$<'&;>

6&"^

*

<$>

<&;>

&"

^

*<$>"'<~$

;>

&"^

*<$>

"^

*<&>"&~

<$;>

6"^

*<&>

<&$;>

$<'&;>6

&<$;>

&~<$;>

<&;>

&"^

*<$>"

'<~$;>

&"^

*<$>

"^

*<&

>"&~<$;>

6

"^

*<&>

H

C

!

;

D

5

6

6;

&~<$;>

~<&;>;

;

&~<$;>

K

!

;

inlet

E

!

6

&~<$;>

&~<$;>

L

!6

6

%<~&$;>

66

%<~&$;>

F

!

~<;>

~<;>

M

!

6"""

&~<$;>

G

!

&<8;>

&<8;>

<&;>

2

&~<$;> &C

!)^&8'&"#

WC!

~C

#)C~~$&*#V8"#V

W!

6;666;6

;6"""

;;

;

!]

;

;

$%

WATER HEATER INSTALLATION

&*~5!

CONDENSATE DRAIN INSTALLATION

C ;

; $ DO NOT;6";

V

;]

& (

*

65!;5!;

&*~5!_;;

;]

&*~5!<

>

!

+;

V;

INSTALLATION NOTES

~ C &*~ 5! !+

"V

V

&

INSTALLATION INSTRUCTIONS

$ ;6

(

}

;<&~;>6

"}

"V

NOTE: C ; ;; ;

& ; 6

6:68$C

;;6

]

/:6+;

" " 8 (

66

"V

&

^;

6

(

" )J~

~ ;

CONDENSATE DRAIN

LINE - FIELD INSTALLED

EXHAUST (VENT)

ELBOW

CLEANOUT PLUG SHOULD

FACE TOWARDS THE FRONT

OF THE WATER HEATER FOR

SERVICE ACCESS

FACTORY INSTALLED

CONDENSATE TRAP

DRAIN LINE TO

TERMINATE NO

MORE THAN 6

INCHES (15.2 cm)

ABOVE DRAIN

BUILDING

DRAIN

Figure 50

PVC PIPE NIPPLE

½” NPT

PVC BUSHING

1 ½” SLIP x ½” SLIP

PVC TEE FITTING

1 ½” SLIP x 1 ½” SLIP x ½” NPT

½” PVC 90° ELBOW

CONDENSATE DRAIN

CONNECTION. FIELD

INSTALLED DRAIN

LINE CONNECTS HERE

PVC BUSHING

1 ½” SLIP x 1 ¼” NPT

½” PVC PIPE NIPPLE

PVC PIPE PLUG

1 ¼” NPT

½” PVC 90°

STREET ELBOW

CLEANOUT PIPE

PLUG SHOULD

BE ORIENTED TO

THE FRONT OF THE

WATER HEATER FOR

SERVICE ACCESS

CONDENSATE TRAP DETAIL

Figure 51

$

SUPPLY GAS LINE INSTALLATION

GAS LINE SIZING

!

;

]

6 6 6 DO NOT

}

^

;

]

;

]

; ; C ;

";6

;

B;

;]

&8+6]

6*

;;;;"

;6

) *; <>

'6

6'

!<&~>

"

;

;#

SUPPLY GAS LINE SIZING U. S. UNITS

Fire and Explosion Hazard

TABLE 8

Do not use water heater with any gas

other than the gas shown on the rating

label.

Excessive gas pressure to gas valve can

cause serious injury or death.

Turn off gas lines during installation.

Contact a qualified installer or service

agency for installation and service.

LENGTH

#=?B/C?=#C()C()<C#!:()>

IN

INPUT IN THOUSANDS BTU/HR

V((

&*~

$*8

&

&&*8

&&*~

~

10

175

$

680

1400

2100

$'

20

120

250

485

950

1460

2750

$

97

200

$%

770

1180

2200

B

;

40

82

170

$~

660

990

1900

50

%$

151

285

580

900

1680

6 ;

&!<~~>

&8 ! <$8' > "

8&86;

]

; ]

(}

; ;

}

C6

;

;

;

66 ;

`

)6

60

66

&$

260

$

810

1520

70

61

125

240

490

750

1400

80

57

118

220

460

690

&$

(

6666

; ;"5;

;

C ; 66 ;

;)

;

;

"}C

;

6

REGULATED GAS

SUPPLY LINE

MAIN GAS

SHUTOFF VALVE

TEE FITTING

SEDIMENT TRAP

(DIRT LEG)

PIPE CAP

Figure 52

(

;

;

<>;

V

~;

;

X C ;; ;

$'

90

$

110

205

8$

650

1220

100

50

&$

195

400

620

1150

125

44

'$

175

$

550

1020

150

40

84

160

$~

500

950

175

$%

77

145

$

460

850

200

$

72

&$

280

8$

800

SUPPLY GAS LINE SIZING METRIC UNITS

TABLE 9

LENGTH

#=?B/C?=#C()C()<C#!:()>

IN

INPUT IN kW

METERS

&*~

$*8

&

&&*8

&&*~

~

$

51

105

199

410

615

1160

&

$

%$

142

278

428

805

'&

28

59

110

225

$8

644

&~~

24

50

94

&'$

290

556

&~

21

44

$

170

264

492

&$

19

40

76

155

~$%

445

~&$

18

$%

70

&8$

220

410

~88

17

$

64

&$

202

$&

~%8

16

$~

60

126

190

$%

$

15

$

57

117

182

$$%

$&

&$

27

51

105

161

299

8%

12

25

47

95

146

278

$$

11

~$

42

88

&$

249

&

10

21

40

82

126

~$8

GAS LINE CONNECTION

& 6;

;

$*8

;

;$*8"

&8!

~8

5 W 56 ]

;DO NOT

}

~ + 6 ]

6 * ;;;;"

; 6 " W

/)$'C

;

_

;;

;

V

$

NOTE: Make the transition to the larger supply gas line as

INSTALL A REDUCER

COUPLING WHEN A

LARGER SUPPLY GAS

LINE IS REQUIRED

J <) > 6

6

~85W56;

6 ;" ;

;

]

% C ; < > V

~ $'

Install a Main Gas Shutoff valve in the supply gas line as

V

~$'

NOTE:)

6

"

BW)

66

TO MAIN

BURNER

FLOW

FIELD INSTALLED

PIPE NIPPLE

8 J;XX

<

;

>

~85W56

66

DO NOT

<)>

;X;;;66

GAS LINE LEAK TESTING

24 VOLT

GAS VALVE

Fire and Explosion Hazard

Use joint compound or Teflon tape

compatible with propane gas.

SUPPLY GAS LINE CONNECTION

120,000 & 150,000 Btu/hr MODELS

Leak test before placing the

water heater in operation.

Figure 53

$ ;

< * >

;X+

;

J

;

]

;</*>

SUPPLY GAS CONNECTION

FACTORY INSTALLED

TEE FITTING

Disconnect gas piping and main

gas shutoff valve before leak

testing.

Install sediment trap in

accordance with NFPA 54.

;

;;

6}

LOW GAS PRESSURE

SWITCH

& V

}&*~<$8>

B W )

56 ; ; " V

~

$' ;

;

~ V

&*~<$8>"

" ;

; BW)

56

COMBUSTION

BLOWER

$ X

;

^

+

;"

";

SUPPLY GAS LINE CONNECTION

199,000 & 250,000 Btu/hr MODELS

8 ?

Figure 54

40

ELECTRICAL WIRING

6

;

;

# ( !" #)C*#V % !

(!"!)!~~&]

;

Connecting An External Supervisory Control

";

""

#(!"#)C*#V%!

(!"!)!~~&

C

;

";

&!

]

6"}

C

~!

;

POWER SUPPLY CONNECTIONS

?]

;)

&8

Correct Polarity:

; 6 6 ; ! ?6 V

; /!+ &~ 5! ;

;

X

}&~5!

;

X

}

;

;

& (

* ; !!^ § !!^

"

!!^

V;<>X

;

&&§

"V

%§

C*

& * ~ /!!^

$ ?;6 ; !!^ 6 !!^

#

66

8 6*

)&

!!^"V

%

)&¤~

)&¤$

/ X

; && !!^§

"V

%V

!

X

;;

% )};&*~

;

X

;

~ ?;6X

}6)

X

}

J X

;

$ !&~5!;

X

}

);V

V

%'

' !!^

!!^

6

(

6

(

8 !&~5!

;

X

}

);V

V

%'

! ; X

} ) ;

V

V

%'

? X

} 6 ;

NOTE:+

;

ENABLE/DISABLE CIRCUIT

6 ;

]

* }

6 ; ^

B;);*

;

;

* ;

6 )&!!^<

>"V

%V

!!^ <6>

}

NOTE: * + } 6 <C( > ; !!^ 41

&?!!^

6

&&?

X

} " X

}J6_

X

}

&~C ]

X

} } 6 !

;}

X

}

&$! }V;

;

&8?

NOTE: 6 } " 6

}

"

6;;;

))

C

&&8

NOTE: (

; ;

+; ;

6

;

WATER LINE CONNECTIONS

T&P VALVE DISCHARGE PIPE

;

;

6 X

W]

6

? 6 ]

;

& B}56&

~ +B&

$ ;

_

?56&

8 !);;(}&

V ;

+;%&

Explosion Hazard

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

Properly sized temperaturepressure relief valve must be

installed in opening provided.

WATER PIPING DIAGRAMS

Can result in overheating and

excessive tank pressure.

;

6;

;"

+;%&

Can cause serious injury or death.

; " " ; 6 ; ;

;

";

;;

;

X

66 ;#6

;)+;

%&

NOTE:C;

_

? 56 <3 66> " ;

;

;

6 " 6;

_

?56

! ; 6;

3

66;

THERMOMETERS (NOT SUPPLIED)

;; ; ; ;

;V

;;

)+;%&

WATER (POTABLE) HEATING AND SPACE HEATING

& ;

~ } ;" ;"

;

#(5(?

;

$ 6 ;

; 6 } ; ;<>

6

_

8 ; ]

};

;}

;}

66;

"B}56&

42

6 * ; ;

_ <3> 66

;

);

_

?56

&;;]

;

CAUTION

Water Damage Hazard

Temperature-Pressure Relief Valve discharge

pipe must terminate at adequate drain.

C366

+ <&~ ;> 6

6X

"";"

66 ;

]

]

;;C

;"

;

;

T&P Valve Discharge Pipe Requirements:

Shall not be smaller in size than the outlet pipe size of the

66"6

)

)};

);

);

;

_

?56

B

;;};

;}6

}

C;"

;;;

]

)666

66

TEMPERATURE REGULATION

HIGH TEMPERATURE LIMIT CONTROL (ECO)

]

(!=<

>

X

;

;(!=;

<6>;

(!=J;

<

>"'(!=

;

};

~~V<'8!>};&8V<8'!>

C (!= 6 < > ; ;

; ;; _ ~8 5 W 56 ;

; ( !

=

<(!=> V

; /!+ C ; `

)6 ;(!=6

(!==;

(!=

)

(!=6";

;

&8V<8'!>;=

;

;

;

THERMOSTAT CONTROL

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

)=)&~V<8'!>

); ) ]

;

TABLE 10

;

~3$

+^

)

Water Temperature

&V<~!>

Nearly instantaneous

&%V<%%!>

Nearly instantaneous

&V<%&!>

&*~

&V<!>

&_&*~

&8V<!>

/

&$V<8!>

$

&~V<8'!>

More than 5 minutes

6 ;

]

; ;

;;

; ;

" ;"

)5V

&

= ) X

;

X

; ;

B

; ;

JCB <

;

> " V

=)X

;'V<8~!>&V

<~!>&~V<8'!>)=)

+X

;8%

X

=)

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

)=)

6;

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

HIGH TEMPERATURE APPLICATIONS

:;

]

;

X

* & }; ;__

;

;

X

6

}

; "

;C

6

]

;

"

;

: ;

; !

; ;

"

;;"

;

;;

;

!

; 6 ;

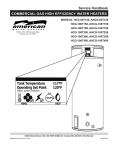

MANUFACTURER / MODEL INFORMATION

Tank Temperature

Operating Set Point

6;

8$

UP

Status: Heating

C

;

; ;} 66 <V

&>

;;

#6;

#66

103°F

120°F

OFF

DN

GAS O

N

MENU

HELP

Figure 55

CONTROL SYSTEM OPERATION

OVERVIEW

THE DESKTOP SCREEN

6;

]

;

;

: ; ; (!= < >" ; "

;

; ;!;

^""~85W

56;

+

; ; + /!+ ;

+

6 V

6;

B

;;

^+