Download Craftsman 919.167802 Troubleshooting guide

Transcript

i CRRFTSMRNq

Oil Lubricated

Two Stage

Stationary

AIR COMPRESSOR

Model No.

919.167802

•

Safety Guidelines

•

Assembly

•

Operation

•

Maintenance

•

Service

•

Troubleshooting

•

Repair

and Adjustments

Parts

CAUTION:

Read the Safety Guidelines and

All Instructions Carefully Before Operating.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

D30092

Rev0

9/26/03

WARRANTY

................................................

2

SPECIFICATION CHART .....................................

SAFETY GUIDELINES ......................................

GLOSSARY ................................................

ACCESSORIES

.............................................

3

3-8

9

9

DUTY CYCLE ..............................................

ASSEMBLY ...............................................

INSTALLATION ..........................................

OPERATION ............................................

9

10

11-13

14-16

MAINTENANCE

.........................................

SERVICE AND ADJUSTMENTS

............................

STORAGE ................................................

TROUBLESHOOTING

GUIDE ..............................

17-20

21-22

22

23-26

REPAIR PARTS .........................................

ESPAI_IOL ..............................................

27-31

32-56

NOTES/NOTAS

.........................................

REPAIR PROTECTION AGREEMENTS .........................

57-58

59

HOW TO ORDER REPAIR PARTS ......................

back cover

ltl__1;| ;[_I_ hi"

FULL ONE YEAR WARRANTY AIR COMPRESSOR

If this CRAFTSMAN Air Compressor fails due to a defect in material or

workmanship within one year from the date of purchase, Sears will at its

option repair or replace it free of charge. Contact your nearest Sears Service

Center (1-800-4-MY-HOME ®)to arrange for repair, or return the Air

Compressor to the place of purchase for replacement.

If this Air Compressor is used for commercial or rental purposes, this warrant

applies for only ninety days from the date of purchase.

This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

D30092

2=ENG

Model No.

919,167802

Max. Developed HP

Running HP

Sore

Stroke

Voltage-Single Phase

Minimum Branch Circuit Requirement

Fuse Type

Air Tank Capacity

Approx. Cut-In

Approx. Cut-out

SCFM @ 100 psig

SCFM @ 175 psig

7

5.5

4.134"

2.165"

240/60/1

30 amps

Time Delay

80

140

175

17.4

16.9

Refer to Glossary for abbreviations.

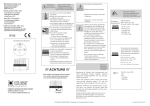

This manual contains information that is important for you to know and

understand. This information relates to protecting YOUR SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this

information, we use the symbols below. Please read the manual and pay

attention to these symbols.

I_'_J_

Indicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a

potentially hazardous

situation which, if not avoided,

result in minor or moderate injury.

I_'_J_'_'_

_T_'_Used

_'_1'_J_

without the

safety alert symbol

indicates a potentially hazardous

situation which, if not avoided, may

result in property damaae.

Ind icat es a

potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Ih_l_o]-'tnq.+1+id_"Y.4_l_,_'d_[IP.[-:-]ljt,ttl_o,]njl[o

_]P.[-.+

_Some

dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals

known (to the State of California) to cause cancer, birth defects or other

reproductive harm. Some example of these chemicals are:

•

lead from lead-based paints

•

crystalline silica from bricks and cement and other masonry products

•

arsenic and chromium from chemically-treated

lumber

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, always wear

MSHA/NIOSR approved, properly fitting face mask or respirator when using

such tools.

When using air tools, basic safety precautions

reduce the risk of of personal injury.

3-ENG

should always be followed to

[330092

Save these instructions

improper operation or maintenance of this product could result in serious injury and

property damage. Read and understand all warnings and operation instructions before

using this equipment.

:r:_rJ:_;!m

WARNING:

Risk of explosion or fire

What Could Happen

How To Prevent It

tt is normal for electrical contacts

within the motor and pressure switch to

spark,

Always operate the compressor in a well

ventilated area free of combustible

materials, gasoline, or solvent vapors.

tf electrical sparks from compressor

come into contact with flammable

vapors, they may ignite, causing fire or

explosion,

if spraying flammable materials, locate

compressor at least 20 feet away from

spray area. An additional length of hose

may be required.

Store flammable materials in a secure

location away from compressor.

Restricting any of the compressor

ventilation openings will cause serious

overheating and could cause fire.

Never place objects against or on top

of compressor. Operate compressor in

an open area at least 12 inches away

from any wall or obstruction that would

restrict the flow of fresh air to the

ventilation openings.

Operate compressor in a clean, dry well

ventilated area. Do not operate unit

indoors or in any confined area.

Unattended operation of this product

could result in personal injury or

property damage. To reduce the risk of

fire, do not allow the compressor to

operate unattended.

Always remain in attendance with the

product when it is operating.

Always disconnect

electrical power by

moving pressure switch lever to the off

position and drain tank daily or after

each use.

D30092

4=ENG

WARNING:

Risk of Bursting

Air Tank', The following conditions could lead to a weakening of the tank, and result

in a violent tank explosion and could cause property damage or serious injury.

What Could Haopen

How To Prevent It

Failure to properly drain condensed

water from tank, causing rust and

thinning of the steel tank.

Modifications

the tank.

or attempted

repairs

Unauthorized

modifications

to the

Drain tank daily or after each use. If

tank develops a leak, replace it

immediately with a new tank or replace

the entire compressor,

to

Never drill into, weld, or make any

modifications to the tank or its

attachments.

unloader valve, safety valve, or any

other components which control tank

pressure.

Excessive vibration can weaken the

air tank and cause rupture or

explosion

ATTACHMENTS

The tank is designed to withstand specific

operating pressures. Never make

adjustments or parts substitutions to

alter the factory set operating

pressures.

& ACCESSORIES:

For essential control of air pressure, you

must install a pressure regulator and

pressure gauge to the air outlet (if not

equipped) of your compressor. Follow the

equipment manufacturers

recommendation

and never exceed the

maximum allowable pressure rating of

attachments. Never use compressor to

inflate small low pressure objects such

as children's toys, footballs,

basketballs, etc.

Exceeding the pressure rating of air

tools, spray guns, air operated

accessories, tires, and other inflatables

can cause them to explode or fly apart,

and could result in serious injury.

-"f.,_'_f.,1

"1=

WARNING:

Risk from Flying Objects

What Could Happen

The compressed air stream can cause

soft tissue damage to exposed skin

and can propel dirt, chips, loose

particles, and small objects at high

speed, resulting in property damage or

personal injury.

How To Prevent It

Always wear ANSI Z87.f approved

safety

glasses

with side shields when using the

compressor,

Never point any nozzle or sprayer

toward any part of the body or at other

people or animals.

Always turn the compressor off end

bleed pressure from the air hose and tank

before attempting maintenance, attaching

tOOlS

5-ENG

or

accessories,

D30092

:f:1"4_;ll

WARNING:

Risk of Electrical Shock

What Could Happen

_J

How To Prevent It

Your air compressor is powered by

electricity. Like any other electrically

powered device, If it is not used

properly it may cause electric shock.

Never operate the compressor outdoors

when it is raining or in wet conditions.

Never operate compressor with

protective covers removed or damaged.

Repairs attempted by unqualified

personnel can result in serious injury

or death by electrocution.

Any electrical wiring or repairs required

on this product should be performed by

authorized service center personnel in

accordance with national and local

electrical codes,

Electrical Grounding: Failure to provide

adequate grounding to this product

could result in serious injury or death

from electrocution.

Make certain that the electrical circuit to

which the compressor is connected

provides proper electrical grounding,

correct voltage and adequate fuse

protection.

See grounding

instructions,

WARNING: Risk of Breathing

What Could Happen

How To Prevent It

The compressed air directly from your

compressor is not safe for breathing.

The air stream may contain carbon

monoxide, toxic vapors, or solid

particles from the tank. Breathing these

contaminants can cause serious injury

or death.

Air obtained directly from the compressor

should never be used to supply air for

human consumption, in order to use air

produced by this compressor for

breathing, suitable filters and in-line

safety equipment must be properly

installed. In-line filters and safety

equipment used in conjunction with the

compressor must be capable of treating

air to all applicable local and federal

codes prior to human consumption.

Sprayed materials such as paint, paint

solvents, paint remover, insecticides,

weed killers, may contain harmful

vapors and poisons,

Work in an area with good cross

ventilation. Read and follow the safety

instructions provided on the label or

safety data sheets for the materials you

are spraying. Use a NtOSH/MSHA

approved respirator designed for use with

your specific application.

D30092

6=ENG

f-'_J-'1_ i

WARNING:

Risk of Burns

How To Prevent It

What Gould Happen

Never touch any exposed metal parts

on compressor

during or immedistely

sft_r operation. Gompressor

will remain

hot for scvcml minutes a_er operation,

Do net r_sch sreund protective shrouds

or attempt mairrtenance

unbl unit has

been allowed to cool,

Touching exposed metal such _ the

oompre_r

hcsd or outlet tubes, _an

result in serious bums.

;F-'YJ-'I:,]J

WARNING:

Risk from

Moving

Parts

_T)

What Could Happen

How To Prevent It

Moving parts such a_ the pulley, flywheel,

and belt can cause serious injury if they

come into _,ontact with you or your

el_hing.

Never operate the compressor with

guards or covers which a_ damaged or

removed,

Attempting to operate compressor with

damaged or missing parts or _cm_ing

to r_pair compressor with profeutivc

shrouds removed c_n expose you to

moving parts and can result in serious

injury.

Any repairs r_quired on this product

should be performed

by authorized

service center personnel,

;F_,yJ_,_!

:,]J

WARNING:

Risk of Falling

What Gould Happen

How To Prevent It

A portable compressor can fall _m a

table, workbench, or roof causing

damage to the compressor and could

result in serious injury or death to the

operator.

Always operate compressor in a stable

secure posibon to prevent accidental

movement of the unit. Never operate

compressor On a roof or ether elevated

position. Use additional air hose to

reach high locations.

7-ENG

L33_92

;7-'_rJ-q

:t J

;7-'_r.L'_!

:t J

WARNING:

Risk

of Unsafe

Operation

What Could Rappen

Unsafe operation of your air compressor

could lead to serious injury or death to

you or others.

SAVE THESE

:I_2

How To Prevent It

Renew and understand all instructions

and warnings in this manual,

Become familiar with the operation and

controls of the air _mprsssor,

Keep operating area clear of all persons,

pets, and obstacles,

Keep children away _m the air

compressor at all itrnes,

Do not operate the product when

fatigued or under the influence of

alcohol or drugs. Stay alert at all times.

Never defeat the safely faatures of this

preduct.

Equip area of operation with a fire

extinguisher.

DO not operate machine with missing,

broken, or unauthorized parts.

INSTRUCTIONS

_ENG

Become familiar with these terms

before operating the unit.

CFM Cubicfest per minute.

SCFM: Standard cubic feet per

minute; a unit of measure of air

delivery.

PSIG: Pounds per square inch

gauge; a unit of measure of pressure.

Code Certification: Products that

bear one or more of the following

marks: UL, CUL, ETL, CETL, have

been evaluated by OSHA certified

independent safety laboratories and

meet the applicable Underwriters

Laboratories Standards for Safety,

Cut*In Pressure: While the motor is

off, air tank pressure drops as you

continue to use your accessory.

When the tank pressure drops to a

certain low level the motor will restart

automatically.

Tr_e low pressure at

which the motor automatically

restarts is called "cut-in" pressure,

Cut-Out Pressure: When an air

compressor is turned on and begins

to run, air pressure in the air tank

begins to build, It builds to a certain

high pressure before the motor

automatically shuts off - protecting

your air tank from pressure higher

than its capacity. The high pressure

at which the motor shuts Off is called

"cut -out" preesure.

Branch Circuit: Circuit carrying

electricity from electrical panel to

outlet,

To Lock Out Power: Place a lock on

the line power switch SOno one else

can turn on the powe_

Trois unit is capable of powering the following Accessories. The accessories are

available through the current Power and Hand Tool Catalog or full-line Sears

stores.

Accessories

•

In Line Filter

•

Tire Air Chuck

•

Air Hose: 1/4", 5/16", or 3/8" OR

1/2" inside diameter in various

lengths

•

Quick Connector

sizes)

Sets (various

•

•

Air Pressure Regulators

Oil Fog Lubricators

Trois air compressor pump is capable

of running continuously. However, to

prolong the life of your air

compressor, it is recommended that a

50%-75% average duty cycle be

_-ENG

maintained; that is, the air

compressor pump should not run

more than 30-45 minutes in any given

hour.

L3_92

iI=l,t'

Contents

1

1

1

1

4

-

of Carton

Multi-Viscosity

motor oils, like

10W 80, should not be used in an air

compressor. They leave carbon

deposits on critical components,

thus reducing performance and

compressor

life. Use air compressor

oil only..

1, Remove the oil drain plug (B) and

washer (C).

Air Compressor

Parts bag containing:

Operator's Manual

Parts Manual

5/8" Washers

Tools Required for Assembly

1 - g/16" socket or open end wrench

1 - electric drill

Unpacking

1.

Remove all packaging,

It may be

necessary to brace

or support one side of the outfit

when removing the pallet because

the air compressor will have a

tendency to tip.

2. Remove and discard the (4)

screws and washers holding the

compressor to the pallet.

3.

2,

Obtain the drain plug extension

([3), from the parts bag,

3,

Apply thread sealant tape to the

threads of the drain plug extension

4,

Assemble the washer (C), drain

plug extension (D), and drain plug

(B) as shown in Figure.

Tighten securely.

Remove the oil fill plug (A),

Fill the crankcase with the

recommended oil. NOTE: Use an

air compressor oil such as SAE-30

(API CG/CD heavy duty motor oil).

Under extreme winter conditions

use SAE-20 weight oil.

Replace the oil fill plug (A) and

tighten securely.

With the help of another person

carefully remove air compressor

from pallet and place on a level

surface,

To Add Oil To Pump

_

Compressore

are

shipped without oil.

A small amount of oil may be

present in the pump upon receipt

of the air compressor. This is due

to plant testing and does not mean

the pump contains oil. Do not

attempt to operate this air

compressor without first adding oil

to the crankcase. Serious damage

can result from even limited

operation unless filled with oil and

broken in correctly. Make sure to

closely follow initial start*up

procedures.

5,

6,

7,

8,

--)_2

1,q-ENG

HOW TO SET UP YOUR

Location

UNIT

Locate the air compressor in a

clean, dry, and well ventilated

area,

•

Locate the air compressor at

least 12" away from the wall or

other obetruc'tions that will

interfere with the flow of air.

•

Place the air compressor

solid, level surface,

2,

Mark the surfaes using the holes

in the air compressor feet as a

template,

Drill holes in the surface for the

concrete anchors. Install

concrete anchors.

of the Air Compressor

•

•

1,

Locate the air compressor as

close to the main power supply

as possible to avoid using long

lengths of electrical wiring.

NOTE: Long lengths of electrical

wiring could cause power loss to

the motor.

3,

4,

5,

Tr_e air filter must be kept clear

of obetruc'tions which could

reduce air flow to the air

on on a

Une-up holes in surface with

holes in air compressor feet.

Place the (4) washers (not

supplied) between the floor and

air compressor feet, If needed,

solid shims may be placed

between the washers and floor to

evenly distribute weight on all

four feet, See next figure.

3/8' Lag

_rew

(net

compressor.

Anchoring

of the Air

Compressor

Excessive Vibration

can weaken the air

tank and cause an explosion. The

compressor must be properly

mounted.

Tr_e air compressor MUST be bolted

to a solid, level surface.

Hardware needed:

--_--

Shim Under

Washer

[not supplied)

Concrete Anchor

(not supplied)

6,

Place the (4) 3/8" lag screws

through the air compressor feet,

washers, shims, and into the

anchors,

7,

Torque 3/8" lag screws to 7-10

fL-Ibs,

4 - Concrete anchors (not supplied)

4 - 3/8" Lag screw to fit concrete

anchors (not supplied)

4 - 5/8" Washer shims (found in

Surface Line

parts bag, if needed)

11-ENG

L33CC9_2

Wiring

Instructions

_Risk

of elec_ical

shock. Improper

electrical grounding can result in

electrical shock. The wiring should

be done by a qualified electrician

to comply with national and local

electrical codes.

A qualified electrician needs to knows

the following before wiring:

1. Tr_e amperage rating of the

electrical box should be

adequate, Refer to the product

specifications, found in the front

of this manual, for this

information.

2.

Tr_esupply line should have the

same electrical charac'tedsfice

(voltage, cycle, phase) as the

motor. Refer to the motor

nameplate, on side of motor, for

this information,

NOTE: Tr_ewiring must be the same

as the motor nameplate voltage plus

or minus 10%. Refer to local codes

for recommended wire sizes, correct

wire size, and maximum wire run;

undersize wire causes high amp draw

and overheafing to the moto_

Risk of electrical

shock. Electrical

wiring must be located away _om

hot surfaces such as manifold

assembly, compressor outlet tubes,

heads, or cylinders.

GROUNDING

INSTRUCTIONS

Air Distribution

Risk of Bursting.

Plastic or PVC pipe

is not designed for use with

compressed air. Regardless of its

indicated pressure rating, plastic

pipe can burst _om air pressure.

Use only metal pipe for air

distribution lines.

The next figure represents a typical

air distribution system, The following

are tips to remember when setting up

the air eompressor's air distribution

system.

Use pipe that is the same size as

the air tank outlet, l=iping that is

too small will restrict the flow of

air.

•

If piping is over 100 feet long,

use the next larger size,

Bury underground lines below

the frost line and avoid pockets

where condensation can gather

and freeze. Fill lines with air

pressure before covering to

make sure pipe joints are free

from leaks.

Install a flexible coupling

between the air discharge outlet

and main air distribution line to

allow for vibration.

NOTE: The shut-off valve is not

supplied with this unit, You must

purehsase the shut-off valve

separately.

Trois product should be connected to

a metallic, permanent wiring system,

or an equipment-grounding

terminal

or lead on the product and comply

with national and local electrical

codes.

A separate regulator is

recommended to control the air

pressure. Air pressure from the

air tank is usually too high for

individual air driven tools,

Refer to the product specification

found in the front of this manual for

the voltage and minimum branch

circuit requirements,

--I_2

System

12-ENG

LEG

AIR

CCM PRE,_OR

TYPICAL

COMPRESSED

AIR DISTRIBUTION

SYSTEM

VALVE

I_Al_J

13-ENG

_CK

_

_

L33_92

Know Your Air Compressor

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNI_ Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments. Save this manual for future

reference,

Description

Of Operation

Tank Pressure Gauge: The tank

Become familiar with these controls

pressure gauge indicates the reserve

before operating the unit.

air pressure in the tank,

Glebe Valve (sold separately):

Opens and closes air discharge valve.

Turn knob counter-clockwise

to open

and clockwise to close,

Regulator (sold separe_ely, not

shown):/_

air pressure regulator or

a separate air transformer which

combines the functions of air

regulation and/or moisture and dirt

removal is recommended for most

applications.

Drain Valve: Tr_e drain valve is

located at the base of the air tank

and is used to drain condensation at

the end of each use,

On/Auto/Off Switch; Turn this switch

ON to provide automatic power to the

pressure switch and OFF to remove

power at the end of each use,

Pressure Switch: The pressure

switch automatically starts the motor

when the air tank pressure drops

below the factory set "cut-in"

pressure, It stops the motor when the

air tank pressure reaches the factory

set "cut-out" pressure.

Safety Valve: If the pressure switch

does not shut off the air compressor

at its "cut-out" pressure setting, the

safety valve will protect against high

pressure by "popping out" at its

factory set pressure (slightly higher

than the pressure switch "cut-out"

setting).

--)_,YJ£2

Cooling System (not shown); This

compressor contains an advanced

design cooling system. At the head 04

this cooling system is an engineered

fan, It is perfectly normal for this fan

to blow air through the vent holes in

large amounts. You know that the

cooling system is working when air is

being expelled,

14-ENG

Air Compressor Pump (not shown):

Compresses air into the air tank.

Working air is not available until the

compressor has raised the air tank

pressure above that required at the

air outlet.

Air Intake Filter (not shown) This

filter is designed to clean air coming

into the pump. Trois filter must always

be clean and ventilation openings

free from obstructions, See

"Maintenance'.

Check Valve: When the air

How to Use Your Unit

compressor is operating, the check

valve is "open", allowing compressed

air to enter the air tank, When the air

compressor reaches "cut-out"

pressure, the check valve "closes",

allowing air pressure to remain inside

the air tank.

How

1,

to Stop:

Set the 0n/Auto/0ff

_,OFF_,.

lever to

Before Starting

Break*in Procedure

Risk of Unsafe

Operation. Serious

damage may result if the following

break*in instructions are not

closely followed.

Pressure Release Valve: The

pressure release valve, located on the

side of the pressure switch, is

designed to automatically release

compressed air from the compressor

head and the outlet tube when the air

compressor reaches "out-out"

pressure or is shut off, Tr_e pressure

release valve allows the motor to

restart freely. When the motor stops

running, air will be heard escaping

from this valve for a few seconds, No

air should be heard leaking when the

motor is running, or continuous

leaking after unit reaches "out-out"

pressure,

This procedure is required before the

air compressor is put into service and

when the check valve or a complete

compressor pump has been

replaced,

1,

Make sure the On/Auto/Off

is in the "OFF" position.

lever

2,

Recheck all wiring, Make sure

wires are secure at all terminals

connections, Make sure all

contacts move freely and are not

obstructed,

3,

Open the globe valve fully to

permit air to escape and prevent

air pressure build up in the air

tank during the braak-in period,

NOTE: The shut*off valve is net

supplied with this unit. You

must purchase the shut-off

valve separately.

4,

15-ENG

Move the 0n/Auto/Off lever to

"0N/AUT0" position, The

compressor will start,

D_CC9_2

5.

Run the cornpressor for 20

minutes, Make sure the globe

valve is open and there is

minimal air pressure build-up in

tank,

6.

Check all air line fittings and

connections/piping

for air leaks

by applying a soap solution,

Correct if necessary. NOTE:

Minor leaks can cause the air

compressor to overwork,

resulting in premature breakdown

or inadequate performance.

7.

8.

How

Check for excessive vibration.

Readjust or shim air compressor

feet, if necessary.

After 20 minutes, close the globe

valve, The air receiver will fill to

"cut-out" pressure and the motor

will stop.

Before

1.

Risk of Bursting.

Too much air

pressure causes a hazardous risk

of bursting. Cheek the

manufacturer's maximum pressure

rating for air tools and accessories.

The regulator outlet pressure must

never exceed the maximum

pressure rating.

lever to

2.

Close the globe valve.

3.

Attach hose and accessories.

NOTE: A regulator MUST be

installed when using accessories

reted at less than 175 PSI,

_-)_,.v3£2

Turn the On/Auto/Off lever to

"AUTO" and allow tank pressure

to build, Motor will stop when

tank pressure reaches "cut-out"

pressure.

2,

When the tank pressure reaches

"cut-out" pressure open the

globe valve,

IMPORTANT: When using regulator

and other accessories refer to the

manufacturer's instructions,

Each Start-Up:

Place On/Auto/Off

._OFF,_"

to Start

1,

I_ENG

kVA

r='llI_ / II =1_V=al

_[_

Customer

Responsibilities

Check Safety Valve

Drain Tank

Check Oil

5_ore Every Every Every Every

_eh

8

_-0

100

180

Every,

500

Yearly

JSe

houi_

hOUP3

hours

houP3

hours

•

•

•

Change Oil

Unusual Noise and/or

Vibration

•_

•_

•

Air Filter

•_

Drive Belt-Condition

•

Motor l=ulley/Flywheel alignrnen

•

Air compressor pump intake

and exhaust valves

Inspect air lines and fittings

for leaks

•

•

Head Bolts - Check the torques of tie headbolts after tie first five hours of operation,

1- more frequent in dusty or humid conditions

2- more frequent if humidity or operating

conditions are extreme.

Risk of Unsafe Operation. Unit cycles automatically when

power is on. When sarvioing, you may be exposed to

voltage sources, compressed air, or moving parts. Before servicing unit

unplug or disconnect electrical supply to the air compressor, bleed tank

of pressure, and allow the air compressor to cool.

To ensure efficient operation and longer life of the air compressor outfit, a

routine maintenance schedule should be prepared and followed, The following

routine maintenance schedule is geared to an outfit in a normal working

environment operating on a daily basis. If necessary, the schedule should be

modified to suit the conditions under which your compressor is used. The

modifications will depend upon the hours of operation and the working

environment, Compressor outfits in an extremely dirty and/or hostile

environment will require a greater frequency of all maintenance checks.

NOTE: See "Operation"

To Check

Safety

section for the location of controls,

Valve

1.

Risk of Bursting. If

the safety valve

does not work properly, overpressurization

may occur, causing

air tank rupture or an explosion.

17-ENG

Before starting compressor, pull

the ring on the safety valve to

make sure that the safety valve

operates freely. If the valve is

stuck or does not operate

smoothly, it must be replaced

with the same type of valve,

D_CC9_2

To Drain Tank

NOTE: Operation of the air

compressor will cause condensation

to build up in the air tank. Always

drain tank on a washable surface or

in a suitable container to prevent

damaging or staining surfaces.

1. Set the On/Auto/Off lever to

_,OFF,_.

2.

3.

Close the globe valve.

Remove the air tool or

accessory.

Open the globe valve and allow

the air to slowly bleed from the

air tank until tank pressure is

approximately 20 psi.

5. Close the globe valve.

6. Drain water from air tank by

opening drain valve (counterclockwise) on bottom of tank.

I_

Risk of Bursting.

Water will

condense in the air tank. If not

drained, water will corrode and

weaken the air tank causing a risk

of air tank rapture.

7. After the water has been

drained, close the drain valve

(clockwise). The air compressor

can now be stored.

4.

NOTE: If drain valve is plugged,

release all air pressure. The valve

can then be removed, cleaned, then

reinstalled.

Changing

1.

2.

Remove the oil fill plug (A).

Remove the oil drain plug (B) and

drain oil into a suitable oontaine_

3.

Replace the oil drain plug (B) and

tighten securely

Sowly add compressor oil until

the oil level is in the middle of the

sightglass (C). NOTE: When

filling the crankcase, the oil flows

very slowly into the pump. If the

oil is added too quickly, it will

overflow and appear to be full.

4.

Oil

NOTE: Use a air compressor oil such

as SAE-30 (API CG/CD heavy duty

motor oil). Under extreme winter

conditions use SAE-20 weight oil.

NOTE: Crankcase oil capacity is

approximately 60 fluid ounces (1.8 l).

Checking

1. The oil level should be to the

middle of the sight glass (C).

2. If needed remove oil fill plug (A)

and slowly add oil until it reaches

the middle of the sight glass.

_-)_,.vJ£2

I_

Overfilling with oil

will cause

premature compressor failure. Do

not overfill.

5,

15-ENG

Replace oil fill plug (A) and

tighten securely.

Air Filter - Inspection

Replacement

and

I_qqPrf_l

Risk of Burns.

Compressor head

and cylinder sleeve are very hot.

Do net touch. Allow compressor to

cool prior to servicing.

A dirty air filter will not allow the

compressor to operate at full

capacity. Keep the air filter clean at

all times,

1. Remove the air filter cover.

2. Remove the air filter from filter

coven

IMPORTANT: Do not operate the

compressor with the air filter

removed,

3. Place new air filter into filter

coven Refer to the "Repair Parts"

for the correct pad number.

4. Replace air filter cover and lock

into place.

5,

Remove the belt and replace

with a new one.

6,

See the "Adjust Belt Tension"

before tightening motor

mounting screws.

Adjusting

Belt Tension

1,

Slide motor into original position,

line the motor up with the mark

made earlier on saddle,

2,

Tighten two outside motor

mounting screws enough to hold

the motor in place for checking

pulley and flywheel alignment,

The belt should delleet 3/16" at

midway between the pulley and

the flywheel when a 5 pound

weight is applied at the midway

point,

3,

Fo,_e

Belt - Replacement

(Refer to the Repair Parts for

replacement belt part number.)

Risk of Moving

Parts. Serious

injury or damage may occur if

parts of the body or loose items

get caught in moving parts. Never

operate the outfit with the belt

guard removed. The belt guard

should be removed only when the

AIR compressor power is

disconnected.

1.

Turn air eompP-_,ssoroff, lock out

the power supply, and relieve all

air pressure from the air tank,

2.

Removethe

3.

Mark pump position on saddle.

4.

Loosen the motor mounting

screws and slide the motor

toward the air compresso_

belt guard,

4,

When proper belt tension is

achieved, tighten all four motor

mounting screws. See Parts

manual for torque specifications.

NOTE: Once the engine pulley has

been moved from its factory set

location, the grooves of the

flywheel and pulley must be aligned

to within 1/16 _]to prevent excessive

belt wear. Verify the alignment by

performing the following Pulley and

Flywheel - Alignment.

19-ENG

EY3CC9_2

7.

Motor Pulley/Flywheel

Alignment

NOTE: Once the motor pulley has

been moved from its factory set

location, the grooves of the flywheel

and pulley must be aligned to within

1/16" to prevent excessive belt wear.

The air compressor flywheel and

motor pulley must be in-line (in the

same plane) within 1/16" to assure

belt retention within flywheel belt

grooves, To check alignment,

perform the following steps:

1. Turn air compressor off, lock out

the power supply, and relieve all

air pressure from the air tank,

2.

Remove belt guard

3.

Place a straightedge against the

outside of the flywheel and the

motor drive pulley.

8.

9,

Visually inspect the motor drive

pulley to verify that it is

perpendicular to the drive motor

shaft. Points B1 and B2 of Figure

should appear to be equal. If

they are not, loosen the setscrew

04 the motor drive pulley and

equalize B1 and B2, using care

not to disturb the belt alignment

performed in step 2.

Retighten the motor drive pulley

setscrew, See Parts manual for

torque specifications,

Reinstall belt guard.

Air Compressor

Pump

and Exhaust Valves

Intake

Once a year have a Trained Service

Technician check the air compressor

pump intake and exhaust valves,

Inspect Air Lines and Fittings

for Leaks

4.

5.

6.

--)_2

Measure the distance between

the edge of the belt and the

straightedge at points A1 and A2

in figure, The difference

between measurements should

be no more than 1/16".

If the difference is greater or less

than 1/16" loosen the set screw

holding the motor drive pulley to

the shait and adjust the pulley's

position on the shaft until the A1

and A2 measurements are within

1/16" of each other.

Tighten the motor drive pulley

set screw, See Parts manual for

torque specifications,

1,

Turn air Compressor off, lock out

the power supply, and relieve all

air pressure from the air tank,

2,

Apply a soap solution to all air

line fittings and

con neations/piping,

3,

Correct any leaks found,

IMPORTAIYT: Even minor leaks can

cause the air compressor to

overwork, resulting in premature

breakdown or inadequate

performance,

Air compressor

Head

Bolts -

Torquing

The air compressor pump head bolts

should be kept propedy torqued,

Check the torques of the head bolts

after the first five hours of operation,

Retighten if necessary. See Parts

manual for torque specifications.

2,0-ENG

ALL MAINTENANCE AND REPAIR

OPERATIONS NOT LISTED MUST BE

PERFORMED BY TRAINED SERVICE

TECHNICIAN,

5,

Unscrew the check valve (turn

counterclockwise) using a 7/8"

open end wrench. Note the

orientation for reassembly.

6,

Using a screwdriver, carefully

push the valve disc up and

down. NOTE: Tr_evalve disc

should move freely up and down

on a spring which holds the valve

disc in the closed position, if not

the check valve needs to be

cleaned or replaced,

F_'_I_'_'_,_'_

Risk of Unsafe

Operation. Unit

cycles automatically

when power is

on. When servicing, you may be

exposed to voltage sources,

compressed air, or moving parts.

Before servicing unit unplug or

disconnect elec_ical supply to the

air compressor, bleed tank of

pressure, and allow the air

compressor to cool.

To Replace

Valve

or Clean

1.

Release all air pressure from air

tank, See "To Drain Tank" in the

Maintenance section.

2.

Turn air compressor off, lock out

the power supply, and relieve all

air pressure from the air tank,

3.

Using an adjustable wrench

loosen outlet tube nut at air tank

and pump. Carefully move outlet

tube away from check valve,

4.

Screwdriver

Check

Using an adjustable wrench

loosen pressure relief tube nut at

air tank and pressure switch.

Carefully move pressure relief

tube away from check valve,

7,

Clean or replace the check valve,

A solvent, such as paint or

varnish remover can be used to

clean the check valve.

8,

Apply sealant to the check valve

threads, Reinstall the check valve

(turn clockwise).

9,

Replace the pressure release

tube. Tighten nuts,

10, Replace the outlet tube and

tighten nuts,

11, Pedormthe Break-in Procedure,

See "Break-in Procedure" in the

Operation section.

21-ENG

EX_92

Motor

4.

Trois motor has a manual thermal

overload protecto_ If the motor

overheats for any reason, the

overload protector will shut off the

motor. The motor must be allowed to

cool down before restarting. To

restart;

IMPORTANT: If the overload

protector shuts the motor off

frequently, check for a possible

voltage problem. Low voltage can

also be suspected when;

1.

Place the On/Auto/Oft

the Off position.

1.

The motor does not get up to full

power or speed.

2.

Allow the motor to cool.

2.

3.

Depress the red reset button on

the motor.

Fuses blow out when starting the

motor; lights dim and remain dim

when meter is started and is

running.

lever in

l=laco the On/Auto/Off lever in

the On/Auto postion to restart

the moto_

Additional

Service

Disassembly or service of the air

compressor beyond what is covered

in this manual is not recommended. If

additional service is required, contact

your nearest Authorized Warranty

Service Center.

Before you store the air compressor,

make sure you do the following;

1.

Review the "Maintenance"

section on the preceding pages

and perform scheduled

maintenance as necessary.

2.

Set the On/Auto/Off

"OFF".

3.

Close the globe valve.

4.

Remove the air tool or accessory.

5.

Open the globe valve and allow

the air to slowly bleed from the

air tank until tank pressure is

approximately 20 psi.

6.

--)_2

I_

Risk of Bursting.

Water will

condense in the air tank. If not

drained, water will corrode and

weaken the air tank causing a risk

of air tank rupture.

7.

lever to

After the water has been drained,

close the drain or drain valve.

NOTE: If drain valve is plugged,

release all air pressure. The valve

can then be removed, cleaned, then

reinstalled.

8.

Drain water from air tank by

opening drain valve (counterclockwise) on bottom of tank.

22-EN_

l=reteet the air hose from

damage (such as being stepped

on or run over).

Risk of Unsafe Operation. Unit cycles automatically

when power is on. When servicing, you may be exposed

to voltage sources, compressed air, or moving parts. Before servicing unit

unplug or disconnect electrical supply to the air compressor, bleed tank

of pressure, and allow the air compressor to cool.

PROBLEM

Excessive tank

pr_ure

(safety valve)

peps

off.

CAUSE

CORRECTION

Pressure switch does not

shut off motor when

compressor reaches "outOUt_"pressure.

Pressure switch "cut-out"

too high.

Move On/Auto/Off lever to

the "OFF" position, if the

outfit does not shut off

contac_ a Trained Service

Technician.

Contact a Trained Service

Technician.

Air leaks at

fittings.

Tube fittings are not tight

enough.

Tighten fittings where air can

be heard escaping. Check

fittings with soapy water

solution, DO NOT

OVER]IGHTE_.

Air leaks at or

inside check

valve,

Check valve seat damaged,

A defective check valve

results in a constant air leak

at the pressure release valve

when there is pressure in the

tank and the compressor is

shut off. Replace check

valve. Refer the "To Replace

or Clean Check Valve" in the

"Operation" section.

Air leaks at

pressure switch

release valve,

(if equipped)

Defective pressure switch

release valve.

Contact a Trained Service

Technician.

Air leaks in air

tank or at air

tank welds.

Defective air tank,

Air tank must be replaced.

Do not repair the leak,

Air leaks

between head

and valve plate.

Leaking seal,

Risk of

Bursting.

DO not drill into, weld or

otherwise modify air tank

or it will weaken. The tank

can rupture or explode.

Contact a Trained Service

Technician,

23-EN_

EY30092

PROBLEM

CORRECTION

CAUSE

Pressure readin¢

on the regulated

pressure gauge

(if equipped)

drops when an

accessory is

used.

It is normal for "some"

pressure drop to occur.

if there is an excessive amount

of pressure drop when the

accessory is used, adjust the

regulator as instructed in the

Operation section,

NOTE: Adjust the regulated

pressure under flow conditions

(while accesory is being used).

Air leak from

safety valve.

Possible defect in safety

valve.

Operate safety valve manually

by pulling on ring. If valve still

leaks, it should be replaced.

Compressor is

not supplying

enough air to

operate

accessodee.

Prolonged excessive use of

Decrease amount of air usage.

Compressor is not large

enough for air requirement.

Hole in hose.

Check the accessory air

requirement, If it is higher than

the SCFM or pressure supplied

by your air compressor, you

need a larger oompresso_

Check and replace if required.

Check valve restricted.

Remove and clean, or replace,

Air leaks.

Tighten fittings.

Restricted air intake filter

Clean or replace air intake

filter. Do not operate the air

compressor with the filter

removed. Refer to the "Air

Filter" paragraph in the

"Maintenance " section,

Loose belt.

Check belt tension, see

Adjusting Belt Tension in the

Maintenance section,

Restricted air

intake,

Dirty air filte_

Clean or replace. See Air Filter

paragraph in the Maintenance

section.

Safety Valve on

pump "pops"

out,

l=ressure switch, check

valve, or pump could be

in need of servicing.

Have checked by a Trained

Service Technician,

--)_2

24-ENG

PROBLEM

Motor will not

run,

CAUSE

Motor overload protection

switch has tripped,

Tank pressure exceeds

3ressure switch

"cut-in"

3ressure.

CORRECTION

Let motor cool off and

overload switch will

automatically reset,

Motor will start automatically

when tank pressure drops

below "cut-in" pressure of

pressure switch,

]hock valve stuck open.

Remove and clean, or replace.

Loose electrical

connections.

Check wiring connection

inside pressure switch and

terminal box area,

Possible defective motor

or starting capacito_

Have checked by a Trained

Service Technician,

Paint Spray on internal

motor parts,

Have checked by a Trained

Service Technician, Do not

operate the compressor in the

paint spray area, See

flammable vapor warning,

Pressure release valve on

pressure switch has not

unloaded head pressure.

Bleed the line by pushing the

lever on the pressure switch to

the "off" position; if the valve

does not open, replace switch,

Fuse blown, circuit breaker

tripped,

1,

2,

3,

4,

25-ENG

Check fuse box for blown

fuse and replace as

necessary. Reset circuit

breaker. Do not use a fuse

or circuit breaker with

higher rating than that

specified for your

particular branch circuit.

Check for proper fuse, You

should use a time delay

fuse.

Check for low voltage

conditions and/or proper

extension cord.

Disconnect the other

electrical appliances from

circuit or operate the

compressor on its own

branch circuit.

L3__*_.9_2

PROBLEM

CAUSE

KnockingNoise. Possible defect in safety

Excessive belt

wear.

Squealing

sound,

CORRECTION

valve.

Operate safety valve manually

by pulling on ring. If valve still

leaks, it should be replaced,

Defective check valve.

Remove and clean, or replace.

Loose pulley.

Tighten pulley set screw,

145-165 in.-Ibs,

Loose flywheel.

Tighten flywheel screw,

33-37 fL-Ibs,

Compressor mounting

screws loose.

Tighten mounting screws,

20-25 fL-Ibs,

Loose belt.

Check belt tension, see

Adjusting Belt Tension in the

Maintenance section

Carbon build-up in pump,

Have checked by a Trained

Service Technician,

Belt to tight,

Check belt tension, see

Adjusting Belt Tension in the

Maintenance section,

Loose belt.

Check belt tension, see

Adjusting Belt Tension in the

Maintenance section,

Tight belt,

Check belt tension, see

Adjusting Belt Tension in the

Maintenance section,

Loose pulley.

Have checked by a Trained

Service Technician,

Pulley misalignment.

See Motor l=ulley/Flywheel

Alignment paragraph in the

Maintenaee section.

Compressor

oil.

See Oil-Checking paragraph in

the Maintenace section,

Loose belt.

pump has no

Check belt tension, see

Adjusting Belt Tension in the

Maintenance section,

I_o]i31_']

27-ENG

L3__._.9_2

Air Compressor

Model Number 919.167802

_20

_19

__44

45

_-)_,.1_32

25-EN_

Air Compressor

KEY

NO.

1

2

3

4

5

6

7

8

g

10

11

12

13

15

16

17

18

19

20

22

23

24

26

27

28

29

30

31

32

37

38

39

40

43

44

45

46

47

Model Number 919.167802

PART NUMBER

AC-0434

D26434

SS-559

D25979

SSF-953-ZN

SSF-8131

91895680

AC-0433

Z-D2671g

SSF-3140-ZN

SSF-8111 -ZN

Z-TA-4439-1

SS-2707

Z-D20596

SSP-555

TIA-4200

AC-0764

Z-GA-360

SSV-6-B

SSW-7482

AC-0763

SSP-7811

SSP-7812

SSF-3159

Z-D27044

SSF-577

AC-0756

AC-0755

DAC-306

DAC-225

AC-0751

D28826

AC-0437

LA-3355

LA-3266

LA-3105

LA-3027

D30084

DESCRIPTION

Outside Belt Guard

Belt

Set Screw

Pulley

Self Tapping Screw 10 x 5/8" (2)

Speed Nut (2)

Screw (4)

Inside Guard Belt

Motor

Screw (4)

Nut Lock (4)

Air Tank

Drain Valve

Pressure Switch Assembly

Nipple

Safety Valve

Manifold

Gauge

Globe Valve

Connector Conduit 3/8"

Pressure Relief Tube

Nut Sleeve Assembly (2)

Nut Sleeve

Screw (4)

Pump

Screw (2)

Adapter Filter

Gasket Filter Adapter

Belt Guard Adapter

Male Connector

Outlet Tube

Check Valve

Filter Kit

Oil Notice Label

Warning Label

Craftsman Label

Drain Tank Label

Performance Label

29-EN_

EY3CC9_2

Air Compressor

3rankcase

_linder

Cover

Head

ntercooler

l"orque

18.1 ft.-Ibs.

T,_,,I

32.8 ft.-Ibs.

18.1 ft.-Ibs.

:lywheel

3onnecting

Model Number 919.167802

32.8 ft.-Ibs.

Rod

3earing Cover

18:1 ft.-Ibs.

18:1 ft.-Ibs.

2O

18

--I_Y,_2

30-ENG

Air Compressor

KEY

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

* 14

* 15

16

17

18

20

21

Model Number 919.167802

PART NUMBER

ABF=-8226501

ABI=-5961405

ABI=-5950057

ABI=-9053203

D25975

ABI=-9022003

ABI=-5940050

ABI=-9101164

ABI=-9162030

ABI=-9004009

ABI=-9110022

ABF-9163020

Z-ABI=-9013013

ABI=-8226502

ABI=-8226503

ABI=-8227093

ABI=-8227092

ABI=-5962000

ABI=-5281100

ABI=-9024011

DESCRIPTION

Hardware Kit

Head

Gasket Kit (Also includes Inner Valve Plate Gasket}

Oil Extension Tube

Flywheel

Sight Glass

Valve Plate Kit (Includes Inner Valve Plate Gasket}

Drain Plug Screw

Drain Plug Seal

Flywheel Washer

Flywheel Screw

Oil Seal

Shell Bearings (1 set)

HP Running Gear Kit

LI= Running Gear Kit

HP Ring Kit

LI= Ring Kit

Intercooler

Replacement Filter

Oil Fill Plug

NOT SHOWN

ABI=-9049020

D30092

D29143

Intercooler Safety Valve

Owners Manual

Starb"Run Capacitor Kit

*Includes piston, rings, piston pin, snap rings, oil dipper, split

bearings, locking nuts, and connecting rod.

31-ENG

L_CC9_2

_T_

..........................................................

CUADRO

DE ESPECIFICACIONES

DEFINIOIONES

DE NORMAS

IMPORTANTES

INb'TRUOCIONES

GLOSARIO

DE SEGURIDAD

.............................

DE $EGURIDAD

33

......................

3_-3;5

..........................................................

ACOESORIOS

39

.......................................................

CICLO DE SERVICIO

EN_AMBLADO

32

...................................... 33

39

..................................................

39

.......................................................

_0

IN_3"ALACIC)N .....................................................

41 -_3

OPERAOION

4_-_6

......................................................

MANTENIMIENTO

.................................................

SERVICIOS Y REGUILACIONES

ALMACENAJE

51-52

.......................................................

GUi'A DE DIAGN_TICO

N OTES/NOTA,S

47-50

......................................

DE PROBLEMAS

52

.............................

53-56

....................................................

CONTP, ATOS DE PROTECCION

I_ISTA DE PARTES

.................................................

COMe

PIEZAS PAR& REPARACION

SOLICITAR

57-5;5

PAPA REPARACIONES

.....................

59

28-31

....................

c&ntmtap_

_11 :tll _ i I r__

GARANTIA TOTAL DE UN A_IO DEL COMPRESOR

DE AIRE

Si eete compresor de aire Craftsman fallase debidc a defec_oe de matedales

o de fabricaci6n dentro del aSo de eu fecha de ccrnpra, Sears, a su cpciSn, Ic

reparar& o reernplazar& sin cceto algunc, Cornunfqueee con el Cenvc de

Servicio Sears rn&s cercano (1-800-4-MY-HOME]

para cccrdinar su

reparaci6n, c devuelva el ccmpresor de aire al lugar dcnde Io ccmpr6 para

que Ic carnbien,

Si este compresor de aire se usase con fines cornerciales o para alquiler, esta

garantfa se aplica s61o durante Ice pdmeros noventa d[as a pariir de su fecha

de compra,

Esta garant[a le otorga derechos especfficos y usted podda tenet otros

derachos que varfan de un estado a otto.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

Modelo

Ne

M_x. HP des_rrollsdo

Potenois de treble

Oi_metro interior

Ca_ra

Veltaj_oorrierltO morlOf_L_ios

Circuito mlnime r_querido

Ti_ de Fusible

Copseidod de oire en el tsnque

Pr_si6n de Corsede entr_do

Pr_si6n de Corsedo _lido

SCFM @ 100 psig

SCFM @ 175 psig

919.167802

7

5,5 HP

4,134 po (60,4ram)

2,165 po (34,3mm)

240/60/1

30A

Acoidn Reto_odo

80 Golones (I 13,6 Iitros}

140 psi 9

175 psi 9

17.4 C_1i_ de libtas p_r puig_ds o._drada

16,9 O_1i_ de libra pot pul_

oJ_ _do

Refierase el glosorio pore descifror los obreviatur_.

SEGURIDAD

Y PREVENCION

DE PROBLEMAS

DEL EQUIPO: Psrs syudsr el

receneoimier, to de esto infermooi6n, heroes utilizodo los sfmbolos mostr_dos sba{o.

81r,,B.seleer el monuol y pr_stsr otenoi6n o diohB_s seooiones.

_

Indioo uno situoei6n de

inminente

r[esgo,

.

Io

ouol, si no es evitods, caus_r_ Io muerte

o lesiones _nos.

potenoislmente

riesgos.9, que si no es

evitsds,

podrfo r_sultar en Io muerte

o

lesiones

series.

Indi_'._ uns situsoi6n

poteneiolmente

peligroso, Io ouol, si no es evitodo, podffs

resultsr on lesiones menores o

moderados.

_

Ussdo sin el slmbolo

do seguridod de

olorto indioo uns situsoi6n potenoiolmento

riesgoso Is que, si no es evitodo, p_drfs

oausar dodos on Is oro_iedodo.

A _b hoe tipo_ de 9ser _'n ¢_EIo_ _r m_O J1118$

el_td_

ce lijado, a_er "ace,

_olsdo,

p_fors_o _ ¢cras act videde4__e IQ ¢o_8t _Jcci6% _ntie_e_

_

nlscerisl_

•

_

qulmico_ cono¢ do_ (on el E_ado de Califor _ia) co_'o _ssntes

de c_JlCer,cefe¢_o_ de

El plomo _iltsr_i_o

en _lg_il_ pintLira_ COn base _e #lorno

Smq

ice cri_tsliz6do provenieilte de lOS 18drilJos,el come,to y ot_

pro_u cto_ de _lb_i_ilet_a

Ars_ico

y creme _rovenieilte_ del trat_n_iento Q_lrn_ico d_o 8 Is n_dera

Su d_o

8 _1¢h_.$ expo_i tie ne-$va 48_ dependielldo _e la f_3Lleilcia con la q_e Listed realice

_iferente_ ti_o8 de trab_jo. P_P6 red Licir $u exposi¢i6n 8 Is aoci6_ _e _icho_ age_

_u _rqico_:

t ¢absje e_ zoi188 bieil veiltil_da$, y h_gslo con equine de $eguridr_d _proba_o, u_,esiemo'e prccecci6_

fsci=J o re_pirado? MSHA/NIOSFI ap_b_do8 ¢_a_do deba L_;IEzs'0i¢_

her,anli_T_r

AJ utilizar hetrsJl_ie_8$

_e red,tit Is posibili_

neLirn_tica$ tsJl_bi6il deben tomsPae p rgc.:sJJ

cioile8 b_ic_

de 4esgo de lesio_e_ pecsonale_r

_-SP

de 8_jMrid_,

8 fin

EY_CCg_2

GUARDE

ESTAS INSTRUCCIONES

La operaci6n o el manten[rniento inadecuados de este producto petit|an ocasionar

serias lesiones y dafios a la propiedad. Lea y comprenda todas las advertencras e

[nstrucc[ones de funcionam[ento antes de utilizar este equ[po.

'J=lq [_;{I

ADVERTENCIA:

qu6

puede

Riesgo de Explosi6n o Incendio

oeeurrir

c45mo prevenido

Para los conta_t¢:_ el_.c_icos e$ normal la

existencia

de chispas silt _eel n_otor y el

i_e_rLlotor 8 p_si_n.

Opere $iempre el compRso_

en _n _ector

biell velltil_do y libre de materiale$

combustibles,

gasolina o emanacic_e$

de

solv_ltte.

Si I_s chispa$ el_icas

0_nier_

d_l

Coil_prg8o_tomaran conta_to Con

emanaciorte$ de mat_i_le$

irtilamables_

egos podr[an a_:ler ori_inrJndo incendio o

explo$i6n.

En _n _es de rociado de r_steri_Je_

irrflsmsbl6s, ubique al compresor per Io

meno$ a 6,1 ra (20 pies) de distancia del _rea

de rociado. PO_r_8 requerirse _lna ex-tensi_n _e

la ¢narl_lef_.

Almace_e

ubicaci6n

los materiales inflaraable$ en una

_gura,

alejados del compresor.

Re$_ringir cusIquiem de Iss aberturas de

ventilaciAn cau_ar_ un serio recalentamiertto

y podrla produci_ un incendio.

Jamds coloque ¢_jeto_ apoyados o sc_re el

compresor. Opere el coml_resor en un secto_

abier to, per Io meno$ a 30 cm (t2 pulgadas)

alejado de cualctuiet pared u obstruction que

restrir_ia el flujo de airs {_s_co a Iss _bertur8_ de

ver_til_i_r_.

Ope_e el comp_e_or en _n _ector lir_pio, _eco, y

bien _,sr_til_o. NO opere la unidad en _pacio$

cerrado$ o cualquie_ _rea confinada.

Dejar desatenido este producto mienb-a$ el

mismo est_ en funcionamiertto

pu_le

resultar en lesiones personales o da_o6 a la

propiedad. Para reducir el riesgo de

in_ndio_ no pe_mita que el Compreso_

opere desatendido.

Mant@ngase sierapre alerta cada vez que el

3roducto este funcionando.

--I_,Y,_2

De,on,ere

_iempre el $uminisb'o el6_t _ico

moviendo la palanea conmutadora de

3resign a la posici_n de apagado {olin, y

drene el t_nque diaHa melee o de_pu_

de

34-SP

'J=lq [_;{I

ADVERTENGIA:

Tanau_

d_rminar

d_ erre: las siguiente_

_u _×plosi6n

qu6 puede

Riesgo

_ondrcrone_

violer_a,

dafios

de Explosi6n

podflan,

causer

a I_ propieded

ocourrir

el debrlrtemiento

o serias

c_mo

del tanqu_,

prevenirlo

Drenaje inadecuado del agu_J condensada

en el tanque_ _iendo la c3usa del 6xido que

reduce el espes_" del tanque de acero,

Drene el tanque diaHamente o despue_s de

c_da uso. Si el t_llque £eller8 u118p_rdida,

reer_pl_lo

in medi_tsr_erlte con _11 _uevo

t_ilqu8 o re_pl_lc8 _1co_p_8or

cor_pleto.

Modificacione$

al tanqu_,

J_m_s per_ore, suelde, o efect_e modificaci6n

alguna al tanque o sub _cceso4os.

o intento de repa Pacic_e$

y

lesiones.

Modifica¢ione$ no _Jut¢_iz_d_J$ a la v_lvula

de de$car_a, v_lvula de seguridad o

cu_Jlquie_ otto compo_ente que controle la

pRsi6n del tanque.

La vib_aci6n excesiva puede debilitar el

tanqu_ d_ aire y c_Ju_Jr su ruptura o

_xplosi6n.

El t_que e_t_ d isei_e_o para resisti_ p_s_iones

oper_iv_

e_pec_cets. Jam_$ ef_ct_

ajustes

o $ustituya partes qu_ alteren la_

regul_ciones de pRsi6n origin_les de

_b_ica.

AGREGADOS

Y ACCESORIOS

El exceso a los ¥_1of_8 de presiSn

establecidos para la$ her_amienta$

_t_'lJrn_iP.,as, pib"b'jl_ n+jcJ_J0_, _c_$orio$

activados For airs, cubierts,s y otros objetos

i_flabls_, puede causar su explosi_

o ser

t_r_ojedo_, pLidiefld0 0P.m_i0n_r _riP+s le-_ioll_.

Para _n ccitt _cl esencial de 18p_i_,

debe

tinted instalar un r_ul_

y Un medi_o_ d_

pmsi_n a la salida del aire _e SLIcomprs+o_ (Si

no _+_Lr_ieseeq_ip_J_ Si£t_ I_ re_r_end_ic4_

_e Io$ _bri_n_es de s_ eQuipo y jsm_ exceda

Ic_ vsIo_ rn_ximo_ de pr_ll

p_rmi_ido_ p_

Ic_ _es_ri_.

Jarn_ u_ el comp_sor papa

inila_ objetos que requieren poma o baja

p_i_n_ tales ¢omo jt_uetes papa los niftos+

pelotas de fdtbd, pelotas de bas_!uet, etc.

'J :1 II [_ ;:II

ADVERTENGIA:

Riesgo de Objetos Arrojados por el Aire

qua" puede occurrir

El chor_o de t_ir+ comp_imido puede causar

da_os sc_re lOS tejido$ blandos de la piel

_xpu_a,

y puede propul_3_ s_cied_,

_tilla$, part_ul_$ suelt_s y p+queiSo_obieto_ a

_na velocidad_ c_-_so_l_ndo d_o8 8 h_

pr_pi_P+d o I_iolle8 personsles.

c6rno prevertirlo

AI u_iliza_ _1 _rnpmso_,

use siempre arlteojos

de seguHdad ANSI 7.87.1 aprobadom+ _n

pro_ecci6n lateral.

Jam_s apurtte ninguna boquilla o

pulYerizador hacia part_$ del Cuerpo, a otras

per_ona_ o

a_imal_.

Apague siempm _1 compres+_r y purgue la

pmsi+n de la mmm£uera del 8i_ y del tmmctue,

a,lte_ d{_ i_ritar

el r_sJ_r_imi{_il_o, _1 acople

de h_rramierita$ o 8¢.¢esorios.

ADVERTENCIA:

qu6

puede

Riesgo

de Descarga

El{_c_rica

occurrir

c_mo

{_/F

prevenirlo

Su cc_mp_or de ak_ _

accion_do pc_

_lg_'trici_d. Como OLtalduJet 0tr0 dispositivo

el_._rico impuls_do el/_'Lrio_mellte, $i no _e Io

utiliza adecuadamente,

podrfa _ausafle una

descarga el_trica,

Jam_s opsre el COil_pr_

a la ir_empsrte

Cu_ndo est_ Ilct_ielldo o ell cored ioiolle$ de

hLimedsd.

Nunca c_ere el compresor sin sus def_ne_s o

sus cul_ie_tas Pemo_das o da_adas.

Las Peparaeiones intentada$ p_r personal

no ¢alificado podrran ocasic41ar serias

lesic4_e$ o la muerte po_ electrocuei6n.

Cualquie_ conexi6n el6ct flea o reparaei6n

Pequefida por este produeto debe se_

_.fect uada pot personal autorizado

de los

servicenvos de _cuerdo _ I_ c_digos

el_¢_rico_ R_ioI1_J_ y Ioceles.

GONEXION A TIERRA: Dejar de proveer una

adecuada cm_exi_n a tierra a este produeto

pedria ocasionar lesiones series o la muerte

pot elecWocuci6n.

Vet ir_struocion_ para la

p ues'_aa tiers.

Aseg_Rse que el ei_uiLo el_ctrico al ¢L_al

est_ coronado el comprssor, suminisl_ra

apropiada cone_d_n a tierra, tensi6n eorre_a

y una adecuada pro_ecci6n de fusible$.

ADVERTENGIIA:

Riesgo de Inhalacidn

qu_ puede occurrir

c_Smo prevenirlo

El air oomprimido

provellierr_ ¢lel _mpr_$or

no _ sano pe_ respira_. El ehorro de aiPr_

puede cozener

mon_ido

de carbono,

vapoPe$ t_.icos o part_ula$ s61ida$

provellie_

del t_u_q_le.La inhalaei6n de

dicho_ contarninantes peede Ilegar a causar

seria$ lesiones o la muerte.

El air ol_ellido dir_c'_al_ellte del cor_pr_or

am_s depe_

se_ utilizado papa p_ovee_ aire

)ara eonsumo humano. Par_ pode_ utilJz_ el

_i_ p_dLioido pot _e oor_pr_o_ y hacerlo

respireble, debe_n

i_alarse

Lin filb_

_ecLlado y Lin equipe de _guridad

inte_alado.

LO_ filbo$ i_terc_l_os ta_to _mo

el equipe de _guHd_d

Litiliz_o en _lljunto

oon el oomp_or,

deber_n _

c*_pece$ de

)_oce_

el b-at amiento del awe de aeuen:lo a

todo$ los c_digos locales y fedePales, previo

al P._o_t_lJRio

hllm_rio.

El rociado de mat_riales t_J_ torso

801ve_,

_Ov_dOr_$

de piiltiJ_,

i_oti¢id_,

n_t_ hierb_ts, c¢_tienen

em_n_eione$

d_il_a6 y retie rlor._.

Tfabaje _1 un _re_ Con buena ventilaci_n

cruz_da. Le_ y $if_a la_ in_t mceiones de

segu_idad pr_vi_s

en el r_tulo o en Io_ d_tos

de l_s h_as de s_ju _id_ del materlal que est_

)ulverlzando,

Use el respi_dor

ap_ol_ado

NIOSH/MSHA

desi_n_do papa utiliz_rse co_ _u

aplicaci_n sspe¢_ioa,

--I_Y,_2

pintLira,

_-SP

ADVERTENCIA:

Riesgo de Quemaduras

qua"puede occurrir

c6mo

p_vertirlo

dam_$ toque parte$ de metal expuesta$ en el

compr_$or dL_a_e 0 ir_mediatamente de_pu&s

de la oper_i6r_, el comp_sor

per manecer_

caliente por vsrios r_ir_uto_ lumjo de la

Tocar el metal expuesto tsl como el C_b_zal

gel compnssor o los tL_bo_ de s_lida gel

e-_c_pe, puede oc_sionarle eeHas

quemaduras,

NO Io cubra _n fur_d_ protecto_

o intentc

rnantenirniento hasta que la unidad haya

aleanzado su e=_riamiento.

ADVERTENGIA:

qu_ puede

Riesgo

de Partes

M6viles

occurrir

_)

c6rno

prevenirlo

Parte$ movible$ tal_s cor_o I_ polea, el

volar_te y la corrsa podHan set la causa de

_r_rias le$ione$ si _11_ e_rarar_ e_ _cto

cor_u_d o sus rop_._,

Nunca opere el compresor sin sus d_erl_6

o _us eL_biert_._ rer_ovid_._ o d_Sadas,

Inte_ar

operar el compresor con sus

partes da_adas o faltantes, o la reparaci_

del comp_$or

con sus pro_ecciones

remo¥ida$, puede exponeflo

a usted a

partes movibles, que podrian Rsultar en

lesiones se_a$.

Cualquie¢ reps_ci6n req_erida por _te

producto debe _e_ efectuada p<w personal

autorizado de los _ervicenbos.

ADVERTENCIA:

qua" puede

Riesgo

de Gafda

oc_urrir

el

_._

c6mo

omvenirlo

Opere siempre el comprr_$or en una posiei6n

e_table y segura a fir_ de pnsver_irel

movir_ie_to _!_ciderl_l d_ I_ _idad. J_m_s

opere el compresor sol)re un _echo u o_ra

posiei6n elevada. Utilice manguera$

_dieiort_l_

de aiPr_p_r8 alP._llz_r po_i_io_e_

altas.

Un _113pr_ff

port_til puede caerse de I_

m_=

el b_o

d_ ±_d_io o gel t_ho da_ando

al cot np_e_¢_ y pudiendo r_sult_r en _ias

lesiones o la muerte del operador.

37-SP

L33CC9_

•J_ q [e];(i

ADVE_ENC;IA:

Riesgo de S_r_as

Transportar

el Compresor

_Fucgo_ inhalaci6n,

qu_

puede

Lesiones

o Dafios

da_o a la Supcrficie

a la Propiedad

de vehfculo$)

occurrir

c_mo

El aceite puede derramaPse y ello poc_r'a

resultar on ssria_ lesione-_ o I_ musrte debido

_1rie_go de irl_lldio o irlllaJ_ci_ll, El der_rne

de eceite dat_a _;_11_br_

pilltU eR8U L_r'a_

_u]_erli¢ies de vehicLilos 0 _ernol_ue_.

al

prevenirlo

Deposite el compRsof sol)re una alfombrilla

protectora cuando Io l_anspor te. a _111

d_

protecjer _1vehicLilo de p_rdid_s por _oteo,

Retire el O011_Dr_r del vShlcLIlo

irlll_Gd i_ll_ellte

d_pLl_

(_e _lJ _rr_bO _1

d_tillo,

:,l=lq [_1;{_

ADVERTENCIA:

qu_

puede

Riesgo

de Operaci6n

occurrir

Lasegura

A

c_Smo prevenido

L_ op_r_cion irls_gura de SIJCOil_D_or de

e_s podr ta oca$ioe_arle serias lesiones o la

mu_rte _ usted u otPos,

Revise y contprenda

_od_

I_ in_Lruccioile_ y

Familiarlc_se con los m6todos de ¢f}_raci_n

y ContrOl c_l _r_pr_or

de _ire.

Mantenga lil0_ I_ zona d_ operaoioile_ c_

pe_n_

alg_il_, _nir_ales dor_e_ti_

y

ObSt_CLIIOS.

Mantenga _lej_dos a Io_ niffo$ d_l ¢or_pn_._r

de aire en todo ntomento.

NO ope_ el produ_to cuando _ e ncue n_L_

fa_gado o bejo la influ_ncia del _lcohol o

dn_a$. Est_ _l_rta en todo momento.

Jant_$ altere los elemento_

e_Le prc_cto.

de seguridad de

Equip_ I_ zon_ de of}_r_cicetes

exUnguido_ de fuego.

con un

NO opere la m_¢!uin_ $i 6$ta _iene parte$

f_l_ant_$_ rota$ o no _lutorJzad_l$.

CONSIERVAR

--I_Y,_2

IESTAS INSTRUCCIONIES

_-SP

Ft_milierTG_s_ con lossiguiente._

tdrminos,

antes de opetar I_unidad:

GFM: (Oubiofeetper minute)PiesoObioos

por minute.

8CFM_ (Stardard cubic feet per minute)

PiSS c0bJcoe est_ndar par minuto; una

unJdad de medJda qua permite medir la

oantided de entrega de sire.

PSlG: (Pounds Per Squ_e inch Gouge) PresJ6n manometrJce creative en IJbras par

pulgade ouedrada; una medide de la

ent_a

de sire.

G6digo do certiflcaoi_n:

los pPoduotos

qua usan una o m&s de lee eiguientes

maPcas: UL, CUL, ETL, CETL, hen sido

evaluedoe pot OSHA, laboratorios

independientes oertifioados en seguridad,

y teOnen los es_ndar_s sus_fiptoepot

Underwriters L_boratoriee Standards for

sai'aty.

PresiSn minima de aorta: Cuendo el

motor est_ epagado, la ptesi6n del tanque

de site baja a medida qua u_ed contin0a

usendo su acoesorJo. Cuendo Is presi6n

del tenque baja al velar fijado on f_brica

coma punto bejo, el motor volvon_ a

ertancer _Jtom&ticemente.

La presidn

baja e la oual elmotor atranca

eutom_ticemente,

se llama ptesi6n

"minima de carte".

Presi_n m_vJma de carte: Cuando un

compresor de aire se enoiende y

comienza a funoionar, la ptesi6n de _re on

el tanque oomienza a aumentar. Aumente

haste un valor de presi6n alto fijado on

f_brice antes de qua el motor

eutom_ticemente

se apague proteqiendo

e su tenque de aire de presiones m_s

sites qua su oapacidad.

La presidn alto a

Is ouel el motor se apega se llama presi6n

"m_ima de carte'.

Ramel: Ci_uito el_trico qua tranepotte

eleotrioidad desde el penal de control

hasta el tomacorriente.

C6mo bloqueer Is alimentaoidn:

Coloque un oerPojo on el interruptor de

elimentaci6n pera impedir qua alguien

poeda enoenderlo,"

Ests unida_t 8s sufi¢iente par_ abaslecer de ene_|a ell'trios a los siguientes aS_SOrt0Sr Esto_ Se

eneuentr_n disponibles a travds dd cat_i[o£o pare herramrent_s e]dotrtcas y manuales, en

eualqurera de los oomeraios que msntiene la lines oomplet_ de SEARS.

Ac_asorios

• Men_uera

• FiltrO on l|nee

• Et_tade do aiPe a neum_ioos

• Jueqoe de oonectores

tamafios)

de aire:

1/4', 5/18,3/8"

medidas

o 1/2"

D.I. en verJ_

r_pidos (varies

• Reguladores de ptesi6n de aire

• Lubrioadores de niebla de aoeite

Esta bombs compresom de aire es topaz

de funoionar oontinuamente, sin embargo

pare prolonger la vide Otil de su

oompresor de air_ee recomJenda

mantener un 01010promedio de servioio