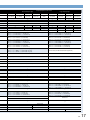

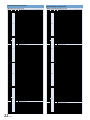

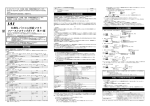

Download Mitsubishi XMP-3350 Specifications

Transcript