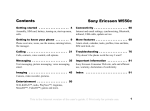

Download ElfinX TX-DSR04 User guide

Transcript