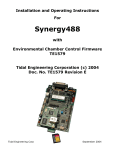

Download Simplicity Synergy X9 Specifications

Transcript