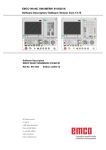

Download EMCO WinNC SINUMERIK 810/820 T Software Description

Transcript