Download Daikin IM-820 Installation manual

Transcript

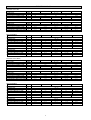

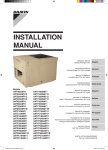

INSTALLATION MANUAL Installation Manual Rooftop Package Units Installationshandbuch Kompaktanlage Für Dachmontage Deutsch Manuel D’installation Conditionneurs D’air En Toiture Français Installatiehandboek Compactsysteem Voor Dakmontage Models UAT180AMY1 UAT240AMY1 UAT280AMY1 UAT320AMY1 UAT450AMY1 UAT560AMY1 UAT700AMY1 UAT850AMY1 UATC10AMY1 UATC12AMY1 UATP180AMY1 UATP240AMY1 UATP280AMY1 UATP320AMY1 UATP450AMY1 UATP560AMY1 UATP700AMY1 UATP850AMY1 UATPC10AMY1 UATPC12AMY1 UATY180AMY1 UATY240AMY1 UATY280AMY1 UATY320AMY1 UATY450AMY1 UATY560AMY1 UATY700AMY1 UATY850AMY1 UATYC10AMY1 UATYC12AMY1 UATYP180AMY1 UATYP240AMY1 UATYP280AMY1 UATYP320AMY1 UATYP450AMY1 UATYP560AMY1 UATYP700AMY1 UATYP850AMY1 UATYPC10AMY1 UATYPC12AMY1 English Manual De Instalación Unidades Del Conjunto Del Tejado Manuale Di Installazione Unità A Pacchetto Per Installazione Sul Tetto Εγχειρίδιο Εγκατάστασης Μονάδες Συσκευασίας Της Κορυφής Της Οροφής Manual De Instalação Unidades De Conjuntos De Telhado Руководство По Установке Компактные Установки Для Кондиционирования Воздуха, Монтируемые На Крыше Здания Kurulum kılavuzu Çatı Tipi Ambalaj Üniteleri Nederlands Español Italiano Ελληνικά Portugues Русский Türkçe OUTLINE AND DIMENSIONS 10 UAT(Y)(P)180AMY1 25 46 150 150 150 150 668 49 10 170 170 36 1142 1100 1192 Return air duct flange 36 1100 668 25 A Detail B Detail Hanger (4 places) 668 232 1000 200 Supply air Return air Control box Condenser Air inlet Drain R 1 71 135 Return air 192 230 Supply air 412 31 360 25 15 (1342) 1000 25 25 540 16- ø3 Holes 15 (1342) B 265 25 46 4-15X25 Mtg. holes 265 200 34 232 16- ø3 Holes 51 Supply air duct flange 34 200 10 49 10 125 125 125 125 20 1020 15 100100 15 20 A 51 (unit ; mm) Except : Drain size. (unit ; inch) 437 Wiring hole 1530 50 1342 1300 1392 1020 Return air 173 Supply air Return air Control box LP1 HP1 71 107 1000 Supply air 50 437 Drain R1 Wiring hole Check Joint 1530 i B Detail 25 20- ø3 25 B 265 Hanger (4 places) 192 230 31 173 412 1020 135 107 1000 25 15 (1342) 4-15X25 Mtg. holes 265 25 46 51 20- ø3 15 (1342) 1020 1300 173 Return air duct flange 36 170 170 36 60 150 150 150 150 150 150 60 49 1020 10 10 Supply air duct flange 49 10 15100100 15 60 150 150 150 150 150 150 60 1020 10 107 51 A 25 46 UAT(Y)(P)240,280,320AMY1 - Side flow 25 A Detail Condenser Air inlet OUTLINE AND DIMENSIONS UAT(Y)(P)240,280,320AMY1 - Down flow 25 46 4-15X25 Mtg. holes B 265 1000 368 15 (1342) 10 96 10 261 812 10 96 Supply air duct flange Return air duct flange 1300 51 265 10 10 49 160 160 87 View C (Bottom view) 281 41 100100 40 832 160 160 160 160 49 1058 49 160 160 160 160 160 160 25 46 51 832 Supply air A 25 Detail B 372 46 140 140 46 Detail A 226 1058 Return air 242 155 45 281 1342 1300 1392 637 372 1038 10 320 160 160 49 25 Condenser Air inlet 15 (1342) 25 25 10 10 16- ø3 Holes 19- ø3 Holes 1000 Hanger (4 places) Drain R 1 Control box Condenser Air inlet 9 71 (4)RT80, 100A only 9 Wiring hole Return air 437 Supply air 1530 C UAT(Y)(P)450,560AMY1 - Side flow 15 (2032) 46 25 51 123 25 Detail A 10 C.O. H.P B 1200 1330 25 A A 1670 1800 49 1990 2032 2082 4-15X25 Mtg. holes B B 235 123 428 1744 Return air C.O. only 123 Return air Detail B Hanger (4 places) Supply air 1200 124 428 169 77 Supply air 25 235 123 1744 46 25 51 123 25 51 123 15 (2032) Supply air & Return air Duct flange Control box Condenser Air inlet Return air Condenser Air inlet Condenser Air inlet HP1 LP1 483 50 HP2 LP2 Drain R 1 Check Joint Wiring hole A ii 428 1744 34 120120 120 34 1744 1990 72 200 200200200200200 200200 72 10 26- ø3 Holes OUTLINE AND DIMENSIONS 368 10 Hanger 10 Detail B (4 places) 1200 Control box C.O. only RT-A RT-AR Return air 483 Supply air Drain R 1 A 8 B 1200 1330 8 77 A 1670 1800 Condenser Air inlet Condenser Air iinlet Condenser Air inlet Wiring hole C UAT(Y)(P)700,850AMY1 383 27.5 15 144 25 144 22.5 Return air 383 A 10 25 144 80 23 2768 2200 165 566 758 100 144 Supply air duct Flange 80 2850 2720 50 Condenser air inlet 1302 1735 Return air duct flange Condenser Air inlet Control box 10 Wiring hole Drain R1 iii 28- 3 10 Condenser Air inlet 320 510 640 Supply air Return air 80 150 150 150 150 80 758 1302 51 150 150 150 150 150 150 150 150 51 640 80 120 120 120 12080 20- 3 1146 43 120 120 120 120 43 566 2200 1912 10 80 80 Supply air Detail A 1412 Supply air duct flange 10 24- ø3 Holes 10 86 1762 1432 180 180 180 180 180 180 180 86 10 10 359 59.5 120120 59.5 25 25 372 46 140140 46 10 1990 2032 2082 15 (2032) 104 51 235 View C (Bottom view) B 235 4-15X25 Mtg. holes B 46 25 1432 1990 Detail A 294 1782 Return air Supply air 264 104 25 91 15 359 Return air duct flange 25 717 372 (2032) 1782 200 200 200 200 200 200 200 200 91 A 51 79 46 25 UAT(Y)(P)450,560AMY1- Down flow 339 10 22- ø3 Holes OUTLINE AND DIMENSIONS 3148 UAT(Y)(P)C10,C12AMY1 iv ELECTRICAL WIRING DIAGRAM MODEL:UAT(P)180AMY1 v ELECTRICAL WIRING DIAGRAM MODEL:UATY(P)180AMY1 vi ELECTRICAL WIRING DIAGRAM MODEL:UAT(P)240,280,320AMY1 vii ELECTRICAL WIRING DIAGRAM MODEL: UATY240,280AMY1 viii ELECTRICAL WIRING DIAGRAM MODEL: UATYP240,280AMY1,UATY(P)320AMY1 ix ELECTRICAL WIRING DIAGRAM MODEL: UAT(P)450,560AMY1 x ELECTRICAL WIRING DIAGRAM MODEL: UATY450,560AMY1 xi ELECTRICAL WIRING DIAGRAM MODEL: UATYP450,560AMY1 xii ELECTRICAL WIRING DIAGRAM MODEL: UAT(P)700,850AMY1 xiii ELECTRICAL WIRING DIAGRAM MODEL: UATY(P)700,850AMY1 xiv ELECTRICAL WIRING DIAGRAM MODEL: UAT(P)C10,12AMY1 xv ELECTRICAL WIRING DIAGRAM MODEL: UATY(P)C10,12AMY1 xvi 1. Outline And Dimensions 2. Electrical Wiring Diagram 3. Installation of the Unit 4. Physical Data 5. Electrical Data page i-iv page v-xvi page 1~4 page 5 page 6 6. Wire connection 7. Operating Range 8. Refrigerant 9. Service and Maintenancen 10. Trouble Shooting page 7~9 page 10 page 11 page 11 page 12 SAFETY PRECAUTIONS Before installing the air conditioner unit, please read the following safety precautions carefully. ! Caution Please take note on the following important points when installing. • Do not install the unit where leakage of flammable gas may occur. If gas leaks and accumulates around the unit, it may cause fire ignition. • Ensure that the drainage piping is connected properly. • Do not overcharge the unit. This unit is factory pre-charged. Overcharge will cause over-current or damage to the compressor. • Ensure that the unit service panel is closed after service or installation. Unsecured panel will cause unit to operate noisily. INSTALLATION OF THE UNIT 1.1 Location For Installation • Install the unit in such way that air distributed by the unit cannot be drawn in again (as in the case of short circuit of discharge air). Allow sufficient space for maintenance around the unit. • When two or more units are installed in a location, they must be positioned such that one unit will not be taking the discharge air from another unit. • Ensure that there is no obstruction of air flow into or out of the unit. Remove obstacles which block air intake or • • • • • • • • • • air discharge. The location must be well ventilated, so that the unit can draw and distribute plenty of air A place capable of bearing the weight of the outdoor unit and isolating noise and vibration. A place protected from direct sunlight. Otherwise use an awning for protection, if necessary. A place where smooth drainage of rain water and water formed by defrosting is acceptable. A place where the unit will not be buried in snow. A place where air outlet port is not exposed to strong wind. A place where the air discharge and operating sound level will not annoy the neighbours. The location must not be susceptible to dust or oil mist. The location where it is not accessible by general public. Keep the unit, power cable and transmission wiring, at least 1 m away from TVs and radios, to prevent distorted pictures and static. (Depending on the type and the source of the electrical waves, static may be heard even when more than 1 m away) 1 English INDEX INSTALLATION OF THE UNIT 1.2 Unit Support Roof curb Unit 1. The figure shows the use of the roof curb for mounting these units. Seal with tar Roof deck 2. The curb should be sealed and fixed to the roof by weather stripping. A suggested means of sealing the unit and roof curb as shown in the left. 4 - ø15 Roof mounting holes 6 - ø15 Unit mounting holes Roof curb 1.3 Duct Construction • • • • • • These unit are equiped with supply and return air openings. Duct connection to the unit should be made with duct flanges and secured directly to the air openings with flexible duct connectors to avoid normal noise transmission. To prevent air leakage, all duct seams should be sealed. Ducts in the spaces that not air-conditioned, must be insulated. Ducts exposed to the outside must be weather proofed. Ducts that entering building through the roof, the entering should be sealed with weather stripping to prevent the rain, sand, dust etc. from entering the bulding. Correct size of filter must be install at the return air duct. 1.4 Unit Lifting UAT 180~560 Hanger brackets at 4 corner of the unit are used for unit lifting purpose. UAT 700,850 Hanger Bracket Chain A The angle A of the chain should be at least 45°, and insulation should be added at 4 corner of the chain to prevent the damage of the panel when lifting. 1.5 Drain piping • Spreader Bar Lifting Beam Chain The drain piping should have a drain trap. B • C • A 1 FPT condensate drain fitting is provided. The drain pipe can be led out at the front side. The drain pipe must be provided with a trap on the outside of the unit and also installed at an incline for proper drainage, as shown in the right. To prevent condensate formation and leakage, provide the drain pipe with insulation to safeguard against sweating. Upon completion of the piping work, check that there is no leakage and that the water drains off properly. A • A ≥ 70mm B ≥ 2C C ≥ 2XE. S. P Drain trap Drain piping The drain pipe should extend below this level. Lifting Holes for shackle (4 corners) Note: ESP = External Static Pressure Drain trap for condensate UAT C10,C12 2 1.6 Space required around units English INSTALLATION OF THE UNIT (unit ; mm) All space value ; minimum clearance UAT 450, 560 300 Condenser inlet (min clearance) 500 Evaporator coil, air filter service 1000 UAT 180~320 300 Condenser inlet 300 Electrical control circuit & compressor service 700 Evaporator coil, air filter service Condenser inlet 1000 700 Evaporator coil, air filter service 1000 300 Electrical control circuit & compressor service (min clearance) 1500 1500 (min clearance) Condenser outlet Condenser outlet Condenser inlet 1000 1500 Electrical control circuit & compressor service Condenser inlet (min clearance) 1000 UAT 700~C12 3000 (min clearance) 1000 Evaporator coil, motor service (min clearance) 2000 1000 3 Condenser outlet INSTALLATION OF THE UNIT 1.7 Unit conversion Please check for accessory parts as below. (Packed in the unit, and available for convertible unit only) 1. Side inlet cover 1 piece 2. Casing leg 2 pieces UAT(Y)(P)240, 280, 320AMY1 4 pieces UAT (Y)(P)450, 560AMY1 In the case of converting to down flow unit, change according to the following steps. STEP 1 Remove top panel 2. Additional casing leg (Accessory parts) STEP 2 Remove supply air cover Remove service panel Remove Remove duct flange STEP 3 Remove duct flange Re-install supply air cover Remove low cover Re-install fan assy STEP 4 Re-install top panel 1. Additional side inlet cover (Accessory parts) Re-install service panel 4 EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) kg CFM L/S mmAq CFM L/S UAT180AMY1 UAT240AMY1 5.2 1800 850 4.0 2826 1334 10 5650 2667 SLM CONTROLLER 7 / 15 : 0.14 SCROLL / 1 WASHABLE SARANET / 1 1020 x 615 x 1 4500 2124 m : mm2 mm kg CFM L/S mmAq CFM L/S UAT280AMY1 R22 5.9 3532 1667 820 x 615 x 1 UAT560AMY1 UAT700AMY1 5.9 x 2 6710 3167 20 11300 5333 10.5 x 2 8000 3776 UAT450AMY1 6.2 3600 1699 4.5 x 2 5651 2667 20 11300 5333 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 WASHABLE SARANET / 2 840 x 667 x 1 8000 3776 UAT850AMY1 R22 10.4 x 2 9600 4531 UATC10AMY1 UATC12AMY1 16.5 / 19.5 11000 5191 19.5 x 2 12500 5899 30 20000 9439 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 m : mm2 mm UAT320AMY1 840 x 667 x 1 WASHABLE SARANET / 2 1370 x 735 x 1 WASHABLE SARANET / 2 & 4 860 x 505 & 600 x 4 HEAT PUMP (R22) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) COOLING ONLY (R407C) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) HEAT PUMP (R407C) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW EXTERNAL STATIC PRESSURE CONDENSER AIR FLOW CONTROL CONTROL WIRE LENGTH (STANDARD / MAX) : SIZE COMPRESSOR (TYPE / QUANTITY) AIR FILTER (TYPE / QUANTITY) AIR FILTER DIMENSION (LENGTH x WIDTH x THICKNESS) kg CFM L/S mmAq CFM L/S UATY180AMY1 UATY240AMY1 4.5 1800 850 4.7 2826 1334 10 5650 2667 SLM CONTROLLER 7 / 15 : 0.14 SCROLL / 1 WASHABLE SARANET / 1 1020 x 615 x 1 4500 2124 m : mm2 mm kg CFM L/S mmAq CFM L/S 820 x 615 x 1 UATY560AMY1 UATY700AMY1 5.6 x 2 6710 3167 20 11300 5333 10.5 x 2 8000 3776 kg CFM L/S mmAq CFM L/S kg CFM L/S mmAq CFM L/S 840 x 667 x 1 kg CFM L/S mmAq CFM L/S UATP180AMY1 UATP240AMY1 4.6 1800 850 4.0 2826 1334 kg CFM L/S mmAq CFM L/S 820 x 615 x 1 UATP560AMY1 UATP700AMY1 4.2 x 2 6710 3167 20 11300 5333 9.6 x 2 8000 3776 UATY850AMY1 R22 9.4 x 2 9600 4531 UATYC10AMY1 UATYC12AMY1 16.0 / 20.5 11000 5191 20.5 x 2 12500 5899 WASHABLE SARANET / 2 & 4 860 x 505 & 600 x 4 UATP280AMY1 R407C 5.9 3532 1667 UATP320AMY1 UATP450AMY1 6.2 3600 1699 4.5 x 2 5651 2667 20 11300 5333 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 WASHABLE SARANET / 2 840 x 667 x 1 8000 3776 UATP850AMY1 R407C 10.4 x 2 9300 4389 UATPC10AMY1 UATPC12AMY1 14.5 / 18.0 11000 5191 18.0 x 2 12500 5899 30 20000 9439 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 840 x 667 x 1 WASHABLE SARANET / 2 1370 x 735 x 1 UATYP180AMY1 UATYP240AMY1 4.3 1800 850 4.7 2826 1334 WASHABLE SARANET / 2 & 4 860 x 505 & 600 x 4 UATYP280AMY1 R407C 5.6 3532 1667 10 5650 2667 SLM CONTROLLER 7 / 15 : 0.14 SCROLL / 1 WASHABLE SARANET / 1 1020 x 615 x 1 4500 2124 820 x 615 x 1 UATYP560AMY1 UATYP700AMY1 5.8 x 2 6710 3167 20 11300 5333 9.4 x 2 8000 3776 UATYP320AMY1 UATYP450AMY1 6.0 3600 1699 5.0 x 2 5651 2667 20 11300 5333 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 WASHABLE SARANET / 2 840 x 667 x 1 10000 4719 UATYP850AMY1 R407C 9.6 x 2 9600 4531 UATYPC10AMY1 UATYPC12AMY1 13.5 / 20.5 11000 5191 20.0 x 2 12500 5899 30 20000 9439 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 m : mm2 mm 10000 4719 10 5650 2667 SLM CONTROLLER 7 / 15 : 0.14 SCROLL / 1 WASHABLE SARANET / 1 1020 x 615 x 1 4500 2124 m : mm2 mm 4.7 x 2 5651 2667 20 11300 5333 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 WASHABLE SARANET / 2 840 x 667 x 1 WASHABLE SARANET / 2 1370 x 735 x 1 m : mm2 mm UATY450AMY1 6.0 3600 1699 SEQUENTIAL CONTROLLER - / 100 : 0.14 SCROLL / 2 m : mm2 mm UATY320AMY1 30 20000 9439 m : mm2 mm UATY280AMY1 R22 5.6 3532 1667 840 x 667 x 1 WASHABLE SARANET / 2 1370 x 735 x 1 5 WASHABLE SARANET / 2 & 4 860 x 505 & 600 x 4 English PHYSICAL DATA COOLING ONLY (R22) MODEL REFRIGERANT REFRIGERANT CHARGE EVAPORATOR AIR FLOW ELECTRICAL DATA COOLING ONLY (R22) MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A HEAT PUMP (R22) MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A COOLING ONLY (R407C) MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A HEAT PUMP (R22) MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A MODEL POWER SUPPLY V/ph/Hz VOLTAGE RANGE V MAX CONTINUOUS CURRENT (COMP) A FULL LOAD CURRENT (FLA, COMP) A LOCKED ROTOR CURRENT (LRA, COMP) A UAT180AMY1 UAT240AMY1 14.0 12.1 74 23.0 15.6 95 UAT560AMY1 UAT700AMY1 26.9 x 2 16.9 x 2 118 x 2 27.5 x 2 22.3 x 2 118 x 2 UATY180AMY1 17.0 15.0 101 UATY560AMY1 31.0 x 2 23.0 x 2 81 x 2 UATP180AMY1 14.0 13.0 74 UATP560AMY1 26.9 x 2 16.9 x 2 118 x 2 UATYP180AMY1 17.0 15.0 101 UATYP560AMY1 26.9 x 2 16.9 x 2 118 x 2 UATY240AMY1 22.0 19.5 84 UATY700AMY1 27.5 x 2 22.3 x 2 118 x 2 UATP240AMY1 23.0 15.9 95 UATP700AMY1 31.0 x 2 22.3 x 2 118 x 2 UATYP240AMY1 23.0 15.9 95 UATYP700AMY1 31.0 x 2 22.3 x 2 118 x 2 6 UAT280AMY1 400 / 3 / 50 380 ~ 415 26.9 16.9 118 UAT320AMY1 UAT450AMY1 27.5 22.3 118 23.0 x 2 15.6 x 2 95 x 2 UAT850AMY1 400 / 3 / 50 380 ~ 415 37.0 x 2 30.0 x 2 198 x 2 UATC10AMY1 UATY280AMY1 400 / 3 / 50 380 ~ 415 31.0 23.0 81 UATY320AMY1 UATY850AMY1 400 / 3 / 50 380 ~ 415 37.0 x 2 30.0 x 2 198 x 2 UATYC10AMY1 UATP280AMY1 400 / 3 / 50 380 ~ 415 26.9 16.9 118 UATP320AMY1 UATP850AMY1 400 / 3 / 50 380 ~ 415 45.0 x 2 30.0 x 2 198 x 2 UATPC10AMY1 UATYP280AMY1 400 / 3 / 50 380 ~ 415 26.9 16.9 118 UATYP320AMY1 UATYP850AMY1 400 / 3 / 50 380 ~ 415 45.0 x 2 32.0 x 2 198 x 2 UATYPC10AMY1 35.0, 50.0 24.0, 30.0 175, 215 27.5 22.3 118 35.0, 50.0 24.0, 30.0 175, 215 31.0 22.3 118 35.0, 50.0 24, 30 175, 215 31.0 22.3 118 35.0, 50.0 24, 30 175, 215 UATC12AMY1 50.0 x 2 30.0 x 2 215 x 2 UATY450AMY1 22.0 x 2 19.5 x 2 84 x 2 UATYC12AMY1 50.0 x 2 30.0 x 2 215 x 2 UATP450AMY1 23.0 x 2 15.6 x 2 95 x 2 UATPC12AMY1 50.0 x 2 30.0 x 2 215 x 2 UATYP450AMY1 23.0 x 2 15.9 x 2 95 x 2 UATYPC12AMY1 50.0 x 2 30.0 x 2 215 x 2 • All electrical work must be carried out by qualified electrician and accordance with local supply requirement and associated regulation. Method for connecting electric wire Before connecting the wire, consult the electric power company of jurisdiction. 2. Remote control wire connection. 1. The entire wiring diagram of unit. a b PE UAT(Y)(P)450, 560, 700, 850, C10, C12AMY1 LCD Remote (Top case) GND +5 B A g c Connection at Mainboard f d GND +5 B A e a. Power supply d. Unit b. Main switch/fuse e. Remote control (field supply) f. Connection wiring for unit & remote controller c. Power supply wiring for unit g. Earth Connection Wire (field supply) Connection behind Top case Note: For UAT(Y)(P)180, 240, 280, 320AMY1, wire is attached the remote control. Connect directly to connector 'CN2' on mainboard. 3. Wiring connection to unit Remove the panel and connect the units power supply wires to terminal block, as shown below. UAT(Y)(P)180, 240, 280, 320AMY1 UAT(Y)(P)450, 560AMY1 Terminal block RT60 only Terminal block Recommended switch box position UAT(Y)(P)700, 850, C10, C12AMY1 Recommended switch box position Terminal block NOTE: While installing the circuit breaker onto the unit, make sure that the screws do not damage the components (e.g. coil) inside of the unit. The circuit breaker also can be installed without attaching to the unit. 7 English WIRE CONNECTION WIRE CONNECTION Arrangement of terminal block for controller are shown below. CONTROL MODULE UAT(Y)(P)180 CONTROL MODULE UATY(P)450,560 UATY(P) only Connector for remote control wires PCB 52F 52C2 R OOM 52C1 ID 4 PCB 52C 52F1 T1 52F2 4W V 1 47 4W V 2 C 2 47 51F1 O U T F AN 1 X1 X2 X3 O U T F AN 2 F1 6 6 L1 L2 F1 95 98 96 51F1 51C2 51C1 51C N L3 X1 X2 TB1 TB2 TB1 L1 L2 L3 N Connector for Terminal Block remote control for power supply wires wires UATY(P) only V R S T A1 U V W A2 X1 W 6 Connector for remote control wires 47 52C2 PCB N R S T A1 U V W A2 X1 X2 RESET 2 UATY(P) only UATY(P) only 52C1 N L U T N CONTROL MODULE UAT(P)450,560 UATY240,280 only N S N L IV E R 52F3 PCB FZ 52F1 52C N Terminal Block for power supply wires CONTROL MODULE UAT(Y)240,280, UAT(Y)(P)320 52F2 TB2 N Connector for remote control wires 51C T A1 V W A2 6 95 98 96 51C1 F1 51C2 TB1 All except for UATY240,280 52F2 Terminal Block for power supply wires R S U S R T N TB1 2 RESET 95 98 96 47 UATY(P) only Terminal Block for power supply wires CONTROL MODULE UATYP240,280 CONTROL MODULE UAT(Y)(P)700,850 F1 PCB 47 NEUTRAL DS4 DS3 DS2 DS1 ID4 ID3 ID2 ID1 W R S T A1 U V W A2 S T A1 U V W A2 HP1 HP2 ON/OFF OUT FAN 4 4WV 1 4WV 3 4WV 2 4WV 4 HEATER 1 HEATER 2 IN FAN COMP 1 COMP 2 COMP 3 N T S R PCB X1 R COMP 4 52F1 52F2 LIVE TRANSFORMER HP3 T OUT FAN 1 V OUT FAN 2 S U A B 5V GND R F1 OUT FAN 3 HP4 ROOM Connector for remote control wires L 52C 52C2 52C1 Connector for remote control wires 52F1 &51F1 R S T N 6 RESET 47 2 95 98 96 51F1 51C TB1 S T A1 U V W A2 N N R S T A1 U V W A2 52F3 52F2 TB2 N R N Terminal Block for power supply wires 51C2 51C1 TB1 Terminal Block for power supply wires X1 X2 L1 L2 L3 UATY(P) only N N 1 2 3 4 TB2&3 CONTROL MODULE UAT(Y)(P)C10,C12 F1 Connector for remote control wires 47 52F 52C1 52F2 52C2 51F1 PCB X1 52F3 TB1 51C1 51C2 TB2 & 3 Terminal Block for power supply wires UATY(P) UATY(P) only only 8 X2 5 Wiring Example and Selection of Circuit Breaker Values of breaker and wire size are recommended as in table below. MODEL UAT(Y)(P)180AMY1 UAT(Y)(P)240AMY1 UAT(Y)(P)280AMY1 UAT(Y)(P)320AMY1 UAT(Y)(P)450AMY1 UAT(Y)(P)560AMY1 UAT(Y)(P)700AMY1 UAT(Y)(P)850AMY1 UAT(Y)(P)C10AMY1 UAT(Y)(P)C12AMY1 POWER CABLE BREAKER (mm2) CAPACITY (A) 8.4 8.4 13.3 13.3 13.3 21.2 33.6 42.4 60.0 60.0 32 32 50 50 50 63 80 100 125 125 380~415V, 50Hz, 3ø OVER CURRENT PROTECTION EARTH2 CABLE (mm over) SWITCH (A) 32 8.4 32 8.4 50 13.3 50 13.3 50 13.3 63 21.2 80 33.6 100 42.4 125 60.0 125 60.0 Note: A main switch or other means for disconnection, having a contact separation in all poles, must be incorporated in fixed wiring in accordance with local and national legislation. • The unit is to be wired directly from an electrical distribution board either by a circuit breaker (preferred) or HRC fuse. • Fix the power supply wiring to control module. Connect control wiring to control terminal block through the control box’s hole. Note: Earth wiring must be connected. The power supply cord must be equivalent to H05VV-F (60227 IEC 52 or 60227 IEC 53) which is the minimum requirement, and to be used in protective tube. Warning: • Before working on this unit, isolate from the power supply. • Electrical wiring to this unit and the remote controller shall be installed in accordance with the appropriate requirements of the local wiring code. e.g. AS3000 9 English WIRE CONNECTION OPERATING RANGE Ensure the operating temperature is in allowable range. Cooling (R22) Cooling (R407C) Cooling Only Unit & Cooling Mode For Heat Pump Unit Cooling Only Unit & Cooling Mode For Heat Pump Unit 50 46 40 Outdoor temp. (°C DB) Outdoor temp. (°C DB) 54 50 30 20 10 0 40 30 20 10 0 -5 -5 -10 10 15 20 24 25 -10 10 30 15 20 24 25 Indoor temp. (°C WB) Indoor temp. (°C WB) Heating (R22 & R407C) Heat Pump Unit Only 20 Outdoor temp. (°C WB) 15 10 5 0 -5 -10 ! Caution : -15 10 15 20 25 27 The use of your air conditioner outside the range of working temperature and humidity can result in serious failure. 30 Indoor temp. (°C DB) 10 30 • All units are pre-charged with R407C refrigerant. • R407C is a zeotropic refrigerant mixture which has zero ozone depletion potential and thus conformed to Montreal Proto • • • • • col regulation. It requires Polyester oil (POE) oil for its compressor lubricant. Its refrigerant capacity and performance are about the same as the refrigerant R22. POE oil is used as lubricant for R407C compressor, which is different from the mineral oil used for R22 compressor. During installation or servicing, exra precaution must be taken not to expose the R407C system too long to moist air. Residual POE oil in the piping and components can absorb moisture from the air. Refrigerant R407C is more easily affected by dust or moisture compared with R22, make sure to temporarily cover the ends of the tubing prior to installation. No additional charge of compressor oil is permitted. No other refrigerant other than R407C. Tools specifically for R407C only (must not be used for R22 or other refrigerant) i) Manifold gauge and charging hose iv) Vacuum pump c/w adaptor ii) Gas leak detector v) Flare tools iii) Refrigerant cylinder / charging cylinder vi) Refrigerant recovery machine SERVICE AND MAINTENANCE ! Warning • Disconnect from the main power supply before servicing the air conditioner unit. • DO NOT pull out the power cord when the power is ON. This may cause serious electrical shocks which may result in the hazards. ! Caution • Before turning off the power supply, set the remote controller's ON/OFF switch to the “OFF” position to prevent the nuisance tripping of the unit. • If this is not done, the unit's fans will start turning automatically when power resumes, posing a hazard to service personnel or the user. SERVICE OF THE FILTER • • • • Remove any dust adhering to the filter by using a vacuum cleaner or wash in lukewarm water (below 40°C) with a neutral cleaning detergent. Rinse the filter well and dry before placing it back onto the unit. Do not use gasoline, volatile substances or chemicals to clean the filter. Clean the filter at least once every 2 weeks. Or more frequently if neccesary. Filter Position The filters are mounted in front of the indoor heat exchanger. * (Air filter : special order or field supply) UAT(Y)(P)180~560 UAT(Y)(P)700~C12 Filter Filter Service panel Filter cover removed when servicing note: both side for unit 450, 560 Filter cover removed when servicing 11 English REFRIGERANT & SPECIAL PRECAUTIONS WHEN DEALING WITH R407C UNIT MAINTENANCE Maintenance Procedures Service Parts Panels Outdoor Heat Exchanger 1. Clean any dirt or dust on the grille or panel by wiping it with a soft cloth soaked in lukewarm water (below 40°C) and a neutral detergent solution. 2. Do not use gasoline, volatile substances or chemicals to clean the indoor unit. 1. If the unit is used for prolonged period, the outdoor heat exhanger will become dirty, and reducing the air conditioner performance. Consult your local dealer or air conditioning contractor on cleaning of the heat exchanger. TROUBLESHOOTING If any malfunction of the air conditioner unit is noted for some simple trouble-shooting tips. Check the following fault conditions and causes for some simple trouble-shooting tips. Causes Problem Unit does not run Action Power failure. Press the [ON/OFF] after power restore. Fuse blown or circuit breaker tripped. Replace fuse or reset circuit breaker. Power supply wiring phase incorrect. Modify the wiring phase. Compressor does not operate in 3 min after unit is started. Protection against frequent starting. Wait for 3 minutes for the compressor to start. Air flow is low. Filter is filled with dust and dirt. Clean the filter There are some obstacles at the air inlet or outlet of the units Remove obstacles. Dirty air filter. Clean the air filter. Temperature setting too low (for cooling). Reset the temperature. Compressor operate continuously. Temperature setting too high (for heating). No cool air delivered during cooling cycle, or no hot air delivered during heating cycle. Temperature setting too high (for cooling). On heating cycle, indoor fan stop suddenly. [UAT(Y)(P)180~320A] Unit is in defrosting cycle. Temperature setting too low (for heating). On heating cycle, delivered air does not warm enough suddenly. [UAT(Y)(P)700~C12A] If the fault persists, please call your authorized local dealer / serviceman. 12 Set the temperature lower. Set the temperature higher. Wait for a while. (It will be resumed after defrosting.)