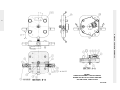

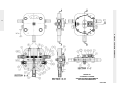

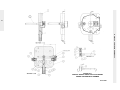

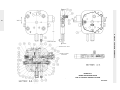

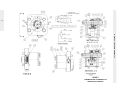

Download Sharp WQ-700H Specifications

Transcript