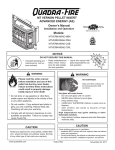

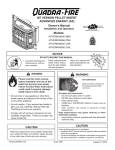

Download Quadra-Fire 810-02901 Owner`s manual

Transcript