Download DYNACO PAS-4 Owner`s manual

Transcript

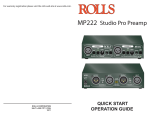

PAS-4

Vacuum Tube Preamplifier

Owner's Manual

VACUUM TUBE PREAMPLIFIER

R

PAS-4

CD

VIDEO

AUX

SOURCE

TUNER

2 to 1

SOURCE

TAPE 1

1 to 2

TAPE 2

LEFT

RIGHT

EPL

PHONO

IN

INPUT

TAPE DUBBING

TAPE MONITOR

BALANCE

PAS-4 Vacuum Tube Preamplifier

MONO

IN

VOLUME

POWER

Contents

Introduction ...................................................................................... 3

Rear Panel Inputs and Outputs ....................................................... 4

Fuse ................................................................................................. 4

Operation ......................................................................................... 5

Tube Replacement .......................................................................... 7

Alternate Tube Types ...................................................................... 8

Minimizing Noise in the System ...................................................... 9

Warranty .......................................................................................... 10

PAS-4 Specifications ....................................................................... 11

Schematics ...................................................................................... 12

PC Board Parts List ......................................................................... 14

Please read this manual thoroughly before operating your new PAS-4.

2

Introduction

Congratulations on your purchase of the Dynaco PAS-4 preamp. This preamplifier

was designed to provide the highest combination of quality and value available,

which is the Dynaco tradition.

Only very high quality components have been used in manufacturing the PAS-4.

Examples of this are the low noise metal-film resistors, polypropylene film

capacitors, and selected (tested) vacuum tubes. Likewise, the high quality rotary

switches and potentiometers provide better performance and reliability than what is

found in most other audio equipment.

Unique to this modern PAS-4 vacuum tube design is its power supply buffering

circuitry - found in no other preamp of this class. We have included a separate

buffer circuit for each of its six tubes, allowing each amplification stage to function

more independently, (as if each has its own separate power supply). This

contributes significantly to the extraordinary sonic clarity of the PAS-4.

The PAS-4 contains a true state-of-the-art phono preamp section. It provides a

front panel switched "external processing loop" for use with a graphic equalizer or

other signal processing equipment. It also includes full provisions for tape dubbing

between two tape decks ("1 to 2" and "2 to 1").

You will find the PAS-4 to sound better than the large majority of other

preamplifiers - both solid state and vacuum tube designs - regardless of price. Its

flexibility and full-featured styling is without parallel in affordable preamps. Your

PAS-4 was designed and built entirely in the USA. We are proud to offer this

outstanding preamplifier to discerning audiophiles the world over.

Dynaco Engineering Group

3

Rear Panel Inputs and Outputs

Inputs - Phono

These inputs will accommodate "moving magnet" or high output "moving coil" cartridges which have

output levels of 1.0mV or higher.

In the lower right hand corner of the rear panel is the preamp's chassis ground terminal. This thumbscrew

is provided for attaching the separate ground wire often provided on turntables. (see Minimizing System

Noise on page 11)

Inputs - Tuner, CD, Video, Aux., Tape 1 & 2

These inputs receive standard line (high level) input signals from other equipment. The Tape Inputs of the

PAS-4 connect to Line Outputs (Play) on tape decks.

Tape Outputs

Signals sent to these outputs are at line level. (Phono signals are first amplified and equalized). Tape

Outputs are unaffected by external processing circuits, the Mono switch, the Volume control, or the

Balance control. The preamp's Tape Outputs connect to the tape deck(s) Line (Record) Inputs .

Preamplifier Main Outputs

Two pairs of outputs are provided for your power amplifier(s). The two left channel RCA jacks are

connected directly together inside of the PAS-4, as is the right channel pair.

EQ (External Processing Loop)

"EQ Out" are line level outputs which can be connected to the inputs of an external signal processor such

as an equalizer, time delay, or noise reduction unit. "EQ In" are for line level inputs coming from the signal

processor outputs.

FUSE

AC Line Fuse:

2 Amp Fast-Blow - 100 or 115 VAC

1 Amp Fast-Blow - 230 VAC

120

PUSH TAB TO RELEASE FUSE HOLDER

To remove the AC line fuse, use a small screwdriver to push forward the tab near the center of the

Power Entry Module.

Always remove the power cord when accessing the AC line fuse.

4

Operation

Turn-On Delay and Visual Indicator

When you turn on the PAS-4, the lamp above the PWR (power) switch glows GREEN and a timer circuit

is evoked which keeps the preamp outputs at zero volts during the warm-up period. This 45-second

warm-up period allows the tube filaments to fully heat, the high-voltage section of the power supply to

reach full potential, and for the preamp output circuitry to settle, (avoiding loud turn-on "thumps"). When

warm-up is finished, the lamp turns to RED and the preamp outputs are operative.

When you turn off the PAS-4, the outputs immediately clamp to zero volts. Turning the preamp back on at

this point will require, again, waiting through the warm-up period.

Input Selection

Your choice of a signal source is indicated by the INPUT switch position you select. This signal source is

what you will hear. It is also sent to the Tape (recording) Outputs and the EQ Outputs, (as long as the

TAPE MONITOR and TAPE DUBBING switches are both set to SOURCE).

Tape Deck Selection - Listening

You may bypass the INPUT switch selection by using the TAPE MONITOR switch, in which case the

signal from the selected tape deck is what you will hear and what is sent to the EQ Out jacks.

When the TAPE MONITOR switch is turned to Tape 1 or Tape 2, what you hear is the signal from the

tape deck playback head, not the original source signal (which is being recorded onto tape via the tape

deck record head). This feature allows direct comparison of the signal source with taped replica without

affecting the recording process. (If a tape deck does not have separate record and playback heads, then

the signal you hear when using the TAPE MONITOR switch is the same signal being sent to the tape

deck to be recorded.)

The following controls affect all signals which are heard through the speakers.

They have no effect, however, on signals being recorded at the Tape Outputs.

EQ Switch

Pushing IN the EQ switch inserts a signal processing device into the preamplifier signal path (if such a

device is connected to the EQ Inputs and Outputs). This part of the signal path is then called the External

Processor Loop (EPL). Such devices include equalizers, time delays or ambiance simulators, expanders,

compressors, and noise reduction systems. When the EQ switch is in the OUT position, any equipment

plugged into the EQ inputs is effectively removed from the preamplifier signal path. Therefore, an

unpowered device connected to the EQ Inputs and Outputs will not deteriorate the PAS-4's performance

(which can happen with some tape decks, as mentioned above).

Note:

The EQ inputs can also be used as a second set of Auxiliary Inputs - (for a second tuner, second

CD player, etc.) Therefore, the EQ switch itself can also function as an additional input selector.

Mono Switch

When this button is IN, left and right channel information is combined and the composite signal is fed to

both left and right outputs. In this mode the sound image should appear to be centrally located between

the loudspeakers. This switch is useful when listening to monophonic program material. It cancels the

unwanted vertical phonograph modulations which are heard as noise from monaural records.

5

Balance Control

This adjusts the proportion of left and right channel signals going to the preamp's line level amplification

stage (and therefore to the preamp's main outputs). Only the left channel signal will be heard with the

Balance Control turned fully counter-clockwise, and only the right channel signal with full clockwise

rotation. The function of the Balance Control is to compensate for unbalanced left and right channel signal

levels (from phonograph records, for instance) or to compensate for non-symmetrical room acoustics

(from furniture, wall reflections, etc.).

Tape Deck Selection - Recording

The TAPE DUBBING switch determines which signals are sent to the tape decks for recording purposes.

If the TAPE DUBBING switch is set to SOURCE, both tape decks receive the same signal - the one

indicated by the position of the INPUT switch.

A copy of a tape can be made when the TAPE DUBBING switch is set to either ‘2 to 1’ or ‘1 to 2’. (When

this is done, the signal source selected by the INPUT switch is disconnected from both tape decks.)

When the TAPE DUBBING switch is set to ‘2 to 1’, the output of tape deck #2 goes to the input of tape

deck #1 to be recorded. When the TAPE DUBBING switch is set to "1 to 2", the output of tape deck #1

goes to the input of tape deck #2 to be recorded.

The TAPE MONITOR switch can be used to listen to the "source" tape deck (the original recording) or the

"target" tape deck (the dubbed recording) while tape dubbing is being done. However, if the TAPE

MONITOR switch is set to SOURCE, one can listen to any music signal selected with the INPUT switch

while tape dubbing is in progress.

___________________________________________

Note:

Some older tape decks which do not have high impedance input circuitry can present non-linear

loads to a preamp's Tape Outputs even when the tape decks are turned off. This can be a

problem because the Tape Outputs are usually connected to which ever signal source has been

selected by the INPUT switch. This “always present” non-linear load can degrade performance on

most preamps.

With the PAS-4 there is a solution to the use of lower input impedance tape decks. Simply keep the TAPE

DUBBING switch positioned to ‘1 to 2’ or ‘2 to 1’ when the deck is not in use. This disconnects the signal

selected by the INPUT switch from both tape decks, as mentioned previously.

6

Tube Replacement

CAUTION: Before replacing tubes on your PAS-4 ensure the AC power cord is un- plugged from its AC

(wall) outlet (or that the AC power cord is unplugged from the back of the unit) and wait for

three minutes to allow the high voltage power supply to discharge. Gloves may be worn

when changing tubes. Never touch live circuit elements in vacuum tube equipment because

lethal voltages are present when these are turned on.

The tubes in your PAS-4 could provide 5,000 to 10,000 hours of use. We recomend that these tubes be

replaced after no more than 3,000 hours of use to avoid the slightly "muffled" sound or slight bass "rolloff" which can begin to occur with old tubes.

Microphonics (various "pinging" or "howling" sounds) is due to a tube being overly sensitive to physical

vibrations. To avoid it, do not operate vacuum tube equipment on top of vibrating surfaces (such as

loudspeakers). But if a tube is so sensitive that just having the preamplfier turned on causes the

microphonic sounds, the tube will have to be replaced. It can happen that a tube becomes microphonic

with age or that it is only microphonic before it warms up (or only after it warms up).

The most common type of problem in tube preamplifiers is excessive noise caused by a worn or faulty

tube. The characteristics of this noise can vary a great deal. If a noise problem occurs with your PAS-4,

99% of the time it will be due to a faulty tube

The most likely source of tube noise in the PAS-4 is the phono section first stage tubes V1 (left channel)

or V4 (right channel). Less likely, but to be suspected next, would be the phono stage second stage

tubes V2 (left) or V5 (right). If the undesirable noise increases as you turn up the volume control, the

faulty tube is likely to be one of the phono section tubes. The line stage tubes are V3 (left) and V6 (right).

(Refer to the tube numbers printed adjacent to pin #1 of each tube on the printed circuit board.)

Note: When removing a tube, grasp the tube socket with one hand and the tube with the other hand.

Move the tube (slightly) from side to side while pulling outward.

The most certain method for confirming a faulty tube

is by substitution of a known good tube.

An easy way to determine if a tube in any particular position is causing un-desirable noise is to

swap the suspected tube with its counterpart in the opposite channel. If the noise jumps to the

other channel, the tube you suspected is indeed faulty.

7

Alternate Tube Types

It is true that vacuum tubes made by different manufactures can actually sound different. The amount and

type of sonic differences can be subtle or fairly obvious to a discerning listener. Also, tube reliability and

longevity often varies according to manufacturer.

Vacuum tube manufacturers are still introducing new versions of older tube designs. These new designs

are commonly labeled with partly or wholly new part numbers. Furthermore, different vacuum tube

manufacturers often use different part numbers for their own versions of “equivalent” tubes. Distributors

sometimes substitute tubes from different manufacturers and/or substitute tubes with alternate part

numbers without informing their customers first.

Some audiophiles feel strongly about which manufacturer and/or particular version of vacuum tube to use

for specific applications. The tubes installed on your new PAS-4 have been selected to provide the best

sound and long life.

As of this writing, vacuum tubes are still produced by manufacturers in Germany (Siemens), Russia

(Sovtek), Czechoslovakia (Telsa), China (Sino), Yugoslavia (EI), and in England. Your dealer can

recommend U.S. tube distributors, if needed.

Alternate tube part numbers which can be used on the PAS-4:

Designator

Common Part Numbers

Alternate Part Numbers

V1, V4

12AX7

ECC83

V2, V3, V5, V6

6DJ8

ECC88, 6922, 7308

If tube replacement becomes necessary, Dynaco can supply you with new

vacuum tubes and/or a list of specifically recommended tubes for the PAS-4.

_______________________________________________________________________

Note: Because it is possible for oxidation to build up on vacuum tube pins, it is a good idea to remove

and clean them with a small (brass bristle) wire brush once a year. At this time it is also recommended

to clean the tube pins with contact cleaner. Contact cleaner leaves a thin coating on the pins which helps

prevent oxidation. The contact cleaner can either be sprayed directly onto the tube pins (don’t get any on

the glass part of the tube) or can be sprayed on a clean cloth which is then used to wipe the tube pins.

8

Minimizing Noise in the System

Hum is caused by amplification of the 50 or 60 Hz AC power line signal that is transmitted via the

magnetic fields around power transformers and power cables. RF interference usually comes from

inadequate shielding of cables or components. If any of these types of noises are encountered, one or

more of the following pointers concerning proper component positioning and grounding may be of use:

➣ Ensure that each system component, especially the preamplifier, is located far enough away from the

other components so that they will not pick up hum from them, and that the AC power cables are not

in close proximity to audio cables.

➣ Ensure that all audio cables are securely pushed into their respective jacks. A faulty audio cable,

although rare, can be a source of hum if its outer shield is broken or disconnected from an RCA plug

at one end of the cable.

➣ The best “system grounding scheme” is to have your preamplifier well grounded to an earth ground

point and function as the system's main ground reference. Other system components are then quite

adequately grounded by being connected to the preamplifier’s ground via their audio cables. Using

this grounding scheme can be as simple as just plugging the preamplifier’s power cable into a three

prong AC outlet. However, if the AC outlet itself does not provide a really "good" ground, the

preamplifier power cable can be plugged into a three-to-two prong adapter and a wire can be run

from the tab on the adapter to the nearest cold water pipe.

➣ Another solution to AC power cable "ground loop" hum problems is to plug the AC power cables from

all of the system components into a common "socket strip" (available from most hardware stores).

➣ If RF noise (usually an AM radio station or CB transmission) is a problem in your area, an AC power

filter can be purchased into which some or all of your system power cords can be plugged. This is

done if the RF is coming in through the building's AC wiring. However, if RF gets into the system via

your turntable, you may have to use tonearm cables with better shielding. (This is tested by

unplugging the turntable from the system and putting "shorting plugs" in the preamplifier’s phono

inputs before listening again.) RF noise is sometimes eliminated by simply moving the turntable or

other components to another location in the room.

➣ Hum from a turntable is usually traced to an adjacent power transformer or a missing or improper

ground. Check to see that the turntable motor is grounded via a wire to the preamplifier’s grounding

post - (or try removing this wire from the ground post if it is already connected there).

9

Warranty

For three years from the date of purchase (one1 year for tubes) Dynaco will repair, for the original owner,

any defect in materials or workmanship that occurs in normal use, without charge for parts or labor.

It is the owner's responsibility to provide transportation to the authorized Dynaco service representative

who will perform warranty service, and to present proof of purchase in the form of a dated sales slip when

requesting service.

Excluded from this warranty is damage that results from abuse, misuse, accidents, shipping, repairs or

modification by anyone other than an authorized Dynaco service representative. This warranty is void if

the serial number has been removed or defaced. This warranty gives you specific legal rights, and you

may also have other rights - which vary from state to state.

If service is required, contact the dealer from whom you purchased the amplifier. If that is not possible,

write Dynaco, giving us:

✓ Your name and address

✓ Make and model of your amplifier

✓ The amplifier’s serial number

✓ When and where you purchased it (copy of sales slip)

✓ Description of the problem

✓ Whether you have the original carton and fillers or need new ones

DYNACO strongly recommends using only its performance checked pre-tested vacuum tubes. Each tube

is guaranteed to perform properly in its intended application for ONE YEAR. Orders for tubes may be paid

for by personal check or money order. Please also include $4.00 for shipping and handling.

Dynaco

A Division of Panor Corporation

125 Cabot Court

Hauppauge, New York 11788

(516) 434-1200

(516) 434-1457 FAX

10

PAS-4 Specifications

Phono Section

GAIN:

40 dB

RIAA ACCURACY:

+/- .5 dB from 20 Hz to 20 kHz

PHONO OVERLOAD:

500mV RMS @ 1kHz

MAXIMUM OUTPUT CAPABILITY:

60V RMS @ 1kHz

THD:

INPUT IMPEDANCE:

50V RMS @ 20kHz (for 1% THD)

less than .025% @ 2V RMS Output

47k shunted by 10pF

TAPE OUTPUT IMPEDANCE:

2k

NOISE:

-86 dB below 10mV RMS Input

ABSOLUTE PHASE:

Non-Inverting

TUBE COMPLEMENT:

2ea 6DJ8 (6922); 2ea 12AX7 (ECC83)

Line Section

GAIN:

18.5 dB

FREQUENCY RESPONSE:

MAXIMUM OUTPUT:

2 Hz to 150 kHz (nominal)

(-3 dB, 20 k ohm load)

40V RMS (for 1% THD)

THD:

.025% @ 2V RMS Output

INPUT IMPEDANCE:

25k nominal (all inputs)

OUTPUT IMPEDANCE:

40 ohms

NOISE:

-90 dB below 2V RMS Output

ABSOLUTE PHASE:

Inverting

SLEW RATE:

40 V/µs

TUBE COMPLEMENT:

2ea 6DJ8 (6922)

Electrical / Mechanical

POWER REQUIREMENTS:

100, 115, or 230 VAC @ 50/60 Hz

POWER CONSUMPTION:

45 Watts

DIMENSIONS:

17" Wide, 3.75" High, 12" Deep

NET WEIGHT:

12 lbs.

SHIPPING WEIGHT:

14 lbs.

11

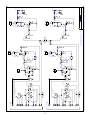

12

EQ IN

EQ OUT

TAPE 2

IN

TAPE 2

OUT

TAPE 1

IN

TAPE 1

OUT

AUX

VIDEO

CD

TUNER

PHONO

RIGHT INPUTS

EQ IN

EQ OUT

TAPE 2

IN

TAPE 2

OUT

TAPE 1

IN

TAPE 1

OUT

AUX

VIDEO

CD

TUNER

PHONO

LEFT INPUTS

2K

R102

2K

R101

2K

R2

2K

R1

8

9

8

7

9

10

1

2

3

2

3

4

16

SW4A

SW2A

22

12

11

10

SW4B

SW2B

TAPE DUBBING

19

SW1B

INPUT SELECTOR

ACTIVE

INACTIVE

EQUALIZER

19

7

11

5

6

4

TAPE DUBBING

13

SW1A

INPUT SELECTOR

ACTIVE

INACTIVE

EQUALIZER

13

1

5

8

2

7

9

1

3

19

SW3B

TAPE MONITOR

13

SW3A

TAPE MONITOR

R103

47K

FB2

R3

47K

FB1

C2

22pF

C102

2

10pF 1

C101

22pF

2

10pF 1

C1

3

6

8

R104

1.37K

8

249K

R106

-3.3V

R7

2M

249K

R6

7

-3.3V

R107

V4

12AX7 2M

.1uF

400V

C103

7

V1

12AX7

.1uF

400V

C3

R4

1.37K

R105

287K

1W

+300V

D

3

6

R5

287K

1W

+300V

A

R110

165K

C105

440pF

R108

6.49K

C104

220pF

301

R109

2

V5A

6DJ8

C6

1

7

3

3

1500pF

C106

1

7

6

6

+300V

E

1500pF

V5B

6DJ8

2

R111

301

R10

165K

C5

440pF

R8

6.49K

220pF

C4

301

R9

V2A

6DJ8

R11

301

V2B

6DJ8

+300V

B

9

R112

249

8

9

R12

249

8

R113

499K

3.3uF

400V

C107

R13

499K

3.3uF

400V

C7

R18

P1B

50K

P2B

50K

VOLUME

MONO

P2A

50K

3W RESISTORS ARE 5%, METAL OXIDE

24.9K

R119

BALANCE

24.9K

R19

BALANCE

1/2W AND 1W RESISTORS ARE 1%, METAL FILM

5.6K

R118

STEREO

SW5

5.6K

P1A

50K

VOLUME

V6B

6DJ8

2

REV B

301

R120 2

V6A

6DJ8

C108

.1uF

400V

R123

301

301

R20

V3A

6DJ8

C8

.1uF

400V

R23

301

V3B

6DJ8

6

C109

3.3uF

400V

C9

9

R126

15K

3W

3.3uF

R125 400V

221

8

9

R26

15K

3W

R25

221

8

R127

499K

140

R128

R27

499K

140

R28

8

12

19 JULY 94

PAGE

1

OF

2

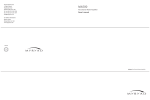

K1-A

N.O.

DWG# 00501

K1-B

2

1

RIGHT

OUTPUTS

N.O.

N.C.

2

1

LEFT

OUTPUTS

10 N.C.

7

4

6

PAS-4 PREAMPLIFIER

301K

R122

R121

221

3

1

2M

R124

7

+300V

F

301K

R22

R21

221

3

1

2M

R24

7

6

+300V

C

13

1

2

4

G

L

N

2A /100V

2A /115V

1A / 230V

F1

FAST

BLOW

POWER

ENTRY

MODULE

C204

C203

R201

100

C201

.01uF

1.4KV

BLK

100V

0.0V

.01uF

1.4KV

(x 2)

AC POWER

SW7A

BRN

WHT

115V

230V BRN/WHT

50/60 Hz

100/115/230 VAC

T1

GRN

GRN

R206

30K

R205

20K

RED

RED

D4

D3

C206

33uF

450V

470

3W

R202

C219

4700uF

25V

FWB1

600V

35A

C207

1000uF

6.3V

I

19.5V @ 1A

R204

1M

1W

R203

332K

O

C220

22uF

25V

G

U1

7812

-3.3V

SOURCE

D5 THRU D11

C205

33uF

450V

D1

D2

421V @ 45mA

C221

470uF

25V

.47 ohm

3W

R216

C208

1.0uF

400V

5.1M

R207A

SW7B

V6

RIGHT

LINE

6DJ8

4

5

4

5

TIMER

V3

LEFT

LINE

6DJ8

C209

1.0uF

400V

C210

1.0uF

400V

5.1M

R207B

ON

OFF

C222

10uF

25V

R217

4.02M

C211

1.0uF

400V

R210

470

C213

.22uF

400V

ZD1

12V

G

Q1

6

2

U2

4

1

I

16

1

G O

G

Q2

IRF 830

S

D

GREEN

RED

ZD4

200V

5W

(1)

R219

470

R218

470

R212

470

I

C215

.22uF

400V

ZD5

12V

G

Q3

O

+300V

C

ZD6

200V

5W

C223

22uF

25V

G

U3

7812

S

D

Q1 - Q6 = IRF 830

ZD2, 4, 6, 8, 10, 12 = 1N5388B

ZD1, 3, 5, 7, 9, 11 = 1N5242B

D1 - D12 = 1N4007

+300V

B

D13

BI-COLOR

LED

(2)

G D S

K1

C214

.22uF

400V

ZD3

12V

FRONT VIEWS

3

D12

7812

8

R211

470

C212

22uF

250V

+300V

A

ZD2

200V

5W

555

R208

1M

R209

1M

S

D

G

Q4

C224

470uF

25V

C216

.22uF

400V

ZD7

12V

.47 ohm

3W

R220

R213

470

ZD8

200V

5W

V2

LEFT

PHONO

6DJ8

B

V1

LEFT

PHONO

12AX7

R214

470

REV

5

4

5

4

+300V

D

V5

RIGHT

PHONO

6DJ8

S

D

5

9

4

R215

470

+300V

E

ZD10

200V

5W

Q6

C218

1uF

400V

ZD11

12V

G

S

D

PAGE

2

OF

2

+300V

F

ZD12

200V

5W

DWG# 00501

PAS-4 PREAMPLIFIER

V4

RIGHT

PHONO

12AX7

S

D

19 JULY 94

5

9

4

C217

.22uF

400V

ZD9

12V

G

Q5

PAS-4 PC Board Parts List

DESCRIPTION

DESIGNATORS

Resistors

100 ohm, 1/2W, metal film

R201

140 ohm, 1/2W, metal film

R28, 128

221 ohm, 1/2W, metal film

R21, 25, 121, 125

249 ohm, 1/2W, metal film

R12, 112

301 ohm, 1/2W, metal film

R9, 11, 20, 23, 109, 111, 120, 123

470 ohm, 1/2W, metal film

R210, 211, 212, 213, 214, 215, 218, 219

1.37K, 1/2W, metal film

R4, 104

2.0K, 1/2W, metal film

R1, 2, 101, 102

5.6K, 1/2W, metal film

R18, 118

6.49K, 1/2W, metal film

R8, 108

20K, 1/2W, metal film

R205

24.9K, 1/2W, metal film

R19, 119

30K, 1/2W, metal film

R206

47K, 1/2W, metal film

R3, 103

165K, 1/2W, metal film

R10, 110

249K, 1/2W, metal film

R6, 106

301K, 1/2W, metal film

R22, 122

332K, 1/2W, metal film

R203

499K, 1/2W, metal film

R13, 27, 113, 127

1M, 1/2W, metal film

R208, 210

2M, 1/2W, metal film

R7, 24, 107, 124

4.02M, 1/2W, metal film

R217

5.1M, 1/2W, metal film

R207A, 207B

287K, 1W, metal film

R5, 105

1M, 1W, metal film

R204

.47 ohm, 3W, metal oxide

R216, 220

470 ohm, 3W, metal oxide

R202

15K, 3W, metal oxide

R26, 126

Capacitors

10pF, 630V, polystyrene

C1, 101

22pF, 630V, polystyrene

C2, 102

220pF, 400V, polypropylene 5%

C4, 5A, 5B, 104, 105A, 105B

1500pF, 400V, polypropylene 5%

C6, 106

.01uF, 1.4 kV, ceramic disc

C201, 203, 204

.1uF, 400V, polypropylene

C3, 8, 103, 108

.22uF, 400V, polypropylene

C213, 214, 215, 216, 217, 218

1.0uF, 400V, polypropylene

C208, 209, 210, 211

3.3uF, 400V, polypropylene

C7, 9, 107, 109

14

PAS-4 PC Board Parts List (cont.)

DESCRIPTION

DESIGNATORS

Capacitors (cont.)

10.uF, 25V, alum electrolytic

C222

22uF, 25V, alum electrolytic

C220, 223

22uF, 250V, alum electrolytic

C212

33uF, 450V, alum electrolytic

C205, 206

470uF, 25V, alum electrolytic

C221, 224

1000uF, 6.3V, alum electrolytic

C207

4700uF, 25V, alum electrolytic

C219

Semiconductors

1N4007 (1A, 1kV)

D1 thru D12

1N5242B (12V, 1/2w Zener)

ZD1, 3, 5, 7, 9, 11

1N5388 (200V, 5w Zener)

ZD2, 4, 6, 8, 10, 12

3506 (35A, 600 PIV Bridge Rectifier)

FWB1

7812 (Regulator)

U1 ,3

555 (Timer)

U2

LED, Bi-Color, (red/green)

D13

IRF 830 (N-Channel FET)

Q1 thru Q6

Tubes

12AX7 (ECC83)

V1, 4

6DJ8 (6922)

V2, 3, 5, 6

Switches

Switch, pushbutton, 2 pole / 2 position

SW7 (AC power)

Switch, pushbutton, dual 2 pole / 2 position

SW4/ 5 (stereo/mono, EQ)

Switch, rotary, 2 pole / 5 position P/N 333125

SW1 (input selector)

Switch, rotary, 4 pole / 3 position P/N 333124

SW2 (tape dubbing)

Switch, rotary, 2 pole / 3 position P/N 333124

SW3 (tape monitor)

Misc.

50K, dual VOLUME potentiometer

P1

50K, dual BALANCE potentiometer

P2

Relay (DPDT) P/N DS2YE-S-DC12V

K1

Ferrite Beads

FB1, 2

Fuse, fast-blow, 2A for 100 or 115VAC - 1A for 230VAC

F1

RCA Jack Assembly - 2x2 P/N RJ-PCM-204

JA1, 2, 3, 4, 5, 7

RCA Jack Assembly - 1x2 P/N RJ-PCM-102

JA6

PC Board

17-0382-B

15