Download Roland PC-12 Specifications

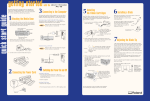

Transcript