Download Wilson Electronics BS4800 Specifications

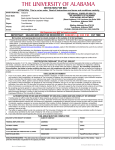

Transcript