Download Clemas & Co Tornado D70Mini Bowser Specifications

Transcript

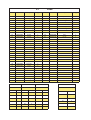

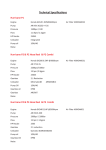

TORNADO ELECTRON MINI BOWSER PRESSURE WASHER OPERATOR MANUAL Clemas & Co. Unit 5 Ashchurch Business Centre, Alexandra Way, Tewkesbury, Gloucestershire, GL20 8NB. Tel: 01684 850777 Fax: 01684 850707 Web: www.clemas.co.uk Email: [email protected] DEMONTORNADOMINIBOWSERRANGE TornadoP1MiniBowser TornadoP2MiniBowser TornadoP4MiniBowser TornadoD70MiniBowser TornadoElectronMiniBowser Includingelectricstartvariantsandbowserwashers DeclarationofConformity (E.H.S.R.) We,DemonInternationalLimitedofAbbotsClose,LeeMillIndustrialEstate, Ivybridge,Devon,PL219GA,declarethatthismachinemustbeoperatedin accordancewiththeoperationandsafetyinstructionsassuppliedwiththis machine. Thismachineismanufacturedinaccordancewiththefollowingstandards andrecommendations. HSEPVBPM29ͲBS5415PartͲBS5415Section2.41986 Thisinstructionmanualisrelevantonlytothefollowingmachineandwillnot bekeptupdatedunlessspecificallyrequestedbythecustomer.However, a n y MachineType SerialNumber WorkingPressure DateofSupply changestotheoperatingprocedureorchangeswhichmightaffectthe safetyofthismachinewillbenotifiedtotheregisteredowner TechnicalSpecifications TornadoP1MiniBowser TornadoP4MiniBowser Engine Pump Pressure Flow HPNozzle Gearbox Unloader PumpOil GearboxOil Noise Engine Pump Pressure Flow HPNozzle Gearbox Unloader PumpOil GearboxOil TornadoP2MiniBowser TornadoD70/ES Engine Pump Pressure Flow HPNozzle Gearbox Unloader PumpOil GearboxOil Noise Engine Pump Pressure Flow HPNozzle Gearbox Unloader PumpOil GearboxOil HondaGX120 RSV3G25D 1500PSI 9lpm 25045 None Integrated 10W/40 N/a HondaGX200 ARXT13Ͳ12 2200PSI 13lpm 25045 2:1Reduction ARMM4B 10W/40 EP90 HondaGX34011HP360rpm ARRKͲ15.20H 2900psi/200Bar 15lp,/3.3gpm 2505 2:1reduction Gymatic3BARGM3B250 10W/40 EP90 YanmarL70 ARXT13.12 2900PSI 13lpm/3.3gpm 2505 2:1Reduction ARGM3B250 10W/40 EP90 TornadoElectron Motor 24vDC HPNozzle 15045 Pump ARXT11Ͳ14 Unloader ARMM4B/C Pressure 1200PSI Flow 11lpm PumpOil 10W/40 Battery 2x140amp/hourAGMSealedBatteries MicroprocessorControlledAutomaticBatteryCharger 24Volt12.5AMP Important—NewP2Machines EachnewP2machinewillbesetat2000psiasopposedto2200psiuntilthemachinehas beenrunforapprox2Ͳ3hourscontinuously. Oncethemachinehasbeenrunthenthepressurecanbeadjustedtoachievethemaximum 2200psibyturningthepressureregulatingvalveuntilitsfullyopen. Kits for the Tornado Mini Bowser Machine P1 P2 P4 Tornado D70 Tornado Electron Valve Kit 2186 1864 1828 1864 1864 Seal Kit 2189 1874 1857 1874 1874 2629 2757 2629 2629 1872 1855 1872 1872 Piston Kit Oil Kit 2188 Support Ring Kit O Rings 1829 2190 FAULTFINDER FAULT CAUSE REMEDY x Machinestopssuddenly Orwillnotstart. Lowoil FlatBattery (Electron) checkandtopupoil Suddenpressureloss. Watersupplyfailed. Nochemical Checkwatersupply. Checkchemicaldrum,closevalve Lowpressure HPnozzlewornor unloaderset Incorrectly. ReplaceHPnozzle.Setunloader tocorrectsetting. Lowpressurewithnoiseand vibration. Valveswornor blocked.Pistonseals worn. Pumpsuckingair. Clean/replaceasrequired. Replace. Checkwatersupplypipeand unions. ReͲcharge PumpwillnotbyͲpass. Nonreturnvalve dirtyorjammed. Cleanorreplace. Waterdripsfrompumpbox. Pumpsealsworn. Replace. Oildripsfrompumpbottom. Oilsealworn. Replace. Oilismilkyincolour. Wateringress Rinsepumpoutandreplaceoil. throughoilfilterplug. IFINDOUBTASK—OURADVICEISFREEANDCANSAVEYOUMONEY MINIMUMSERVICESCHEDULES DAILYCHECKTHEFOLLOWING a. b. c. d. OillevelͲtopupasrequired. FueltankͲtopupasrequired. AllhoseunionsforleaksͲreplaceOringsifleaking. HoseconditionͲcutsetc. EVERY500HOURSORSIXMONTHS(WHICHEVERCOMESFIRST) a. b. c. d. e. Drainandreplacepumpoil. Drainandrefillfueltank. Replacefuelfilter. Cleanwaterfilter. Replacehighpressurenozzle. EVERY1000HOURSOR12MONTHS(WHICHEVERCOMESFIRST) a. b. c. d. Complete500hourservice. Replacepumpseals. Replaceoilseals. Checkunloadingpressureandsafetyvalvepressureandadjust. Theaboveserviceschedulesareintendedasaguideonly,actualservicetimes andreplacementspartsrequiredwillvaryaccordingtotheareaandtheusage ofthemachine. OPERATINGINSTRUCTIONS SAFETY I II III A B C D E F G H I J Waterathighpressureisdangerousandcancauseseriousinjury.Thismachineistobe usedwithgreatcaution. Petrolisextremelyflammableandexplosiveundercertainconditions. EXHAUSTFUMESCONTAINCARBONMONOXIDE–InhalationofsuchfumescanKILL. Dieselisflammableandharmfulifswallowed. Alwaysrefuelinanareawhichisadequatelyventilated. DONOTsmokewhenrefueling. Avoidoverfilling. Shouldfuelbespilt,wipeoffanyfuelspiltonmachineorengine. Movetheequipmentawayfromtheareawherefuelhasbeenspilt. DONOTrefuelwhentheengineisrunning. DONOTruntheengineinanareawhichhasahazardousorexplosiveatmosphere. Alwaysensurethatthefuelcapissecureafterrefueling. Keeptheengineatleast3metresormoreawayfromanyotherequipmentor Building. Takecarenottogetfuelonyourclothing.Ifthishappens–CHANGEyourclothing IMMEDIATELY. DONOTstartanenginewhenclothinghasbeencontaminatedwithfuel. K Useonlyapprovedtypecontainersforfuel.DONOTstandthemoutinstrongsunlight, keepthemintheshade. L M N O P Q R Alwaysensurethatthereisasuitabletypefireextinguisheravailableandiswithin access. easy DONOTleaveanenginerunningunattended,ALWAYSSTOPitbeforeleavingthearea. NEVERpointthehighpressuresprayjetatanyperson,animal,glassorother Materialwhichmayshatter. PREVENTanyoversprayfrominjuringotherpeopleordamagingproperty. DONOTeventrytouseapressurewasheronmachineryorelectricalequipmentthatis connectedinanywaytothemainssupply(ALLswitchesintheOFFposition,pulloutplugs, ifpossibleremovefuses).Coverorsealelectricmotorsandfittingstoprevententryof water.Beforereconnectingelectricmainssupplycheckforwaterpenetration. DOALLyoucantokeepplugsandsocketsinadryplaceorcoveredtoprevententryof water. ALWAYSwhenusingthismachine:Ͳ x wearsafetygogglesandhelmetorhelmetwithavisor. x Wearwaterproofclothingandgloves. x Takepaticularcarewithdetergentsandchemicals. NEVERattempttodisconnectanyhosewithpressureinitorallowthehosetobeflattened S orkinked. T DONOTuseahighpressurehosefromaladder.Useaplatformtowerorproper scaffolding. U Shouldtheequipmentfailtooperate,DONOTattempttorectifyorrepair,butcontactthe nearestServiceCentreforadvice. VAlwaysrinseyourpumpoutafterusingseawater. PREPARATION WaterSupply: A Ensurethereisanadequatewatersupplyeitherfromthemainsorareservoir. B AttachwatersupplyhosestosuitabletaporimmersethesuctionhosewithapprovedsucͲ tionfilterintothereservoir. NOTE:ONLYCLEANWATERSHOULDBEUSED.THEPUMPMAYBEDAMAGEDIFDIRTYOR CONTAMINATEDWATERISALLOWEDTOPASSTHROUGHTHEPUMP. Hoses:Lowpressureinlet. Formodelsupto13litresperminuteuse½“boresuctionhoseorfeedpipe. Formodelsfrom13litresto24litresperminuteuse¾”boresuctionhoseorfeedpipe. Hoses:Highpressureoutlet. Forallmodelsuse3/8”RITor3/8”R2Thoses. A Checktheconditionofthe“O”ringsintheendsofthehose. B Attachthehighpressurehosetothepumpconnection. C Attachthesprayguntooppositeendsofthehighpressurehose. OPERATION A Turnonthewatersupply. B Starttheengine C Directlanceontosurfacetobecleaned.Pressthelancetrigger. ELECTRON D Fullychargebattery6Ͳ8hoursorovernight. E TostartDCMotorturnkeyandpullswitchup. D E F g. h. Adjustpressureregulatorasrequiredtoobtainworkingpressureifrequired. NOTE;:Thehighpressurewaterwillcausethegunto“kick”.Makesureyouhaveafirmgrip ofgunandlance. Oncompletionofoperationstoptheengine. Operatelancetrigger Turn“OFF”watersupply Releaseresidualpressureingunandlancebyoperatingtrigger. i. WhenusingCleaningAgents: A. Setmachineupasforwater. B. Connectdetergenthosetomachineandplacefilterendintodetergent. C. Oncompletionofwork,flushthroughhoseandgunwithcleanwatertoremoveanyresidͲ ualdetergent. NOTE:CHEMICALPICKUPONLYOPERATESATPRESSURESBELOW250PSI. OPENLANCEVALVEFULLYTOOBTAINTHISPRESSUR Electron TheElectronisfittedwithabatterymonitorwhichwillindicatetheconditionofthebatteries. Theindicatorisfittedwithanaudiblealarmwhichwillsoundwhenthebatterychargeissuch astorequirereͲcharging.Thebatteryindicatorwillshowthecurrentconditionofthebattery bywayofagaugeandpercentagelevel.FailuretoreͲchargethebatterieswhenthealarm indicatesmayleadtodamageandlifeexpectancyofthebatteries.Batteriesmustbe reͲchargedfullyusingthesuppliedintelligent240vchargerbeforeusingtheElectron,after theindicatoralarmhasbeenactivated. Electronscanbefittedwithamotor/batteryprogrammablecontroller. IfyourElectronhasthisfacilityitwillmonitorthebatterydischargeandissettooperatewhen thevoltagefallsbelowapreprogrammedsetting. Whenthecontrolleractivatesthemotorwillslowitsrevolutionsandthepressurewilldrop. AtthistimeitisrequiredthattheElectronbereͲcharged. Thecontrollerisdesignedtopreventlowvoltagedamagetothebatteryplates. ThecontrollerisnottobereͲsetotherthanbyaqualifiedDemonelectronicsengineer. TornadoMiniͲBowserͲGeneralArrangement SuctionFilter (Insidetank) Hosereel MTM20021 TankLidTOR0116 LidSealsTOR01115 15MtrHose HH00050MVG PumptoHose ReelHose HH00188 BrakedCasterWheel Wheel500 Wheel Wheel400 Engine P1HondaGX120 P2HondaGX200 ChemicalPickͲUpPipe DEM10115 Pump UnloaderValve PressureGuage DEM20620 FastDrain TornadoElectronͲGeneralArrangement Lockable Emergency Stop DEM 100751 Battery Controller BAT013 Relay BAT015 Dual Voltage Charger BAT010 WARRANTY Thiswarrantycoversthecostofallreplacementpartsandlabourchargesincurred,butdoesnot coverthecostoftransportorcarriage.Itistheownersresponsibilitytoreturnthemachinetoa servicedepotorpaythetravellingexpensesofaengineertoattend.DemonInternationals decisioninwarrantymattersisfinalandbinding. DemonInternationalLtd,undertaketorepairorreplaceattheirdiscretion,anycomponentwhich mayfailduetoamanufacturingfaultwithinaperiodof12monthsfromthedateofpurchase, providedthatanyfaultordamagewasnotsustainedby; A Lackofregularandpropermaintenance,usernegligence,misuse,ordamagecausedby iceorfrost. B Theeffectsofcontaminatedfuelorwater,theuseofnonͲapprovedchemicals,oranin sufficientorunsuitableelectricalsupply. C TheeffectsofunͲauthorisedmodificationanduse. D Compressiondamagetohighpressurehose.(Hosesarewarrantedforonemonthonly) E Wornoutitemsconsideredwearandtear. Partswhichmayormaynotwearoutduringthefirstyearandwhichareconsideredservice itemswhichwillneedreplacingfromtimetotime:Highpressurenozzle,lance,trigger,hoses, fuelnozzle,fuelfilter,pistonseals,valves,unloaderseatsandseals,waterfilter,nonͲreturn valve,chemicalbarbs,chemicalpipes,andpumpoilseals. ItistheownersresponsibilitytoensurethepressurewasheriskeptinasafeandsuitableenviͲ ronmentandanyfaultsreportedbyoperativestoberectifiedattheearliestpossibledate. ItistheoperatorsresponsibilitytocheckthepressurewasherforanyfaultsandreportthemimͲ mediately,andtousethepressurewasherinaccordancewiththemanufacturersspecifications andguidelines. DemonInternationalLtd,undertaketousethehighestqualitycomponentsavailableduring manufacture,butcannotbeheldresponsibleforanyundueconsequencearisingfromtheuseof theirpressurewashers. ThiswarrantyisgiventheoriginalpurchaseronlyandisnottransferablewithoutthefullyauthorͲ izedandwrittenconsentofDemonInternationalLtd. WarrantyProcedure EndUsers Ifyourmachinedevelopsaproblem: 1. PhoneDemonforadvicewiththemodelandserialnumbertohand. 2. Describefullytheproblemasbestyoucan. 3. Iftheproblemcannotberesolvedoverthephonethenthemachinecanbebookedinfor repairandifthefaultsarecoveredbythewarrantytherepairwillbecarriedoutfreeofcharge. 4. Ifyoucannotbringthemachineinforrepairthenwewilldespatchanengineer.Ifthefault is covered by the warranty then we will not charge for labour or spares used, however the transportchargewillbepayableweatherornottherepairiswarranty. HireCentresandDealers Ifyourmachinedevelopsaproblem: 1. PhoneDemonforadvicewiththemodelandserialnumbertohand. 2. Describefullytheproblem. 3. Wewilladviseyouonthebestcourseofaction,howeverifpartsarerequiredyoumustraise apurchaseordernumbertocovertheparts.Whenthepartsarefittedtheymustbereturned forexaminationbeforeacreditnoteisissued. 4. Ifyouareunabletorepairthemachinethenwewilldespatchanengineertocarryoutthe repair.Wewillneedapurchaseordertocoverthecostoftransporttoandfromthesiteandfor partsandlabouriftherepairisnotcoveredunderthewarranty. 5. IfrequiredDemonwillarrangeforacarriertocollectadamagedmachine,ifthewarranty claimisvalidwewillpaythiscost,ifnotitwillbechargedtothecustomer. ForpartswarrantyringDemonandrequestawarrantyclaimformfaxedtoyou.Thisformmust accompanyanyreturnedparts. Notes: Youwillnotinvalidatethewarrantybyinvestigatingfaultsandrepairingthemyourselfproviding youfollowouradvice.HireCentresandDealersareexpectedtocarryoutallrepairsthemselves withDemoncreditingfaultypartsuponreceiptandinspection. Sparepartsfittedtomachinesareguaranteedfor1monthonlyortheremainderofthewarͲ rantyperiodwhicheverislonger. Description N/A N/A Hot Water Lance DEM10032B 045 Blue Hot Water Lance 05 Red DEM10032R DEM10031R N/A N/A WM4 WM1 Storm 1 & 2, FS1 FS4 Wall Mounted Storm Cold Water Lance 05 Red Cold Water Lance DEM10031B 045 Blue Part Number N/A N/A P4 & D1 P1 & P2 Hurricane Evo1 & Evo 2 N/A N/A N/A Evolution N/A N/A P4 & D1 P1 & P2 Tornado & Mini-Bowser Company/marketing/lancechartissue306/10 Typhoon 1, 2 & P4 N/A Tempest 1, 3 & 4 (13.17 pump) Tempest 4 (15.20 Pump) N/A N/A Typhoon N/A N/A Tempest Inc Cabinet LanceandMachineColourCodes AdjustableNozzle QRLamceP2 N26001/15045 N26001/1505 MTM90040 DEM10031B DEM10031Y DEM10031R DEM10030 MTM70012 1 1 2 3 3 3 4 5 MVGCoupling QRTrigger QRLanceP4&D1ES QRLanceP1 NozzleP4&D1ES NozzleP2 NozzleP1 N26001/1504 1 Description PartNo Pos COLDWATERLANCES 1 1 1 1 1 1 1 1 1 Qty 3 1 Nut HighPressureHose HoseJoiner 2. 3. 4. 15Metre 30Metre 2 HH00100MVG HH00050MVG MV00500 HH00030MVG MV00490(items1&2) AlternativeHoseLengths HoseInsert 1. 4 High Pressure Hoses XT1450 Pos CodeNo Description Qty Pos CodeNo Description Qty 1 AR1322730 Screw 6 40 AR1320020 PumpHead 1 2 AR620301 Plug 1 41 AR180101 ORing 1 7 AR1260162 Plug 6 42 AR820361 Plug 1 8 AR960160 ORing 6 43 AR1260200 Crankshaft 1 9 AR1269050 CompleteValve 6 43 AR1320260 Crankshaft 1 10 AR880830 ORing 6 44 AR1380520 Key 1 11 AR1320340 SupportRing 3 45 AR1320370 Bearing 1 12 AR1260220 Gasket 3 46 AR1260750 Seal 1 13 AR1320351 PistonGuide 3 47 AR1260470 Screw 4 14 AR1260420 ORing 3 48 AR1263890 Base 2 15 AR1260450 Gasket 3 83 AR1260790 Circlip 1 16 AR1260460 Seal 3 85 AR1381550 Washer 6 19 AR1260790 Circlip 1 88 AR1269222 PumpHeadpreͲass 1 20 AR1320370 Bearing 1 89 AR1266740 Cap 1 21 AR1320330 Bushing 1 22 AR1320010 PumpHousing 1 23 AR880130 OilPlug 1 24 AR1260110 Nut 3 25 AR1260100 Washer 3 26 AR1260210 Piston 3 27 AR480480 ORing 3 28 AR1260091 Spacer 3 29 AR1260070 GuidingPiston 3 30 AR1260080 PistonPin 3 31 AR1260760 Screw 6 32 AR1269101 CompleteCover 1 32 AR1320910 CompleteCover 1 36 AR1260060 ConRoad 3 36 AR1320140 ConRoad 3 37 AR1260040 Gasket 1 38 AR740290 ORing 2 39 AR1980740 Plug 2 ARKIT1864 ARKIT2629 ValveKit PistonKit ARKIT1872 ARKIT1874 OilSealKit WaterSeals Pos Qty Pos Qty Pos Qty 9 6 24 3 16 3 10 6 25 3 37 1 26 3 46 1 27 3 89 28 3 11 3 12 3 14 3 1 15 3