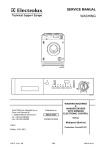

Download ZANKER Washer-dryer Service manual

Transcript