Download Siemens EI645EC11 Repair manual

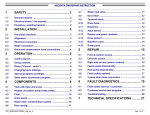

Transcript