Download Citizen CT-P293 Service manual

Transcript

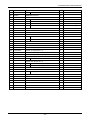

Service Manual COMPACT LINE THERMAL PRINTER CT-P292/293 Series Revision 1.00 2010.2.15 CT-292/293 Series Service Manual REVISIONS Rev No. Date 1.00 2010/2/15 Page Comment Newly issued CITIZEN is a registered trademark of CITIZEN HOLDINGS CO., LTD., Japan. CITIZEN es una marca registrada de Citizen Holdings Co., Japón. -1- CT-292/293 Series Service Manual CONTENTS INTRODUCTION .............................................................................................4 1. 2. 3. DISASSEMBLY AND REASSEMBLY.......................................................4 1-1. Tools Used .........................................................................................................................4 1-2. Disassembly Procedure .....................................................................................................5 1-2-1. Disassembling the Printer....................................................................................5 1-2-2. Disassembling “UNIT, MECHANISM” ..................................................................8 1-3. Assembly Procedure........................................................................................................16 1-4. Oiling................................................................................................................................17 TROUBLESHOOTING ...........................................................................18 2-1. Error Indication.................................................................................................................18 2-2 Explanations of Error Conditions......................................................................................20 2-2-1 Head Overheat Error .........................................................................................20 2-2-2 Cover Open Error ..............................................................................................20 2-2-3 Cutter Lock Error ...............................................................................................20 2-2-4 Memory Check Error..........................................................................................20 2-2-5 Low Voltage Error ..............................................................................................20 2-2-6 High Voltage Error .............................................................................................20 2-2-7 Paper End..........................................................................................................20 2-2-8 Macro Execution Wait ........................................................................................20 2-3. Troubleshooting Procedure..............................................................................................21 2-4. Troubleshooting Guide.....................................................................................................21 SERVICE PARTS LIST ..........................................................................24 3-1. Mechanical Exploded Diagrams.......................................................................................26 -2- CT-292/293 Series Service Manual 4. CIRCUIT DIAGRAMS.............................................................................31 4-1. MAIN PCB .......................................................................................................................31 4-1-1. Main Control Board (CPU).................................................................................31 4-1-2. Main Control Board (RAM, ROM) ......................................................................32 4-1-3. Main Control Board (EXTEND PORT) ...............................................................33 4-1-4. Main Control Board (HEAD) ..............................................................................34 4-1-5. Main Control Board (FEED MOTOR, CUTTER) ................................................35 4-1-6. Main Control Board (SENSOR) .........................................................................36 4-1-7. Main Control Board (PARALLEL I/F)..................................................................37 4-1-8. Main Control Board (USB I/F)............................................................................38 4-1-9. Main Control Board (SERIAL I/F, POWER)........................................................39 -3- CT-292/293 Series Service Manual INTRODUCTION This manual describes the disassembly, reassembly, and maintenance procedures of CT-P292/293 Series. 1. DISASSEMBLY AND REASSEMBLY Note the following items when performing maintenance of the printer. • Do not disassemble, reassemble, or adjust the printer unnecessarily when the printer operation is satisfactory. • Do not loosen the screws that fasten the components unless it is absolutely necessary. • After finishing inspection, perform a check to ensure that there is no irregularity before turning on the printer. • Use caution not to leave any part or screw used for maintenance inside the printer. • When handling the print head and electronic components, care must be taken to avoid static electricity. • When disassembling or reassembling the printer, check the wires and cords for damage. Do not draw any wire or cord by force. • Lubricate the components as necessary when reassembling them. 1-1. Tools Used • Phillips screwdriver #0, #1, and #2 • Precision flat head screwdriver (2.0 mm) • Tweezers • Long-nose pliers • Brush -4- CT-292/293 Series Service Manual 1-2. Disassembly Procedure 1-2-1. Disassembling the Printer 1. Disassembling “COVER, OPE-PANE” Press in the lugs on the right and left at “COVER, OPE-PANE” and remove “COVER, OPE-PANE” toward you. Lugs COVER, OPE-PANE <Precaution at reassembly> Engage the lugs at “COVER OPE-PANE” to “CASE L”. Try to pull “COVER OPE-PANE” toward you to check that it is securely fitted. 2. Disassembling “CASE L” Remove two “SCREW, PHT (ST#3), M3.0 × 6” that fasten “SA, FRAME BASE”, and pull it toward you while holding the both edges of “SA, DOOR FRONT”. Metallic parts SCREW, PHT (ST#3), M3.0 × 6 SA, DOOR FRONT <Precaution at reassembly> When reassembling “CASE L”, put it smoothly without hitch. If it cannot be inserted smoothly, pull it toward you and insert it back again. Check that the metallic part comes into view through the holes at “CASE L”. -5- CT-292/293 Series Service Manual 3. Disassembling “DOOR FRONT” Flip down “SA, DOOR FRONT” toward you. Remove “E-RING, 2.0” that fasten “LINK, FRONT DOOR” and “SA, LEVER PLATEN” at the right and left, and disengage “LINK, FRONT DOOR” from “DOOR FRONT”. SA, LEVER PLATEN E-RING, 2.0 LINK, FRONT DOOR <Precaution at disassembly / reassembly> Keep the bosses at “LINK, FRONT DOOR” facing inwardly and hang them to “DOOR FRONT”. Put “LINK, FRONT DOOR” to the pins at “SA, LEVER PLATEN” and secure it using “E-RING”. Open “DOOR FRONT” and detach it from the shaft at “HOLDER PAPER”. On the left side, align the grooves at the shaft with the notches at “DOOR FRONT”, and slide “DOOR FRONT” to the right to remove it. Right Left Align the grooves. <Precaution at disassembly / reassembly> Note that the left side of “DOOR FRONT” can be inserted or removed only in a correct orientation. When reassembling, insert the right side first, then the left side. -6- CT-292/293 Series Service Manual 4. Disassembling “UNIT, MAIN PCB” Remove four “SCREW, PHT (ST#3), M3.0 × 6”, and detach “UNIT, MAIN PCB” that is secured between “PLATE SHIELD” and “SA, FRAME BASE”. SCREW, PHT (ST#3), M3.0 × 6 PLATE SHIELD UNIT, MAIN PCB Raise the front edge of “UNIT, MAIN PCB” and disconnect “FFC CABLE” from the connectors at the “HEAD ASSY” side and the “UNIT, MAIN PCB” side. Then, remove the other connectors and cut the cable tie. Auto-cutter model (CT-P293) only CN4: CUTTER Route the cable away from the frame edge. CN5: COVER SW CN3: PE CN3: MOTOR HEAD ASSY Cable tie COVER SW <Precaution at disassembly / reassembly> When connecting or disconnecting “FFC CABLE”, keep it straight. Insert “FFC CABLE” while facing the character-printed side upward. When routing the cable for “COVER SW”, keep the cable away from the frame edge and do not tie it together with any other cables. Secure the other cables using a cable tie. (Loop back the motor cable only.) Be careful not to allow the cables to get caught unnecessarily. -7- CT-292/293 Series Service Manual 1-2-2. 1. Disassembling “UNIT, MECHANISM” Disassembling “SA, HOLDER PAPER” Remove “SCREW, PHT (BT#3), M3.0 × 8”, that fasten “SA, FRAME BASE” and “SA, HOLDER PAPER”, from the right and left sides, respectively. SCREW, PHT (BT#3), M3.0 × 8 <Precaution at reassembly> Securely fit the bosses at “SA, HOLDER PAPER” into the slots at “SA, FRAME BASE”. Remove “CUTTER CABLE” from the groove at “SA, HOLDER PAPER”, and draw it out from the hole. Move “SA, HOLDER PAPER” along the groove at “SA, FRAME BASE” and remove it. Remove the cable from this groove. Draw out “CUTTER CABLE” from this hole. Auto-cutter model (CT-P293) only <Precaution at disassembly / reassembly> Fit the boss at “FRONT DOOR ASSY” into the hole at “SA, HOLDER PAPER”. Fit the boss in the following procedure. Fit the projection at the gear here. Fit the opposite boss here. Fit the boss into the hole. -8- Fit the boss into the hole. CT-292/293 Series Service Manual <Precaution at disassembly / reassembly> Take up slack from the cable. For the auto-cutter model, route the cable outside the screw for “GUIDE, PAPER ADJUST”, and insert it into the groove at “SA, HOLDER PAPER” without any slack on the cable. Insert the cable into this groove. Route the cable outside the screw. Auto-cutter model (CT-P293) only Remove “PE, PCB ASSY” from “SA, HOLDER PAPER”. Pull the hooks at the right and left outwardly, detach the lower lugs and pull “PE, PCB ASSY” upwardly to remove it. Hooks Hooks PE, PCB ASSY Lugs SA, HOLDER PAPER <Precaution at disassembly / reassembly> When disassembling, do not pull the hooks excessively. Doing so may damage them. When reassembling, insert “PE, PCB ASSY” while fitting the lugs first and then the hooks. 2. Disassembling “SA, FRONT DOOR ASSY” Remove “E-RING, 2.0”, that fasten “SA, FRONT DOOR ASSY” and “SA, FRAME BASE”, from the right and left sides. Left Right -9- CT-292/293 Series Service Manual Detach the boss at “SA, FRAME BASE” from “FRAME, FRONT DOOR” while pulling “FRAME, FRONT DOOR” outwardly. Detach two lugs that fasten “GUIDE FRONT DOOR”. Detach two lugs from the right and left sides of the platen roller. <Precaution at disassembly / reassembly> For the auto-cutter model, the cable is secured with the hook at “GUIDE FRONT DOOR”. When removing the cable, remove it while pushing the hook in the arrow direction. When attaching the cable, make it flat and insert it into the hook while pulling the cable toward the connector side to avoid slack on the cable. Auto-cutter model (CT-P293) only - 10 - CT-292/293 Series Service Manual Remove “SPRING, PLATEN LOCK” from the right and left sides of “FRAME, FRONT DOOR”. Face them inwardly. SA, LEVER PLATEN L SA, LEVER PLATEN R <Precaution at reassembly> When reassembling, keep the end of “SPRING, PLATEN LOCK” facing inwardly under the “FRAME, FRONT DOOR”. Press “SA, LEVER PLATEN L & R” and check that they can be moved smoothly. 3. Disassembling “PLATEN” Remove “E-RING, 4.0” that fasten “PLATEN GEAR”, and pull out “PLATEN GEAR”. Remove two “E-RING, 4.0” that fasten “PLATEN” and “PLATEN BUSH” at the right and left sides. E-RING PLATEN GEAR PLATEN E-RING Move “PLATEN” to the right and pull it out from the shaft support at “FRAME, FRONT DOOR”. When removing “PLATEN”, pull it out together with “PLATEN BUSHING” to the upper left. Left Move “PLATEN” to the right. Right PLATEN BUSHING Pull out “PLATEN” to the upper left. PLATEN - 11 - CT-292/293 Series Service Manual <Precaution at reassembly> When reassembling, insert “PLATEN”, together with “PLATEN BUSHING”, into “FRAME, FRONT DOOR” from the right. Since the shaft length of “PLATEN” differs between the right and left, be careful not to insert “PLATEN” in a wrong orientation. 4. Disassembling “AUTO CUTTER” (CT-P293) or “DUMMY, CUTTER FRAME” (CT-P292) Remove two “SCREW, PHT (ST#3), M3.0 × 6”, that fasten “FRAME, FRONT DOOR”, from the right and left sides. SCREW, PHT (ST#3), M3.0 × 6 Slide “CUTTER” or “DUMMY, CUTTER FRAME”, and remove it while holding the side frames of “FRAME, FRONT DOOR” outwardly. Check the orientation. <Precaution at reassembly> When reassembling, pull “FRAME, FRONT DOOR” outwardly and slide “CUTTER” or “DUMMY, CUTTER FRAME” onto “FRAME, FRONT DOOR” from a slanting direction. Align the holes with the internal bosses at the right and left sides of “FRAME, FRONT DOOR”. Check the mounting orientation. (The paper guide faces the “PLATEN” side.) BOSS BOSS Left side Left side - 12 - CT-292/293 Series Service Manual AUTO CUTTER (CT-P293) DUMMY, CUTTER FLAME (CT-P292) Paper guide 5. Paper guide Disassembling “SA, LEVER PLATEN L & R” Remove two “E-RING, 2.0” from the right and left sides of “FRAME, FRONT DOOR”. Left side Right side <Precaution at reassembly> Be sure to assemble “SA, LEVER PLATEN” in a correct orientation. 6. Disassembling “SA, F BLADE STAY” Remove two “SCREW, PHT (ST#3), M3.0 × 6” that fasten “SA, FRAME BASE” and “SA, F BLADE STAY”. SCREW, PHT (ST#3), M3.0 × 6 Align the bosses. <Precaution at reassembly> Align the bosses at “SA, F BLADE STAY” with the holes at “SA, FRAME BASE”. - 13 - CT-292/293 Series Service Manual Remove “SCREW BHT (ST), M2.0 × 4” that fastens “SA, F BLADE STAY” and “F-BLADE”. Align the bosses. Auto-cutter model (CT-P293) only <Precaution at reassembly> Align the bosses at “F BLADE STAY” with the holes at “SA, FRAME BASE”. Check the orientation of “F-BLADE”. 7. Disassembling “HEAD ASSY” Remove “HEAD ASSY” while pulling the side edges at “SA, FRAME BASE” outwardly and keeping it clear of “HEAD SPRING”. HEAD ASSY HEAD SPRING <Precaution at disassembly / reassembly> When disassembling, be careful not to loose “HEAD SPRING”. When reassembling, mount “HEAD ASSY” first and “SA, BLADE STAY” next. Then insert two “HEAD SPRING”. Check that “HEAD ASSY” is correctly inserted into “SA, FRAME BASE” and that the bosses at “HEAD ASSY” are located inside “HEAD SPRING”. Insert “HEAD ASSY” into the window hole. Check the bosses at “HEAD ASSY”. - 14 - CT-292/293 Series Service Manual 8. Disassembling “PE SWITCH ASSY” Remove “SCREW, PHT (BT#3), M1.7 × 6” that fastens “SA, FRAME BASE” and “PE SWITCH ASSY”. SCREW, PHT (BT#3), M1.7 × 6 Hole for screw Keep the cable away from the frame. Hole for boss <Precaution at reassembly> When reassembling, align the screw and the boss with the holes for them, respectively, then tighten the screw. Keep the cable away from the frame. 9. Disassembling “SA, FRAME BASE” Remove two “SCREW, PHT (ST#3), M3.0 × 6” that fasten “SA, FRAME BASE R & L”. Remove “E-RING, 2.0” and detach “GEAR1, REDUCTION” from “SA, FRAME BASE R”. Then remove “REDUCTION GEAR”. E-RING 2.0 SCREW, PHT (ST#3), M3.0 × 6 GEAR1, REDUCTION Hole for boss REDUCTION GEAR <Precaution at reassembly> Align the bosses at “SA, FRAME BASE L” with the holes at “SA, FRAME BASE R”. 10. Disassembling “MOTOR ASSY” Remove “SCREW, PHT (ST#3), M3.0 × 6” that fastens “SA, FRAME BASE R” and “MOTOR ASSY”. MOTOR ASSY - 15 - CT-292/293 Series Service Manual <Precaution at reassembly> Turn “MOTOR ASSY” and insert the lower flange into the fixture. Then secure “MOTOR ASSY” with a screw. 1-3. Assembly Procedure When reassembling the parts, follow the procedure of “1-2 Disassembly Procedure” in reverse. - 16 - CT-292/293 Series Service Manual 1-4. Oiling 1) Oil Used (Grease) • FLOIL G-602S (Kanto Kasei) 2) Oiling Positions (1) Pins at the gear on “SA, FRAME BASE R” (2 positions) (2) Mating section of “SA, FRAME BASE R & L” and “SA, LEVER PLATEN R & L” (3) Slideways at “SA, FRAME FRONT DOOR” and “SA, LEVER PLATEN R & L” (4) Edges at “CUTTER F- BLADE”, slideways for “FIX BLADE” - 17 - CT-292/293 Series Service Manual 2. TROUBLESHOOTING 2-1. Error Indication When an error is detected, the three LEDs indicate the error status in the following patterns. LED on the panel 1) 2) 3) POWER LED (green) Lit: Power supplied Blinking: Memory check error, hex-dump mode, memory switch setting mode Not lit: Power not supplied ERROR LED (red) Lit: Cover open, paper end Blinking: Occurrence of an error, waiting for macro execution Not lit: Normal operation PAPER LED (orange) Lit: Paper end Blinking: Not blink Not lit: Normal operation Status Head overheat Cover open error *1 (MSW3-8 is set to OFF.) Cover open error *2 (MSW3-8 is set to ON.) Cutter lock error POWER LED ERROR LED PAPER LED (Green) (Red) (Orange) Lit − Lit − Lit − Lit − Memory check error Low voltage error High voltage error − − Lit − Lit − - 18 - CT-292/293 Series Service Manual Status Paper end Macro execution wait *1, 2: POWER LED ERROR LED PAPER LED (Green) (Red) (Orange) Lit − Lit Lit When the front cover is opened during paper feed or printing, the paper sensor may be activated, resulting in the paper end error. *2: After closing the front cover, reset the error by using a command. - 19 - CT-292/293 Series Service Manual 2-2 Explanations of Error Conditions 2-2-1 Head Overheat Error When the head temperature is raised (approx. 75°C or above), the ERROR LED blinks and printing operation is stopped to protect the print head from overheat. When the head temperature is lowered (approx. 70°C or lower), printing operation is automatically restarted. 2-2-2 Cover Open Error When the front cover is opened during paper feed or printing, the ERROR LED blinks. When MSW3-8 is set to OFF: The error is reset when the front cover is closed (auto restore). When MSW3-8 is set to ON: The error is reset when the front cover is closed and a command is given. Note: When the front cover is opened during paper feed or printing, the paper sensor may be activated, resulting in the paper end error. 2-2-3 Cutter Lock Error The cutter cannot be moved. An error has occurred. To reset the error, remove the cause of the error, and press the FEED switch or give a command. 2-2-4 Memory Check Error Memory read/write check operation is not correctly performed. (Restoration not possible) 2-2-5 Low Voltage Error The voltage supplied to the printer drops. When this error occurs, immediately turn the power off. 2-2-6 (Restoration not possible) High Voltage Error The voltage supplied to the printer rises excessively. When this error occurs, immediately turn the power off. 2-2-7 (Restoration not possible) Paper End When the paper has run out, the paper sensor in the paper path is activated, the ERROR and PAPER LEDs light up, and then printing operation is stopped. Open the front cover and set new paper. 2-2-8 Macro Execution Wait When the ESC/POS command is specified, the macro execution wait state will take effect. Press the FEED switch. - 20 - CT-292/293 Series Service Manual 2-3. Troubleshooting Procedure When a fault occurs, confirm its phenomenon, locate the problem in accordance with “2.2 Troubleshooting Guide”, and troubleshoot it as described below. Phenomenon Find the fault phenomenon in this column. If there are multiple phenomena, take all the applicable items into consideration. This will help you locate hidden problems as well. Cause Possible causes are listed here. Find probable causes from the list and follow the check method to identify the cause of the fault. Check Method The check method for identifying the cause of the fault is described. Remedies Take the remedies described in this column. By following the above-mentioned procedure, you can troubleshoot problems efficiently with fewer misjudgments. 2-4. Troubleshooting Guide ● Power Supply Failure Phenomenon Cause Power cannot be turned on. The power cable is not connected. (AT model) (The POWER LED not illuminated.) The main power of the power source is off. A cable is disconnected. Check Method Remedies Check if the plug is correctly Connect the power cable. connected. Turn the main power on. Check if the main power is turned on. Check if a cable at the power Replace the wire connected supply line is disconnected from the power source with a using a tester. new one. Modify the damaged wire. − The control PCB is faulty. - 21 - Replace “UNIT, MAIN PCB”. CT-292/293 Series Service Manual ● Printing Failure Phenomenon No printing Cause Check Method The control PCB is faulty. The thermal head connector has a bad contact or connection. − Check the contact or connecting condition. The thermal head is faulty. Paper setting is wrong side out. Part of printing is not done. Print is pale. Print is uneven. Print is faint. − Remedies Replace “UNIT, MAIN PCB”. Re-insert the thermal head connector or replace it with a new one. Replace the thermal head with a new one. Check the paper orientation. Set the paper correctly. The thermal head connector Check the contact, has a bad contact or connecting or mounting connection or faulty mounting. condition. Re-insert the thermal head connector or “HEAD ASSY”. The thermal head is faulty. Replace the thermal head with a new one. The supply voltage is low. − Check the supply voltage with a tester. The thermal head is faulty. − Use the printer within the specified supply voltage range. Replace the thermal head with a new one. The thermal head has fouling. Check the thermal head for fouling. Remove fouling using ethyl alcohol soaked cotton swab or soft cloth. Paper other than recommended is used. Check if the paper being used meets the specification. Replace it with the specified paper. The platen roller is not mounted correctly. Check the mounting Mount the platen roller condition of the platen roller. correctly. - 22 - CT-292/293 Series Service Manual ● Paper Feed Failure Phenomenon Paper is not fed. Paper feed is not straight. Cause Check Method Remedies The motor connector has a bad connection. Check the connecting condition of the connector. The motor is faulty. Measure the supply voltage Replace “MOTOR ASSY”. with a tester or oscilloscope. The supply voltage is low. Check the supply voltage with a tester. − The control PCB is faulty. Connect the connector correctly. Use the printer within the specified supply voltage range. Replace “UNIT, MAIN PCB”. The platen roller is not mounted correctly. Check the mounting Mount the platen roller condition of the platen roller. correctly. Paper feed is faulty. Check if paper is jammed, torn or caught in the paper path. Foreign substances are stuck Check the gear for any in the gear. A gear is broken. foreign substance or breakage. Remove unnecessary paper and set the paper correctly. Eliminate foreign substance. If any gear is broken, replace it with a new one. ● Faulty Sensor Phenomenon Paper presence or absence cannot be detected. Paper near end cannot be detected. Cause The paper sensor is faulty. An error cannot be reset. The sensor at the operation panel cover is faulty. Check Method Remedies Check the indication at the Replace “SA, PE PCB”. LCD or LED when the paper ends. Correctly attach the operation panel cover and check again. The front cover switch is faulty. After setting paper and closing the front cover, check if the error is reset. Replace “UNIT, MAIN PCB”. Replace the front cover switch. ● Auto Cutter Failure (CT-P293) Phenomenon Cause The auto cutter does not The connector has a bad operate. connection. The auto cutter is faulty. Check Method Check the connecting Connect the connector condition of the connector at correctly. the control PCB. Measure the supply voltage If the supply voltage is normal, with a tester or oscilloscope. replace the auto cutter with a new one. − The control PCB is faulty. Paper feed is faulty. (paper jams) Remedies Check if paper is jammed, torn or caught in the paper path. - 23 - Replace “UNIT, MAIN PCB”. Remove unnecessary paper and set the paper correctly. CT-292/293 Series Service Manual 3. SERVICE PARTS LIST Remarks: All the parts used in the product are contained in “SERVICE PARTS LIST” in this Service Manual. However, note that all of them are not available with customers. When placing an order for service parts, refer to the Parts Price List published separately. If you need the Parts Price List, consult the local distributor from whom you purchased this product. No. Part No. Part Name Q’ty Remarks 1 SA, FRAME BASE R 1 Not supplied 2 SA, FRAME BASE L 1 Not supplied 3 DW25901-00F CUTTER STEP MOTOR ASSY 1 4 600377-00 REDUCTION GEAR (CTS-300) 1 5 ZH20201-00F GEAR 1, REDUCTION 1 STAY, F BLADE 1 7 (500318-00) (F-Blade-31 SEC3699) 1 8 100107-00 HEAD ASSY 1 9 700021-00 HEAD SPRING (CTS-300) 2 10 25-0347 FFC (SEC2310) 1 11 200036-000 PE Switch Assy (SEC3789) 1 ZH66702-00F SA, PE PCB 6 12 13 HOLDER, PAPER 1 Not supplied Not supplied 1 14 GUIDE, PAPER ADJUST 1 Not supplied 15 FRAME, FRONT DOOR 1 Not supplied 16 SA, LEVER PLATEN L 1 Not supplied 17 SA, LEVER PLATEN R 1 Not supplied 18 ACS530 Cutter (with Fix Brade) (1) for CT-P293 Not supplied 19 DUMMY, CUTTER FRAME (1) for CT-P292 Not supplied 20 CUTTER, MANUAL (1) for CT-P292 Not supplied 21 GUIDE, EX PAPER (1) for CT-P293 Not supplied 22 800452-00 PLATEN (CTS-300) 1 23 650001-00 PLATEN BUSHING (CTS-300) 2 24 600376-00 PLATEN GEAR (CTS-300) 1 25 ZH24203-00F GUIDE, FRONT DOOR 1 26 ZH43601-00F SPRING, PLATEN LOCK 2 27 ZH54202-00F DOOR, FRONT 1 28 RINK, FRONT DOOR 2 29 ZH66801-00F UNIT, MAIN PCB (WITH ROM) (1) 30 ZH66802-00F UNIT, MAIN PCB USB (WITH ROM) (1) Not supplied for USB model 31 PLATE, SHIELD 1 Not supplied 32 CASE L 1 Not supplied 33 COVER, OPE-PANE 1 Not supplied 34 SHEET, OPE-PANE 1 Not supplied CAUTION LABEL PAPER 1 Not supplied CAUTION HOT 1 35 36 37 80-0276 CAUTION EDGE 1 - 24 - Not supplied CT-292/293 Series Service Manual No. Part No. 38 Part Name PLATE,MOUNTING 292 39 25-0355 CORD ASSY CA212-5 40 ZH67901-00F CORE, I/F CABLE Q’ty 1 Remarks Not supplied (1) 1 41 36AD2-J (1) OPTION 42 SA, POWER BOARD (1) for AT model, Not supplied 43 COVER, POWER CON BOARD (1) for AT model, Not supplied 44 SA, I/F CABLE HOSIDEN (1) for AT model, Not supplied 45 CLAMP, WIRE 1 OPTION 46 CD-ROM, USER’S MANUAL JPN/ENG 1 OPTION 47 PAPER, ROLL 1 OPTION UNIT, BOX CTP290 1 48 ZH76701-00F 49 AC CORD J (1) for JAPAN, OPTION 50 AC CORD U (1) for USA, OPTION 51 TA44114-00F COVER FF, OPE-PANE 1 52 GUIDE, QUICK START JPN (1) OPTION 53 GUIDE, QUICK START ENG (1) OPTION 101 E11830-060F SCREW, PHT (INT.TW) M3 × 6 (toothed lock) 1 102 E11126-060F SCREW, PH (ST#3) M2.6 × 6 1 103 E11717-060F SCREW, PHT (BT#3), M1.7 × 6 1 104 E11130-060F SCREW, PHT (ST#3), M3 × 6 12 105 E14020-040F SCREW, BHT (ST), M2 × 4 107 5 SCREW, PHT, M3 × 12 106 E11730-080F SCREW, PHT (BT#3), M3 × 8 1 2 108 SCREW, PHT (ST#3), M3 × 12 2 109 SCREW, PHT (BT#3), M3 × 12 (2) 110 E60320-000F E-RING, 2.0 7 111 E60340-00F E-RING, 4.0 3 112 Not supplied NUT, (#2) M3 Not supplied for AT model Not supplied 1 Not supplied 201 ZH44710-00F SA, ACS530 CUTTER (1) for CT-P293 202 ZH44709-00F SA, DUMMY CUTTER (1) for CT-P292 203 ZH44708-00F SA, FRONT DOOR FRAME 1 204 ZH54701-00F SA, OPE-PANE COVER 1 205 ZH44707-00F SA, HOLDER PAPER 1 206 ZH74701-00F SA, MOUNTING PLATE 1 207 ZH67703-00F SA, POWER BOARD-I/F CABLE HOSIDEN - 25 - (1) for AT model CT-292/293 Series Service Manual 3-1. Mechanical Exploded Diagrams Overall exploded diagram - 26 - CT-292/293 Series Service Manual Exploded diagram - configuration of No. 201 Exploded diagram - configuration of No. 202 - 27 - CT-292/293 Series Service Manual Exploded diagram - configuration of No. 203 Exploded diagram - configuration of No. 204 - 28 - CT-292/293 Series Service Manual Exploded diagram - configuration of No. 205 Exploded diagram - configuration of No. 206 - 29 - CT-292/293 Series Service Manual Exploded diagram - configuration of No. 207 - 30 - CT-292/293 Series Service Manual 4. CIRCUIT DIAGRAMS 4-1. MAIN PCB 4-1-1. Main Control Board (CPU) - 31 - CT-292/293 Series Service Manual 4-1-2. Main Control Board (RAM, ROM) - 32 - CT-292/293 Series Service Manual 4-1-3. Main Control Board (EXTEND PORT) - 33 - CT-292/293 Series Service Manual 4-1-4. Main Control Board (HEAD) - 34 - CT-292/293 Series Service Manual 4-1-5. Main Control Board (FEED MOTOR, CUTTER) - 35 - CT-292/293 Series Service Manual 4-1-6. Main Control Board (SENSOR) - 36 - CT-292/293 Series Service Manual 4-1-7. Main Control Board (PARALLEL I/F) - 37 - CT-292/293 Series Service Manual 4-1-8. Main Control Board (USB I/F) - 38 - CT-292/293 Series Service Manual 4-1-9. Main Control Board (SERIAL I/F, POWER) - 39 -