Download Worcester R40HE Technical data

Transcript

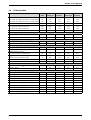

Installation and Servicing Instructions R29 & R40 HE conventional Wall mounted condensing boiler for central heating 6 720 610 577-01.10 6 720 611 445 GB (03.11) TD ZB 7-28 R29 HE GC-Number: 47 311 60 ZB 11-40 R40 HE GC-Number: 47 311 61 Contents Contents Safety precautions 3 Symbols 3 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 Details of the appliance EC Declaration of Conformity Standard package Description of appliance Accessories Casing dimensions Layout of appliance Function Electrical wiring diagram Technical data 4 4 4 4 5 5 6 7 8 9 2 Installation regulations 11 3 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.8.1 3.8.2 3.8.3 Installation Important remarks System Siting the appliance Wall mounting frame assembly Pre-piping the system Fitting the appliance Checking the connections Flue Systems Siting the Flue Terminal Installation of the flue Flue duct preparation and assembly 11 11 11 13 14 14 15 16 16 17 18 19 4 4.1 4.2 Electrical connections Connecting the appliance Wiring to your system 21 21 22 5 5.1 5.2 5.3 5.4 5.5 5.6 Commissioning Commissioning Switching the appliance on/off Switching on the Boiler System controls Frost protection Fault Condition 23 23 24 24 24 24 25 6 6.1 6.1.1 6.2 6.2.1 6.2.2 Individual settings Mechanical settings Setting the boiler flow temperature Settings on the Bosch Heatronic Operating the Bosch Heatronic Setting the anti-cycle time (Service Function 2.4) 6.2.3 Setting the maximum boiler flow temperature (Service Function 2.5) 2 6.2.4 Setting the switching difference (Service Function 2.6) 6.2.5 Setting the heating output (Service Function 5.0) 6.3 Setting the gas/air ratio 27 27 28 7 Converting the appliance to different gas types 29 7.1 Setting the gas/air ratio 29 7.2 Testing combustion air/flue gas at set heat output 31 7.2.1 Testing the O2 or CO2 level in the combustion air 31 7.2.2 Testing CO and CO2 31 8 8.1 8.2 8.3 8.3.1 8.3.2 8.3.3 8.3.4 8.3.5 8.3.6 8.3.7 8.3.8 Maintenance Pre-Service Check List Description of servicing operations Replacement of Parts PCB control board and transformer Fan Assembly Sensors Gas Valve Electrode assembly Pressure Relief Valve Burner Primary Heat Exchanger 32 33 34 37 37 38 38 38 39 39 39 39 9 9.1 9.2 9.3 9.4 9.5 9.5.1 Appendix Fault Codes Short parts list Heating/hot water output settings (N.G) Heating/hot water output settings (L.P.G) Operational Flow diagrams Central heating function 40 40 41 41 41 42 42 26 26 26 26 26 27 27 6 720 611 445 GB (03.11) Safety precautions Safety precautions If you smell gas B Turn off gas service cock at the meter. B Open windows and doors. B Do not operate any electrical switches. B Extinguish any naked flames. B Telephone your gas company. If you smell fumes from the appliance B Switch off appliance (see page 24). B Open windows and doors. Unpacking IMPORTANT HANDLING INSTRUCTIONS B Two people should transfer the packaged appliance from the van to the point of installation B Open the top of the carton, remove and place the component tray and both side bars of the wall mounting frame to one side B Lie the packaged appliance on its back. (The back has “TRUCK HERE” printed on the carton) B One person firmly holds the packaging while the other straddles the boiler and slides it from the packaging Fitting and modifications B Fitting of the appliance or any controls to the appliance may only be carried out by a competent engineer in accordance with the Gas Safety (Installation and Use) Regulations 1998. B Flue systems must not be modified in any ways other than as described in the fitting instructions. B This appliance is for use with fully pumped, sealed and open vent systems only. B Two persons are then required to lift one end and stand the appliance upright with the flue at the top Maintenance B The user is recommended: to have the system regularly serviced in order to ensure that it functions reliably and safely. B Use only original spare parts! Check the contents against the packing list. Additional requirements for roof space installation B Two people should use two step ladders and share lifting the unpacked boiler up to the loft hatch B Where the boiler enters the loft space, tilt and slide the boiler on its back to the point of installation Symbols Safety instructions in this document are identified by a warning-triangle symbol and are printed on a grey background. Combustible materials B Do not store or use any combustible materials (paper, thinners, paints etc.) in the vicinity of the appliance. Health and safety B This appliance contains no asbestos products. B There is no potential hazard due to the appliance being electrically unsafe. B There are no substances used in the construction that are a potential hazard in relation to the COSHH Regulations (Control of Substances Hazardous to Health Regulations 1988). i Notes containing important information are identified by the symbol shown on the left. They are bordered by horizontal lines above and below the text. Combustion air/Ambient atmosphere B The combustion air/ambient atmosphere should be kept free of chemically aggressive substances (e.g. halogenated hydrocarbons which contain chlorine or fluorine compounds). This will prevent corrosion. Instructions to the customer B Explain to the customer how the appliance works and how to operate it. B Advise the user that he/she must not make any modifications to the appliance or carry out any repairs on it. B These instructions are to be left with the user or at the Gas meter. B Important: These instructions apply in the UK only. 6 720 611 445 GB (03.11) 3 Details of the appliance 1 Details of the appliance 1.3 Description of appliance • Wall-mounted appliance 1.1 EC Declaration of Conformity • Natural gas models are low-emission appliances This appliance is in accordance with the applicable requirements of the Gas Appliance Directive, Boiler Efficiency Directive, Electromagnetic Compatibility Directive and the Low Voltage Directive. • Multi function display PIN CE-0085 BL 0507 Category UK II2H 3P • Full safety systems incorporating Bosch Heatronic with flame ionisation monitoring, solenoid valves and temperature sensors Appliance Type C13, C33 • Bosch Heatronic control system • Automatic ignition • Modulating control • Concentric flue/air duct with testing point for CO2/CO • Regulated speed fan Table 1 • Pre-mix burner 1.2 Standard package • Gas condensing boiler for central heating • Wall mounting frame • Fixings (screws etc.) • Set of documentation for appliance • Pre-plumbing manifold • Condensate drain pipe. 4 • Temperature control for boiler flow • Safety temperature limiter in 24 V electrical circuit • Flue gas temperature limiter (105 °C) • Condensate Trap • Connecting possibility for 3 port or 2 x 2 port motorised valve systems • Suitable for fully pumped sealed and open vent systems. 6 720 611 445 GB (03.11) Details of the appliance 1.4 Accessories diameter) for flue lengths up to 13m (R 29 HE ) or 10m (R 40 HE) and vertical flue systems for flue lengths up to 13.7 m (R 29 HE) or 10.7m (R 40 HE). Fitting instructions are sent with these kits. • Standard horizontal flue kit at 100 mm outside diameter for flues up to 4 m in length (3.5m for the R 40 HE). • Flue duct kits for horizontal (125 mm outside 1.5 Casing dimensions min min 10* 10* Z 600* X Y 850 850 120 101 13 103 30 200 35 360 395 * 200 440 6 720 610 601- 01.4O Fig. 1 13 101 103 X Manifold assembly Outer case Facia cover Standard Concentric Horizontal Flue System: min. 160 mm Alternative Concentric Flue System: min. 220 mm Y Standard Concentric Horizontal Flue System: 40 mm Alternative Concentric Flue System: 70 mm Z Standard Concentric Horizontal Flue System: 105 mm Alternative Concentric Flue System: 130 mm * For servicing the appliance Note: Horizontal flue only: dimension X may need to increase due to the incline of the flue. 6 720 611 445 GB (03.11) 5 Details of the appliance 1.6 Layout of appliance 120 221.1 221.2 226 102 27 32.1 29 36 271 6 415 43 9 63 416 358 64 423 4.4 7 15 361 295 4 417 Fig. 2 4 4.4 6 7 9 15 27 29 32.1 36 43 63 64 102 120 6 Heatronic control Y-S module Heat exchanger safety temperature limiter Testing point for gas supply pressure Flue gas temperature limiter Relief valve Automatic air vent Air gas Mixer unit Electrode assembly Temperature sensor in boiler flow Flow pipe Adjustable gas flow restrictor Adjusting screw for min. gas flow volume Inspection window Fixing points 221.1 221.2 226 295 271 358 361 415 416 417 423 Flue duct Combustion air intake Fan assembly Appliance type sticker Flue duct Condensate trap Drain valve Cover plate for cleaning access Condensate collector Clip for fixing outer case Siphon 6 720 611 445 GB (03.11) Details of the appliance 1.7 Function 4.4 361 Fig. 3 4 4.4 6 7 9 13 15 27 29 29.1 30 32 33 35 36 43 45 47 52 52.1 55 56 57 61 63 64 69 221 226 229 Bosch Heatronic control Y-S module Temperature limiter, heat exchanger Testing point for gas supply pressure Flue gas temperature limiter Manifold Safety valve Automatic air vent Mixer unit Bi-metallic thermostat for combustion air compensation Burner Flame sensing electrode Igniter electrode Heat exchanger with cooled combustion chamber Temperature sensor in boiler flow Boiler flow Gas inlet Return Solenoid valve 1 Solenoid valve 2 Filter Gas valve CE 427 Main valve disc Reset button Adjustable gas flow restrictor Adjusting screw for min. gas inlet flow volume Control valve Flue duct Fan Inner casing 6 720 611 445 GB (03.11) 317 358 361 423 443 Display Condensate trap Drain valve Siphon Diaphragm 7 Details of the appliance 1.8 Electrical wiring diagram o - orange bl - black r - red 33 365 364 61 366 363 367 ECO 4.1 25 V 153 230V/AC 230 V 136 310 135 312 328 302 313 151 124 789 L N Ns Ls LR 161 300 9 6 M r r mains supply o 226 52 4.4 52.1 56 o bl bl bl bl 36 32 6 720 610 601-03.2O Fig. 4 4.1 4.4 6 9 32 33 36 52 52.1 56 61 135 136 151 153 161 226 300 302 310 8 Ignition transformer Y-S module Temperature limiter, heat exchanger Flue gas temperature limiter Flame sensing electrode Ignition electrode Temperature sensor in boiler flow Solenoid valve 1 Solenoid valve 2 Gas valve CE 427 Reset button Master switch Temperature control for boiler flow Fuse, slow 2.5 A, AC 230 V Transformer Link Fan Code plug Earth connection Function control (Service only) 312 313 328 363 364 365 366 367 Fuse, slow T 1,6 A Fuse, slow T 0,5 A Terminal block for AC 230 V Mains supply Indicator lamp for burner Indicator lamp for power supply “Chimney sweep” button Service button No function 6 720 611 445 GB (03.11) Details of the appliance 1.9 Technical data Units R29 HE Natural gas R29 HE Propane R40 HE Natural gas R40 HE Propane kW kW kw 29.3 29.0 27.4 29.3 29.0 27.4 41.4 41.4 39.1 41.4 41.4 39.1 Max. rated heat input net kW 27.7 27.7 40 40 Min. rated heat output net 40/30°C Min. rated heat output net 50/30°C Min. rated heat output net 80/60°C kW kW kW 8.4 8.3 7.4 11.6 11.4 10.5 12.9 12.8 11.4 16.2 16.1 14.3 Min. rated heat input net kW 7.6 10.8 11.8 14.8 4.2 - Max. rated heat output net 40/30°C central heating Max. rated heat output net 50/30°C central heating Max. rated heat output net 80/60°C central heating Maximum gas flow rate – After 10 minutes from lighting Natural gas G20 (CVnet 34.02 MJ/m3) m3/h 2.9 - MJ/m3) kg/h - 2.1 Natural gas G20 (CVnet 34.02 MJ/m3) mbar 20 - 20 - LPG (CVnet 88 MJ/m3) mbar - 37 - 37 Flue gas temp. 80/60°C, rated/min. load °C 67/55 67/55 87/58 87/58 Flue gas temp. 40/30°C, rated/min. load °C 43/32 43/32 65/43 65/43 Residual delivery pressure (inc. pressure drop in air intake duct) Pa 80 80 100 100 CO2 level at max. rated heat output CO2 level at min. rated heat output % % 9.2 8.8 10.8 10.5 9.2 9.2 10.8 10.8 5 5 5 5 A A A A LPG (CVnet 88 3.2 Gas supply pressure Flue NOx-class SEDBUK figure Band Condensate Max. condensation rate (tR = 30°C) l/h 2.3 2.3 3.5 3.5 4.8 4.8 4.8 4.8 AC ... V 230 230 230 230 Frequency Hz 50 50 50 50 Max. power consumption W 43 43 113 113 dB(A) 36 36 42 42 IP X4D X4D X4D X4D Max. boiler flow temperature °C nom. 90 nom. 90 nom.90 nom.90 Max. permissible operating pressure (boiler) bar 3 3 3 3 Permissible ambient temperatures °C 0 - 50 0 - 50 0 - 50 0 - 50 Nominal capacity of appliance l 3.75 3.75 3.75 3.75 Weight (excluding packaging) kg 43 43 43 43 pH-value, approx. General Data Electrical power supply voltage Noise output level Appliance protection rating with blanking plate fitted Table 2 6 720 611 445 GB (03.11) 9 Details of the appliance Gas supply Condensate analysis, mg/l Ammonium 1.2 ≤ 0.01 Lead Nickel 0.15 Mercury ≤ 0.0001 Cadmium ≤ 0.001 Sulphate Chromium ≤ 0.005 Zinc ≤ 0.015 Tin ≤ 0.01 Halogenated hydrocarbons ≤ 0.002 Hydrocarbons 0.015 Vanadium Copper 0.028 pH-value 1 Total length of gas supply pipe (metres) 3 6 Pipe diameter (mm) 9 Gas discharge rate (m3/h) 8.7 5.8 4.6 22 18.0 12.0 9.4 28 ≤ 0.001 4.8 Table 8 Table 3 Flue system HORIZONTAL 100 mm – Standard FLUE SYSTEM Overall Diameter of Duct mm 100 Flue Terminal / Duct Assembly Length mm 600 Extension Duct Length mm 1000 Max. R29 4m R40 3.5m (including turret) Table 4 VERTICAL 100mm FLUE SYSTEM Overall Diameter of Duct mm 100 Flue Terminal / Duct Assembly Length mm 1140 Max. (Excl. terminal) R29 5m R40 4m Table 5 HORIZONTAL 125 mm FLUE SYSTEM Overall Diameter of Duct mm 125 Flue Terminal / Duct Assembly Length mm 1030 Max. R29 13m R40 10m (including turret) Table 6 VERTICAL 125 mm FLUE SYSTEM Overall Diameter of Duct mm 125 Flue Terminal / Duct Assembly Length mm 1365 Max. (EXCL) terminal) R29 13.7m R40 10.7m Table 7 Elbow - 90 ° Equivalent length 2 m Bend - 45 ° Equivalent length 1m 10 6 720 611 445 GB (03.11) Installation regulations 2 Installation regulations Gas Safety (Installation & Use) Regulations 1998: All gas appliances must be installed by a competent person. Failure to install correctly could lead to prosecution. The manufacturers notes must not be taken, in any way, as overriding statutory obligations. The appliance must be installed in accordance with the current IEE Wiring Regulations, local Building Regulations, Building Standards (Scotland) (Consolidation), bye-laws of the local Water Company, Health and Safety Document 635 (Electricity at Work Regulations 1989) and any other local requirements. Product Liability regulations indicate that, in certain circumstances, the installer can be held responsible, not only for mistakes on his part but also for damage resulting from the use of faulty materials. We advise the installer to avoid any risk by using only quality approved branded fittings. The relevant British Standards should be followed i.e. • BS 6798: Specification for the installation of gas fired hot water boilers of rated input not exceeding 60kW • BS 5449: Central Heating for Domestic Premises • BS 5546: Installation of gas hot water supplies for domestic purposes • BS 5440:1: Flues and ventilation for gas appliances of rated input not exceeding 70 kW (net): Flues • BS 5440:2: Flues and ventilation for gas appliances of rated input not exceeding 70 kW (net): Air Supply • BS 6891: Installation of low pressure gas pipe work installations up to 28 mm (R1). • BS 7074:1: Code of practice for domestic heating and hot water supply • BS 7671: Requirements for Electrical Installation. These instructions must be followed. 3 Installation B Always turn off the gas cock before carrying out any work on components which carry gas. i 3.1 Fixing of the appliance, gas and flue connections, commissioning of the system and electrical connections may only be carried out by competent persons authorised by CORGI. Important remarks B Appliance should only be installed in fully pumped sealed and open vent central heating systems. B To avoid gas formation in the system, galvanised radiators or pipes must not be used. B Do not fit a thermostatic radiator valve on the radiator in the primary room where a room thermostat is used. B Add a suitable anti-freeze fluid compatible with aluminium to the water in the central heating system. Suitable products are available from Betz-Dearborn Tel: 0151-4209563 and Fernox Tel: 01799550811. B In our experience, the addition of sealing agents to the water in the central heating system can cause problems (deposits in the heat exchanger). For that reason we advise against their use. 3.2 System The system must comply with the requirements of BS 6798 and BS 5449. General The appliance is only suitable for connection to indirect fully pumped sealed and open vented systems. The minimum static head is 1m and the maximum is 30m. The controls must be wired to ensure that the boiler does not cycle when the electronically controlled zone valves are closed. Note 1: An automatic bypass is required if the controls i.e. 2-port valves, can result in the closure of the CH and DHW circuits when the boiler is hot. If mechanically operated thermostatic control valves are fitted on all radiators an automatic bypass is required, located at least 2m from the boiler. Note 2: A bypass is not usually required for systems using a 3-way diverter valve (with one valve is open to flow at all times) unless TRV’s are used throughout the system. Refer to the current Building Regulations or the Good Practice Guide 302 which lists all the above requirements. Plastic pipes must not be directly connected to the appliance. A copper to plastic transition piece should be positioned a minimum of 600mm from the appliance. 6 720 611 445 GB (03.11) 11 Installation Some plastics are permeable to oxygen and must be avoided, a pipe with a polymer barrier should be used. tee. The pH value of the system water must be less than 8 or the appliance guarantee will be invalidated. Sealed System Suitable products are available from Betz-Dearborn Tel: 0151-4209563 and Fernox Tel: 01799-550811. A sealed system must include an expansion vessel, pressure gauge and pressure relief valve set to operate at 3 bar - these are available as proprietary kits. The expansion vessel and fittings must be connected at the neutral point of the system on the entry to the pump. Suitable pump and diverter valves are also required. Refer to Fig. 5 & Fig. 6. The sealed system must be filled through a WRAS approved filling kit. Refer to Fig. 7. The appliance must not be operated without the system being full of water and correctly pressurised. All connections in the system must be able to withstand a pressure up to 3 bar. The system and appliance must be properly vented. Repeated venting loses water from the system and usually indicates a leak. A drain cock to BS 2879 must be fitted to the lowest point on the system. No galvanised radiators or pipes must be used. If any system water treatment is required then only products suitable for use with Aluminium shall be used i.e Fernox- Copal or Super concentrate or Sentinal X100, in accordance with the manufacturers instructions. The use of any other substances will invalidate the guaran- IMPORTANT: Check that no dirt is left in the water pipe work as this could damage the appliance. Thoroughly flush the heating system and the mains water supply before fitting the appliance to the wall in accordance with the recommendations of BS7593:1992. Domestic Hot Water The appliance is NOT suitable for direct water supply. Do not connect to a direct cylinder. The appliance can be connected to any indirect cylinder i.e. unvented or thermal store to realise the benefits from a “dry loft”. For more information contact Worcester Heat Systems Helpline 08705 266241. Note: Indirect coil type cylinders with an immersion calorifier suitable for a pressure of 0.35 bar above the setting of the pressure relief valve may be used. Single feed indirect cylinders are not suitable for sealed systems. Any connection to the mains water supply must conform to the relevant Buildings and Water Regulations and be approved by the local water company. FEED & VENT CISTERN S.H. HEATING VENT Minimum diameter 22mm. PRIMARY COLD FEED Minimum diameter 15mm. S.H. MINIMUM STATIC HEAD 1.0m MEASURED FROM THE HIGHEST POINT IN THE HEATING SYSTEM (TOP SURFACE OF THE APPLIANCE OR HIGHEST POINT IN THE HEATING SYSTEM) TO THE WATER LEVEL IN THE FEED AND EXPANSION TANK. DOMESTIC HOT WATER CYLINDER S.H. RADIATOR RADIATOR RADIATOR RADIATOR 150mm max. DIVERTER VALVE PUMP BOILER TYPICAL OPEN VENTED SYSTEM DRAIN COCK Fig. 5 12 6 720 611 445 GB (03.11) Installation AUTOMATIC AIR VENT DOMESTIC HOT WATER CYLINDER RADIATOR RADIATOR RADIATOR RADIATOR DIVERTER VALVE SAFETY VALVE PRESSURE GAUGE PUMP EXPANSION VESSEL BOILER TO SYSTEM FILLING DEVICE DRAIN COCK TYPICAL FULLY PUMPED SEALED SYSTEM Fig. 6 Fig. 7 3.3 Siting the appliance and fitted furniture. The specified clearances must be maintained. Regulations concerning the Installation Site B Relevant national regulations must be complied with section 3.8.1. B Consult the installation instructions for details of minimum clearances required. Combustion air Cupboard/Compartment The appliance can be installed in a cupboard/compartment need for airing clothes providing that the requirements of BS 6798 and BS 5440:2 are followed. The low casing losses from the appliance eliminate the need for ventilation openings in the compartment. In order to prevent corrosion, the combustion air must not contain any corrosive substances. Substances classed as corrosion-promoting include halogenated hydrocarbons which contain chlorine and fluorine compounds and are contained in some solvents, paints, adhesives, aerosol propellants and household cleaners, for example. Surface temperature The max. surface temperature of the casing and the flue is less than 85 °C. This means that, no special safety precautions are required with regard to flammable building materials 6 720 611 445 GB (03.11) 13 Installation 3.4 Wall mounting frame assembly B Take the wall mounting frame out of the package and screw together with 6 screws as shown in fig. 8. Use the inner lugs on the top and bottom horizontal sections. B Screw the pre-plumbing manifold with two screws to the wall mounting frame. 6 720 610 576-11.1O Fig. 10 6 720 610 576-04.1O 3.5 Pre-piping the system Fig. 8 200 B Hold the wall-mounting frame against the wall ensuring that it is vertical. B Mark the holes for the wall mounting frame onto the wall, drill and plug the holes and screw the wall mounting frame to the wall with the screws provided. B Mark the position of the flue duct hole if a rear flue is to be used. Refer to fig. 1 and 17. 171 112 172 43 47 35 50 120-130 260 6 720 610 576-06.1O Fig. 11 Manifold 43 47 112 171 172 6 720 610 576-05.1O Fig. 9 14 Boiler flow Boiler return Gas cock Not used Not used B Remove valves 171 and 172 from manifold, see Fig. 11. B A drain tap should be fitted at the lowest point of the central heating system. 6 720 611 445 GB (03.11) Installation Condensate Termination and Route The appliance has a built-in syphonic condensate trap eliminating the need for external traps. Connect to the 22mm plastic drain pipe and extend the pipe run away from the control panel and appliance witha constant fall of 2.5° or 25mm in every metre. See Fig. 13. The condensate pipe can terminate into any of four areas: If there is no alternative and the condensate pipe has to be externally run, the following should be considered: • The pipe run should take the shortest practical route. • The pipework should be insulated with weather resistant insulation. • The pipe should terminate as close as possible to the ground or drain, whilst still allowing the condensate to safely disperse. This would prevent wind blowing up the pipe. Boiler Boiler Ø 22 min. Sink Siphon No length restriction Siphon Ø 22 min. 75 min. trap Open end of pipe direct into gully, below ground but above water level. Use waterproof pipe work insulation in very exposed positions The gradient of the discharge pipe should be 2.5¡ (40 mm/m) minimum Open end of pipe direct into gully, below ground but above water level An internal waste system 3.6 The gradient of the discharge pipe should be 2.5¡ (40 mm/m) minimum Benchmark: For optimum performance after installation, this boiler and its associated central heating system must be flushed in accordance with the guidelines given in BS5793:1992 “Treatment of water in domestic hot water central heating systems”. Boiler Internal soil and vent stack Ø 22 min. No length restriction Sink Siphon The gradient of the discharge pipe should be 2.5¡ (40 mm/m) minimum 75 min. trap 450 min. Ø 22 min. 75 min. trap Fitting the appliance An external waste system Boiler No length restriction • The pipework should be installed with the minimum of horizontal runs and with a downward slope of at least 2.5 °. Invert The rainwater system Open end of pipe direct into gully, below ground but above water level The gradient of the discharge pipe should be 2.5¡ (40 mm/m) minimum An external purpose made soakaway 6 720 610 596 -03.2TD Fig. 12 Whilst all of the above methods are acceptable it is always the best practice to terminate the condense pipe via an internal waste system.This will eliminate the need for any external condensate pipe runs which can be susceptible to freezing in extreme weather. Removing the outer case i The outer case is secured against unauthorised removal by two screws (electrical safety).Always secure the outer case with those screws again after refitting. B Remove retaining screws (1.). B Slide the outer case upwards and then forwards to remove (2.). B Remove the plastic caps from the boiler connections. 2 1 Fig. 13 Recommended route of the condensate drain External condensate pipework The syphonic condensate trap collects condensate into a trap which releases it in 100 ml quantities. This helps to prevent the discharge from freezing. 6 720 611 445 GB (03.11) Fig. 14 15 Installation Fixing the appliance 3.7 B Fit the washers onto the gas and water connections. Water connections B Lift the boiler onto the wall-mounting frame. The lugs pass through the rectangular holes in the boiler back panel. B Take care not to disturb the washers on the connections. Connecting the flue assembly B Fit flue duct connector onto appliance flue spigot. B Secure with the screws supplied. B Turn on the service valves for boiler flow and return. B Check all seals and unions for leaks. Open vent systems: It is not necessary to connect a drain pipe to the pressure relief valve outlet as it is not operational and should be blanked off. B Check that the seal is in place before tightening the connection. B Turn off gas cock to protect gas valve against damage from excessive pressure. Flue seal Appliance Flue Socket B Check that the O-rings or seals are in place before tightening the connection. Gas supply pipe Flue Turret Retaining Screw Checking the connections B Check gas supply pipe. B Release the pressure on the gas supply pipe. Flue Turret to Boiler Sealing Gasket 6 720 610 599 - 01.TD Fig. 15 B For remaining installation of flue assembly, refer to the relevant installation instructions. 3.8 Flue Systems The only flue systems that may be used are those supplied by Worcester Heat Systems. The flue system must be installed in accordance with the requirements of BS 5440:1. Standard 100 mm flue system The standard concentric flue system provides for a horizontal length of up to 4m (R29) and 3.5m (R40). Full instructions for fitting this flue are in Subsection 3.8.2 “Installation of the flue”. Alternative 125 mm diameter flue systems Installation instructions for the alternative flue systems are sent with the appropriate flue kit. Systems are available to give a maximum horizontal length of 13m (R29) and 10m (R40). A vertical flue system up to a height of 13.7m (10.7m R40) is available. 45° and 90° flue bends can be used with a corresponding reduction in flue length of 2 m for each 90° bend and 1 m for each 45° bend used. IMPORTANT: Any horizontal flue system fitted to a condensing boiler must incline from the appliance at an angle of 3° (30 mm per metre length) to prevent condensate dripping from the flue terminal. Note, the standard 100mm horizontal flue requires only a 0.5° incline from the boiler as the inner exhaust pipe is inclined at 2.5° inside the outer pipe. This means that the clearance above the appliance must be increased to match the duct length. Refer to fig. 1 on page 5. 16 6 720 611 445 GB (03.11) Installation 3.8.1 lighting, activated by passive infra-red sensing heads. If the terminal is less than 2 m above a surface to which people have access then a guard must be fitted. The guard must be evenly spaced about the terminal with a space of 50 mm in each direction and fixed with plated screws. A guard Type K6 for the standard horizontal flue, can be obtained from Tower Flue Components, Vale Rise, Tonbridge TN9 1TB. Siting the Flue Terminal The flue must be installed in accordance with BS 5440:1 and the Building Regulations. Flue terminals in carports and under balconies are to be avoided. The terminal must be positioned so that it does not cause an obstruction nor the combustion products a nuisance. See fig. 16 and table 9. The terminal will, at times, give out a plume of water vapour and consideration must be given to this when choosing a terminal position. Keep clear of security P Q boundary Q I D,E Q B H C F J N A L G M H I H K Fig. 16 Minimum dimensions of flue terminal positions (all types) (see fig. 16) Dimension Terminal Position (kW input expressed in net) A1) Directly below an opening, air brick, opening windows, etc. 1) Balanced flues room sealed: Fanned draught 300 mm Above an opening, air brick, opening window, etc. 300 mm C1) Horizontally to an opening, air brick, opening window, etc. 300 mm D Below gutters, soil pipes or drain pipes E Below eaves 200 mm F Below balconies or car port roof (lowest point) Not recommended G From a vertical drain pipe or soil pipe H From an internal or external corner or to a boundary alongside the terminal I Above ground roof or balcony level J From a surface or boundary facing the terminal 1200 mm B 75 mm 75 mm 300 mm 300 mm K From a terminal facing the terminal 2000 mm L From an opening in the car port (e. g. door, window) into the dwelling Not recommended M Vertically from a terminal on the same wall 1500mm N Horizontally from a terminal on the same wall 300 mm P From a vertical structure on the roof 500 mm Q Above intersection with roof 300 mm Table 9 1) In addition, the terminal should not be nearer than 150 mm (fanned draught) to an opening in the building fabric formed for the purpose of accommodating a built-in element such as a window frame. 6 720 611 445 GB (03.11) 17 Installation 3.8.2 Installation of the flue The standard 100 mm diameter horizontal flue system is suitable for lengths up to 4m (R29) & 3.5m (R40). Flues up to 650 mm do not require an extension duct assembly. Flues between 600 mm and 4000 mm (3500 mm R40) require extension duct assemblies. NOTE: Flue lengths between 650 mm and 730 mm cannot be accommodated. Refer to fig. 18, 19, 20. Flue Turret Standard 100mm system comprise: • Flue turret Maximum 650mm Outer Wall Minimum 100mm • Flue turret clamp • Terminal assembly Clamp • Wall sealing gasket and cover plate. Terminal Assembly 6 720 610 599 - 01.TD Refer to fig. 21. Instructions for fitting other flue systems are packed with the relevant flue kit. Check that the position chosen for the appliance is satisfactory. Refer to fig. 17. Centre line of flue/air duct H Fig. 18 Standard Flue m 120m 3° Top of wall mounting frame (not boiler) Appliance Drilling point for flue duct opening H = 40mm for the Standard 100mm Horizontal Flue H = 70mm for the Optional 125mm Horizontal Flue 6 720 610 602-08.3O Centre line of flue opening and appliance (30mm/metre) Standard 100mm horizontal flue 0.5° (5mm/metre) Fig. 17 Marking the position of the side flue opening. Note: ensure there is adequate access to the air/flue sampling points in the flue turret. 18 6 720 611 445 GB (03.11) Installation Maximum 1600mm Outer Wall Flue Turret Extension Duct Clamp Terminal Assembly 6 720 610 599 - 00.TD Fig. 19 Flue with one extension Outer Wall Flue Turret Clamp Extension Duct Clamp Extension Duct Clamp Terminal Assembly 6 720 610 599 - 01.TD Fig. 20 Flue with extensions Flue Turret Clamp Flue Terminal Extension Flue Duct Wall Sealing Gasket 6 720 610 599 - 01.TD Fig. 21 Flue components 3.8.3 Flue duct preparation and assembly Measure the flue length L. Refer to fig. 22, 23. 6 720 611 445 GB (03.11) 19 Installation The assembly will be made easier if a solvent free grease is lightly applied i.e Silicone lubricant, to the male end of the ducts. L NOTE: An inner wall sealing plate is provided which should be fitted to the ducts before assembly. Push the assembly through the wall and fix the turret to the appliance using the screws provided. Refer to fig. 25. 120 6 720 610 599 - 01.TD Flue Turret Fig. 22 Flue length - rear Flue seal L Retaining Screw Appliance Flue Socket Flue Turret to Boiler Sealing Gasket 6 720 610 599 - 01.TD Fig. 25 Flue turret 6 720 610 599 - 01.TD Fig. 23 Flue length - side Measure ‘L’ from the end of the metal section of the flue terminal to the centre of the flue outlet on the boiler as shown in Fig. 22 & Fig. 23 and deduct 90mm from that measurement. Cut both inner and outer flue pipe square at the opposite end to the terminal without creasing the tubes. Ensure that the turret is fully entered to the socket on the boiler. If the terminal is within 2 m of the ground where there is access then an approved terminal guard must be fitted. The guard must give a clearance of at least 50 mm around the terminal and fixed with corrosion resistant screws. Remove any burrs before fitting the terminal to the turret. Outer Wall Face Flue Terminal Wall Sealing Gasket 6 720 610 599-00.TD Fig. 24 Flue terminal position Assemble flue system completely. Push the ducts fully together and clamp in the positions. The slope of the terminal outlet must be directed as per Fig. 24. 20 6 720 611 445 GB (03.11) Electrical connections 4 Electrical connections B Remove screw and slide terminal cover forwards to remove. Refer to fig. 27. B Always disconnect the power supply to the appliance at the mains before carrying out any work on the electrical systems and components. 3 0 4 2 5 1 E All control and safety systems are built into the appliance. B Allow mains cable to protrude at least 50 cm from wall. B To maintain the splash-proof (IP) design: cut the cable grommet hole size to match the diameter of the cable, see fig. 28. 6 720 611 137 -07.1O B The appliance must be earthed. Fig. 27 B It must be possible to completely isolate the appliance with at least 3mm contact separation in both poles. B Cut cable grommet to diameter of cable. 3 0 2 The wiring between the appliance and the electrical supply shall comply with current IEE Wiring Regulations (and any local regulations which apply) for fixed wiring to a stationary appliance. 4 5 1 E • Supply: 230 V ~ 50 Hz, 150 Watts • External fuse 3 A • The system connected to the boiler must NOT have a separate electrical supply 8-9 • Water Protection IPX4D (with fascia blanking plate fitted or IP20 without blanking plate). 4.1 5-7 Connecting the appliance To gain access to the mains connection remove the drop down facia cover. The drop down cover is removed by lowering it to the horizontal position and pushing firmly upwards at the rear of the supports to release the cover. Lift cover from the appliance. After installation (or in the event of an electrical fault) the electrical system shall be checked for short circuits, fuse failure, incorrect polarity of connections, earth continuity and resistance to earth. 10-12 13-14 6 720 611 137-08.1O Fig. 28 B Feed cable through cable grommet and connect the mains supply cable, see fig. 29. B Secure cable in cable grommet by means of cable grip. L N NS B Pull out cover panel at the bottom and remove. Refer to fig. 26. 3 0 2 4 5 1 E 6 720 611 137-09.1O Fig. 29 Fig. 26 6 720 611 445 GB (03.11) 21 Electrical connections 4.2 Wiring to your system Mains electricity supply: The boiler should be connected to the permanent mains supply as described in section 4.1 This also provides the electrical supply to the system. Y-S-Module Note: This must be the only electrical supply to the system. This ensures the safety of a single fused supply. LR LS NS PE PE DV LS NS The boiler can only be wired to a remote system junction box. Note: A pump is not built into the boiler and must be fitted externally. The diagram shows the overall wiring details. A cable is fitted at the factory, between the boiler control panel and the Y-S module. This module is designed to provide the correct voltage interface. TO BOILER AND SYSTEM INSIDE OF BOILER INSTALLATION WIRING OUTSIDE OF BOILER Other connections to Terminal Strip according to Proprietary instructions Timer Table 10 Y-S Module Remote Junction Box LS L NS N PE E (Earth) DV Demand (Switched Live) REMOTE PRE-WIRED ˜ JUNCTION BOX MAINS SUPPLY L N E System Water Valve(s) Note: MAINS 230V LIVE SUPPLY Frost Stat Upon completion of the electrical connections check for earth continuity, correct polarisation and resistance to earth. N NS LS LR L Room Stat If a room thermostat and/or frost thermostat is required, these must also be connected to the junction box according to the proprietary instructions. HEATRONIC CONNECTOR CONTROL BOARD Tank Stat The other connector in the module must be used for wiring to the remote junction box as shown. It is the responsibility of the installer to connect all other system components i.e. water valve/s, pump, programmer etc. to the proprietary junction box according to the instructions supplied with the box. Worcester Heat Systems cannot be held responsible for any incorrect wiring to these parts of the system. PRE-WIRED BOILER/PUMP ˜DEMAND Terminal Strip PUMP This must be the only electrical supply to the Junction Box Fig. 30 Wiring to the Y-S module 22 6 720 611 445 GB (03.11) Commissioning 5 Commissioning 27 136 365 61 317 366 367 358 ECO 364 363 135 E 310 295 15 361 170 170 172 6 720 611 137-11.1O Fig. 31 15 27 61 135 136 170 172 295 310 317 358 361 363 364 365 366 367 Safety valve Automatic vent Reset button Master switch Temperature control for boiler Service cocks on boiler flow and return Gas cock (shown in on position) Appliance type sticker Function control (Service only) Multi function display Condensate trap Drain valve Indicator lamp for burner Indicator lamp for power supply “Chimney sweep” button Service button No function 6 720 611 445 GB (03.11) 5.1 Commissioning Never run the appliance when empty or unpressurised. i The operational CO2 level is set at the factory and no adjustment is necessary when installing a natural gas fired appliance. Benchmark Water Treatment: For optimum performance after installation, this boiler and its associated central heating system should be flushed in accordance with the guidelines given in BS 7593:1992 - Treatment of water in domestic hot water systems. Full instructions are supplied with proprietary cleansers sold for this purpose. If an inhibitor is to be used after flushing, it should be used in accordance with the inhibitor manufacturers instructions. The inhibitor must not be added until all the cleaner has been removed. 23 Commissioning To drain the appliance shut the system valves and open the drain valve. Suitable flushing agents and inhibitors are available from Betz-Dearborn Tel: 0151-4209563 and Fernox Tel: 01799-550811. Instructions for use are supplied with the these products. B Before commissioning, the gas supply pressure must be checked at the gas supply pressure test point (see page 6, fig. 2, item 7). Natural gas appliances must not be operated if the gas supply pressure is below 18 mbar or above 24 mbar. LPG appliances must not be operated if the supply pressure is not 37 mbar at the inlet to the appliance. B Unscrew the condensation trap (358) and pull out, fill with approx. 1/4 l of water and refit. Refer to fig. 31. B Open all system radiator valves. B Check the automatic air vent is open (27) see Fig. 31 B Turn on service valves (170), fill central heating system. B Vent radiators. B Check that the gas type specified on the identification plate matches that of the gas supply. Switching off the appliance B Set the master switch to (0). The green indicator lamp goes out. B Always disconnect the appliance from the power supply (fuse, circuit breaker) before carrying out any work on the electrical systems or components. 5.3 Switching on the Boiler The central heating flow temperature is adjustable between 50°C and 88°C. refer to table 11, page 26. B Turn the temperature control to set the flow temperature to a level appropriate to the type of central heating system: – Low-temperature heating: setting “E” (approx. 75°C) – Central heating systems for flow temperatures up to 88 °C: limited “max” setting for low-temperature operation (see page 26). When the burner is alight, the red indicator lamp lights up. B Turn on gas cock (172). Refer to fig. 31. B If a domestic hot water cylinder is fitted, set the hot water cylinder thermostat to 60°C. 5.2 Switching the appliance on/off Switching on B Switch on the appliance at the master switch (I). The indicator lamp shows green and the display will show the boiler flow temperature. 6 720 611 137-12.1O Fig. 33 5.4 System controls B Set room thermostat to the desired room temperature. B Set time clock and the on/off periods. Refer to the instructions with the control. 6 720 610 333-04.1O 5.5 Fig. 32 i If the display alternates between -II- and the boiler flow temperature, the trap filling programme is active. The trap filling programme ensures that the condensation trap is filled after the appliance has been installed or after the appliance has been out of use for a long period or the mains supply has been interrupted. For that reason, the appliance remains at minimum heating output for 15 minutes. 24 B Set the thermostatic radiator valves to the desired settings. Frost protection The appliance has an in-built frost protection device which is generally suitable for most applications. B Leave master switch switched on. If the appliance is to be left for long periods switch the central heating off: B Add a suitable anti-freeze fluid to the water in the central heating system. Suitable products are available from Betz-Dearborn Tel: 0151-4209563 and Fernox Tel: 01799550811. 6 720 611 445 GB (03.11) Commissioning 5.6 i Fault Condition A list of faults that may occur is given on page 40. In the unlikely event of a fault occurring while the appliance is in operation: The display then shows a fault code and the button may also flash. If the button flashes: B Press and hold the button until the display shows “– –”. The appliance will then start up again and the display will show the boiler flow temperature. If the button does not flash: B Switch the appliance off and then on again at the master switch. The appliance will start up again and the boiler flow temperature will be displayed. 6 720 611 445 GB (03.11) 25 Individual settings 6 Individual settings 6.1 Mechanical settings 6.2 Settings on the Bosch Heatronic 6.1.1 Setting the boiler flow temperature 6.2.1 Operating the Bosch Heatronic The central heating flow temperature can be set to between 50°C and 88°C. The Bosch Heatronic enables easy setting and checking of a large number of appliance functions. Limited maximum setting for low-temperature operation This description is limited to those functions required for commissioning. The temperature control is factory limited to setting E, giving a maximum flow temperature of 75°C. For a full description of all available functions, please refer to the Service booklet for the Engineer, order no. 7-181-465-346. Adjustment of the heating output to the calculated heat demand is not required by the heating systems regulations. 2 5 1 Removing the maximum setting limit For heating systems which require higher flow temperatures, the maximum setting limit can be removed. B Lift off the yellow button on the temperature control with a screwdriver. 6 720 611 137-14.1O 4 3 Fig. 35 Appliance controls 6 720 611 137-13.1O Fig. 34 B Rotate yellow button through 180° and replace (dot facing inwards). The boiler flow temperature is no longer limited. Control setting boiler flow temperature 1 2 3 4 5 E max approx. 50°C approx. 55°C approx. 60°C approx. 65°C approx. 70°C approx. 75°C approx. 88°C Table 11 1 2 3 4 5 Service button “Chimney sweep” button Temperature control for boiler flow Function control Display Selecting service function: i Note the positions of the temperature controls and . After completing the settings, return the temperature controls to their original positions. The service functions are subdivided into two levels: Level 1 comprises service functions up to function 4.9, Level 2 consists of service functions from 5.0 upwards. B To select a service function on Level 1: press and hold the button until the display shows – –. B To select a service function on Level 2: press and hold the buttons and simultaneously until the display shows = =. B Then turn the temperature control to select the required function. Service function Code no. See page Anti-cycle time Max. boiler flow temperature Switching difference Max. heating output 2.4 27 2.5 2.6 5.0 27 27 27 Table 12 The service function 5.0 may be reset. 26 6 720 611 445 GB (03.11) Individual settings Entering a setting B To enter the setting for a function, turn the function control. B Press and hold the and buttons simultaneously until the display shows = =. The and buttons will light up. Storing a setting B Level 1: press and hold the play shows [ ]. button until the dis- B Level 2: press and hold the and buttons simultaneously until the display shows [ ]. 6 720 611 137-15.1O After completing the settings B Reset the temperature controls control to their original positions. 6.2.2 and the function Setting the anti-cycle time (Service Function 2.4) Fig. 36 B Turn the temperature control until the display shows 5.0. After a short delay, the display then shows the set heating output in percent. This service function is only active if Service Function 2.7, automatic anti-cycle time, is deactivated. The anti-cycle time can be set to between 0 and 15 minutes (is factory set to 3 minutes). If the setting 0 is entered, the anti-cycle time is inactive. The shortest possible anti-cycle time is 1 minute (recommended for single-pipe and hot-air heating systems). 6.2.3 Setting the maximum boiler flow temperature (Service Function 2.5) The maximum flow temperature can be set to between 50°C and 88°C (factory setting). 6.2.4 i Setting the switching difference (Service Function 2.6) If the appliance is connected to an outside temperature controlled programmer, the programmer sets the switching difference. It does not need to be set on the appliance. The switching difference is the permissible divergence from the specified flow temperature. It can be set in increments of 1°C. The adjustment range is 1 to 30°C (is factory set to 0°C). Minimum flow temperature is 30°C. 6.2.5 Fig. 37 B Refer to the settings tables for heating and cylinder charging output to obtain the relevant code for the desired heating output in kW (see page 41). B Turn the function control until the display shows the desired code number. The display and the and buttons will flash. B Measure the gas flow rate and compare with the figures specified for the code number displayed. If figures do not match, adjust the code number! B Press and hold the and buttons simultaneously until the display shows [ ]. The heating output is now stored. Setting the heating output (Service Function 5.0) The heating output can be set to any level between min. rated heat output and max rated heat output to limit it to the specific heat requirements. i 6 720 611 137-16.1O The full rated heat output is still available for hot water or charging the hot water cylinder even if the heating output has been limited. 6 720 611 137-17.1O Fig. 38 B Return the temperature controls and to their original positions. The display will revert to the boiler flow temperate. The factory setting is the max. rated heat output. B Set the room thermostat and thermostatic radiator valves to max. temperature. 6 720 611 445 GB (03.11) 27 Individual settings 6.3 Setting the gas/air ratio The appliance is set at the factory and adjustment to the CO2 settings (gas/air ratio) is only required where the appliance has been stripped down and assembled or if the fan, burner or gas valve are replaced or the appliance has been converted to a different gas type, see section .7 28 6 720 611 445 GB (03.11) Converting the appliance to different gas types 7 Converting the appliance to different gas types The setting is factory sealed at maximum. Adjustment to the rated heat input and min. heat input is not necessary. Checking the gas supply pressure B Check the gas supply pressure at the gas supply pressure testing point. i Natural gas appliances must not be operated if the gas supply pressure is below 18 mbar or above 24 mbar. LPG appliances must not be operated if the supply pressure is below or above 37 mbar. Natural gas 7.1 Setting the gas/air ratio The gas/air ratio may only be adjusted on the basis of a CO2 measurement at max. heat output and min. heat output using an electronic tester. B Switch off the appliance at the master switch (O). B Remove the outer case (see page 15, refer to fig. 14). B Switch on the appliance at the master switch (I). B Set room thermostat to maximum temperature. B Open thermostatic radiator valves. B Unscrew sealing plug from flue gas testing point (234). Refer to fig. 39. B Insert testing probe about 135 mm into the flue gas testing point and seal testing point. • Appliances for natural gas type G20 are factory set to Wobbe-Index 15 kWh/m3 and 20 mbar supply pressure and sealed. 234 6 720 610 599 - 01.TD Fig. 39 B Press and hold button until the display shows – –. The button will light up. 6 720 611 137-18.1O Fig. 40 B Turn the temperature control until the display shows 2.0 . After a short delay, the current operating mode setting will be displayed (0. = Normal mode). 6 720 611 137-19.1O Fig. 41 6 720 611 445 GB (03.11) 29 Converting the appliance to different gas types B Turn the function control until the display shows 2. (= max. rated heat output). The display and the button will flash. B Remove the seal from the gas valve adjusting screw (64) and adjust the CO2 level to the figure given in Table 13 for min. rated heat output. 64 6 720 611 137-20.1O Fig. 42 B Measure the CO2 level. B Prise off the seal on the gas flow restrictor. B Adjust the gas flow restrictor (63) to obtain the CO2 level given in Table 13. Refer to fig. 43. 3928-74.1R Fig. 45 B Re check the levels at min. and max. rated heat output and re-adjust if necessary. B Turn the temperature control anti-clockwise as far as the stop so that the display shows 0. (= Normal operating mode). The display and the button will flash. 63 B Press and hold the shows [ ]. button until the display B Reset the temperature controls and function control to their original positions. The display will revert to the boiler flow temperature. 6 720 610 332-64.1R Fig. 43 Gas Type Natural gas type G20 LPG G31 (propane) B Remove testing probe from the flue gas testing point (234) and refit sealing plug. B Re-seal gas valve adjusting screw and gas flow restrictor. CO 2 reading at max. rated heat output CO 2 reading at min. rated heat output 9.2 % 8.8 % 10.8 % 10.5 % B Replace outer case and secure. B Set room thermostat and thermostatic radiator valves to the desired temperature. Table 13 B Turn the temperature control anti-clockwise until the display shows 1. (= min. rated heat output). The display and the button will flash. 6 720 611 137-21.1O Fig. 44 B Measure the CO2 level. 30 6 720 611 445 GB (03.11) Converting the appliance to different gas types 7.2 Testing combustion air/flue gas at set heat output 7.2.1 Testing the O 2 or CO2 level in the combustion air i By testing the O2 or CO2 level in the combustion air the gas tightness of a type C13 or C33 flue system can be checked. The O2 level must not be less than 20,6 %. The CO2 level must not exceed 0,2 %. B Press and hold the button until the display shows – –. “Chimney sweep” mode is now active. The button will light up and the display shows the boiler flow temperature. i In “chimney sweep” mode, the appliance switches to max. rated heat output or the set heating output. You then have 15 minutes in which to measure the levels. After that, the appliance switches back from “chimney sweep” mode to normal mode. B Remove sealing plug from combustion air testing point (234.1, Fig. 46). 7.2.2 Testing CO and CO 2 B Press and hold the button until the display shows – –. “Chimney sweep” mode is now active. The button will light up and the display shows the boiler flow temperature. i You have 15 minutes in which to measure the levels. After that, the appliance switches back from “chimney sweep” mode to normal mode. B Remove sealing plug from flue gas testing point (234, fig. 46). B Insert testing probe about 135 mm into the testing point and seal testing point. B Measure CO- and CO2 levels. B Refit sealing plug. B Press and hold button until the display shows – –. The button will stop flashing and the display shows the boiler flow temperature. B Insert testing probe about 80 mm into the testing point and seal testing point. 234.1 234 6 720 610 599 - 01.TD Fig. 46 B Measure O2 and CO2 levels. B Refit sealing plug. B Press and hold button until the display shows – –. The button will stop flashing and the display shows the boiler flow temperature. 6 720 611 445 GB (03.11) 31 Maintenance 8 Maintenance B Always disconnect the appliance from the electrical power supply (fuse, circuit breaker) before carrying out any work on the electrical systems or components. B Always turn off the gas cock before carrying out any work on components which carry gas. i There is a special Service booklet for the Engineer, order no. 7-181-465-346, available to competent persons. i All safety and control systems are monitored by the Bosch Heatronic. In the event of a component fault, the display shows a fault code. B The User should be recommended to have the appliance serviced regularly by a competent person (see Maintenance Contract). B Use only genuine spare parts B Refer to the Spare Parts List when ordering spare parts. B Always renew seals and O-rings removed during servicing or repair work. B Use only the following types of grease: – Water valve: WRAS approved silicon based grease – Unions: approved sealant. B To drain the appliance shut the system valves and open the drain valve. B Upon completion of any electrical work check for earth continuity, correct polarisation and resistance to earth. 32 6 720 611 445 GB (03.11) Maintenance 8.1 Pre-Service Check List Date 1 Call up the last fault stored by the Bosch Heatronic, Service Function .0, (see page 34). 2 Check ionisation current, Service Function 3.3, (see page 34). 3 Perform visual check of air/flue duct.Visual check of diaphragm for soiling and splits (see page 36). 4 Check gas supply pressure (see page 29). 5 Test combustion air/flue gas (see page 31). 6 Check CO2 setting for min./ max. (gas/air ratio) (see page 29). mbar min. % max. % 7 Check gas and water systems for leaks (see page 16). 8 Check heat exchanger (see page 34). 9 Check burner (see page 35). mbar 10 Clean condensation trap (see page 35). 11 Check electrical wiring for damage. 12 Check heating programmer settings. 13 Check appliances that are part of the heating system. Table 14 6 720 611 445 GB (03.11) 33 Maintenance 8.2 Description of servicing operations The combustion performance must be checked before and after any servicing work on the combustion and burner components. Refer to section 7.1. B Unscrew condensation trap and place suitable container underneath. Refer to fig. 48. B Remove the fan and the burner as described in the text headed “Burner” (see page 35). Check “Last fault stored”: B Select Service Function .0 (see page 26 “Selecting service function”). There is a list of the fault codes in the Appendix (see page 40). To delete “Last fault stored”: B Turn function control anti-clockwise as far as the stop. B Press and hold the button until the display shows [ ]. The last fault stored has now been deleted. 6 720 610 332-72.1R Fig. 48 Checking the ionisation current, Service Function 3.3 B Select Service Function 3.3 (see page 26 “Selecting service function”). B Loosen any deposits in the heat exchanger from top to bottom using the cleaning blade. Refer to fig. 49. If the display shows 2 or 3, the ionisation current is OK. If the display shows 0 or 1, the electrode assembly (32.1, page 6) must be cleaned or replaced. Primary Heat exchanger There is a special accessory kit (no. 840) for cleaning the heat exchanger, order no. 7 719 001 996. B Check control pressure on the air - gas mixer unit at max. rated heat output using an electronic manometer. 6 720 610 332-73.1R Fig. 49 B Clean the heat exchanger from top to bottom using the brush. Refer to fig. 50. 6 720 610 332-69.1R Fig. 47 i The heat exchanger should only be cleaned if the control pressure is 4.2 mbar (R29 HE) 6.2 mbar (R40 HE) (depression) or less. 6 720 610 332-74.1R Fig. 50 B Flush the heat exchanger from the top. B Remove cleaning access cover (415, page 6) and the metal plate below it, if present. Refer to fig. 2. 34 6 720 611 445 GB (03.11) Maintenance B Clean out the condensate collector and trap connection (with other end of brush). 6 720 610 332-75.2R Fig. 51 B Refit the clean-out cover using a new seal and tighten screws to torque of approx. 5 Nm. Burner B Check that the gas cock is turned off and the master switch is in the OFF position. B Remove the clips (1.) and unscrew the two bolts (2.). Refer to fig. 52. B Unscrew and remove the two hexagon screws securing the fan (3.). 7 181 465 330-09.2R Fig. 53 B Re-assemble burner in reverse order, inspect seal for damage and replace if necessary. B Adjust gas/air ratio. Refer to section 7.2. B Slacken fully the rear securing bolt (4.). Condensation trap B Remove the burner coverplate. In order to prevent spillage of condensate, the condensation trap should be completely removed, (see page 34, fig. 48). 4. B Unscrew condensation trap and check connection to heat exchanger is clear. B Remove condensation trap cover and clean. 2. B Fill condensation trap with approx. 1/4 l of water and refit. 3. 1. Electrode assembly B Switch off the master switch. B Pull off the leads from the electrodes. Refer to fig. 2. Fig. 52 B Unscrew the two fixing screws and carefully remove the electrode assembly. Refer to fig. 47. B Remove the burner skin and clean components. Do not use a wire brush. Refer to fig. 53. B Clean the electrodes with a non-metallic brush. (The spark gap should be 4 mm ± 0.5 mm.) 7 181 465 330-04.1R B Replace and re-connect the assembly taking care not to mislay the inspection window. 6 720 611 445 GB (03.11) 35 Maintenance B Refit and prime the siphon. Diaphragm in mixer unit Take care not to damage diaphragm (443) when removing and refitting it. B Open mixer unit (29). B Carefully withdraw diaphragm (443) from fan intake tube and check for soiling and splits. Condensate Drain Siphon 3. Drain plug 443 29 6 720 611 137 - 23.1O Fig. 55 Electrical wiring 1. B Check the electrical wiring for physical damage and replace any damaged wires. 2. 6 720 610 790-07.2R Fig. 54 B Carefully refit diaphragm (443) the correct way round into the fan intake tube. i The flaps of the diaphragm (443) must open upwards. B Seal the mixer unit (29). Siphon B Unscrew the clip and disconnect the pipe to the siphon. B Remove the drain plug to drain the siphon. B Unscrew the securing nut from beneath the side facia and remove the siphon. Refer to figure below. 36 6 720 611 445 GB (03.11) Maintenance 8.3 B Remove the pcb control board. Replacement of Parts Before changing any components check that the gas is turned off and that the appliance is electrically isolated. When necessary close the system valves and drain the appliance. Refitting is a reverse of the procedure for removal using new seals or o-rings as appropriate. 8.3.1 PCB control board and transformer B Switch off the appliance. B Disconnect appliance from the power supply. B Unplug all connectors from the control box (inc. keyed plug). Access is gained by removing the covers. Refer to fig. 26, 27. B Remove screw holding power connector earth lead and remove earth lead. B Remove two top fixing screws from the control box. Refer to fig. 56. 1 3 2 4 7 181 465 330-10.1R 3 1 4 3 2 4 2 5 Fig. 57 1 E Fuses 1 3 2 4 B Remove the connections covers. Refer to fig. 26, 27. 6 720 611 137 - 23.1O Fig. 56 B Lower the control box. B Unscrew earth lead. B Unscrew four fixing screws from cover plate. Refer to fig. 63. The fuses are located adjacent to the mains connector block and connector ST18. Refer to fig. 4. Fuse, item 312, is only replaceable by removing the pcb. Spare fuses are fixed to the connections cover. A fuse pack is available: Part number 8 744 503 010 0. B Prise off cover plate. B Pull off transformer. B Remove pcb holder. 6 720 611 445 GB (03.11) 37 Maintenance 8.3.2 Fan Assembly 8.3.4 3. Gas Valve B Check that the gas cock is turned off. B Lower the control panel. Refer to fig. 59. 2. 1. 1. 4. 6 720 611 137- 25.1O 2. B Pull off the solenoid connections at the rear of the valve. B Undo the union, within the inner casing, securing the valve to the gas/air tube. Refer to fig. 58. B Remove the white plastic cap from the gas valve. B Release the gas inlet union at the manifold assembly. B Unscrew the two screws securing the gas valve assembly bracket to the back panel and withdraw the assembly. 1. 7 181 465 330-05 1R Fig. 58 B Switch off the appliance. B Disconnect the appliance from the power supply. B Undo lower pipe union on gas pipe (1.). Refer to fig. 58. B Transfer the bracket and inlet pipe assembly to the new gas valve. B Check for gas soundness when the new gas valve has been fitted. B Recheck the combustion performance as described in section 7.1. B Remove fan lead and earth connector (2.). The earth connector has a positive clip fixing. B Remove fixing screws attaching fan to the burner cover (3.). B Remove fan together with gas pipe and mixer unit. B Separate the fan from the pipe and mixer unit by twisting the mixer unit to release it (4.). 8.3.3 Sensors B Check that the appliance is electrically isolated. Central Heating Flow Temperature Sensor – Item 36, fig. 2 B Pull-off the connector. B Release the sensor clip and withdraw the sensor. B Apply heat transfer paste to the replacement sensor. Safety Temperature Limiter – Item 6, fig. 2 B Pull-off the connectors. B Unscrew the sensor. Flue Temperature Limiter – Item 9, fig. 2 B Pull-off the connectors. B Unscrew the sensor. 38 6 720 611 445 GB (03.11) Maintenance B Undo the central heating flow union. B Undo the grey plastic cap at the base of the heat exchanger. B Unscrew and remove the condensate trap. Refer to section 8.2. B Unscrew and remove the two screws securing the heat exchanger top bracket to the rear panel. B Lift up the flue duct, item 271, refer to fig. 2. B Pull forward from the top and lift the heat exchanger from the casing. B Transfer components, as necessary, to the new heat exchanger. B Ensure that all the seals are in place and all of the connections are tight before re-commissioning the appliance. 6 720 610 602 - 04.1O Fig. 59 8.3.5 Electrode assembly B Refer to section 8.2. B Use a new seal if the existing seal is damaged. 8.3.6 Pressure Relief Valve B Drain the appliance. B Disconnect the drain pipe from the valve. Refer to fig. 31. B Pull-out the clip securing the valve. B Pull-out the valve. B Ensure that the replacement valve is fully entered before fitting the clip. 8.3.7 Burner B Refer to section 8.2. 8.3.8 Primary Heat Exchanger 6 720 610 602 - 06.10 Fig. 60 B Drain the appliance. B Check that the gas supply is turned off. B Check that the appliance is electrically isolated. B Remove the fan assembly complete with the gas/air tube and mixer assembly. Refer to section 8.3.2. B Remove the burner. Refer to section 8.2. B Disconnect the sensors. Refer to section 8.3.3. 6 720 611 445 GB (03.11) 39 Appendix 9 Appendix 9.1 Fault Codes More detailed fault finding procedures are described in the Service booklet for the Engineer number 7 181 465 346. Display code Description Remedy b1 Code plug not detected. Insert code plug correctly, test and replace if necessary. C1 Fan speed too low. Check fan lead and connector, and fan; replace as necessary. d3 Jumper 8-9 not detected. Connector not connected, link missing, underfloor heating limiter tripped. E2 boiler flow NTC sensor defective Check boiler flow NTC sensor and connecting lead. E9 Safety temp. limiter in boiler flow has tripped. Check system pressure, check safety temp. limiters, check pump operation, check fuse on pcb, bleed appliance. EA Flame not detected. Is gas cock turned on? Check gas supply pressure, power supply, igniter electrode and lead, ionisation sensing electrode and lead, flue duct and CO2 level. F0 Internal error. Check electrical connector contacts, programmer interface module ignition leads are not loose; replace pcb if necessary. F7 Flame detected even though appliance switched off. Check electrode assembly, dry pcb. Flue clear? FA Flame detected after gas shut off. Check gas valve and wiring to gas valve. Clean condensation trap and check electrode assembly. Flue clear? Fd Reset button pressed by mistake. Press reset button again P1, P2, P3, P1... Please wait, initialisation in progress. 24 V fuse blown. Replace fuse. Table 15 40 6 720 611 445 GB (03.11) Appendix 9.2 Short parts list Key Description Qty GC Spare part number 1 Sensor - Flue gas temp. 1 8 729 000 144 0 2 Sensor - boiler flow temp. 1 8 714 500 087 0 3 Control board 1 8 748 300 418 0 4 Gas valve 1 8 747 003 516 0 5 Fan assembly 1 8 717 204 373 0 6 Fan washer 1 8 729 000 183 0 7 Relief valve 1 8 717 401 012 0 8 Electrode assembly 1 8 718 107 077 0 9 Electrode lead 1 8 714 401 999 0 10 Burner skin seal 1 8 711 004 168 0 11 Transformer - facia 1 8 747 201 358 0 12 Heat exchanger washer 1 8 710 103 153 0 13 Washer set Condensation Trap 1 8 710 103 154 0 14 Fuse set 1 8 744 503 010 0 15 Primary heat exchanger 1 8 715 406 615 0 Table 16 9.3 Heating/hot water output settings (N.G) 9.4 Heating/hot water output settings (L.P.G) Propane Natural gas G20 Heat output, kW Heat input, kW Gas vol. flow rate (l/min at tV/tR = 80/60°C) Display code Heat output kW Heat input kW 40 11.0 11.1 30 8.2 8.3 14.5 50 13.7 13.9 40 11.0 11.1 19.4 60 16.5 16.6 50 13.7 13.9 24.2 70 19.2 19.4 60 16.5 16.6 29.1 80 21.9 22.2 70 19.2 19.4 33.9 90 24,7 24.9 80 21.9 22.2 38.8 100 27.4 27.7 90 24,7 24.9 43.6 100 27.4 27.7 48.5 Display code Table 18 Table 17 6 720 611 445 GB (03.11) 41 Yes * Minimu m heat input for 15min. No Boiler operates to ma tch system load and temperature control setting. Ignition sequence Ignition spark for 5 seconds. Burner lights. Red light ON. Yes Heat demand satisfied. Gas va lve closes. Red light OFF. No 6 720 611 445 GB (03.11) Repeats 5 times (N.G.) or 3 times (L.P.G.) before lock out Fan runs to purge gas from burner. * NOTE : The sequence ensures that the condensate siphon is not empty after long OFF periods. (More than 24 hours without a dema nd). 6 720 611 137 - 24.1O Appendix Fan min. speed for 90 secs. Boiler unused for long period.* Operational Flow diagrams Heat demand. Fan speed reduces over 15 secs. 9.5 Temperature control knob ON. Burner stabilises at start speed for 5-10 secs Central heating function Green light ON. External External Pump ON Fan to start speed. Gas va lve opens. 9.5.1 Fig. 61 42 Mains switch ON. Room thermostat and/or mains programmer or link ON Over temperat ure shut-down if water tempera ture is 5°C above set va lue. Gas valve shuts. External pump Pump ON. remains ON Burner rem ains OFF until flow temperature is below set value. Appendix 6 720 611 445 GB (03.11) 43 Appendix EXCELLENCE COMES AS STANDARD Manufactured exclusively for British Gas by The Bosch Group Bosch Group, Worcester Heat Systems, Cotswold Way, Warndon, Worcester WR4 9SW. Telephone: (01905) 754624 Fax: (01905) 754619