Download Mendota FV33-M-PF2-0813 Operating instructions

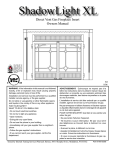

Transcript