Download Windsor TRIDENT COMPACT TCZOE Operating instructions

Transcript

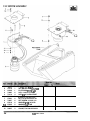

HA R D F L O O R S C R U B B E R (ELECTRIC VERSIONS) Operating Instructions (ENG) M I E L SMOWN: TC20T MODEL: TCZOE (20”Non- Traction) - VOLTAGE 115V C€ QEsr... for Continuous Improvement. Wipgsor’s Quality Management System is Certified IS0 9QOl. IPX4 Read these instructions before operating the machine. TC20E 98447 03/13/00 MACHINE DATALOG MODEL . DATE OF PURCHASE SERIAL NUMBER . . SALES REPRESENTATIVE . DISTRIBUTOR NAME . OPERATIONS GUIDE NUMBER .98447 PUBLISHED .7/1/96 @Copyright1996 Windsor Industries. Printed in U.S.A. TABLE OF CONTENTS Cover ...................... 1 Squeegee Assembly ..............14 Data Log / Table of Contents .... 2 Squeegee Assembly Parts List ......15 Safety Precautions ............ 3 Valve Assembly ..................16 ...... 4 Valve Assembly Parts List ..........17 Safety/Operations............. 5 Scrub Deck Assembly .............18 Safety Precautions (cont.) Operation Controls ............ 6 Maintenance . . . . . . . . . . . . . . . . . 7 Maintenance (cont.) ........... 8 Maintenance (cont.) Scrub Deck Assembly Parts List Mechanical Controls ..............20 Mechanical Controls Parts List ........... 9 Control Panel Assembly Trouble Shooting Guide ........ 10 Wiring Diagram (1 15V)......... 11 Tanks. and Frame Assembly Tanks and Frame Parts List 2 .... 12 ..... 13 .....19 ......21 ...........22 Control Panel Assembly Parts List Vac Motor Assembly ...23 ..............24 Scrub Deck Assembly (Hex Drive) ...25 ....................... 26 Warranty TC I 7/209841 7 7/1/97 SAFETY IMPORTANT SAFETY INSTRUCTIONS When using an electrical appliance, basic precautions should always be fallowed, including the following: READ ALL INSTRUCTIONS BEFORE USING MACHINE TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY: Connect machine to a properly grounded outlet only. See grounding instructions. Do not leave appliance when plugged in. Unplug from outlet when not in use and before servicing. Do not use outdoors on wet surfaces. Do not allow to be used as a toy. Close attention is necessary when used by or near children. Use only as described in this manual. Use only manufacturers recommended attachments. Do not use with damaged cord or plug. If appliance is not working as it should, has been dropped, damaged, left outdoors, or dropped into water, return it to an authorized service center. Do not pull or carry by cord, use cord as a handle, close a door on a cord, or pull cord around sharp edges or corners. Do not run appliance over cord. Keep cord away from heated surfaces. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord. Do not handle plug or appliance with wet hands. Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may reduce air flow. Keep hair, loose clothing, fingers, and all parts of body away from opening and moving parts. Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes. Turn off all controls before unplugging. Do not use to pick up flammable or combustible liquids such as gasoline or use in areas where they may be present. Rotating fan blades inside the cover. Before opening cover, switch off machine. Wait until the fan/brush stops completely or dust and debris may be ejected. Dry mop floor before using. SAVE THESE INSTRUCTIONS TCPOE 98447 7/1/97 3 SAFETY The following symbols are used throughout this guide as indicated in their descriptions: HAZARD INTENSITY LEVEL WHEN TRANSPORTING MACHINE I N A TRAILER: Make sure the ramp angle is no more than 0 There are three levels of hazard intensity identified by signal words -WARNING, CAUTION and FOR SAFETY. The level of hazard intensity is determined by the following definitions: 0 0 0 WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death. 0 0 0 lo", and the ramp is strong enough to support the machine. Make sure ramp is clean and dry. Put ramp into position. Remove squeegee assembly & brushes before loading. Align the machine on a level surface ten (10) feet behind the ramp. Push machine up ramp carefully. Securelv fasten the machine to the trailer. ~ CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property damaae. FOR SAFETY: To Identify actions which must be followed for safe operation of equipment. The following information signals indicate potentially dangerous conditions to the operator or equipment. Read this guide carefully. Know when these conditions can exist. Locate all safety devices on the machine. Report machine damage or faulty operation immediately. Do not use the machine if it is not proper operating condition. For SAFETY: DO NOT OPERATE MACHINE: 0 Unless Trained and Authorized 0 Unless Operation Guide is Read and understood. 0 In Flammable or Explosive areas. WHEN USING MACHINE: 0 Go slow on grades and slippery surfaces. 0 Use care when backing machine. 0 Do not carry riders on machine. 0 Always follow basic safety and traffic rules. BEFORE LEAVING OR SERVICING MACHINE: Stop on level surfaces. 0 Turn off machine. WHEN SERVICING MACHINE: 0 Avoid moving parts. Do not wear loose jackets, shirts, or sleeves when working on machine. 0 Block machine wheels before jacking machine up. 0 Use hoist or jack of adequate capacity to 0 0 4 THIS PRODUCT IS FOR COMMERCIAL USE ONLY. ELECTRICAL: In the USA this scrubber operates on a standard 15 amp 115 volt A.C. power circuit (120V nominal). Special voltage models are available for international applications. The amp, hertz, and voltage are listed on the data label found on each machine. Using voltages above or below those indicated on the data label will cause serious damage to the motors. GROUNDING INSTRUCTIONS: This appliance must be grounded. If it should malfunction or break down, grounding provides a path of least resistancefor electric current to reduce the risk of electric shock. This appliance is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be inserted into an appropriate outlet that is properly installed and grounded in accordancewith all local codes and ordinances. Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the appliance if it will not fit the outlet, have a proper outlet installed by a qualified electrician. - This appliance is for use on a nominal 120-volt circuit, and has a grounded plug that looks like the plug in "Fig. A" below. A temporary adaptor that looks like the adaptor in "Fig. C below may be used to connect this plug to a 2-pole receptacle as shown in "Fig. B" below. The temporary adaptor should be used only until a properly grounded outlet (Fig. A) can be installed by a qualified electrician. The green colored rigid ear, lug, or the like extending from the adaptor must be connected to a permanent ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be held in place by a metal screw. NOTE: Check local electrical codes before using an adaptor. Adaptors are not allowed in Canada. lift machine. Use Windsor approved replacement parts. TCPOE 98447 7/1/97 SAFETY/OPERATIONS PREPARING FOR OPERATION(Cont..) EXTENSION CORDS: If an extension cord is used, the wire size must be at least one size larger than the power cord on the machine, and the cord must be a type SJTW/SSTW:A. HOW IT OPERATES The TRIDENT COMPACT is a walk-behind scrubber. The main scrubbing components include a solutiodrecovery tank,single disc-type brush or pad, a rear squeegee and a vacuum motor. Detergent solution and water flow from the solution tank to the scrub brush. The rotating brush scrubs the floor. As the machine moves forward, the rear squeegee collects the dirty solution and channels it into the vacuum of the squeegeepickup hose. The pickup hose deposits the dirty solution into the recovery tank. 4.) Plug the power cords together and twist into locked position. Attatch the power cord to the yellow strain relief as shown. Plug power cord into a properly grounded wall outlet. 5.) Turn vacuum motor switch on and off to make sure there is electrical power at machine. OPERATING THE MACHINE (PERFORM DAILYMAINTENANCEAS SHOWN ON PAGE 7.) 1. Adjust the operator control handle to a comfortable position. (see item 3, page 6) 2. 3. Release solution. (Pull solution control lever rearward.) (see item 6, page 6) NOTE: The amount of solution can be regulated during operation depending on the type of floor and the traverse speed of the machine. Pulling the lever farther rearward releases more solution. PREPARING FOR OPERATION (PERFORM DAILY MAINTENANCE AS SHOWN ON PAGE 7.) Fill Solution Tank Remove cover and fill. (see item 19, page 14) 1.) Use a clean bucket or hose to fill the tank 2.) with water. 3.) Add a cleaning concentrate for use in automatic floor scrubbers. Closely follow the manufacturer’s instructions found on container. Read ingredients listed on the container to ensure compatible chemicals are used. Use only the suitable chemicals listed below. Using incompatible chemicals may damage the machine. Damages of this type are not covered under the WINDSOR Three Year Protection Plan. Carefully read ingredients on manufacturer’s label before using any product in this machine. I I SUITABLE CHEMICALS INCOMPATIBLE CHEMICALS Alkalis Defoaming Agents Detergents Hydroxides Aldehydes Carbon Tetrachloride Chlorinated Hydrocarbons Methyls (MEK) Perchlorethylene(per) Phenols Trichlorethylene D-Limonene Switch on main power switch. (see item 1, page 5) 4. Switch on brush drive motor. (see item 1, page 6) 5. Switch on vacuum motor. (see item 2, page 6) 6. Lower scrub deck. Pull scrub deck lift lever rearward. (see item 8, page 6) is stationary. 7. Lower squeegee. Pull squeegee lift lever back. (see item 7, page 6) NOTE: Adjust squeegee as shown on page 9. 8. Move machine forward bv aDDlvinrr , . - - even pressure on the main haidle . Forward motion is assisted by the scrubbing action of the brushlpad driver. Take extra care not to run machine over cord or catch cord on squeegee when turning. 7. Plan your cleaning route to work away from the electrical source. Move machine forward at a steady pace TCPOE 98447 7/1/97 5 OPERATION CONTROLS 1 6 Brush Switch. Turns brush on/off. \ TOP VIEW 2 Vacuum Switch. Turns vacuum motor on/off. 3 Main Handle. 4 Brush Motor Circuit Breaker. Protects brush motor from overheating. 5 Vacuum Motor Circuit Breaker. Protects vacuum motor from overheating. 6 Solution Lever. Controls the amount of solution flow to the floor. 7 Squeegee Lift Lever. Raises and lowers squeegee. 8 Scrub Deck Lift Lever. Raises and lowers scrub deck. 9 Recovery Tank Drain Hose. \ 1 2 BA 10 Solution Tank Drain Hose. 11 Squeegee Release Latch. Releases the rear squeegee blade for adjustment or replacement. d 12 Battery Compartment Door Latch. Opens back of machine for access to batteries. 13 13 Vacuum Hose. r ' 1 11 6 TCSOE 98447 7/1/97 (1 4 MAINTENANCE Maintenance Item Daily Weekly Monthly Annually * * * Before Starting Check Vac Hose Connections the Work Period Clean the Squeegee Blades Inspect Brush or Pad I * I Inspect Vac Fan Foam Breaker Inspect power cord for wear End of Work Period Before Storing * @ Drain & Rinse Tanks I * I Raise Squeegee Assembly Remove the BrushPad Clean Squeegee Blades & Foam Breaker * * * Remove lint build-up from screen in the recovery tank well. Remove tank lid and allow recoverv to drv between uses. * * Check Solution Strainer Check Casters & Wheels for proper lubrication I I I I 2. 3. 4. I I I I * * I I I I I I * Inspect Tanks and Hoses Inspect all Motors for Carbon Motor Brush wear. 7. 2. I * Check the BrushLPad for Damage and or wear NOTE: I * Details on these maintenance items can be found on the following pages. This cable will lay on wet surfaces. To prevent electrical shock immediatly replace cords with frayed or cracked insulation. Periodically inspect the recovery tank and decontaminate if necessary, using a Hospital Grade Virucide or a 7-70 bleach to water solution. Wastewater should be disposed of properly. Occasionally check in line filter screen, rinse with hot water if necessary. Frayed or cracked hoses should be replaced to avoid vacuum or solution pressure loss. LUBRICATION: The following symbols are found throughout the manual indicating the items requiring lubrication: EXAMPLE: @ Apply Grease Use Spray Lubricant. Thread Locker (Red or blue). Use Anti-Seize when repairing. TCZOE 98447 7/1/97 7 MAINTENANCE VACUUM MOTOR 7. 2. 3. 4. Disconnect battery leads and remove batteries from compartment. Remove (6) bolts holding vac motor/ plate assembly to recovery tank. Disconnect vac motor lead from connector and lift out vac motor/ plate assembly. Check motor brushes. When wom to 3/8"replace both brushes. After the machine has been used for any wet pickup, allow the vacuum motor to run 1-2 minutes, to help reduce moisture build-up in the vacuum motor. Drying out the vacuum motor after each use will extend the life of your vacuum motor. Hazardous Voltage. Shock can result. Disconnect batteries before working on machine. Only qualified personnel should work inside machine. Wire Terminal 7 Important: When replacing carbon vac motor brushes loosen wire terminal BEFORE removing screws on bracket. Important: Replace carbon vac motor brushes if worn down to 318" in length. These brushes wear quicker as the length shortens due to increased heat. Spring inside brush housing will damage motor if brushes are allowed to completely wear away NOTE: Periodically check the length of the carbon brushes. Replace carbon brushes which are less than 3/8" long. II I PART NO. 14695 BRUSH Brush Installation: 1. Slide brush or pad driver under drive plate. 2. Align one metal lug on the brush or pad driver with the scrub deck sight hole and a keyhole in the drive plate. 3. Raise the brush or pad driver upward and twist clockwise until locked. Brush Removal: 1. Raise brush or pad driver off floor. 2. Reach under brush or pad driver and rotate so that the metal lug in the drive plate is visible through the scrub deck sight hole. 3. Quickly twist brush or pad driver counterclockwis to release. Wire 8Terrqinal SOLUTION STRAINER 1. An inline solution strainer is located under chassis behind left wheel. Remove sediment bowl and screen periodically and rinse clean with hot water. Be careful not to misplace the gasket. Note: Place stop in groove. 8 U TCSOE 98447 7/1/97 MAINTENANCE SQUEEGEE DEFLECTION SQUEEGEE ASSEMBLY Before and during use of machine, use a damp cloth to wipe the outside and inside of squeegee to remove buildup of foreign material on the squeegee blades. This prevents streaking and residue on the floor. Squeegee wear: After extended use, the squeegee blades will wear. To improve squeegee performance and extend wear, proceed as follows: 1. Turn off all switches and place the machine on a level surface. Raise the squeegee to the transport position. 2. Loosen knobs on the left and right hand sides of squeegee until squeegee can be removed from the squeegee bracket. 3. Loosen the fasteners on front of squeegee to replace or adjust front blade. 4. Unlatch rear squeegee latch to replace rear blade. INCORRECT NOTENOUGH Adjusting Squeegee Assembly TOO MUCH ber -t knob 1. 2. 3. Lower the squeegee and move the machine forward. Observe the level of the squeegee for an even curl along the length of the blade. Use camber adjustment knob to achieve even curl if required. Adjust the down pressure nut located on squeegee mounting assembly. Do not apply excessive force. TCPOE 98447 7/1/97 TROUBLE SHOOTING GUIDE Dead electrical circuit Check building circuit breaker or fuse box Power switch failure Replace Faulty power cord Replace Follow grounding instructions exactly. Contact an electrician to check building’s wiring. Have a trained service technician check machine’s wiring Replace Replace I 1 Faulty switch Replace Center and seal dome over tank. Replace or repair using acrylic plastic cement only. With power off clean screen. Tighten cuffs turning counterclockwise. Replace. Wash out with hose. Pick lint out with a wire. Vac motor, hose or dome gasket I Improper solution hose connection Prop Screen in filter clogged Replace. Check for positive connection Remove and clean with hot water. Clean or replace if damaged. Check to be sure filter screen is in place. Be sure to pre-mix cleaning chemicals. Valve clogged TCZOE 98447 7/1/97 J 4 + WHT 880094 76050 VACUUM SWITCH BRUSH CIRCUIT BREAKER I BLK I BRUSH SWITCH c POWER IN SWITCH REARVIEW TANKS AND FRAME 22 REAR VIEW I2 TC20E 98447 12-01-99 TANKSAND FRAME PARTS LIST Ref PartNo. CNy 1 2 3 4 20046 2 11 1 1 1 CLAMP 2 25 HVSt WASHER, 1/4FlAT CUFF, 1.5’ BLK HOSE CORD, DRAIN HOSE PLUG CUFF, 1.5 SLIP X 1.5 HOSE 1 w 1 1 1 1 1 1 1 1 1 DOME, TC MODIF. FRAME,MAlN FLOAT, RECOVERY SHUT-OFF GASKET,DOME , . DKAlN HOSEASM,VAC HOSEBARB, 1.5 DOUBLE LABEL, WINDSOR LOGO LABEL, EXPLOSIONWARNING WASHtK,.31LABEL, TC17 “COMPACT’ LABEL, TC20 “COMPACT’ OPEN LID, SOLUTIONTANK NUT, 1/4-20 NvmcR PLI U AXLE, WHEEL 17.8 L X .625 OD PANELASM,REAR F‘LUG,DRAlNHOSE SCR, 1/4-20X 1.5 HHCS 5 87090 27759 27188 27282 L1416 28055 34303 34305 35060 39472 39383 40019 50485 50742 80819 50518 50519 6 7 8 9 10 11 12 13 14 15 16 17A 178 18 19 20 21 22 23 24 61320 66152 70010 26 27 28 29 70114 70251 70393 81379 30 34306 31 32 33 34 35 36 37 38 39 75152 75234 89181 57119 40 21408 4 2 87003 8 73437 78294 36150 34258 27417 70191 14665 4 1 1 1 1 2 41 42 43 44 45 46 47 48 49 50 51 52 53 51138 51041 03058 IW72 87025 27266 70266 54 55 56 39338 27051 4W13 57044 57 40022 58 20042 39380 59 60 61 62 63 2 2 2 - 1 3 1 1 1 6 3 3 2 1 1 1 1 2 4 4 2 2 - 9 . w SCR, #I0 X 3/4 POLYFAST SET SCREW, 1/4-20X 1HHMS SET SCREW, 1/4-20 X 1.25L FllTING, SEALED BULKHEAD I-UAMmtAKtK TANK,SOLUTlON TANK,RECOVERY WHEEL.MAlN NUT, 3/8-16 HEX NYLOCK PLTD St I YGK, s / l b m G P WASHER, 114 STAR CAP,WHEELHUB OPEN SCR, 3/8-16X 1.O HHCS GR5 PLTD COLLAKASM,AXLt OPEN WASHER, 3/8ID X 7/8 OD SS OPEN SPACER, 1.OO OD X .688ID X .3L TUBt,VACMGF(SRMOD. GASKET,VAClNTAKE INTAKE, FILTER VAC CORD,1/8XIT‘ SCREW, 1032 X 1R HKTC TYPE 23 1 BKKT., m - OPEN OPEN HOSE, 1.5 BLU VAC X 45” CABLE TIE, 11.38” UUCSA HOSEBAKB, 18 M I T X 112 NUT, 3/8NPT HEX BRASS HOSEBARB, 1R MPTX 1R POLY CLAMP, 3/8HOSE PSLOT HOSE, 1R ID NYLOBRAID6” VPtN OPEN OPEN CLAMP.2NYLON 1 1 1 1 1 1 1 20002 Description 1 B 5001372- t / TCPOE 98447 12-01-99 13 SQUEEGEE ASSEMBLY SQUEEGEE SUB ASSEMBLY A 35 --t v l*l -19 58 -7 7 35 -% 74 TCPOE 98447 1 I/l 1/99 9 SQUEEGEE ASSEMBLY PARTS LISTT 57 58 59 60 61 62 87080 87083 1 11 87178 87137 89059 1 2 2 - WASHER, .5 X 1.25 FLAT GR8 PLTD WASHER, 5/16 SPLIT LOCK PLTD OPEN WASHER, 5/8lD X 2 X .5 THK WASHER, 5/81D X 2.00D X 3/32 THK WHEEL, SQUEEGEE BUMPER TC20E 98447 I1/ I 1/99 15 VALVE GROUP 8 (FROM SOLUTION TANK) 10 (SOLUTION DRAIN HOSE) w ' - Detail -A- 16 TCPOE 98447 3/26/98 VALVEASSEMBLY PARTS LIST 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 140146 20042 27372 27726 70088 57104 39380 39381 39444 1 3 1 1 2 1 1 1 1 - - 73383 1 - - 40027 2 41184 1 - - 57030 59021 5 1 - - 70066 40013 70403 73405 78212 1 1 1 1 1 Brkt, Solution Valve Mtg. Clamp, 3/8 Hose CAP,STRAlNER Cable, Solution Scr, 10-32 x 1/2 PPHMS SS Nut, 10-32 w/star washer PLTD Hose, 1/2 id nylobraid 6" Hose, 1/2 ID Clear x 22" Hose, 1/2x5" Clear OPEN STRAINER, 3/8 NPT 20 MESH OPEN Hosebarb, 3/8 MPTxl/2 90"nyl OPEN Housing, strainer OPEN OPEN NUT, 10-32 NYLOCK PLTD O-ring, filter seal OPEN Scr, 10-32 x 3/4 PPHMS SS Hosebarb, 3/8 MPT x 1/2 Scr, # I 0 x 112 Polyfast Ph Phil Screen, 80 mesh Tee, 3/8 FPT TCPOE 98447 3/26/98 (All models except X) 17 SCRUB DECKASSEMBLY 23 I 18 ' TCPOE 98447 3/26/98 SCRUB DECK ASSEMBLY PARTS LIST Ref PsrtNo. Qty 1 2 20077 27527 1 1 - 34 serial No.. I Descriptlon From CLAMP, WUKM #HS356 CONDUIT, PT17E BRUSH MOTOR OPEN I Notes To I 80604 TCPOE 98447 3/26/98 19 MECHANICAL CONTROLS ASSEMBL Y 37 44 n-11 47 -> - 9 32 ____ 20 TCPOE 98447 03/13/00 44 26 -Q MECHANICAL CONTROLS PARTS LIST Ref PartNo. Qty 1 2 3 4 140153 27413 2 2 73659 27724 27725 27726 29151 38184 36132 38208 1 1 1 1 1 1 48030 70251 3 1 50477 51142 51184 51185 57006 1 1 4 1 4 57032 50926 66068 1 1 1 66116 80604 66133 66055 66257 67138 67224 67226 67360 67361 2 4 1 2 2 1 1 1 1 1 5 6 7 8 9 - 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 - - - - - 70228 70298 8 2 73236 73169 78220 87003 87018 87029 87030 87080 1 1 1 1 12 2 2 2 66270 70249 1 1 - - 61320 1 Serial No. Deilecrtption From To Notes: BEARING, .753 X .627 X 1.0 L CABLE, REAR CMPRT. DOOR OPEN STANDOFF, 1/4-20 X 1.O HEX INS CABLE,SCRUBDECK CABLE,SQUEEGEE CABLE,SOLUTION DOOR, REAR COMPARTMENT HANDLEW1FOAM GRIP, HANDLEX21.5” HANDLE, TC17/20 MAIN OPEN KNOB, HANDLE SET SCR, 1/4-20 X 1.0 PLTD OPEN LABEL, PT17 CHARGER WARNING LEVER, HANDLE CLAMP LOCK, HANDLEADJ. LEVER,SOLUTlON NUT,1/4-20HEX OPEN NUT, 3/8-16 SERRATED FLNG. LABEL, OPERATIONAL SLOPE PIN, 1/8X5/8ROLL OPEN PIN, 1/4 X 314 CLEVIS RING, RUE COTTER 1 / 4 PLTD PIN, 3/16 X .88 L CLEVIS PIN, ROLL 114 X 1.0 L PIVOT, CABLE LEVER RING,3/8EXTSNAP ROD,HANDLEADJ. ROD, CMPRTMNT DOOR LOCK ROD ASM, SCRUB DECK LIFT ROD ASM, SQUEEGEE LIFT OPEN OPEN OPEN SCR, 10-32 X 1/4 PHMS SS SHOULDER BOLT, 5/160DX3/8L OPEN SPRING, 1.12 COMPRESSION STRAIN RELIEF, CORD HOOK TUBE,HANDLEADJ. WASHER, 3/8 ID X 718 OD WASHER,#IOFLAT WASHER,5/16FLAT WASHER, 3/8 X 3/4 NYLON WASHER, 1/2” FLAT OPEN PIN CLEVIS, 3/16 X .75 L SCR, 1/4-20X1.25 HHCS PLTD OPEN PANELASM,REAR TCPOE 98447 03/13/00 21 CONTROL PANEL ASSEMBLY -21 12 REAR VIEW (CONTROL PANEL) 22 TC20E 98447 2/4/99 CONTROL PANEL ASSEMBLY PARTS LIST serial No. Ref Partk. Qty Dsgcrfption 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 140074 14520 14462 23556 57040 57049 57104 57106 57132 61341 67029 67382 70248 70394 72067 78373 87161 57047 57030 87090 50486 50487 57157 32042 14942 87018 50776 2 1 1 1 1 6 2 3 2 1 1 1 3 14 2 1 6 2 1 2 1 1 8 1 2 1 1 BREAKER, 9A CIRCUIT CLIP, DRAIN HOSE TERM. BLOCK, 25A 250V 1-1-2 WIRE ASM, TC-E PIGTAIL NUT, 1/2 MPT CONDUIT NUT,6-32NYLOCKSS NUT, 10-32 W/STAR WSHR PLTD NUT, 8-32 W/STAR WSHR PLTD NUT, 3/8-27 DRESS PANEL PANEL, CONTROL COVER RECTIFIER, BRIDGE RELAY. DPST-NO 30A SCR, 8-32 X 1.O PHMS BLK NYL. SCR, 6-32 X 1/2 THMS BLK F m Po Notesr: SWITCH, 125V SPST LIT RKR W/BT TRANSFORMER ASM, 115V/24V WASHER,MFLAT NUT, 1/4-20 NYLOCK PLTD NUT, 10-32 NYLOCK PLTD WASHER, 1/4-20 X 3/4 OD PLTD LABEL, SQUEEGEE/SOLUTION LABEL,SCRUBDECK NUT, 6-32 U-TINNERMAN ENCLOSURE, CONTROL PANEL BOOT, 3/8 CIRCUIT BREAKER WASHER, # I 0 X 9/16 OD LABEL,FORSAFETY TCPOE 98447 2/4/99 23 V a l No. Ref PartNo. Qty Oesffiptlon 1 2 3 4 5 6 7 8 9 10 11 12 27519 53778 62360 70085 70114 73419 57030 70607 87018 87025 87090 20035 1 1 1 6 4 3 6 6 6 6 1 2 COVER,VACMOTOR VAC MOTOR ASM, TC17/20E PLATEASM, PT17EVAC SCR, 1/4-20 X 1/2 PHMS SCR, # I 0 X 3/4 POLYFAST SPACER,VACMOTOR NUT, 10-32 NYLOCK PLTD SET SCREW, 10-32 X 1.OO WASHER, # I 0 X 9/16 OD WASHER, 1/4 STAR WASHER, 1/4 ID X 3/4 OD PLTD CLAMP, 7/16 DIA NYLON UL 24 Fwan TCPOE 98447 3/26/98 To :-N 7- ’1 I I - 6 2 3 4 5 6 7 8 9 10 48040 70305 87029 87067 81578 70577 78362 73576 48025R 1 1 1 1 1 1 1 1 1 KEY, 1/4 SQ. X 1.OO SCR, 5/16-18 X 3/4 HHCS PLTD WASHER, 5/16 FLAT SAE WASHER, 5/16 LCK INT STAR PLTD PAD DRIVER ASM, 2 0 POLY SCR. 3/8-16 X 3.5 SCHS STL TUBE, 50 OD .058W .85L DOM SPRING, COMP .60D X 2.0L X .045W KNOB, 1.75 X 3.8-16 F BRUSH AND PAD (20’3 OPTION LIST: P/N 02340 02357 02358 02359 02360 02361 DESCRIPTION PAD DRIVER, 20” HEX BRUSH, 20” POLYPROPYLENE HEX BRUSH, 20” NYLON HEX BRUSH, 20” NYLON POLISH HEX BRUSH, 20” MILD GRIT HEX BRUSH, 20” SUPER AGGRESSIVE HEX TCPOE 98447 3/26/98 25 LIMITED WARRANTY Windsor Industries, Inc. warrants new machines against defects in material and workmanship under normal use and service to the original purchaser. The warranty period is subject to the conditions stated below. 3 YEARS FOR PARTS AND 1 YEAR FOR SERVICE LABOR Exceptions: Rotationally molded polyethylene tanks carry a 6 year parts and 1 year service ® labor warranty. VERSAMATIC models carry a 3 year warranty on brush motors, vacuum ® motors, and belts, and a 1 year service labor warranty. SENSOR models carry a 2 year warranty on vacuum motors and belts, and a 1 year service labor warranty. Extractor brush ® motors, pump motors, pc boards and electronics, vac motors (other than VERSAMATIC and ® SENSOR ), pumps, and FLEXSOL™ diaphragms, all RADIUS™ and TITAN™ Wet/Dry Vacs carry a 1 year parts and service labor warranty. Propane equipment has a 2 year ® manufactured parts warranty. The Onan engines have a 3 year manufacturers’ warranty. The ® ® Honda /Kawasaki engines have a 2 year manufacturers’ warranty. NOTE: The engine warranty is administered through the engine manufacturer and must be repaired at an authorized service center. Normal wear items including, but not limited to, belts, brushes, capacitors, carbon brushes, casters, clutches, cords, filters, finishes, gaskets, hoses, light bulbs, rectifiers, switches, squeegees, bearings, pulleys, relays, actuating cables, tires, Propane batteries and wheels will be warranted for manufacturing defects for 90 days from the purchase date. The warranty commences on the purchase date by the original end user from an authorized Windsor Agent, subject to proof of purchase. The Machine Registration Card must be completed and returned immediately at the time of purchase. If proof of purchase cannot be identified, the warranty start date is 90 days after date of sale to an authorized Windsor distributor. Parts replaced or repaired under warranty are guaranteed for the remainder of the original warranty period. 90 DAY WARRANTY EXTENSION AVAILABLE Upon receipt of the Machine Registration Card, Windsor will extend the warranty period an additional 90 days from the purchase date. Does not include items warranted 90 days for manufacturing defects. STATED WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED. Any statutory implied warranties, including any warranty of merchantability or fitness for a particular purpose, are expressly limited to the duration of this written warranty. Windsor will not be liable for any other damages, including but not limited to indirect or special consequential damages arising out of or in connection with the furnishing; performance, use or inability to use the machine. This remedy shall be the exclusive remedy of the buyer. This warranty shall not apply to: 1.damage in transit; 2.misuse or abuse(including the use of incompatible or corrosive chemicals or overloading of capacity); 3. failure due to lack of proper maintenance and care (including cleaning); 4.any design alterations performed by an organization not authorized or specified by Windsor; 5.batteries and chargers. 6. high pressure washing. 7.electrical components exposed to moisture. If difficulty develops during the warranty period, contact the authorized Windsor Agent from whom the product was purchased. Windsor, Inc. may elect to require the return of components to validate a claim. Any defective part to be returned must be shipped freight pre-paid to an authorized Windsor Distributor/Service Center or to the Windsor factory. USE OF PARTS NOT APPROVED BY WINDSOR, INC. WILL VOID ALL WARRANTIES. This warranty is valid only for all products sold after July 1, 1995. A product sold before that date shall be covered by the limited Warranty in effect at the date of sale to the original purchaser. z 1999 Windsor Industries, Inc. All rights reserved. REVISED 05/01/02