Download Whirlpool GI7FVCXWY - Bottom Freezer Refrigerator Specifications

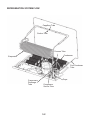

Transcript

R-109 TECHNICAL EDUCATION 2009 Whirlpool 27' French Door IDI Models KBFA20ER & KBFA25ER Models: GI7FVCXWA GI7FVCXWB GI7FVCXWQ GI7FVCXWY JOB AID 8178777 FORWARD This Job Aid, (Part No. 8178777), provides the technician with information on the installation, operation, and service of the Whirlpool 27' French Door Bottom-Mount Refrigerator. For specific information on the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the Whirlpool 27' French Door Bottom-Mount Refrigerator. The Wiring Diagrams used in this Job Aid are typical and should be used for training purposes only. Always use the Wiring Diagram supplied with the product when servicing the refrigerator. GOALS AND OBJECTIVES The goal of this Job Aid is to provide information that will enable the service technician to properly diagnose malfunctions and repair the Whirlpool 27' French Door Bottom-Mount Refrigerator. The objectives of this Job Aid are to: • Understand and follow proper safety precautions. • Successfully troubleshoot and diagnose malfunctions. • Successfully perform necessary repairs. • Successfully return the refrigerator to its proper operational status. WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on our products by anyone other than Authorized Service Technicians. Copyright © 2009, Whirlpool Corporation, Benton Harbor, MI 49022 - ii - TABLE OF CONTENTS Page GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Refrigerator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Whirlpool Model And Serial Number Designations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Model And Serial Number Label And Tech Sheet Locations. . . . . . . . . . . . . . . . . . . . . . . . 1-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Whirlpool Corporation Major Appliance Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 PRODUCT OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Main Control Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Refrigeration System Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Machine Compartment Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Cabinet Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 Cabinet Water Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 Ice Compartment And Freezer Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6 Accessing Dispenser Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 Using The Control Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 COMPONENT ACCESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Component Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Removing The Facade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 Removing The Ice Maker Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 Removing The Heat Shield And Thermal Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7 Removing The Ice Maker LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8 Accessing The Water Valve And Reservor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9 Removing The Water Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11 Removing The Test Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13 Accessing The Motorized Air Damper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14 Accessing The Machine Compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15 Removing The Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16 Accessing The Electronic Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17 Removing The Drain Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18 Leveling Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19 Dropping The Machine Compartment Pan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20 Removing Left Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21 Removing The Evaporation Pan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22 Removing The Condenser Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23 Disassembling The Dispenser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24 Accessing The Door Hinges And Water Tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29 Preparation For Left Door Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30 Removing The Ice Maker Fill Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31 - iii - TABLE OF CONTENTS (continued) COMPONENT TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . For Service Technician's Use Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Component Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DIAGNOSTICS AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 5-1 5-2 6-1 6-1 6-3 WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Main Control Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 Main Control Board Connector Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3 - iv - GENERAL REFRIGERATOR SAFETY Your safety and the safety of others is very important. We have provided many important safety messages in this Job Aid and on the appliance. Always read and obey all safety messages. This is the safety alert symbol. This symbol alerts you to hazards that can kill or hurt you and others. All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These words mean: DANGER You can be killed or seriously injured if you don’t immediately follow instructions. WARNING You can be killed or seriously injured if you don’t follow instructions. All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed. 1-1 WHIRLPOOL MODEL & SERIAL NUMBER DESIGNATIONS MODEL NUMBER MODEL NUMBER G I 7 F V C X PRODUCT GROUP G = WHIRLPOOL PRODUCT IDENTIFICATION I = EXTERNAL ICE & WATER CAPACITY 7 = 27 CU. FT. MODEL/SERIES F = RETAIL MODEL FEATURE VARIANTS V = SPECIAL VARIATION MODEL FEATURE CODE C = IN DOOR ICE DISPENSER DOOR SWING X = FRENCH DOOR YEAR OF INTRODUCTION W = 2009 COLOR CODE A = SATINA ON MONO CABINET B = BLACK Q = WHITE Y = SS ON MONO CABINET SERIAL NUMBER SERIAL NUMBER K Y 16 MANUFACTURING RESPONSIBILITY K = AMANA YEAR OF PRODUCTION Y = 2009 WEEK OF PRODUCTION 16th = WEEK PRODUCT SEQUENCE NUMBER 1-2 12345 W A MODEL & SERIAL NUMBER LABEL & TECH SHEET LOCATIONS The Model & Serial Number label location is shown below. Model & Serial Number Label The Tech Sheet location is shown below. Bottom Grille Tech Sheet 1-3 SPECIFICATIONS 1-4 WHIRLPOOL CORPORATION MAJOR APPLIANCE WARRANTY 1-5 — NOTES — 1-6 INSTALLATION REQUIREMENTS INSTALLATION INSTRUCTIONS LOCATION REQUIREMENTS ELECTRICAL REQUIREMENTS 2-1 WATER SUPPLY REQUIREMENTS CONNECT THE WATER SUPPLY 2-2 REFRIGERATOR DOORS AND DRAWER 2-3 2-4 Electrical Shock Hazard Disconnect power before removing doors. Failure to do so can result in death or electrical shock. 2-5 REFRIGERATOR USE OPENING AND CLOSING DOORS 2-6 CRISPER HUMIDITY CONTROL WATER AND ICE DISPENSER (on some models) 2-7 2-8 ICE MAKER AND STORAGE BIN 2-9 WATER FILTRATION SYSTEM REFRIGERATOR CARE CLEANING 2-10 CHANGING THE LIGHT BULB TROUBLESHOOTING REFRIGERATOR OPERATION 2-11 ICE AND WATER TEMPERATURE AND MOISTURE 2-12 2-13 — NOTES — 2-14 PRODUCT OPERATION Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. MAIN CONTROL BOARD Control System Overview: The control provides independent temperature control for the Refrigerator, Freezer and Ice Maker compartments by monitoring NTC Thermistors for the actual temperature of each compartment. It also considers the ambient temperature measured by a sensor. It receives temperature set points of each compartment from an externally connected user interface, except for the Ice Maker compartment which is internally defined. Based on these inputs, the control determines the required state of the Compressor, Evaporator Fan and Air Baffle. The optimal defrost times are determined by monitoring the length of time required to defrost the evaporator compared to an ideal defrost length. Board Over Temperature Operation – Control Board has an onboard thermistor. If thermistor detects a temperature of 75 C/167F or higher, all thermostatic loads will turn off. Normal operation will resume when the thermistor senses a temperature of 60C/140F or less. Compartment Lights – All compartment lights turn off after 10 minutes of door being open, no matter which door is open. Note: In Service Mode, in the diagnostic steps the lights work normally and will turn off after 10 minutes of elapsed time. 3-1 REFRIGERATION SYSTEM FLOW Cappillary Tube Suction Tube Process Tube Condenser Evaporator Post Condenser Tube Compressor Discharge Tube Dryer Compressor Suction Tube 3-2 MACHINE COMPARTMENT AIR FLOW Condenser Fan Assembly Compressor Drip Pan Condenser 3-3 CABINET AIR FLOW Ice Bin Air Return Refrigerator Return Air Tunnel Refrigerator Return Air Tunnel Freezer Air Supply Grille Freezer Return Air Through Louvers At Bottom Of Evaporator 3-4 CABINET WATER FLOW 1/4" O.D. Plastic Tubing Foamed-in Conduit 5/16" O.D. Plastic Tubing Water Valve Foamed-in Conduit 5/16" O.D. Plastic Tubing Dispenser Ice Maker Fill Tube Water Filter 1/4" O.D. Plastic Tubing 5/16" O.D. Plastic Tubing Water Tank Foamed-in Conduit Incoming Water Line Connection For 1/4" O.D. Copper tube Compression Fitting 3-5 ICE COMPARTMENT AND FREEZER FAN OPERATION Ice Compartment and Freezer Fan Operation Freezer Compartment Calling For Cooling - Evaporator Fan On 100%, Compressor Speed Varies Depending On the Freezer Temperature Refrigerator Compartment Calling For Cooling - Damper Open, IC Fan On 30%, And Evaporator Fan On 100% RC Calling for Cooling and Ice Maker in Freeze Cycle - Damper Open, IC Fan On 55%, And Evaporator Fan On 100% RC Satisfied and Ice Maker in Freezing Mode - Damper Closed, IC Fan On 55%, And Evaporator Fan On 100% Ice Maker Harvesting - Damper Open, IC Fan Off, and Evaporator Fan On 100% Ice Bin Melting 30 degrees or ^ - Damper Closed, IC Fan On 90% And Evaporator Fan On 100% Defrost Cycle - Damper Closed, IC Fan Off, And Evaporator Fan Off 3-6 ACCESSING DISPENSER SWITCHES Ambient Thermistor The ambient thermistor information is used in an equation to adjust the control temperature values. As the ambient temperature changes the control value will shift to correct for the change. This helps maintain the compartment temperatures at the set value on the user interface. The ambient temperature may or may not be used for all of the compartments but it can be. It depends on a regression equation calculated from results of testing performed in the lab. The Humidity sensor is used in an equation to adjust the Wattage output of the mullion heater. The mullion heater operates at 0, 30, 70 or 100% of its rated Wattage Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. User Interface Board Humidity Sensor The Humidity sensor is used in an equation to adjust the Wattage output of the mullion heater. The mullion heater operates at 0, 30, 70 or 100% of it's rated Wattage. Humidity Sensor and Ambient Thermistor are Located on the User Interface Board. The user interface board is sold as an assembly. 3-7 USING THE CONTROL DISPLAY Overview of UI (home state) SCREENSAVER AND MEASURED FILL Sleep Mode / Sleep Mode State Measured fill / Measured off (=Home) 3-8 SCREENSAVER AND MEASURED FILL (continued) Measured fill / Measured off (=Home) Measured fill / Dispensing State Measured Fill / Complete / Standby State 3-9 Cooling / Home State COOLING ON / OFF SCREEN Cooling Off Countdown State Cooling Off Countdown State 3-10 COOLING ON / OFF SCREEN (continued) Cooling Off Countdown State Cooling Off Indicator / Cooling Off Active State Cooling Off Indicator / Cooling Status Information State 3-11 COOLING ON / OFF SCREEN (continued) Cooling Off Indicator / Home State Cooling On / Off / Cooling On Countdown State Cooling On / Off / Cooling On Countdown State 3-12 COOLING ON / OFF SCREEN (continued) Cooling On / Off / Cooling On Countdown State Cooling Off Indicator / Home State Cooling On / Off / Fast Cool Disabled State 3-13 COOLING ON / OFF SCREEN (continued) Cooling Off Indicator / Locked State TEMPERATURE SETTING SCREEN Cooling / Home State Cooling / Cooling Setup State 3-14 TEMPERATURE SETTING SCREEN (continued) Cooling / Setting Unit State Cooling / Setting Temperature State Cooling / Setting Unit Complete State 3-15 ALERT SCREEN – DOOR AJAR, FILTER RESET Door Alarm Indicator / Door Alarm Active State Door Alarm Indicator / Door Alarm Alert Screen State Door Alarm Indicator / Door Alarm Snooze State (=Active State) 3-16 ALERT SCREEN – DOOR AJAR, FILTER RESET (continued) Water Filter Indicator / Water Filter Order State Water Filter Status / Water Filter Setup State Water Filter Alert / Water Filter Confirmation State 3-17 ALERT SCREEN – DOOR AJAR, FILTER RESET (continued) Water Filter Alert / Water Filter Countdown State Water Filter Status / Water Filter Setup State 3-18 ALERT SCREEN – GLOBAL ALERTS Alert Indicator Management / Multiple Alert Indicators State ADVANCED FEATURES SCREEN Features / Features Menu State Dispenser Lock / Unlocked State 3-19 ADVANCED FEATURES SCREEN Dispenser Lock / Lock Confirmation State Dispenser Lock / Lock Countdown State Dispenser Lock / Lock Complete State 3-20 ADVANCED FEATURES SCREEN (continued) Dispenser Unlock / Locked State Dispenser Unlock / Unlock Confirmation State Dispenser Unlock / Unlock Countdown State 3-21 ADVANCED FEATURES SCREEN (continued) Dispenser Unlock / Unlock Complete State Features / Features Menu State Fast cool Setup / Fast cool Off State 3-22 ADVANCED FEATURES SCREEN (continued) Fast cool Setup / Fast cool Off State Fast cool Indicator / Fast cool Indicator On State Features / Features Menu State 3-23 ADVANCED FEATURES SCREEN (continued) Timer / Timer Setup State Timer / Timer Running State Timer / Timer Running Maximized State 3-24 ADVANCED FEATURES SCREEN (continued) Timer / Timer Running State Timer / Timer Running in Memory State Timer / Timer Running Minimized State in Home Screen 3-25 ADVANCED FEATURES SCREEN (continued) Timer / Timer Running State Timer / Timer Complete State Options / Options Menu State 3-26 ADVANCED FEATURES SCREEN (continued) Power Out History / Power Out History View State Power Out Alert / Power Out Alert State Power Outage Alert / Power Outage Alert Confirmation State 3-27 ADVANCED FEATURES SCREEN (continued) Power Out Alert / Power Out Alert Countdown State ADVANCED FEATURES SCREEN – SETTINGS & PREFERENCES Home State Options / Options Menu State 3-28 ADVANCED FEATURES SCREEN – SETTINGS & PREFERENCES (con't) Brightness Setting / Brightness Setup State Volume Setting / Volume Setup State Time & Date Setting / Time & Date Setup State 3-29 ADVANCED FEATURES SCREEN – SETTINGS & PREFERENCES (con't) Time & Date Setting / Time & Date Setup State Settings / Settings Menu State Factory reset Setting / Factory reset Setup State 3-30 ADVANCED FEATURES SCREEN – SETTINGS & PREFERENCES (con't) Factory reset Setting / Factory reset Setup State Features / Features Menu State Preferences / Preferences Menu State 3-31 ADVANCED FEATURES SCREEN – SETTINGS & PREFERENCES (con't) Ice Preference / Ice Preference Setup State Water Preference / Water Preference Setup State Language Preference / Language Preference Setup StateState 3-32 ADVANCED FEATURES SCREEN – SETTINGS & PREFERENCES (con't) Dispense Preference / Dispense Preference Setup State TEMPORARY ALERT Temporary Alert for Disabled Buttons / Temporary Alert State ADVANCED FEATURES SCREEN – ICE MAKER Options / Options Menu State 3-33 ADVANCED FEATURES SCREEN – ICE MAKER (continued) Ice maker Setting / Ice maker Setup State Ice maker Setting / Ice maker Setup State 3-34 SHOWROOM FLOOR MODE, DEMO MODE, SERVICE DIAGNOSTICS MODE Service Mode / Service Menu State Service Mode / Service Menu State Service Mode / Demo Mode State 3-35 SHOWROOM FLOOR MODE, DEMO MODE, SERVICE DIAGNOSTICS MODE (continued) Service Mode / Service Menu State Service Mode / Service Menu State Service Mode / Service Diagnostics State 3-36 SHOWROOM FLOOR MODE, DEMO MODE, SERVICE DIAGNOSTICS MODE (continued) Service Mode / Service Diagnostics State Service Mode / Service Diagnostics State Service Mode / Service Menu State 3-37 – NOTES – 3-38 COMPONENT ACCESS This section instructs you on how to service each component inside the French Door BottomMount Refrigerator. The components and their locations are shown below. COMPONENT LOCATIONS 4-1 REMOVING THE FACADE Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. Open the refrigerator compartment door. 3. Tape indicates where to insert tool to release facade. 4. Use a wide flat blade screwdriver or putty knife to release 4-2 REMOVING THE FACADE (continued) Front Tabs Rear Tabs 4-3 REMOVING THE ICE MAKER ASSEMBLY Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Remove the ¼” hex head screw securing the ice maker assembly to the cabinet. 3. Rest the assembly on the upper shelf 2. Pull the ice maker assembly out and down to remove. 4-4 REMOVING THE ICE MAKER ASSEMBLY (continued) 4. Disconnect the wiring harness. . Critical Sealing Areas Top and side view of icemaker assembly. Foam Air Seal 5. Slide out the assembly. Grommet 6. When reassembling, make sure the grommet is installed properly to ensure a tight air seal. 4-5 Continued next page. REMOVING THE ICE MAKER ASSEMBLY (continued) Lip of Ice Maker Air Diffuser Slips into Channel in Housing Insert Screw Driver Blade and Twist 7. Unsnap fasteners securing fan cover and lift off. 9. Remove the icemaker cover. Test Switch 8. Roll out the ice maker to disengage lip on air diverter from ice maker housing and remove 4-6 REMOVING HEAT SHIELD AND THERMAL FUSE Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. View of the bottom of the new small cube ice maker. 1. Unplug refrigerator or disconnect power. Depress Locking Tab and Remove Harness 2. Remove 3 screws securing air difffuser to ice maker mold. 6 cavity Small cube ice maker core. 3. Unclip the thermal fuse from the ice maker mold. 4-7 REMOVING THE ICE MAKER LED Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 3. Insert straight blade and pop out assembly. 1. Unplug refrigerator or disconnect power. 2. Insert straight blade screwdriver into slot in light lens to release tabs and lift out. NOTE: If the LED cannot be pulled out to unplug the wiring harness, the assembly must be split apart to remove. 4-8 ACCESSING THE WATER VALVE AND RESERVOIR Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Remove ¼” hex head screw on left and right side of cover. 4-9 Continued next page. ACCESSING WATER VALVE AND RESERVOIR (continued) Release Clip Release Clip 2. Release the clips on left and right side of the cover as it is pulled downward. 3. Drop the front of the cover and slide cover back. There are two tabs on the rear of the cover that fit into slots in the rear of the cavity.. 4-10 REMOVING THE WATER VALVE Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. Turn off the water supply to the refrigerator. 5. Release the retainer tabs on the left and right side of the valve as you pull down on the valve. 3. Remove the water tubes from the valve 4. Release the water tubes from the John Guess fittings and remove. 6. Drop the valve down and remove the inlet water tube. 4-11 Continued next page. REMOVING THE WATER VALVE (continued) 7. Disconnect harness and chassis ground connector . 4-12 REMOVING THE TEST SWITCH Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 3. Remove switch. 1. Disconnect wires from switch. 2. Use a straight blade screw driver to release locking tab on the side of the switch. 4-13 ACCESSING THE MOTORIZED AIR DAMPER Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. Lift motorized damper from the housing. View of damper door. 4-14 ACCESSING THE MACHINE COMPARTMENT Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. The Rear Cover Is Removed In Three Pieces Compressor: Wattage – 60HZ/113Watts Locked Rotor – 3.3 amps Full Load – 3.3 amps Resistance all windings – 6.4 Ohms Inverter Voltages: Red/White 120 VAC ORG/Red and ORG/ WH 3-6 VDC Embraco variable speed compressor 4-15 REMOVING THE COMPRESSOR Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 3. Straighten locking tab 2. Turn counterclockwise 4. Lift off dog bone 4-16 ACCESSING THE ELECTRONIC BOARDS Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. Main Control Board 1. Unplug refrigerator or disconnect power. 2. Remove 4 screws securing cover. 3. Unsnap and remove plastic cover. 4-17 New Power Supply Board REMOVING THE DRAIN TUBE Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 3. Insert a straight blade screwdriver vertically from the top of the drain tube opening to release locking tab. 2. A locking tab must be released to remove drain tube. 4. Lift off drain tube. 4-18 LEVELING LEGS Front roller adjustment 3/8” Hex Head Bolt Clockwise raises cabinet Counterclockwise lowers cabinet. After leveling unit, adjust brake so rubber foot contacts floor. 4-19 DROPPING THE MACHINE COMPARTMENT PAN Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. Tilt condenser fan side of cabinet 2. Remove the 2 Torx screws securing the base pan to the cabinet and drop the down the base pan 4-20 REMOVING LEFT ROLLER 1. Slide pin out of bracket and remove the roller. 4-21 REMOVING THE EVAPORATION PAN Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 4. Release the 2 evaporation pan tabs inserted into the cabinet 1. Unplug refrigerator or disconnect power. 2. Lift the condenser line out of the evaporation pan bracket 5. Tabs on the evaporation pan secure the front of the pan to the base. 3. Release the 2 evaporation pan tabs inserted into the cabinet 4-22 REMOVING THE CONDENSER FAN ASSEMBLY Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. Unsnap tab on the bottom of the fan assembly 2 and slide assembly channels out of evaporator pan. Locking Tab 4-23 DISASSEMBLING THE DISPENSER Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. Remove drip pan and tray. 4-24 DISASSEMBLING THE DISPENSER (continued) Remove the User Interface Board 3. Remove the User Interface Board . 4 5. Pull out on the bottom of the user interface board as you pull down. Tabs on the top of the user interface engage slots in the dispenser housing. Release the clips on the left and right side on the bottom of the user interface board 6. Disconnect wire harnesses. 4-25 Continued next page. DISASSEMBLING THE DISPENSER (continued) 7. Unsnap water tube from divider. 10. Remove the divider. 8. Remove the two 1/4” hex head screws. 11. Disconnect the wiring harnesses. 9. Release the clips on the left and right side of the dispenser divider. 4-26 DISASSEMBLING THE DISPENSER (continued) 12. Remove the two 1/4” hex head screws securing the lower pan to the housing. 13. Remove the pan. 15. Disengage the facade tabs from the slots in the housing. 14. Depress the rear of the dispenser facade and and lift. 4-27 Continued next page. DISASSEMBLING THE DISPENSER (continued) 16. Slide switches up to disengage from housing tabs. 4-28 ACCESSING THE DOOR HINGES AND WATER TUBES Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. Figure 3 3. Remove the Phillips head screw securing the “T” shaped cover to the top of the cabinet, see figure 4. 1. Unplug refrigerator or disconnect power. Figure 1 Figure 4 4. Remove the cover to expose the water tubes and wiring harness, see figure 5. Figure 2 2. Remove the right and left hand hinge cover, see figures 1,2 and 3. Figure 5 4-29 PREPARATION FOR LEFT DOOR REMOVAL Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 1. Unplug refrigerator or disconnect power. 2. Disconnect John Guess Fitting, see figure 1. 3. Unplug Wire Harness, see figure 2. Figure 2 Figure 1 4-30 REMOVING THE ICEMAKER FILL TUBE Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 4-31 – NOTES – 4-32 COMPONENT TESTING Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in death or electrical shock. 5-1 5-2 DIAGNOSTICS & TROUBLESHOOTING DIAGNOSTIC TESTS 6-1 DIAGNOSTIC TESTS (continued) 6-2 WIRING DIAGRAMS 7-1 MAIN CONTROL BOARD CONNECTOR IDENTIFICATION 7-2 PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION SOURCES IN THE UNITED STATES: FOR PRODUCT SPECIFICATIONS AND WARANTY INFORMATION CALL: FOR WHIRLPOOL PRODUCTS: 1-800-253-1301 FOR KITCHENAID PRODUCTS: 1-800-422-1230 FOR ROPER PRODUCTS: 1-800-447-6737 FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL: THE TECHNICAL ASSISTANCE LINE: 1-800-253-2870 HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN AUTHORIZED SERVICER FOR LITERATURE ORDERS: PHONE: 1-800-851-4605 FOR TECHNICAL INFORMATION AND SERVICE POINTERS: www.servicematters.com IN CANADA: FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL: 1-800-461-5681 FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL: THE TECHNICAL ASSISTANCE LINE: 1-800-488-4791 HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN AUTHORIZED SERVICER