Download Bona MiniEdge Technical data

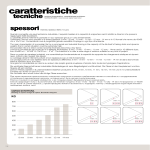

Transcript