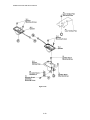

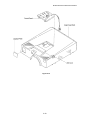

Download Epson PowerLite 5000 Service manual

Transcript