Download Daikin LRLEQ15AY1(E) Service manual

Transcript

SiENBE28-901

Service

Manual

Air Cooled Refrigeration

Condensing Unit

LRLEQ5AY1(E)

LRLEQ6AY1(E)

LRLEQ8AY1(E)

LRLEQ10AY1(E)

LRLEQ12AY1(E)

LRLEQ15AY1(E)

LRLEQ20AY1(E)

LRMEQ5AY1(E)

LRMEQ6AY1(E)

LRMEQ8AY1(E)

LRMEQ10AY1(E)

LRMEQ12AY1(E)

LRMEQ15AY1(E)

LRMEQ20AY1(E)

SiENBE28-901

Air Cooled Refrigeration

Condensing Unit

LRMEQ5AY1, 6AY1, 8AY1, 10AY1, 12AY1, 15AY1, 20AY1

LRLEQ5AY1, 6AY1, 8AY1, 10AY1, 12AY1, 15AY1, 20AY1

Air Cooled Refrigeration Condensing Unit 1

1

LRMEQ5AY1, 6AY1, 8AY1, 10AY1, 12AY1, 15AY1, 20AY1 1

LRLEQ5AY1, 6AY1, 8AY1, 10AY1, 12AY1, 15AY1, 20AY1 1

1. Introduction .............................................................................................2

2. Standard Specification ............................................................................7

2.1

2.2

2.3

2.4

2.5

2.6

Standard Specification .............................................................................7

Set Values for Functional Components and Protection Devices............13

Operation Limits .....................................................................................14

Wiring Diagram.......................................................................................15

Piping Diagram.......................................................................................18

Description and Layout of Functional Parts and Piping Diagram ...........21

3. Field Settings ........................................................................................30

3.1 Field Setting From Outdoor Unit.............................................................30

4. Description of Functions and Operation................................................40

4.1 Operating Mode......................................................................................40

4.2 Outline of Functions ...............................................................................47

4.3 Detailed Description of Functions...........................................................48

5. Test Operation ......................................................................................57

5.1

5.2

5.3

5.4

5.5

5.6

Refrigerant Piping...................................................................................57

Field Wiring ............................................................................................63

Inspection and Pipe Insulation ...............................................................66

Checks after Work Completion...............................................................69

Additional Refrigerant Charge ................................................................69

Test Run.................................................................................................71

6. Troubleshooting ....................................................................................73

6.1

6.2

6.3

6.4

6.5

6.6

6.7

Checking Points at Servicing..................................................................73

List of Malfunction Codes .......................................................................76

Checking Malfunction Codes by LED Lamps on PCB............................77

Checking Malfunction Codes of the Condensing Unit ............................79

Troubleshooting by RAM Monitor...........................................................80

Flow Chart for Troubleshooting ..............................................................84

Maintenance.........................................................................................141

7. Appendix (Supplementary Information)...............................................149

7.1

7.2

7.3

7.4

Restriction Matter of Showcase............................................................149

Selection of Expansion Valve...............................................................149

Trouble Case with Present Machine (R-407C).....................................150

Option List ............................................................................................154

Air Cooled Refrigeration Condensing Unit

1

Introduction

SiENBE28-901

1. Introduction

Safety Precautions

Before performing design, construction, or maintenance, thoroughly read the "Safety

Precautions" and also the "Installation Manual" and "Operation Manual" that come with this

product.

Precautions are classified as " WARNING" or " CAUTION" for the purpose of this Section.

Items that mishandling highly potentially induces serious consequences such as death or serious

injury are specially described under " WARNING". Furthermore, even items described under

" CAUTION" potentially induce serious consequences depending on circumstances. All are

important items for safety and must be followed without fail.

Pictograms

This symbol alerts you to precautions to be taken.

Sections under this symbol provide the specific descriptions of precautions.

This symbol alerts you to prohibited acts.

Sections under or in the vicinity of this symbol provide the specific

descriptions of prohibited acts.

This symbol alerts you to mandatory acts or instructions.

Sections under or in the vicinity of this symbol provide the specific

descriptions of instructions.

After the completion of construction or repair work, conduct test run on the equipment to check it

for any abnormalities, and also explain precautions for use of the equipment to customer.

<I. Precautions for Construction and Repair>

WARNING

(1) To overhaul the equipment,

be sure to turn OFF all power

supplies.

Not doing so will result in an electric

shock.

To repair the equipment or check for

circuits with power applied, pay utmost

attention not to touch any live part.

(2) If a refrigerant gas belches

during work, do not touch the

refrigerant gas.

Doing so will result in

frostbite.

(3) To remove a welded part

from the suction or discharge

pipe of compressor, remove

it in a well-ventilated area

after thoroughly discharging

a refrigerant gas.

gas or refrigerant oil to belch, thus

resulting in injury.

(4) If a refrigerant gas leaks

during work, ventilate the

working area.

If the refrigerant gas comes

into contact with a flame,

toxic gas will be generated.

(5) The electrical parts of

outdoor unit carry a high

voltage.

To repair these

parts, thoroughly

discharge

electricity from the

capacitor.

Not doing so will result in an electric

shock.

Not doing so will cause the refrigerant

2

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Introduction

CAUTION

(6) Do not start or stop the air

conditioner using the POWER

SUPPLY switch.

Doing so may result in a

failure or water leakage.

(10) To clean the equipment, be

sure to set the POWER

SUPPLY switch to "OFF" to

turn OFF all power supplies.

Not doing so may result in injury

because the internal fan rotates at

high speeds.

(7) Do not repair electrical parts

with wet hand.

Doing so may result in an

electric shock.

(11) To dismount the equipment,

pay careful attention not to

tilt it.

Tilting the equipment may

cause water remaining in the

equipment to fall in drops,

thus wetting goods kept in

storage.

(12) Check whether or not the

refrigerating cycle part gets

hot, and then repair the

equipment.

(8) Do not wash the air

conditioner in water.

Doing so may result in an

electric shock or a fire.

Not doing so may result in a burn.

(9) Be sure to establish a ground

for the equipment.

(13) Use a welder in wellventilated areas.

Using the welder in an

enclosed room may result in

lack of oxygen.

Not doing so may result in

an electric shock.

<II. Precautions for Equipment after Construction and Repair>

WARNING

(14) To repair the equipment, be

sure to use parts listed in the

List of Service Parts for the

applicable model and proper

tools. Furthermore, NEVER

make any modification to the

equipment.

Not observing this warning will result

in an electric shock, heat generation,

or a fire.

Air Cooled Refrigeration Condensing Unit

(15) To install or relocate an air

conditioner, select a location

capable of supporting the

weight of the air conditioner.

The insufficient strength of the

location or improper installation of the

air conditioner will cause the unit to

drop, thus resulting in injury.

3

Introduction

SiENBE28-901

WARNING

(16) Conduct electrical works

according to information in

the "Electrical Equipment

Technical Standards",

"Internal Wiring

Regulations", and Installation

Manual, and further be sure

to use dedicated circuits.

Insufficient capacity of the

power supply circuit and

faulty electrical works will

result in an electric shock or

a fire.

(17) To make wirings between

indoor and outdoor units, use

specified wires to securely

connect them, and fix them so

that the external force of cables

will not be transmitted to

terminal connections.

Imperfect connections or fixing will

result in heat generation or a fire.

(18) To make wirings between

indoor and outdoor units or

for power supply, form wires

so that structures such as the

service lid will not be lifted,

and properly mount the lid.

Improperly mounting the lid will result

in heat generation of the terminal part,

an electric shock, or a fire.

(19) Do not cause damage to or

process the power supply cord.

Doing so will result in an

electric shock or a fire.

Putting heavy things on,

heating, or pulling the power

supply cord will result in

damage to it.

(20) Do not cause anything other

than the specified refrigerant

(e.g. air) to get mixed in the

refrigerant system.

Doing so will cause the refrigerant

system to have abnormally high

internal pressure, thus resulting in

damage to the equipment or bodily

injury.

(21) Should the equipment have

leakage of refrigerant gas,

locate leaking points, and then

repair them without fail.

Subsequently, refill the

equipment with a specified

quantity of refrigerant.

If no leaking points are located and

thereby repair work is to be

discontinued, perform pump-down

operation, and then close the service

valve. Not doing so will result in

refrigerant gas leakage.

The refrigerant gas itself is

harmless, but if it comes

into contact with a flame

from a fan heater, stove, or

stove burner, toxic gas will

be generated.

CAUTION

(22) A ground leakage circuit

breaker needs to be mounted.

Mounting no ground leakage circuit

breaker may result in an electric shock

or a fire.

4

(23) Do not install the equipment

in places with the potential

for leakage of flammable gas.

Should a flammable gas

leak to accumulate

around the equipment,

the gas may catch fire.

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Introduction

<III. Precautions after Construction and Repair>

WARNING

(24) Check power supply terminals

for deposition of dust or for

any loose terminals.

Deposition of dust on or

imperfect connections of

the terminals will result in

an electric shock or a fire.

Not doing so will result in an

electric shock, heat generation,

or a fire.

(26) Do not connect the power

supply cord halfway or with

many loads of other electrical

fittings on one electric outlet.

(25) Be sure to replace flawed or

deteriorated power supply

cord or lead wires.

Doing so will result in

an electric shock, heat

generation, or a fire.

CAUTION

(27) Check to be sure that the

mounting positions and

wiring conditions of parts as

well as the connections of

soldered parts and crimpstyle

terminals are all normal.

If any of these items is abnormal, an

electric shock, heat generation, or a

fire may result.

(28) If the installation base or

mounting frames are reduced

in strength due to corrosion,

replace them.

(30) After the completion of repair,

be sure to make measurement

of insulation resistance to

prove that it is not less than

1MΩ.

Insulation failures may result in an

electric shock.

(31) After the completion of repair,

be sure to check the indoor

unit for drainage.

Insufficient draining from the indoor

unit may result in the entry of water

into a room, thus wetting furniture

and household goods.

Not doing so may cause the equipment

to drop, thus resulting in injury.

(29) Check for the grounding

state. If the ground is in

an imperfect state,

rectify it.

Imperfect ground may

result in an electric shock.

Air Cooled Refrigeration Condensing Unit

5

Introduction

SiENBE28-901

Air Cooled Refrigeration Condensing Unit

Nomenclature

Outdoor unit

LR

M

E

Q

5

A

Y1

Power supply symbol

Y1: 3φ 380-415V, 50Hz

Indicates major design category

Capacity indication

5: 5HP

Refrigerant

Q: R-410A

Compressor type

E: Intermediate INJ type

Temperature zone to be used

M: Medium temperature (MT)

L: Low temperature (LT)

Product category

L: Low temperature air conditioner

R: Outdoor unit

6

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Standard Specification

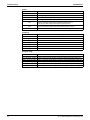

2. Standard Specification

2.1

Standard Specification

LRMEQ5AY1

[LRMEQ5AY1E]

Model 1

Power Supply

3 phase 50Hz 380-415V

Capacity 2

kW

Range of Suction Pressure Equivalent

Saturation Temperature

°C

Range of Outdoor Temperature

°C

Casing Color

12.2

-20~+10

-15~+43

mm

1680×635×765

Heat Exchanger

Cross fin coil

Type

Piston Displacement

Compressor Number of Revolutions

Motor Output × Number of Units

Hermetically sealed scroll type

m3/h

10.04

13.85

r.p.m

4740

6540

kW

2.3

Starting Method

Propeller fan

Motor Output

kW

Air Flow Rate

m3/min

0.35×1

95

Drive

Liquid Pipe

φ9.5 C1220T (Brazing connection)

Gas Pipe

φ19.1 C1220T (Brazing connection)

Mass

5.4

kg

Capacity Control

175

High Pressure Switch, Fan Driver Overload Protector, Overcurrent Relay,

Inverter Overload Protector, Fusible Plug

Safety Devices

Refrigerant

Oil

102

Direct drive

Receiver Volume

Refrigerant

3.2

Direct-on-line (Inverter system)

Type

Connecting

Pipes

14.4

Ivory white (5Y7.5/1) [Light camel (2.5Y6.5/1.5)]

Dimensions: (H×W×D)

Fan

LRMEQ6AY1

[LRMEQ6AY1E]

%

33~100

Refrigerant Name

Charge Volume

kg

5.2

Refrigerant Oil Name

Charge Volume

Operating Sound 3

24~100

R410A

DAPHNE FVC68D

L

dBA

Standard Accessories

1.7+2.5

54

56

Installation Manual, Operation Manual, Connection Pipes, Clamps

Notes:

H1 [ ] shows the anti-corrosion treatment type.

H2 Rated conditions of the refrigeration equipment :

Saturated temperature equivalent to suction pressure: -10°C

Outdoor air: 32°C, Suction SH: 10°C

H3 Measurement place: Front: 1m, Height: 1.5m

4 The minimum connection load with inside unit: 2.0kW

Air Cooled Refrigeration Condensing Unit

7

Standard Specification

SiENBE28-901

LRMEQ8AY1

[LRMEQ8AY1E]

Model 1

Power Supply

kW

Range of Suction Pressure Equivalent

Saturation Temperature

°C

Range of Outdoor Temperature

°C

18.6

21.8

-15~+43

Ivory white (5Y7.5/1) [Light camel (2.5Y6.5/1.5)]

Dimensions: (H×W×D)

mm

1680×930×765

Heat Exchanger

Cross fin coil

Type

Piston Displacement

Compressor Number of Revolutions

Motor Output × Number of Units

Hermetically sealed scroll type

m3/h

19.68

23.36

25.27

r.p.m

4320, 2900

6060, 2900

6960, 2900

kW

2.1+3.6

3.0+3.6

3.4+3.6

Starting Method

Direct-on-line (Inverter system)

Type

Propeller fan

Motor Output

kW

Air Flow Rate

m3/min

0.75×1

171

Drive

Liquid Pipe

φ9.5 C1220T (Brazing connection)

Gas Pipe

φ25.4 C1220T (Brazing connection)

Mass

Capacity Control

255

High Pressure Switch, Fan Driver Overload Protector, Overcurrent Relay,

Inverter Overload Protector, Fusible Plug

%

17~100

Refrigerant Name

Charge Volume

Charge Volume

14~100

13~100

R410A

kg

7.9

Refrigerant Oil Name

Operating Sound 3

191

8.1

kg

Safety Devices

Refrigerant

Oil

179

Direct drive

Receiver Volume

Refrigerant

24.4

-20~+10

Casing Color

Connecting

Pipes

LRMEQ12AY1

[LRMEQ12AY1E]

3 phase 50Hz 380-415V

Capacity 2

Fan

LRMEQ10AY1

[LRMEQ10AY1E]

DAPHNE FVC68D

L

dBA

Standard Accessories

1.7+2.1+3.0

57

59

61

Installation Manual, Operation Manual, Connection Pipes, Clamps

Notes:

H1 [ ] shows the anti-corrosion treatment type.

H2 Rated conditions of the refrigeration equipment :

Saturated temperature equivalent to suction pressure: -10°C

Outdoor air: 32°C, Suction SH: 10°C

H3 Measurement place: Front: 1m, Height: 1.5m

4 The minimum connection load with inside unit: 2.0kW

8

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Standard Specification

LRMEQ15AY1

[LRMEQ15AY1E]

Model 1

Power Supply

3 phase 50Hz 380-415V

Capacity 2

kW

Range of Suction Pressure Equivalent

Saturation Temperature

°C

Range of Outdoor Temperature

°C

Casing Color

32.2

37.0

-20~+10

-15~+43

Ivory white (5Y7.5/1) [Light camel (2.5Y6.5/1.5)]

Dimensions: (H×W×D)

mm

1680×1240×765

Heat Exchanger

Cross fin coil

Type

Piston Displacement

Compressor Number of Revolutions

Motor Output × Number of Units

Hermetically sealed scroll type

m3/h

30.00

35.80

r.p.m

5640, 2900

6960, 2900

kW

2.8+3.6+3.6

Starting Method

Propeller fan

Motor Output

kW

Air Flow Rate

m3/min

0.75×2

230

Drive

Connecting

Pipes

Liquid Pipe

φ12.7 C1220T (Brazing connection)

Gas Pipe

φ31.8 C1220T (Brazing connection)

Mass

12.1

kg

Capacity Control

355

High Pressure Switch, Fan Driver Overload Protector, Overcurrent Relay,

Inverter Overload Protector, Fusible Plug

Safety Devices

Refrigerant

Oil

240

Direct drive

Receiver Volume

Refrigerant

3.4+3.6+3.6

Direct-on-line (Inverter system)

Type

Fan

LRMEQ20AY1

[LRMEQ20AY1E]

%

10~100

Refrigerant Name

Charge Volume

kg

11.5

Refrigerant Oil Name

Charge Volume

Operating Sound 3

9~100

R410A

DAPHNE FVC68D

L

dBA

Standard Accessories

1.7+2.1+2.1+4.0

62

63

Installation Manual, Operation Manual, Connection Pipes, Clamps

Notes:

H1 [ ] shows the anti-corrosion treatment type.

H2 Rated conditions of the refrigeration equipment :

Saturated temperature equivalent to suction pressure: -10°C

Outdoor air: 32°C, Suction SH: 10°C

H3 Measurement place: Front: 1m, Height: 1.5m

4 The minimum connection load with inside unit: 2.0kW

Air Cooled Refrigeration Condensing Unit

9

Standard Specification

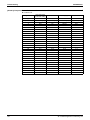

SiENBE28-901

LRLEQ5AY1

[LRLEQ5AY1E]

Model 1

Power Supply

3 phase 50Hz 380-415V

Capacity 2

kW

Range of Suction Pressure Equivalent

Saturation Temperature

°C

Range of Outdoor Temperature

°C

Casing Color

5.4

-45~-20

-15~+43

mm

1680×635×765

Heat Exchanger

Cross fin coil

Type

Piston Displacement

Compressor Number of Revolutions

Motor Output × Number of Units

Hermetically sealed scroll type

m3/h

10.04

13.85

r.p.m

4740

6540

kW

2.3

Starting Method

Propeller fan

Motor Output

kW

Air Flow Rate

m3/min

0.35×1

95

Drive

Liquid Pipe

φ9.5 C1220T (Brazing connection)

Gas Pipe

φ19.1 C1220T (Brazing connection)

Mass

5.4

kg

Capacity Control

175

High Pressure Switch, Fan Driver Overload Protector, Overcurrent Relay,

Inverter Overload Protector, Fusible Plug

Safety Devices

Refrigerant

Oil

102

Direct drive

Receiver Volume

Refrigerant

3.2

Direct-on-line (Inverter system)

Type

Connecting

Pipes

6.3

Ivory white (5Y7.5/1) [Light camel (2.5Y6.5/1.5)]

Dimensions: (H×W×D)

Fan

LRLEQ6AY1

[LRLEQ6AY1E]

%

33~100

Refrigerant Name

Charge Volume

kg

5.2

Refrigerant Oil Name

Charge Volume

Operating Sound 3

24~100

R410A

DAPHNE FVC68D

L

dBA

Standard Accessories

1.7+2.5

54

56

Installation Manual, Operation Manual, Connection Pipes, Clamps

Notes:

H1 [ ] shows the anti-corrosion treatment type.

H2 Rated conditions of the refrigeration equipment :

Saturated temperature equivalent to suction pressure: -35°C

Outdoor air: 32°C, Suction SH: 10°C

H3 Measurement place: Front: 1m, Height: 1.5m

4 The minimum connection load with inside unit: 1.6kW

10

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Standard Specification

LRLEQ8AY1

[LRLEQ8AY1E]

Model 1

Power Supply

kW

Range of Suction Pressure Equivalent

Saturation Temperature

°C

Range of Outdoor Temperature

°C

8.0

9.4

-15~+43

Ivory white (5Y7.5/1) [Light camel (2.5Y6.5/1.5)]

Dimensions: (H×W×D)

mm

1680×930×765

Heat Exchanger

Cross fin coil

Type

Piston Displacement

Compressor Number of Revolutions

Motor Output × Number of Units

Hermetically sealed scroll type

m3/h

19.68

23.36

25.27

r.p.m

4320, 2900

6060, 2900

6960, 2900

kW

2.1+3.6

3.0+3.6

3.4+3.6

Starting Method

Direct-on-line (Inverter system)

Type

Propeller fan

Motor Output

kW

Air Flow Rate

m3/min

0.75×1

171

Drive

Liquid Pipe

φ9.5 C1220T (Brazing connection)

Gas Pipe

φ25.4 C1220T (Brazing connection)

Mass

Capacity Control

255

High Pressure Switch, Fan Driver Overload Protector, Overcurrent Relay,

Inverter Overload Protector, Fusible Plug

%

17~100

Refrigerant Name

Charge Volume

Charge Volume

14~100

13~100

R410A

kg

7.9

Refrigerant Oil Name

Operating Sound 3

191

8.1

kg

Safety Devices

Refrigerant

Oil

179

Direct drive

Receiver Volume

Refrigerant

10.3

-45~-20

Casing Color

Connecting

Pipes

LRLEQ12AY1

[LRLEQ12AY1E]

3 phase 50Hz 380-415V

Capacity 2

Fan

LRLEQ10AY1

[LRLEQ10AY1E]

DAPHNE FVC68D

L

dBA

Standard Accessories

1.7+2.1+3.0

57

59

61

Installation Manual, Operation Manual, Connection Pipes, Clamps

Notes:

H1 [ ] shows the anti-corrosion treatment type.

H2 Rated conditions of the refrigeration equipment :

Saturated temperature equivalent to suction pressure: -35°C

Outdoor air: 32°C, Suction SH: 10°C

H3 Measurement place: Front: 1m, Height: 1.5m

4 The minimum connection load with inside unit: 1.6kW

Air Cooled Refrigeration Condensing Unit

11

Standard Specification

SiENBE28-901

LRLEQ15AY1

[LRLEQ15AY1E]

Model 1

Power Supply

3 phase 50Hz 380-415V

Capacity 2

kW

Range of Suction Pressure Equivalent

Saturation Temperature

°C

Range of Outdoor Temperature

°C

Casing Color

13.6

15.1

-45~-20

-15~+43

Ivory white (5Y7.5/1) [Light camel (2.5Y6.5/1.5)]

Dimensions: (H×W×D)

mm

1680×1240×765

Heat Exchanger

Cross fin coil

Type

Piston Displacement

Compressor Number of Revolutions

Motor Output × Number of Units

Hermetically sealed scroll type

m3/h

30.00

35.80

r.p.m

5640, 2900

6960, 2900

kW

2.8+3.6+3.6

Starting Method

Propeller fan

Motor Output

kW

Air Flow Rate

m3/min

0.75×2

230

Drive

Connecting

Pipes

Liquid Pipe

φ12.7 C1220T (Brazing connection)

Gas Pipe

φ31.8 C1220T (Brazing connection)

Mass

12.1

kg

Capacity Control

355

High Pressure Switch, Fan Driver Overload Protector, Overcurrent Relay,

Inverter Overload Protector, Fusible Plug

Safety Devices

Refrigerant

Oil

240

Direct drive

Receiver Volume

Refrigerant

3.4+3.6+3.6

Direct-on-line (Inverter system)

Type

Fan

LRLEQ20AY1

[LRLEQ20AY1E]

%

10~100

Refrigerant Name

Charge Volume

kg

11.5

Refrigerant Oil Name

Charge Volume

Operating Sound 3

9~100

R410A

DAPHNE FVC68D

L

dBA

Standard Accessories

1.7+2.1+2.1+4.0

62

63

Installation Manual, Operation Manual, Connection Pipes, Clamps

Notes:

H1 [ ] shows the anti-corrosion treatment type.

H2 Rated conditions of the refrigeration equipment :

Saturated temperature equivalent to suction pressure: -35°C

Outdoor air: 32°C, Suction SH: 10°C

H3 Measurement place: Front: 1m, Height: 1.5m

4 The minimum connection load with inside unit: 1.6kW

12

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

2.2

Standard Specification

Set Values for Functional Components and Protection

Devices

Component

Inverter

Compressor

STD1

STD2

Electric symbol

Type

Overcurrent protection device

Type

Overcurrent protection device

Type

Overcurrent protection device

Output

Fan motor

Overcurrent protection device

Output

Overcurrent protection device

PCB

M2C

M3C

M1F

M2F

A1P

PCB for compressor INV

A3P

JT17GFKTNYE@SB

—

13A

—

—

—

—

1.5A

3.0A

—

—

750W

—

—

3.0A

Standard:EB09058

Standard:PC0509-2

A7P

—

EB0292(C)

—

A9P

EC0729(A)-29

UKV-A023

UKV-A023

UKV-A024

DC12V, 0.26A

DC12V, 0.26A

DC12V, 0.26A

UKV-32D49

0~480pls

Coil

Y2E

(Gas)

UKV-A023

UKV-A023

UKV-A024

DC12V, 0.26A

DC12V, 0.26A

DC12V, 0.26A

UKV-18D20

Body

0~480pls

Coil

Y3E

(M1C)

Body

Coil

Four way valve

Body

Coil

Body

Solenoid valve

Coil

Body

Type

Set value

Type

High pressure

switch

Pressure protection device

Set value

Type

Set value

UKV-A023

UKV-A024

—

DC12V, 0.26A

DC12V, 0.26A

—

UKV-32D49

Y3S

Y2S

(M2C)

Y5S

(M3C)

S1PH

S2PH

S3PH

0~480pls

STF-G01AQ531A1

STF-G01AQ532A1

STF-0404G

STF-0713G

STF-G01AQ537A1

STF2011G

—

NEV-MOAJ562D1

NEV-MOAJ562D1

—

VPV-603D

VPV-603D

—

—

NEV-MOAJ562C1

—

—

VPV-603D

ACB-1TB29W

ACB-1TB28W

ACB-1TB27W

OFF 3.8

+0

-0.1

MPa

—

ON 2.85±0.15MPa

ACB-1TB27W

—

OFF 3.8

+0

-0.1

ACB-1TB27W

MPa

ON 2.85±0.15MPa

—

—

ACB-1TB27W

—

—

OFF 3.8 -0.1 MPa

ON 2.85±0.15MPa

+0

ACB-JB285

S4PH

DC5V ON: 2.96

+0

-0.1

MPa OFF: 2.16±0.15MPa

Low pressure sensor

S1NPL

150NH4-L2

200NH4-L2

200NH4-L2

High pressure sensor

S1NPH

150NH4-H4

150NH4-H4

200NH4-H4

Fusible plug

Thermistor

—

—

Type

Set value

EB0292(C)

EC0726(A)-9

Body

Electronic expansion valve

PC0511-2(A)

FN354-H-1(A)

—

Y1E

(Main)

PC0511-1(A)

—

EB0568(A)

A6P

Coil

13A

750W

—

A2P

JT17GFKTNYE@SB

350W

A8P

PCB for noise filter

PCB for earth leakage detection

14.7A

—

PC0511-3(A)

A5P

LRMEQ15AY1,20AY1

LRLEQ15AY1,20AY1

JT1GFDKTNYR@SB

A4P

PCB for operation input

PCB for current sensor

LRMEQ8AY1,10AY1,12AY1

LRLEQ8AY1,10AY1,12AY1

M1C

Main PCB

PCB for fan INV

LRMEQ5AY1,6AY1

LRLEQ5AY1,6AY1

—

Open: 70~75°C

Outdoor air thermistor

R1T

ST8603

Suction pipe thermistor

R2T

ST0602

Outdoor heat exchanger outlet

thermistor

R3T

ST8602A

Subcooling heat exchanger outlet

thermistor

R5T

ST0601

Subcooling heat exchanger inlet

thermistor

R6T

ST0601

R31T

Discharge pipe thermistor

ST0901

R32T

—

R33T

—

ST0901

—

Fuse (A1P)

F1U, F2U

250VAC 3.15A, Class T

Fuse

F3U, F4U

250VAC 1.0A, Class T

S1S

AR22PR-311B Z9

Operation switch

Air Cooled Refrigeration Condensing Unit

ST0901

13

Standard Specification

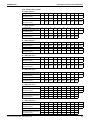

2.3

SiENBE28-901

Operation Limits

LRLEQ5, 6, 8, 10, 12, 15, 20AY1(E)

43

40

30

25

20

15

10

5

0

Range for pull down operation

Range for continuous operation

Outdoor temperature (°CDB)

35

-5

-10

-15

-45 -40 -35 -30 -25 -20 -15

5

10

30

35

40

Evaporating temperature (°C)

4D064913

LRMEQ5, 6, 8, 10, 12, 15, 20AY1(E)

43

40

Range for pull down

operation

30

Range for continuous operation

Outdoor temperature (°CDB)

35

25

20

15

10

5

0

-5

-10

-15

-20 -15 -10

-5

0

5

10

30

35

40

Evaporating temperature (°C)

4D064914

NOTES

∗1. “Range for continuous operation” SHOWS POSSIBLE RANGE OF CONTINUOUS OPERATION.

∗2. “Range for pull down operation” SHOWS POSSIBLE RANGE OF SHORT-TIME OPERATION.

• DO NOT SELECT THE MODEL IN THE RANGE FOR PULL DOWN OPERATION.

• TO BE MORE THAN 3°C/HOUR THAT THE TEMPERATURE OF INDOOR UNIT DROPS.

DO NOT OPEN THE DOOR AND DO NOT ENTER THE GOODS IN PULL DOWN OPERATION AS

MUCH AS.

14

Air Cooled Refrigeration Condensing Unit

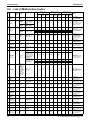

X1A

X2A

RY1

X3A

NOTE)10

A9P

BLK

RED

L1 L2 L3 N

WHT

T2A

N=1

: TERMINAL STRIP

3.

X400A

A2P

M1C

MS

3~

V

U

R50 R59

C66 C63

: CONNECTOR

Z3C

N=5

WHT

P2

L1R

WHT

P1

A3P

K4M

W

Z10C

N=4

GRN

GRN

X5A

P3

N3

t°

R1T

BLK

RED

X1A

Z5C

N=1

F1U

P1

Z2C

N=1

X1A

X3A

X5A

A4P

Z4C

N=1

X4A

X6A

X61A

X402A

BLK

BLU

RED

M1F

MS

3~

5

5

F2U

F1U

X2A

X4A

X2A

V1R

R10

N1

X20A

X28A

X1A

A1P

: PROTECTIVE EARTH (SCREW)

X111A

X41A

: TERMINAL

X11A

V1R

R95

K1R

V2R

PS

X1A

X10A

K2M

X403A

C1

X401A

F400U

K3R

Z1F

WHT

CAPACITOR

REFER TO TECHNICAL GUIDE FOR THE OPERATION TIMING DIAGRAM.

10. RY1 POINT CONTACT IS OPEN BEFORE TURNING ON POWER SUPPLY.

MAGNETIC RELAY

MAGNETIC CONTACTOR (M1C)

K2M, K4M

PILOTLAMP (SERVICE MONITOR-GREEN)

K1R, K3R

HAP

H1P~8P

PILOTLAMP (SERVICE MONITOR-ORANGE)

[H2P] MALFUNCTION DETECTION --- LIGHT UP

FUSE (T, 6.3A, 250V) (A2P)

F400U

DIP SWITCH (A1P)

CAPACITOR (A3P)

7. HOW TO USE BS1~5 AND DS1 AND DS2 SWITCH, REFER TO "SERVICE PRECAUTION" LABEL ON EL. COMPO. BOX COVER.

DS1, DS2

C63, C66

C1

R95

R1T

OFF

ON

1234

DS2

R5T

t°

X30A

PRESSURE SENSOR (HIGH)

MAGNETIC RELAY (A9P)

THERMISTOR (HEAT EX, OF SUBCOOL INLET)

THERMISTOR (HEAT EX, OF SUBCOOL OUTLET)

THERMISTOR (HEAT EXC, DEICER)

THERMISTOR (M1C DISCHARGE)

THERMISTOR (SUCTION)

THERMISTOR (FIN) (A3P)

THERMISTOR (AIR) (A1P)

RESISTOR (CURRENT LIMITING)

RESISTOR (A3P)

RESISTOR (CURRENT SENSOR) (A4P)

PHASE REVERSAL DETECT CIRCUIT

SWITCHING POWER SUPPLY (A1P, A3P)

MOTOR (FAN)

MOTOR (COMPRESSOR)

REACTOR (A3P)

Z1F

R1T

S4PH

M

Y2E

M

Y1E

W

X2A

X1A

OUTER SHELL

M1C

A2P

A3P

X1M

S1S

X3M

A4P

L1R

A1P

3D059917C

NOISE FILTER (WITH SURGE ABSORBER) (A2P)

NOISE FILTER (FERRITE CORE)

SOLENOID VALVE (4 WAY VALVE)

ELECTRONIC EXPANSION VALVE (GAS)

ELECTRONIC EXPANSION VALVE (MAIN)

TERMINAL STRIP (REMOTE SWITCH)

TERMINAL STRIP

TERMINAL STRIP (OPERATION) (A5P)

TERMINAL STRIP (POWER SUPPLY)

CONNECTOR (M1F)

DIODE BRIDGE (A3P)

POWER MODULE (A3P, A4P)

SAFETY DEVICES INPUT

CURRENT SENSOR (A9P)

PRESSURE SWITCH (HIGH)

OPERATION SWITCH (REMOTE / OFF / ON)

PRESSURE SWITCH (HIGH)

(BACK)

(FRONT)

X2M

A5P

CONTROL, BOX

CONTROL, BOX

A9P

M1F

V

LAYOUT OF M1C, M1F

U

TERMINAL OF M1C

PRESSURE SENSOR (LOW)

5

WHT BLK

5

S1NPH

S1NPL

P<

t°

Z1C~5C, Z10C

Y3S

Y2E

Y1E

X3M

X2M

X1M

X1M

X1A, X2A

V2R

V1R

V1CP

T2A

S4PH

S1S

S1PH

S1NPL

R6T

t°

BLK

X21A

X32A

X31A

X18A

X36A

X22A

MAGNETIC RELAY (OPERATING OUTPUT)

MAGNETIC RELAY (WARNING OUTPUT)

MAGNETIC RELAY (Y3S)

MAGNETIC RELAY (CAUTION OUTPUT)

SWITCH

NOTE)4

R3T

R2T

X29A

COMPONENT LEAD WIER.

R31T

X3M

1

2

HAP

CIRCUIT BOARD.

IS CONNECTOR COLOR FOR COMPONENT.

IS DISCRIMINATION COLOR FOR

t°

S1NPH

RY1

R6T

R5T

R3T

R31T

R2T

R1T

1234

DS1

t°

R50, R59

R10

OFF

ON

BS1 BS2 BS3 BS4 BS5

H1P H2P H3P H4P H5P H6P H7P H8P

IS CONNECTOR COLOR FOR PRINTED

PS

t°

Q1RP

PS

M1F

M1C

PRINTED CIRCUIT BOARD (EARTH LEAKAGE DETECTOR)

PUSH BUTTON SWITCH

(MODE, SET, RETURN, TEST, RESET)

A9P

BS1~5

6. BE NOTED THAT THE CAPACITY OF CONTACT IS AC220~240V, 0.5A. (OPERATING OUTPUT)

9. COLORS BLK: BLACK RED: RED BLU: BLUE WHT: WHITE GRN: GREEN.

K6R

L1R

PRINTED CIRCUIT BOARD (ABC I / P)

K10R

PRINTED CIRCUIT BOARD (FAN)

A5P

FUSE (8A, DC650V) (A4P)

8. WHEN OPERATING, DON'T SHORTCIRCUIT THE PROTECTION DEVICE (S1PH).

1

K3R

2

ON

A4P

FUSE (T, 3.15A, 250V) (A1P)

5. BE NOTED THAT THE CAPACITY OF CONTACT IS AC220~240V, 0.5A. (TOTAL OF CAUTION OUTPUT, WARNING OUTPUT)

OFF

PRINTED CIRCUIT BOARD (INV)

3

REMOTE

4

S1S

C

A3P

B

X2M

PRINTED CIRCUIT BOARD (MAIN)

A

FUSE (T, 1.0A, 250V)

(FOR THE REMOTE SWITCH, USE NON-VOLTAGE CONTACT FOR MICROCURRENT (NOT MORE THAN 1mA DC12V))

THE POINT OF CONTACT OF THE INPUT MUST USE THE ONE FOR A SLIGHT CURRENT.

P1 P2

PRINTED CIRCUIT BOARD (NOISE FILTER) K5R

X1M

C1 W1

F4U

X14A

A2P

X1A

A5P

C

X10A

CAUTION WARNING OPERATING

OUTPUT OUTPUT

OUTPUT

NOTE)5

NOTE)5

NOTE)6

F3U

Y3S

X9A

K10R

A1P

X66A

X7A

K3R

F3U, F4U

X4A

X3A

X2A

K5R

F1U, F2U

V1CP

S1PH

P<

Q1RP

K6R

F1U

4. AT THE TIME OF FACTORY SHIPMENT, SETTING OF "OFF". WHEN OPERATING, SETTING OF "ON" OR "REMOTE".

: FIELD WIRING.

2.

ONLY TO THE OUTDOOR UNIT.

NOTES)

1. THIS WIRING DIAGRAM IS APPLIED

X1M

RED

RED

BLU

RED

Z1C N=1

WHT

WHT

BLU

POWER SUPPLY

BLK

BLK

BLK

Y1: 380-415V 3N~50Hz

RED

Air Cooled Refrigeration Condensing Unit

WHT

2.4

BLK

L1 L2 L3 N

SiENBE28-901

Standard Specification

Wiring Diagram

LRLEQ5A, 6AY1(E)

LRMEQ5A, 6AY1(E)

15

X3A

Z7C

N=5

U

M2C

M

3~

V

W

U

T

W

S

V

R

K2M

BLK

A6P

T1A

X1A

: TERMINAL STRIP

3.

M1C

MS

3~

W

V

U

R50 R59

C66 C63

: CONNECTOR

Z3C

N=5

WHT

P2

GRN C1

X403A

t°

RED

BLK

X1A

Z5C

N=1

X1A

X3A

X5A

A4P

Z4C

N=1

X4A

X6A

X61A

X402A

F1U

P1

Z2C

N=1

BLK

BLU

RED

MS

3~

M1F

5

5

F2U

F1U

X2A

X4A

X2A

V1R

R10

N1

X20A

X28A

X26A

X1A

A1P

: PROTECTIVE EARTH (SCREW)

X111A

X41A

X5A

P3

N3

X1A

PS

R1T

: TERMINAL

X11A

V1R

R95

K1R

V2R

K2M

X10A

X401A

K3R

F400U

Z1F

GRN

A2

K2M

A

B

3

REMOTE

4

S1S

C

1234

DS2

R3T

t°

R5T

t°

Q1RP

PS

PHASE REVERSAL DETECT CIRCUIT

SWITCHING POWER SUPPLY (A1P, A3P)

MAGNETIC CONTACTOR (M2C)

K2M

S1NPH

RY1

R6T

R5T

Z1C~7C, Z10C

MAGNETIC RELAY

THERMSITOR (HEAT EX, OF SUBCOOL OUTLET)

PILOTLAMP (SERVICE MONITOR-GREEN)

R3T

MAGNETIC CONTACTOR (M1C)

Y3S

THERMSITOR (HEAT EXC, DEICER)

R31T, R32T

[H2]MALFUNCTION DETECTION---LIGHT UP

Y3E

Y2S

PRESSURE SENSOR (HIGH)

MAGNETIC RELAY (A9P)

THERMSITOR (HEAT EX, OF SUBCOOL INLET) Z1F

THERMSITOR (SUCTION)

Y2E

THERMSITOR (M1C, M2C DISCHARGE)

R2T

PILOTLAMP (SERVICE MONITOR-ORANGE)

THERMSITOR (FIN) (A3P)

R1T

FUSE (T, 6.3A, 250V) (A2P)

Y1E

X3M

X2M

X1M

X1M

X1A, X2A

H1P~8P

THERMSITOR (AIR) (A1P)

RESISTOR (CURRENT LIMITING)

RESISTOR (A3P)

RESISTOR (CURRENT SENSOR) (A4P, A5P)

F400U

R1T

R95

R50, R59

R10

V

W

M

Y3E

M

Y2E

M

Y1E

X2A

CONTROL, BOX

A2P

A3P

A6P

A4P

L1R

X3M

3D059918C

NOISE FILTER (WITH SURGE ABSORBER) (A2P)

NOISE FILTER (FERRITE CORE)

SOLENOID VALVE (4 WAY VALVE)

SOLENOID VALVE (M2C)

ELECTRONIC EXPANSION VALVE (M1C)

ELECTRONIC EXPANSION VALVE (GAS)

ELECTRONIC EXPANSION VALVE (MAIN)

TERMINAL STRIP (REMOTE SWITCH)

TERMINAL STRIP

TERMINAL STRIP (OPERATION) (A5P)

TERMINAL STRIP (POWER SUPPLY)

CONNECTOR (M1F)

DIODE BRIDGE (A3P)

POWER MODULE (A3P, A4P)

SAFETY DEVICES INPUT

CURRENT SENSOR (A9P)

CURRENT SENSOR (A6P)

PRESSURE SWITCH (HIGH)

OPERATION SWITCH (REMOTE/OFF/ON)

PRESSURE SWITCH (HIGH)

A1P

K2M

(BACK)

(FRONT)

X1M

X2M

S1S

A5P

OUTER SHELL

M2C

M1C

CONTROL. BOX

A9P

X1A

M1F

LAYOUT OF M1C, M2C, M1F

U

TERMINAL OF M1C, M2C

PRESSURE SENSOR (LOW)

5

WHT BLU

5

WHT BLK

5

S1NPH

FUSE (T, 1.0A, 250V)

FUSE (T, 3.15A, 250V) (A1P)

FUSE (8A, DC650V) (A4P)

DIP SWITCH (A1P)

CAPACITOR (A3P)

CAPACITOR

V2R

V1R

V1CP

T2A

T1A

S4PH

S1S

R1T

S4PH

S1NPL

S1PH, S2PH

S1NPL

t°

P<

F3U, F4U

F1U, F2U

F1U

DS1, DS2

C63, C66

C1

MOTOR (FAN)

M1C, M2C

M1F

REACTOR (A3P)

L1R

MAGNETIC RELAY (OPERATING OUTPUT)

MOTOR (COMPRESSOR)

K10R

(MODE, SET, RETURN, TEST, RESET)

R6T

t°

X23A

BLU

BLK

X21A

X32A

X31A

X18A

X22A

MAGNETIC RELAY (WARNING OUTPUT)

MAGNETIC RELAY (Y3S)

MAGNETIC RELAY (Y2S)

MAGNETIC RELAY (CAUTION OUTPUT)

MAGNETIC RELAY (K2M)

SWITCH

NOTE)4

R2T

t°

X30A

PUSH BUTTON SWITCH

BS1~5

HAP

IS CONNECTOR COLOR FOR COMPONENT.

IS DISCRIMINATION COLOR FOR

COMPONENT LEAD WIRE.

PRINTED CIRCUIT BOARD (EARTH LEAKAGE DETECTOR)

HAP

9. COLORS BLK:BLACK RED:RED BLU:BLUE WHT:WHITE CRN:GREEN.

OFF

ON

IS CONNECTOR COLOR FOR

PRINTED CIRCUIT

1234

DS1

BS1 BS2 BS3 BS4 BS5

X36A

H1P H2P H3P H4P H5P H6P H7P H8P

PRINTED CIRCUIT BOARD (CURRENT SENSOR)

K6R

K5R

K4R

K3R

K1R

X3M

1

2

R32T

t°

X29A

ON

OFF

PS

A9P

PRINTED CIRCUIT BOARD (ABC I/P)

PRINTED CIRCUIT BOARD (FAN)

PRINTED CIRCUIT BOARD (INV)

PRINTED CIRCUIT BOARD (NOISE FILTER)

2

t°

R31T

ON

1

X2M

OFF

PRINTED CIRCUIT BOARD (MAIN)

X1M

OPERATING

OUTPUT

NOTE)6

P1 P2

F4U

X14A

K10R

A6P

A5P

A4P

A3P

A2P

A1P

X1A

C1 W1

X10A

CAUTION WARNING

OUTPUT OUTPUT

NOTE)5 NOTE)5

C

F3U

Y3S

X9A

K2M, K4M

X66A

A5P

Y2S

X8A

K4R

K1R, K3R

X5A

K1R

K3R

X7A

K5R

REFER TO TECHNICAL GUIDE FOR THE OPERATION TIMING DIAGRAM.

WHT

RED

X4A

X3A

X2A

K6R

10. RY1 POINT CONTACT IS OPEN BEFORE TURNING ON POWER SUPPLY.

8. WHEN OPERATING, DON'T SHORTCIRCUIT THE PROTECTION DEVICE (S1PH, S2PH).

7. HOW TO USE BS1~5 AND DS1 AND DS2 SWITCH, REFER TO "SERVICE PRECAUTION" LABEL ON EL. COMPO. BOX COVER.

6. BE NOTED THAT THE CAPACITY OF CONTACT IS AC220~240V, 0.5A. (OPERATING OUTPUT)

P<

P<

Q1RP

V1CP

S2PH

S1PH

A1

5. BE NOTED THAT THE CAPACITY OF CONTACT IS AC220~240V, 0.5A. (TOTAL OF CAUTION OUTPUT, WARNING OUTPUT)

NON-VOLTAGE CONTACT FOR MICROCURRENT (NOT MORE THAN 1mA DC12V))

POINT OF CONTACT OF THE INPUT MUST USE THE ONE FOR A SLIGHT CURRENT. (FOR THE REMOTE SWITCH, USE

4. AT THE TIME OF FACTORY SHIPMENT, SETTING OF "OFF". WHEN OPERATING, SETTING OF "ON" OR "REMOTE". THE

: FIELD WIRING.

2.

TO THE OUTDOOR UNIT.

WHT

P1

A3P

K4M

T2A

N=1 Z1C

N=1

X400A

L1R

A2P

Z6C

N=1

1. THIS WIRING DIAGRAM IS APPLIED ONLY

NOTES)

NOTE) 10

X2A

RY1

X1A

N BLU

N

A9P

L3

L3

Z10C

N=4

WHT

WHT

L2

RED

L2

RED

BLU

POWER SUPPLY

Y1: 380-415V 3N~50Hz

BLK

RED

WHT

RED

WHT

BLK

BLK

WHT

BLK

RED

RED

L1

BLK

X1M

WHT

16

L1

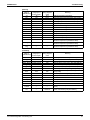

Standard Specification

SiENBE28-901

LRLEQ8A, 10A, 12AY1(E)

LRMEQ8A, 10A, 12AY1(E)

Air Cooled Refrigeration Condensing Unit

W

: TERMINAL STRIP

TO THE OUTDOOR UNIT.

: FIELD WIRING.

P1

A3P

: CONNECTOR

M1C

MS

3~

W

V

R50 R59

C66 C63

U

WHT

P2

L1R

K4M

X400A

Z1C

N=1

K3R

Z3C

N=5

P3

N3

t°

X111A

X41A

X5A

PS

X1A

X403A

BLU

:TERMINAL

X11A

V1R

R95

K1R

V2R

K2M

X10A

X401A

WHT

R1T

GRN

F400U

Z1F

C1

BLK

RED

F1U

P2 N1

Z2C

N=1

M1F

MS

3~

N2

X2A

X3A

5

5

X20A

X28A

X25A

X26A

X2A

X4A

X51A

RED

WHT

F1U

A5P

4

3

REMOTE

S1S

OFF

C

2

PUSH BUTTON SWITCH

CAPACITOR (A3P)

R6T

t°

MAGNETIC RELAY (Y2S)

RESISTOR (CURRENT LIMITING)

RESISTOR (A3P)

THERMISTOR (M1C~3C DISCHARGE)

THERMISTOR (HEAT EXC, DEICER)

R2T

R31~33T

R3T

[H2P] MALFUNCTION DETECTION---LIGHT UP

MAGNETIC CONTACTOR (M1C)

MAGNETIC CONTACTOR (M2C, M3C)

MAGNETIC RELAY (K2M, K3M)

K2M, K3M

K1R, K2R

S1NPL

S1NPH

RY1

R6T

PILOTLAMP (SERVICE MONITOR-GREEN) R5T

MAGNETIC RELAY

K2M, K4M

PRESSURE SENSOR (LOW)

PRESSURE SENSOR (HIGH)

MAGNETIC RELAY (A9P)

R1T

Y5S

Y3S

Y2S

Y3E

Y2E

Y1E

X3M

X2M

X1M

X1M

X105A

X1A~4A

V2R

V1R

V1CP

T2A

T1A

S1S

S4PH

Z1F

5

V

W

M2F

A2P

A3P

X1M

X2A X4A

X1A X3A

A9P

(BACK)

X3M

A5P

3D063035B

NOISE FILTER (WITH SURGE ABSORBER) (A2P)

NOISE FILTER (FERRITE CORE)

SOLENOID VALVE (M3C)

SOLENOID VALVE (4 WAY VALVE)

SOLENOID VALVE (M2C)

ELECTRONIC EXPANSION VALVE (M1C)

ELECTRONIC EXPANSION VALVE (GAS)

ELECTRONIC EXPANSION VALVE (MAIN)

TERMINAL STRIP (REMOTE SWITCH)

TERMINAL STRIP

TERMINAL STRIP (OPERATION) (A5P)

TERMINAL STRIP (POWER SUPPLY)

CONNECTOR (S3PH)

CONNECTOR (M1F, M2F)

DIODE BRIDGE (A3P)

POWER MODULE (A3P, A4P, A8P)

SAFETY DEVICES INPUT

CURRENT SENSOR (A9P)

CURRENT SENSOR (A6P, A7P)

OPERATION SWITCH (REMOTE/OFF/ON)

PRESSURE SWITCH (HIGH)

A8P

A4P

L1R

K3M

A7P

A1P

(FRONT)

K2M

A6P

X2M

S1S

CONTROL. BOX

OUTER SHELL

M3C

M2C

M1C

CONTROL, BOX

PRESSURE SWITCH (HIGH)

M

Y3E

M

Y2E

M

M1F

LAYOUT OF M1C~M3C, M1F, M2F

U

TERMINAL OF M1C~M3C

Y1E

WHT BLU

5

WHT BLK

5

S1NPH

S1NPL

THERMISTOR (HEAT EX, OF SUBCOOL INLET) Z1C~10C

THERMISTOR (HEAT EX, OF SUBCOOL OUTLET)

THERMISTOR (SUCTION)

THERMISTOR (FIN) (A3P)

PILOTLAMP (SERVICE MONITOR-ORANGE)

R1T

H1P~8P

THERMISTOR (AIR) (A1P)

t°

P< S4PH

S1PH~3PH

BLU

RESISTOR (CURRENT SENSOR) (A4P, A8P)

PHASE REVERSAL DETECT CIRCUIT

SWITCHING POWER SUPPLY (A1P, A3P)

MOTOR (FAN)

MOTOR (COMPRESSOR)

REACTOR (A3P)

MAGNETIC RELAY (Y5S)

MAGNETIC RELAY (OPERATING OUTPUT)

MAGNETIC RELAY (WARNING OUTPUT)

MAGNETIC RELAY (Y3S)

FUSE (T, 6.3A, 250V) (A2P)

K1R,K3R

9. COLORS BLK:BLACK RED:RED BLU:BLUE WHT:WHITE GRN:GREEN.

R5T

t°

X23A

MAGNETIC RELAY (CAUTION OUTPUT)

SWITCH

R3T

t°

X30A

BLK

X21A

X32A

X31A

X18A

X22A

F400U

R1T

R95

R50, R59

R10

Q1RP

PS

M1F, M2F

M1C~3C

L1R

K11R

K10R

K6R

1234

DS2

FUSE (T, 1.0A, 250V)

FUSE (T, 3.15A, 250V) (A1P)

FUSE (8A, DC650V) (A4P, A8P)

DIP SWITCH (A1P)

K4R

K5R

OFF

ON

F3U, F4U

F1U, F2U

F1U

DS1, DS2

C63, C66

CAPACITOR

(MODE, SET, RETURN, TEST, RESET)

PRINTED CIRCUIT BOARD (EARTH LEAKAGE DETECTOR)

C1

PRINTED CIRCUIT BOARD (CURRENT SENSOR)

A6P, A7P

BS1~5

A5P

A9P

PRINTED CIRCUIT BOARD (FAN)

PRINTED CIRCUIT BOARD (ABC I/P)

A4P, A8P

PRINTED CIRCUIT BOARD (NOISE FILTER)

K3R

R2T

R33T

R32T

R31T

NOTE)4

t°

t°

X3M

1

2

1234

DS1

IS CONNECTOR COLOR FOR COMPONENT.

IS DISCRIMINATION COLOR FOR

COMPONENT LEAD WIRE.

t°

ON

1

PRINTED CIRCUIT BOARD (MAIN)

B

X29A

OFF

ON

HAP

X36A

H5P H6P H7P H8P

BS1 BS2 BS3 BS4 BS5

H1P H2P H3P H4P

IS CONNECTOR COLOR FOR PRINTED

CIRCUIT BOARD.

PS

t°

P1 P2 X2M

PRINTED CIRCUIT BOARD (INV)

A

X1M

C1 W1

Y5S

X15A

X14A

A3P

A2P

A1P

X1A

C

F4U

CAUTION WARNING OPERATING

OUTPUT OUTPUT

OUTPUT

NOTE)5

NOTE)5

NOTE)6

F3U

Y3S

X10A

X9A

HAP

5

WHT

X4A

RED

X4A

X6A

X66A

Y2S

X8A

X7A

REFER TO TECHNICAL GUIDE FOR THE OPERATION TIMING DIAGRAM.

M2F

MS

3~

5

X4A

X3A

X2A

K2R

X5A

K1R

X2A

V1R

R10

N1

RED

WHT

WHT

RED

V1CP

X105A

P<

P<

Q1RP

10. RY1 POINT CONTACT IS OPEN BEFORE TURNING ON POWER SUPPLY.

8. WHEN OPERATING, DON'T SHORTCIRCUIT THE PROTECTION DEVICE (S1PH~S3PH).

7. HOW TO USE BS1~5, DS1 AND DS2 SWITCH, REFER TO "SERVICE PRECAUTION" LABEL ON EL. COMPO. BOX COVER.

6. BE NOTED THAT THE CAPACITY OF CONTACT IS AC220~240V, 0.5A. (OPERATING OUTPUT)

5. BE NOTED THAT THE CAPACITY OF CONTACT IS AC220~240V, 0.5A. (TOTAL OF CAUTION OUTPUT, WARNING OUTPUT)

(FOR THE REMOTE SWITCH, USE NON-VOLTAGE CONTACT FOR MICROCURRENT (NOT MORE THAN 1mA DC12V))

THE POINT OF CONTACT OF THE INPUT MUST USE THE ONE FOR A SLIGHT CURRENT.

RED

X3A

Z9C

N=1

X1A

X3A

P1

A2

K3M

A1

A2

K2M

A1

P<

S2PH

S1PH

F2U

F1U

S3PH

X5A

A8P

X1A

A1P

BLK

RED

X2A

V1R

R10

RY1

NOTE) 10

X1A

A9P

BLK

BLU

RED

:PROTECTIVE EARTH (SCREW)

X1A

Z5C

N=1

X1A

X3A

X5A

P1

A4P

Z4C

N=1

X4A

X6A

X61A

X402A

BLK

4. AT THE TIME OF FACTORY SHIPMENT, SETTING OF "OFF". WHEN OPERATING, SETTING OF "ON" OR "REMOTE".

3.

2.

A2P

WHT

1. THIS WIRING DIAGRAM IS APPLIED ONLY

M3C

V

M2C

U

M

3~

W

M

3~

V

U

Z7C

N=5

Z8C

N=5

W

V

K3M

U

W

T

V

S

R

T1A

A7P

T1A

X1A

Z6C

N=1

T2A

N=1

BLU

BLK

A6P

X1A

N

L3

L2

T

S

K2M

U

R

NOTES)

N

L3

RED

L2

WHT

BLK

WHT

K3R

L1

RED

K4R

L1

WHT

RED

RED

BLK

RED

BLK

WHT

BLK

WHT

GRN

RED

Z10C

N=4

BLK

K5R

RED

WHT

K6R

X1M

RED

K10R

POWER SUPPLY

BLK

Air Cooled Refrigeration Condensing Unit

WHT

K11R

Y1: 380-415V 3N~50Hz

SiENBE28-901

Standard Specification

LRLEQ15A, 20AY1(E)

LRMEQ15A, 20AY1(E)

17

Standard Specification

2.5

SiENBE28-901

Piping Diagram

LRLEQ5A, 6AY1(E)

LRMEQ5A, 6AY1(E)

FILTER

CHECK VALVE

RECEIVER

DOUBLE PIPE

HEAT EXCHANGER

SERVICE PORT

CHECK VALVE

ELECTRONIC

EXPANSION

VALVE

FUSIBLE

PLUG

CHECK VALVE

PRESSURE

REGULATING

VALVE

FILTER

SIGHT GLASS

ELECTRONIC

EXPANSION

VALVE

FILTER

M

HPS

STOP VALVE

FAN

HEAT EXCHANGER

STOP VALVE

SERVICE PORT

FOUR WAY VALVE

GAUGE PORT

HIGH PRESSURE

SWITCH

(DEFROST)

HIGH PRESSURE SENSOR

SENPH

CAPILLARY

TUBE

FILTER

OIL

SEPARATOR

GAUGE PORT

LIQUID PIPE

φ9.5 C1220T

SERVICE PORT

CHECK VALVE

HIGH PRESSURE

HPS

SWITCH

LOW PRESSURE

SENSOR

SENPL

COMPRESSOR

INV

GAS PIPE

φ19.1 C1220T

STOP VALVE (WITH SERVICE PORT φ7.9mm FLARE CONNECTION)

3D064606A

18

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Standard Specification

LRLEQ8A, 10A, 12AY1(E)

LRMEQ8A, 10A, 12AY1(E)

CHECK VALVE

RECEIVER

FILTER

ELECTRONIC

EXPANSION

VALVE

SERVICE PORT

PLATE TYPE HEAT

EXCHANGER

CHECK VALVE

FUSIBLE

PLUG

CHECK VALVE

PRESSURE

REGULATING

VALVE

FILTER

SIGHT GLASS

ELECTRONIC

EXPANSION

VALVE

FAN

S4PH

FOUR WAY VALVE

STOP VALVE

HIGH PRESSURE

SWITCH

(DEFROST)

FILTER

HEAT EXCHANGER

M

STOP VALVE

SERVICE PORT

GAUGE PORT

HIGH PRESSURE SENSOR

S1NPH

CHECK VALVE

CHECK VALVE

LOW PRESSURE

SENSOR

HIGH PRESSURE

S1PH

SWITCH

CHECK

VALVE FILTER

CAPILLARY

TUBE HIGH PRESSURE

SWITCH S2PH

OIL

SEPARATOR

CAPILLARYFILTER

TUBE

OIL

SEPARATOR

GAUGE PORT

LIQUID PIPE

φ9.5 C1220T

SERVICE PORT

FILTER

SV

ELECTRONIC

EXPANSION

VALVE

COMPRESSOR

INV

COMPRESSOR

SOLENOID CHECK STD

VALVE

VALVE

S1NPL

GAS PIPE

φ25.4 C1220T

STOP VALVE (WITH SERVICE PORT φ7.9mm FLARE CONNECTION)

3D064605

Air Cooled Refrigeration Condensing Unit

19

Standard Specification

SiENBE28-901

LRLEQ15A, 20AY1(E)

LRMEQ15A, 20AY1(E)

CHECK VALVE

RECEIVER

FILTER

ELECTRONIC

EXPANSION

VALVE

SERVICE PORT

PLATE TYPE HEAT

EXCHANGER

CHECK VALVE

FUSIBLE

PLUG

CHECK VALVE

PRESSURE

REGULATING

VALVE

FILTER

SIGHT GLASS

FAN

ELECTRONIC

EXPANSION

VALVE

S4PH

FOUR WAY VALVE

STOP VALVE

HIGH PRESSURE

SWITCH

(DEFROST)

FILTER

HEAT EXCHANGER

M

STOP VALVE

SERVICE PORT

GAUGE PORT

HIGH PRESSURE SENSOR

S1NPH

CHECK VALVE

CHECK VALVE

CHECK VALVE

CHECK

VALVE FILTER

CHECK

VALVE FILTER

LOW PRESSURE

SENSOR

S1NPL

HIGH PRESSURE

S1PH

SWITCH

CAPILLARY

TUBE HIGH PRESSURE

SWITCH S3PH

SV

ELECTRONIC

EXPANSION

VALVE

SV

COMPRESSOR

COMPRESSOR

SOLENOID CHECK STD1

INV

VALVE

OIL

SEPARATOR

CAPILLARY

TUBE HIGH PRESSURE

SWITCH S2PH

OIL

SEPARATOR

CAPILLARYFILTER

TUBE

OIL

SEPARATOR

GAUGE PORT

LIQUID PIPE

φ12.7 C1220T

SERVICE PORT

FILTER

VALVE

COMPRESSOR

SOLENOID CHECK STD2

VALVE

VALVE

GAS PIPE

φ31.8 C1220T

STOP VALVE (WITH SERVICE PORT φ7.9mm FLARE CONNECTION)

3D064603

20

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

2.6

Standard Specification

Description and Layout of Functional Parts and Piping

Diagram

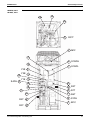

LRMEQ5, 6AY1

LRLEQ5, 6AY1

No.

Name

Symbol

1

Inverter compressor (INV)

M1C

2

M1F

Y1E

Not used.

Y2E

5

6

7

Fan motor

Electronic expansion valve

(Main: EV1)

Electronic expansion valve

(Injection: EV2)

Four way valve

High pressure sensor

Low pressure sensor

Function

An inverter-driven compressor, which runs at operating frequencies in the

range of 52Hz to 218Hz.

Used to operate a fan for heat exchange through an air heat exchanger.

8

High pressure switch

S1PH

9

High pressure switch

S4PH

10

Fusible plug

—

11

Pressure regulating valve

—

Used to control the injection flow rate and the compressor overheat

protection.

Not used.

Used to detect high pressure.

Used to detect low pressure.

In order to prevent the increase of high pressure when a malfunction

occurs, this switch activated at high pressure of 3.8MPa or more to stop the

compressor operation.

Not used.

When the refrigerant of the receiver unit reaches a temperature of 70°C to

75°C, the fusible head of plug will melt, thus discharging the refrigerant of

high temperature and high pressure.

Opens when the pressure reaches 4.0 MPa. This prevents an excessive

pressure rise caused by the pipes being completely filled with liquid when

not in operation.

12

—

Used to cool the liquid refrigerant from the liquid receiver.

—

Used to service.

—

Used to service.

15

16

17

Double pipe heat

exchanger

Stop valve (Heat

exchanger on primary side)

Stop valve (Double pipe

heat exchanger on

secondary side)

Service port

Service port

Service port

—

—

—

18

Oil separator

—

19

Liquid receiver

—

20

—

D

Sight glass

Thermistor (Outdoor air:

Ta)

Thermistor (Suction pipe:

Ti)

Thermistor (INV discharge

pipe: Td1)

Thermistor (Heat

exchanger deicer: Tce)

For gas (high pressure).

For liquid (high pressure).

For gas (low pressure).

Refrigerant gas discharged from the compressor contains lubricating oil in

the compressor. If the amount of this lubricating oil is large, the oil quantity

in the compressor will become short, which may result in defective

lubrication.

Furthermore, this oil stains the heat transfer surface of condenser or

evaporator and reduces the effectiveness of the heat exchanger. To avoid

that, an oil separator is installed in close proximity to the discharge pipe of

the compressor, where oil is separated and collected to return to the

compressor.

Used to compensate the variations in handling of refrigerant, thus providing

stable operating conditions at all times. In order to repair in the refrigerant

circuit, this receiver collects the refrigerant and facilitates the repairing of

the parts.

Used to test run and service.

E

Thermistor (Double pipe

heat exchanger outlet: Tg)

R5T

F

Thermistor (Double pipe

heat exchanger inlet: TL)

R6T

3

4

13

14

A

B

C

Y3S

S1NPH

S1NPL

Air Cooled Refrigeration Condensing Unit

R1T

Used to detect the outdoor temperature and control the fan operation.

R2T

R31T

Used to detect the suction pipe temperature of M1C compressor and

protect this compressor.

Used to detect the discharge pipe temperature of M1C compressor and

control over discharge pipe temperature of this compressor for protection.

R3T

Not used.

Used to detect the gas temperature at evaporator side of double pipe heat

exchanger, and keep the constant overheated degree of double pipe heat

exchanger.

Used to detect the gas saturation temperature at evaporator side of double

pipe heat exchanger.

21

Standard Specification

SiENBE28-901

LRMEQ5, 6AY1

LRLEQ5, 6AY1

FILTER

CHECK VALVE

(F)

(16)

(E)

SERVICE PORT

(19)

RECEIVER

(12)

DOUBLE PIPE

HEAT EXCHANGER

FUSIBLE(10)

PLUG

CHECK VALVE

PRESSURE

REGULATING

VALVE

(11)

ELECTRONIC

EXPANSION (4)

VALVE

FILTER

(D)

SIGHT GLASS (20)

CHECK VALVE

FAN

ELECTRONIC

EXPANSION (3)

VALVE

(2)

HEAT EXCHANGER

M

S4PH

(A)

FILTER

STOP VALVE

FOUR WAY VALVE

(13)

(5)

STOP VALVE

(14)

HIGH PRESSURE

SWITCH

(DEFROST)

GAUGE PORT

HIGH PRESSURE SENSOR

(9)

S1NPH

(6)

CHECK VALVE

SERVICE PORT

(17)

GAUGE PORT

SERVICE PORT

CAPILLARY

TUBE

LIQUID PIPE

φ9.5 C1220T

FILTER

OIL

SEPARATOR

(15)

(18)

HIGH PRESSURE

(8) SWITCH

S1PH

(C)

LOW PRESSURE

SENSOR

COMPRESSOR

INV

S1NPL

(1)

(7)

GAS PIPE

φ19.1 C1220T

(B)

STOP VALVE (WITH SERVICE PORT φ7.9mm FLARE CONNECTION)

22

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Standard Specification

LRMEQ5, 6AY1

LRLEQ5, 6AY1

19

10

18

C

R31T

2 M1F

17

6 S1NPH

12

7 S1NPL

Y3S 5

13

Y2E 4

Y1E 3

S4PH 9

14

15

16

B R2T

11

A R1T

20

R5T E

F R6T

8 S1PH

1 M1C

R3T D

Air Cooled Refrigeration Condensing Unit

23

Standard Specification

SiENBE28-901

LRMEQ8, 10, 12AY1

LRLEQ8, 10, 12AY1

No.

Name

Symbol

1

Inverter compressor (INV)

M1C

2

3

M2C

M1F

Y1E

Not used.

5

Standard compressor (STD)

Fan motor

Electronic expansion valve

(Main: EV1)

Electronic expansion valve

(Injection: EV2)

Function

An inverter-driven compressor, which runs at operating frequencies in the

range of 52Hz to 232Hz.

A compressor, which runs with commercial power supply.

Used to operate a fan for heat exchange through an air heat exchanger.

Y2E

6

Electronic expansion valve

(M1C: EV3)

Y3E

7

8

9

10

13

Solenoid valve

Four way valve

High pressure sensor

Low pressure sensor

High pressure switch (for

INV)

High pressure switch (for

STD)

High pressure switch

Used to control the injection flow rate and the compressor overheat

protection.

Returns the oil to the inverter compressor and creates a gas-injection

economizer circuit.

In addition, this controls the difference in discharge pipe temperatures

between INV compressor and STD compressor.

Returns the oil to the M2C and creates a gas-injection economizer circuit.

Not used.

Used to detect high pressure.

Used to detect low pressure.

14

Fusible plug

—

15

Pressure regulating valve

—

16

—

—

Used to service.

—

Used to service.

19

20

21

Plate type heat exchanger

Stop valve (Heat

exchanger on primary side)

Stop valve (Double pipe heat

exchanger on secondary side)

Service port

Service port

Service port

Not used.

When the refrigerant of the receiver unit reaches a temperature of 70°C to

75°C, the fusible head of plug will melt, thus discharging the refrigerant of

high temperature and high pressure.

Opens when the pressure reaches 4.0 MPa. This prevents an excessive

pressure rise caused by the pipes being completely filled with liquid when

not in operation.

Used to cool the liquid refrigerant from the liquid receiver.

—

—

—

22

Oil separator

—

23

Liquid receiver

—

24

Sight glass

Thermistor (Outdoor air:

Ta)

Thermistor (Suction pipe:

Ti)

Thermistor (INV discharge

pipe: Td1)

Thermistor (STD discharge

pipe: Td2)

Thermistor (Heat

exchanger deicer: Tce)

Thermistor (Plate type heat

exchanger outlet: Tg)

Thermistor (Plate type heat

exchanger inlet: TL)

—

For gas (high pressure).

For liquid (high pressure).

For gas (low pressure).

Refrigerant gas discharged from the compressor contains lubricating oil in the

compressor. If the amount of this lubricating oil is large, the oil quantity in the

compressor will become short, which may result in defective lubrication.

Furthermore, this oil stains the heat transfer surface of condenser or evaporator

and reduces the effectiveness of the heat exchanger. To avoid that, an oil

separator is installed in close proximity to the discharge pipe of the compressor,

where oil is separated and collected to return to the compressor.

Used to compensate the variations in handling of refrigerant, thus providing

stable operating conditions at all times. In order to repair in the refrigerant

circuit, this receiver collects the refrigerant and facilitates the repairing of the

parts.

Used to test run and service.

4

11

12

17

18

A

B

C

D

E

F

G

24

Y2S

Y3S

S1NPH

S1NPL

S1PH

S2PH

S4PH

In order to prevent the increase of high pressure when a malfunction

occurs, this switch activated at high pressure of 3.8MPa or more to stop the

compressor operation.

R1T

Used to detect the outdoor temperature and control the fan operation.

R2T

R32T

Used to detect the suction pipe temperature of M1C and M2C compressor

and protect this compressor.

Used to detect the discharge pipe temperature of M1C compressor and

control over discharge pipe temperature of this compressor for protection.

Used to detect the discharge pipe temperature of M2C compressor and

control over discharge pipe temperature of this compressor for protection.

R3T

Not used.

R31T

R5T

R6T

Used to detect the gas temperature at evaporator side of double pipe heat exchanger,

and keep the constant overheated degree of double pipe heat exchanger.

Used to detect the gas saturation temperature at evaporator side of double

pipe heat exchanger.

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Standard Specification

LRMEQ8, 10, 12AY1

LRLEQ8, 10, 12AY1

CHECK VALVE

(14)

(G)

(23)

ELECTRONIC

EXPANSION (5)

VALVE

(20)

SERVICE PORT

(F)

PLATE TYPE HEAT(16)

EXCHANGER

RECEIVER

FILTER

FUSIBLE

PLUG

(15)

CHECK VALVE

PRESSURE

REGULATING

VALVE

(E)

FILTER

SIGHT GLASS (24)

CHECK VALVE

(3)

FAN

ELECTRONIC

EXPANSION (4)

VALVE

HEAT EXCHANGER

M

(A)

S4PH

(17)

FILTER

STOP VALVE

FOUR WAY VALVE

STOP VALVE

(18)

HIGH PRESSURE

SWITCH

(DEFROST)

(13)

(8)

SERVICE PORT (19)

GAUGE PORT

HIGH PRESSURE SENSOR

(9)

S1NPH

CHECK VALVE

CHECK VALVE

LOW PRESSURE

SENSOR

CAPILLARYFILTER

TUBE

HIGH PRESSURE

(11) SWITCH

(22)

CAPILLARY

TUBE HIGH PRESSURE

(12) SWITCH S2PH

S1PH

(C)

ELECTRONIC

EXPANSION

(6)

VALVE

CHECK

VALVE FILTER

COMPRESSOR

INV

(1)

S1NPL

OIL

SEPARATOR

GAUGE PORT

LIQUID PIPE

φ9.5 C1220T

SERVICE PORT

(21)

OIL

SEPARATOR

FILTER

(22)

(D)

SV

COMPRESSOR

SOLENOID CHECK STD

VALVE

(7)

VALVE

(2)

(10)

(B)

GAS PIPE

φ25.4 C1220T

STOP VALVE (WITH SERVICE PORT φ7.9mm FLARE CONNECTION)

Air Cooled Refrigeration Condensing Unit

25

Standard Specification

SiENBE28-901

LRMEQ8, 10, 12AY1

LRLEQ8, 10, 12AY1

Y3E Y2S

23 14 22 6 7

16

D R32T

C

R31T

3 M1F

9 S1NPH

19

17

S4PH 13

21

10 S1NPL

Y3S 8

B R2T

Y1E 4

Y2E 5

11 S1PH

12 S2PH

20

15

18

24

R6T G

A R1T

1 M1C

2 M2C

R3T E

R5T F

26

Air Cooled Refrigeration Condensing Unit

SiENBE28-901

Standard Specification

LRMEQ15, 20AY1

LRLEQ15, 20AY1

No.

Name

Symbol

1

Inverter compressor (INV)

M1C

2

3

4

5

M2C

M3C

M1F

M2F

7

Standard compressor (STD 1)

Standard compressor (STD 2)

Fan motor

Fan motor

Electronic expansion valve

(Main: EV1)

Electronic expansion valve

(Injection: EV2)

8

Electronic expansion valve

(M1C: EV3)

Y3E

9

10

11

12

13

14

15

16

17

Solenoid valve

Four way valve

Solenoid valve

High pressure sensor

Low pressure sensor

High pressure switch (for INV)

High pressure switch (for STD 1)

High pressure switch (for STD 2)

High pressure switch

Y2S

Y3S

Y5S

S1NPH

S1NPL

S1PH

S2PH

S3PH

S4PH

18

Fusible plug

—

19

Pressure regulating valve

—

20

—

—

Used to service.

—

Used to service.

23

24

25

Plate type heat exchanger

Stop valve (Heat

exchanger on primary side)

Stop valve (Double pipe heat

exchanger on secondary side)

Service port

Service port

Service port

Not used.

When the refrigerant of the receiver unit reaches a temperature of 70°C to

75°C, the fusible head of plug will melt, thus discharging the refrigerant of

high temperature and high pressure.

Opens when the pressure reaches 4.0 MPa. This prevents an excessive

pressure rise caused by the pipes being completely filled with liquid when

not in operation.

Used to cool the liquid refrigerant from the liquid receiver.

—

—

—

26

Oil separator

—

27

Liquid receiver

—

28

A

Sight glass

Thermistor (Outdoor air: Ta)

—

R1T

B

Thermistor (Suction pipe: Ti)

R2T

C

Thermistor (INV discharge

pipe: Td1)

Thermistor (STD 1

discharge pipe: Td2)

Thermistor (STD 2

discharge pipe: Td3)

Thermistor (Heat

exchanger deicer: Tce)

Thermistor (Plate type heat

exchanger outlet: Tg)

Thermistor (Plate type heat

exchanger inlet: TL)

R31T

R33T

For gas (high pressure).

For liquid (high pressure).

For gas (low pressure).

Refrigerant gas discharged from the compressor contains lubricating oil in the

compressor. If the amount of this lubricating oil is large, the oil quantity in the

compressor will become short, which may result in defective lubrication.

Furthermore, this oil stains the heat transfer surface of condenser or evaporator

and reduces the effectiveness of the heat exchanger. To avoid that, an oil

separator is installed in close proximity to the discharge pipe of the compressor,

where oil is separated and collected to return to the compressor.

Used to compensate the variations in handling of refrigerant, thus providing stable

operating conditions at all times. In order to repair in the refrigerant circuit, this

receiver collects the refrigerant and facilitates the repairing of the parts.

Used to test run and service.

Used to detect the outdoor temperature and control the fan operation.

Used to detect the suction pipe temperature of M1C~M3C compressor and

protect this compressor.

Used to detect the discharge pipe temperature of M1C compressor and

control over discharge pipe temperature of this compressor for protection.

Used to detect the discharge pipe temperature of M2C compressor and

control over discharge pipe temperature of this compressor for protection.

Used to detect the discharge pipe temperature of M3C compressor and

control over discharge pipe temperature of this compressor for protection.

R3T