Download Coates CPH SERIES Instruction manual

Transcript

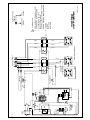

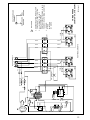

POOL HEATER with built-in flow switch EXPORT MODELS: 32212CE-E thru 32272PHS-E 33812CE-E thru 33872PHS-E 34112CE-E thru 34172PHS-E installation, operation and maintenance DO UL SW I co ate G PO s MM IN MO D .N O. kW MA X. TO DIS C W EIT UN ON A HE IT B NEC RN R EF T TE O AL ING SE RM RE L P RV IN RE OW AL MO E I CO VIN R NO PAN CE A VE G R T O EL CC ES BS S TR UC T AM WO PS RK IN G OL AN D SE SP AH RIA LN VO PH O. LT AS S, PR E 50 ES /60 SU CY RE CL EA kW P.S .C . EA .I. HY CH D EL TE EM ST EN T EA TE R P.S .I. EL EM EN T ON FL OW OF F TE MP CO ERA NT TU RO RE L ET TL OU T LE IN Publication 1-2012 WARNING Only qualified personnel, as defined by National Electric Code Article 100, should install and maintain this equipment. Unauthorized alteration or improper maintenance of this unit may release the manufacturer from any warranty claims. The installation must be in accordance with the instructions in this manual and applicable local plumbing and electrical codes. INTRODUCTION This manual provides installation procedures, operating and maintenance instructions and a parts list for the Coates Pool Heater. Your Coates Electric Swimming Pool Heater has been designed and engineered to provide you with the most progressive quality heating system possible. Its operation is efficient and pollution-free. Models are available for every size or make of pool. To insure a long life of trouble-free service, your Coates Pool Heater should be carefully installed in accordance with the instructions given in this manual. Failure to do so may damage the pool heater and the pool equipment to which it is connected. Only qualified personnel should install and maintain this unit, and, of course, local plumbing and electrical codes have precedence over these instructions. 1.0 DESCRIPTION The Coates Swimming Pool Heater consists of a heating tank with external enclosure, and the electrical heating and control system. In order to help maintain the heater in a satisfactory manner, a brief description of its components and their operation is included for the customer’s convenience. The pressure vessel and its enclosure comprise the main mechanical portion of the pool heater. The pressure vessel, in conjunction with the flow switch and heating element are the only portions of this equipment in contact with the water. The external enclosure is a sheet steel case totally enclosing the pressure vessel and electrical components. The enclosure is coated with a rust inhibiting, powder coat finish. The electrical system, which is the heart of this unit, can be considered as three separate systems engineered to provide optimum use of energy. They are as follows: 2 (1) The heating elements; mounted on a four-bolt flange. There are either 2, 3 or 4 elements. (2) The control system; consists of the pilot switch, high limit thermostat, flow switch, temperature control, magnetic contactors and transformer. These controls are wired into a 120V or 220V control circuit designed to control the temperature of the water leaving the heater. The high-limit thermostat is designed to open the control circuit and cut off the power in the event of excessive temperature. A flow switch is built-in to prevent the pool heater from operating without water flow. The flow switch will activate at flow rates of 20 GPM (1.26 L/sec) or greater. (3) The main current-carrying components; are the contactors. These are wired into circuits which carry the full amperage draw of the elements. The contactors function during a high temperature condition to deenergize the elements. The heater has a temperature controller adjustable from 70°F(21°C) to 104°F(40°C) and has one manual reset type high temperature limit thermostat set at 122°F (50°C). 2.0 LOCATION AND PLUMBING A. Installation: Location Coates swimming pool heaters are quiet, do not expel exhaust fumes, and may be conveniently located in shed or basement. Normal positioning of the pool heater should be in close proximity to the pool filtration system. Select a location conveniently close to incoming electrical service and where excessively long piping runs are not required. Minimum clearance: Front Left Right Top Back PHS/CPH 36 (914)# 18 (457) * 18 (457) 6 (153) CE 36 (914)# 4 (102) 4 (102) 20 (508) * * Required clearance is based on plumbing configuration used. # Refer to NEC Table 110.26 (A)(1) - Dimensions: Inches (mm) - Temperature control is located on the front side. B. Installation: Plumbing Pipe the heater as shown in Figure 2 to the inlet and outlet openings on the right side. Connect the heater in line between the filter discharge and pool. The water line coming from the filter should be connected to the heater inlet, and the discharge line to the pool should be connected to the outlet. The pool will not heat properly unless it is plumbed correctly. If plastic pipe is used, it should be suitable for at least 122°F (50 °C). Ground wires must be insulated copper conductor and the same size as supply wiring, but not less than #12 AWG (4 mm2). Table 1 WIRE SIZE: AWG(mm2) 220V/3Ø 380V/3Ø 415V/3Ø 8(10) 10(6) 10(6) 8(10) 10(6) 10(6) 6(16) 8(10) 8(10) 4(25) 8(10) 8(10) 3(35) 6(16) 6(16) 2(35) 6(16) 6(16) 1(50) 4(25) 4(25) 3/0(95) 3(35) 3(35) 3/0(95) 3(35) 3(35) 3/0(95) 2(35) 3(35) 4/0(120) 1(50) 2(35) KW 12 15 18 24 30 36 45 54 57 60 72 A plumbing bypass around the pool heater is not necessary unless flow rates though the heater exceed 80 GPM (5 L/sec). A minimum flow rate of 20 GPM (1.26 L/sec) is required. Lack of sufficient flow will not allow the flow switch to activate the heater. It may be necessary, in larger Olympic-sized or public pools, to use two or more heaters to obtain sufficient KW capacity. If so, the heaters must be placed in parallel, so that each heater takes equal flow. Suggested size for insulated copper conductor wires. Based on 125% correction factor for wire with 90°C insulation. A. 3.0 ELECTRICAL INSTALLATION First: 1. Check nameplate rating to insure the heater matches your electrical supply. 2. CHECK ELECTRICAL CONNECTIONS TO ALL COMPONENTS within the heater for tightness. These can become loose during shipment and handling. 3. Check components for any moisture, rust, or dust which may have accumulated during shipping, and clean or dry where necessary. To Connect Pool Heater to Power Supply These pool heaters have branch supplemental fusing already installed in the element circuitry; see wiring diagrams. To connect to the power supply, one needs only to protect the main supply lines, either with a circuit breaker or fused disconnect switch (Figure 1). Suggested wire sizes are shown in Table 1. or All pool heaters covered in this manual have integral thermostats, transformers, contactors and sequencers where required. All other internal connections are completed and tested at the factory. Ground Line 1 Line 2 Line 1 Line 2 Ground Wiring Diagram: Single-Phase Models Wiring diagrams on pages 6 through 14 show internal wiring and required field connections for various models. Consult your local electrical code for proper wire and conduit sizes, and other local requirements. or Do not connect the pool heater to, or operate at, a voltage other than the voltage rated on the nameplate. Bring wires of adequate size from a fused disconnect switch or circuit breaker with an ampere rating of 125% of the ampere rating shown on heater nameplate. Refer to Table 1 for wire sizes. Connect the power conductors to bus assembly on inside of the heater. ØA ØB ØC ØA ØB ØC Ground Ground Wiring Diagram: Three-Phase Models Figure 1 3 B. Startup Procedure: 4.0 1. Make sure that the pump is on and that there is at least 20 GPM (1.26 L/sec) flow through the pool heater. The heating elements will fail if allowed to operate dry. MAINTENANCE Element Inspection and Replacement: 1. Turn off power at main disconnect switch and turn off water at water supply line. 2. Drain pool heater. 3. Remove left end service access panel. 4. Disconnect element leads. 5. Remove the four (4) element flange retaining nuts and extract element. 6. Installation is the reverse of steps 1 through 5. (Reinstall element with new gasket) 2. Check temperature control setting, also, examine wiring for loose connections, etc. 3. Set temperature control to the desired temperature. Note: for each degree the temperature control setting is increased, power usage may increase up to 10%. Semi-Annual Cleaning: Accumulated sludge in the tank is the greatest cause of element failure. Twice yearly (before summer start-up and before winter), the pool heater should be drained and cleaned to remove any scale or sludge. More frequent cleaning may be required if pool water contains sediment or any amount of foreign matter. 1. Turn off system at main disconnect switch. 2. Open drain valve. 3. Permit water to run until it is clear. 4. Close valve and restart normally. 4. Turn on power at main disconnect switch. 5. Turn on pilot switch on pool heater. When closing down the pool for any length of time, shut off the power at the main disconnect switch and drain the water from the system. Water must not be allowed to freeze in the heater, as this will cause severe damage. If high temperature causes manual reset high limit switch to shut off the heater, disconnect power at disconnect switch and determine the cause before resetting. PROTECT ING YOUR COAT ES HEAT ER W IT H PROPER WAT ER CHEMIST RY Proper water balance is important to extending the life of your Coates Heater. While pH control is critical, the control of alkalinity and calcium hardness will protect against scaling and also help to prevent corrosion. A CID HEAT ER CA N BE DA MA GED A LKA LINE CORROSIV E WAT ER 0 1 2 3 4 5 IDEA L RA NGE 6 7 7.2-7.8 A LKA LINE WAT ER 8 9 10 11 12 13 14 HEAT ER CA N BE DA MA GED The correct level of sanitizer, pH, total alkalinity and calcium hardness will very, depending on the type of pool (plaster, fiberglass or vinyl) and the chemical content of the fill water. Water that is out of balance can damage your pool heater and void the warranty. This heater is not for use in salt water pools. ** NOTICE ** NO PRESSURE RELIEF VALVE IS SHIPPED WITH THIS HEATER AND NONE IS REQUIRED PER UL STD 1261. DO NOT INSTALL SHUT OFF VALVE BETWEEN THE HEATER AND POOL OR SPA. A CHECK VALVE IS ACCEPTABLE AND IN ACCORDANCE TO UL STD 1261 REVISED JULY 1983. 4 CAUTION DO NOT INSTALL ANY SHUT-OFF VALVE ON DISCHARGE SIDE OF HEATER. A SWING CHECK VALVE IS PERMITTED. Exception: If a 30 psi (2.1 Kg/cm2 ) pressure relief valve is installed between the heater and valve , the valve may be of the shut-off (ball or gate) type. CHECK VALVE POOL or SPA FILTER COATES POOL HEATER DRAIN VALVE PUMP BALL OR GATE VALVE BALL OR GATE VALVE 5 380VOLT 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 4 4 4 4 4 4 1 1 2 2 2 2 1 2 1 3 2 3 4 4 1 1 1 1 1 1 1 1 1 1 1 44000250 2 2 2 2 2 4 4 4 4 4 4 20006046 1 20006039 1 2 20006009 2 20006010 2 2 1 20006011 2 1 3 2 3 4 20006065 20006004 4 20006029 1 20006036 1 HEATING ELEMENT GASKET HEATING ELEMENT, 6kW @ 240V HEATING ELEMENT, 9kW @ 240V HEATING ELEMENT, 12kW @ 240V HEATING ELEMENT, 15kW @ 240V HEATING ELEMENT, 18kW @ 240V HEATING ELEMENT, 18kW @ 380V HEATING ELEMENT, 15kW @ 208V HEATING ELEMENT, 9kW @ 208V HEATING ELEMENT, 6kW @ 208V 13 12 12 12 12 12 12 12 12 12 1 1 1 1 1 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 3 3 3 3 3 3 3 3 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 2 2 2 3 2 1 3 2 3 4 4 2 2 2 2 2 4 4 4 4 4 4 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 3 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 3 3 4 4 4 4 2 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 3 3 4 4 4 4 2 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 1 22003820 22002150 22002001 29034620 29034648 23000105 21006010 2 2 2 3 3 4 4 4 4 2 2 2 2 2 2 2 2 TEMP LIMIT SWITCH, TS1 TEMP CONTROL, TS3 TEMP CONTROL, TS2 PILOT LIGHT, AMBER, PL1, 2 & 4 PILOT LIGHT, AMBER, PL3 FLOW SWITCH RELAY, 30AMP, 240V COIL, K8 2 2 18 23 27 36 46 55 68 82 87 91 109 17 21 25 33 42 50 63 75 79 83 100 11 8 8 9 9 6 14 29016310 29015054 22010954 22010904 31 39 47 63 79 94 118 142 150 157 189 1 1 1 1 1 2 2 2 2 2 3 1 1 1 1 1 1 1 1 1 1 1 10 PILOT SWITCH, PS2 415 VOLT 12 15 18 24 30 36 45 54 57 60 72 12 15 18 24 30 36 45 54 57 60 72 12 15 18 24 30 36 45 54 57 60 72 21001000 1 1 1 2 2 3 3 3 3 3 3 23001521 1 1 1 1 1 1 1 1 1 1 1 TOTAL kW PER HEATER AMPERAGE AT FULL LOAD ELEMENTS PER HEATER FUSE, F5, 1A @ 600VAC FNQ-R-1 FUSE, F6, 1/2A @ 250VAC FNM 1/2 XFMR, T3 380*600/120V-50VA XFMR, T4 380*415/120V-75VA Part No. 220VOLT EXPLIST-Q 32 32 32 32 32 32 32 32 32 32 32 34 34 34 34 34 34 34 34 34 34 34 3 3 3 3 3 3 3 3 3 3 3 21 21 21 22 23 23 24 25 25 26 27 381 381 381 382 383 383 384 385 385 386 387 1 1 1 1 1 1 1 1 1 1 1 2C 5C 8C 4C 0C 6P 5P 4P 7P 0P 2P 2C 5C 8C 4C 0C 6P 5P 4P 7P 0P 2P 12C 15C 18C 24C 30C 36P 45P 54P 57P 60P 72P H H H H H H H H H H H H H H H H H E E E PH PH S S S S S S E E E PH PH S S S S S HS E E E PH PH S S S S S S 3 4 4 3 4 4 4 3 4 4 3 4 4 3 4 4 4 3 17 CONTACTOR, CR7 3P 220V COIL 3 4 7 7 ILLUSTRATION ITEM 6 15 14 18 NOTE: REFERENCE THE POOL HEATER PARTS LIST FOR COMPONENT PART NUMBERS AND QUANTITIES. 10. PILOT SWITCH, LIGHTED "ON/OFF" 11. TEMPERATURE LIMIT SWITCH 12. HEATING ELEMENT 13. HEATING ELEMENT GASKET 14. FLOW RELAY 15. SEQUENCE TIMER (WHEN REQUIRED) 16. CONTACTOR (4-POLE) 17. CONTACTOR (3-POLE) 18. HEATER CIRCUIT FUSING 19. VESSEL 20. ENCLOSURE 1. POWER DISTRIBUTION BLOCK 2. GROUND LUG 3. CONTROL TRANSFORMER PRIMARY FUSING 17 4. CONTROL TRANSFORMER SECONDARY FUSING 5. EXTERNAL CONTROL CONNECTION 6. FLOW SWITCH 7. CONTROL TRANSFORMER (WHEN REQUIRED) 16 8. TEMPERATURE CONTROL 9. PILOT LIGHTS – ELEMENT, FLOW, RESET 12 13 11 19 20 8 10 9 1 2 6 5 3 4 7 DPH-ILL D FLOW PL2 "FLOW" ISOLATED BUS K8 #1 COPPER #3 ALUMINUM #2 BRASS COM NO RS2 TB1 J3 C TS1 J4 NO AC J2 J9 AC J1 B W R TS3 TEMP 1 2 3 4 7 F5 F5 PL1 "ELEMENT" COIL PL4 "RESET” W #8 R R #8 B B W W R R HEATING ELEMENTS CR7 #8 B B W BUSS ASSEMBLY A B C NOT USED POOL GROUND E3M1218D THREE PHASE 220V-12, 15 & 18kW 4. LEGEND; R = RED B = BLACK W = WHITE 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT 14 AWG. POWER CIRCUIT; AS NOTED. 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL 8 #1 COPPER #3 ALUMINUM #2 BRASS RS2 NO COM PL2 "FLOW" ISOLATED BUS K8 FLOW TB1 J3 C TS1 J4 NO AC J2 J9 AC J1 B W R TS3 TEMP 1 2 3 4 COIL PL1 "ELEMENT" F5 F5 W #8 R R #8 B B W W #8 R R #8 B B W CR7 #8 BUSS ASSEMBLY A B C HEATING ELEMENTS CR7 #8 COIL PL4 "RESET” NOT USED POOL GROUND E3M2430E THREE PHASE 220V-24 & 30kW 4. LEGEND; R = RED B = BLACK W = WHITE 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT 14 AWG. POWER CIRCUIT; AS NOTED. 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL #1 COPPER #3 ALUMINUM #2 BRASS RS2 NO COM PL2 "FLOW" ISOLATED BUS K8 FLOW TB1 J3 C TS1 J4 NO AC J2 J9 AC J1 B W R TS3 TEMP 1 2 3 4 9 COIL PL1 "ELEMENT" F5 F5 W #8 R R #8 B B W CR7 #8 R R #8 B B W CR7 #8 HEATING ELEMENTS W #8 BUSS ASSEMBLY A B C COIL COIL PL4 "RESET” W R R #8 B B W #8 CR7 #8 NOT USED POOL GROUND E3M3645E THREE PHASE 220V-36 & 45kW 4. LEGEND; R = RED B = BLACK W = WHITE 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT 14 AWG. POWER CIRCUIT; AS NOTED. 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL #1 COPPER #3 ALUMINUM #2 BRASS RS2 NO COM PL2 "FLOW" ISOLATED BUS K8 FLOW TB1 J3 C J4 NO AC J2 J9 AC J1 B W R TS3 TEMP TS1 F5 F5 PL1 "ELEMENT" COIL 10 1 2 3 4 W #8 R R #8 B B COIL W CR7 #8 W #8 R R B B W CR7 #8 W #8 R R #8 BUSS ASSEMBLY B C COIL HEATING ELEMENTS #8 A B B W CR7 #8 COIL PL4 "RESET” W #8 R R #8 B B W CR7 #8 NOT USED POOL GROUND 4. LEGEND; R = RED B = BLACK W = WHITE E3M5472E 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT 14 AWG. POWER CIRCUIT; 8 AWG 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL #1 COPPER #3 ALUMINUM #2 BRASS NO COM PL2 "FLOW" ISOLATED BUS K8 FLOW PL4 "RESET” J3 C J4 NO AC J9 AC B W R TS3 TEMP J2 J1 F6 W PL3 "ELEMENT" 220V T3 380V/415V R R F5 10GA. W R 8 GA. R B B 8 GA. HEATING ELEMENTS B W 10GA. 10GA. B COIL F5 8 GA. 8 GA. W CR7 BUSS ASSEMBLY A B C 8 GA. 8 GA. RS2 1 2 3 4 11 FLOW SWITCH POOL GROUND 4. LEGEND; R = RED B = BLACK W = WHITE EEFG1218D EEFG2430E 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT WIRING; 14 AWG. POWER CIRCUIT WIRING; AS NOTED. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL #1 COPPER #3 ALUMINUM NO COM PL2 "FLOW" ISOLATED BUS K8 FLOW J3 C J4 NO AC J2 J9 AC J1 B W R TS3 TEMP W PL3 "ELEMENT" 220V T3 R R 8 GA. COIL B B 10GA. W 10GA. 10GA. 8 GA. #2 BRASS F6 F5 8 GA. W R 8 GA. 380V/415V R 8 GA. W CR7 COIL HEATING ELEMENTS B B 8 GA. F5 8 GA. 8 GA. BUSS ASSEMBLY A B C 8 GA. W 8 GA. 12 R 8 GA. R 8 GA. RS2 1 2 3 4 PL4 "RESET” B B W CR7 FLOW SWITCH POOL GROUND 4. LEGEND; R = RED B = BLACK W = WHITE EEFG3645F 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT WIRING; 14 AWG. POWER CIRCUIT WIRING; AS NOTED. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL COM PL2 "FLOW" ISOLATED BUS K8 FLOW TB1 J3 C J4 NO AC J2 J9 AC J1 B W R TS3 TEMP TS1 F6 COIL W R R B 10GA. W 10GA. 10GA. F5 B PL3 "ELEMENT" 220V T3 380V/415V 8 GA. 8 GA. #1 COPPER #3 ALUMINUM 8 GA. W 8 GA. #2 BRASS R 8 GA. R 8 GA. F5 B B COIL HEATING ELEMENTS W CR7 8 GA. 8 GA. BUSS ASSEMBLY A B C 8 GA. W 8 GA. NO R 8 GA. R 8 GA. RS2 1 2 3 4 13 PL4 "RESET” B B 10GA. W 10GA. 10GA. CR7 W NOT USED POOL GROUND R R B B W EEFG5460F THREE PHASE 380/415V - 54, 57 & 60kW 4. LEGEND; R = RED B = BLACK W = WHITE 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT WIRING; 14 AWG. POWER CIRCUIT WIRING; AS NOTED. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL 14 #1 COPPER #3 ALUMINUM #2 BRASS RS2 NO COM PL2 "FLOW" ISOLATED BUS K8 FLOW TB1 J3 C TS1 220V 380V J4 NO AC J2 J9 AC J1 B W R F6 TS3 TEMP 1 2 3 4 COIL PL1 "ELEMENT" T3 W #8 R R #8 F5 F5 B B COIL W CR7 #8 W #8 R R B B W CR7 #8 W #8 R R #8 BUSS ASSEMBLY B C COIL HEATING ELEMENTS #8 A B B W CR7 #8 COIL PL4 "RESET” W #8 R R #8 B B W CR7 #8 NOT USED POOL GROUND 4. LEGEND; R = RED B = BLACK W = WHITE E3F72G 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT 14 AWG. POWER CIRCUIT; 8 AWG 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL #1 COPPER #3 ALUMINUM #2 BRASS RS2 NO COM PL2 "FLOW" ISOLATED BUS K8 FLOW TB1 J3 C TS1 220V 415V J4 NO AC J2 J9 AC J1 B W R F6 TS3 TEMP 1 2 3 4 15 COIL PL1 "ELEMENT" T3 W #8 R R #8 F5 F5 B B COIL W CR7 #8 W #8 R B B W CR7 #8 W #8 R R #8 BUSS ASSEMBLY B C COIL HEATING ELEMENTS R #8 A B B W CR7 #8 COIL PL4 "RESET” W #8 R R #8 B B W CR7 #8 NOT USED POOL GROUND 4. LEGEND; R = RED B = BLACK W = WHITE E3EG72G 3. ALL WIRING TO BE 105°C INSULATED, MINIMUM. CONTROL CIRCUIT 14 AWG. POWER CIRCUIT; 8 AWG 2. SEE INSTRUCTION MANUAL FOR COMPONENT IDENTIFICATION. 1 ENCLOSURE GROUND HEATER GROUND TERMINAL HEATER CO., INC. P.O. Box 1750 Kent, WA 98035 coatesheater.com