Download Carrier 38AH024-034 Specifications

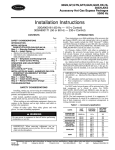

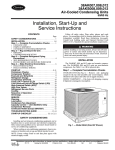

Transcript