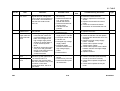

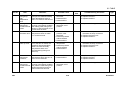

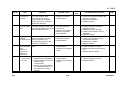

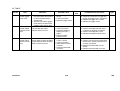

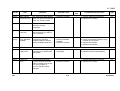

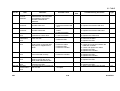

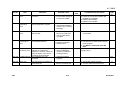

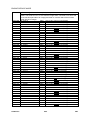

Download Ricoh Aficio C7535n Service manual

Transcript