Download Samsung RS20NESW Specifications

Transcript

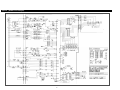

SAMSUNG Home Appliance Service For the latest parts information, please access to our service web site (http://www.e4buyer.com/refrigerator) SIDE-BY-SIDE REFRIGERATOR Model: RS20NCSL RS20NCSW RS20NESL RS20NESW WARNING IMPORTANT SAFETY NOTICE The service guide is for service men with adequate backgrounds of electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or dealer cannot be responsible for the interpretation of this information. SAMSUNG ELECTRONICS Technical Service Guide Copyright ⓒ2002 All rights reserved. This service guide may not be reproduced in whole or in part in any form without written permission from the SAMSUNG ELECTRONICS Company. 2 Contents 1. SAFETY WARNINGS 4 2. INSTRUCTION 6 3. INSTALLATION 7 4. NOMENCLATURE 8 5. SPECIFICATIONS 9 6. INTERIOR VIEWS AND DIMENSIONS 12 7. FREEZING CYCLE AND COOL AIR CIRCULATION ROUTE 14 8. MECHANICAL DISASSEMBLY 16 9. FUNCTIONS AND OPERATION 22 10. CIRCUIT DESCRIPTION 27 11. DIAGNOSIS AND TROUBLESHOOTING 36 12. ILLUSTRATED PARTS CATALOGUE 42 APPENDIX Ⅰ (CIRCUIT DIAGRAM) 57 3 1. SAFETY WARNINGS ● Pull the power plug out already for the change or repair of electric parts. → Be careful the electric shock. ● When exchanging the parts, use the correct parts. → Check the model name, rating voltage, rating current, running temperature symbols. ● When troubleshooting, connect firmly the types of harness. → Make not to be separated when some power is imposed. ● Check the traces of water infiltration at the electric parts. → If there is a trace of water infiltration, exchange or tape the parts. ● Check the assemble status of parts after troubleshooting. → It should be done indiscriminately as before the repair. ● Check the use circumstance of refrigerator. → If the refrigerator is installed at the place that is damp or wet, or status of installation is unstable, change the installation place. ● Do earth in case of need. → Particularly, Be sure to earth when there is a risk of an electric leakage by humidity or wetness. ● Do not use multi plugs in a plug socket at the same time. Check the power cord and socket is damaged, pressed, squeezed, or fired. → If the plug or plug socket is damaged, repair or exchange that immediately. ● Do not store the foods unstable or bottles in the freezing room. ● Do not repair the refrigerator by user himself. ● Do not store another materials except the foods. → Drugs or scientific materials : difficult to keep a precise temperature. → The inflammables(alcohol, benzene, ether, LP gas, butane gas etc.): have a risk of explosion. 4 1. SAFETY WARNINGS CAUTION / WARNING SYMBOLS DISPLAYED SYMBOLS Warning Caution means “Prohibition”. Indicates that a danger of death or serious injury exists. means “Do not disassemble”. means “No contact”. means ”The things to be followed”. Indicates that a risk of personal injury or material damage exists. means “Power cord should be unplugged from the consent” means “Earth to prevent Electric shock”. Caution Use the rated components on the replacement. ●Check the correct model, rated voltage, rated current, operating temperature and so on. On repair, remove completely dust or other things of housing parts, harness parts, and check parts. ●Cleaning may prevent the possible fire by tracking or short. Pull the power plug out to exchange the interior lamp of the refrigerator. On repair, make sure that the wires such as harness are bundled tightly. ● It may cause electric shock. ●Bundle tightly wires in order not to be detached by the external force and then not to be wetted. After repair, check the assembled state of components. Check if there is any trace indicating the permeation of water. ●It must be in the same assembled state when compared with the state before disassembly. 5 ●If there is that kind of trace, change the related components or do the necessary treatment such as taping using the insulating tape. 2. INSTRUCTION A newly developed SAMSUNG side by side refrigerator has the following characteristics. 1) Multi-Flow System Cool air circulates through multiple vents on each shelf level. This provides even distribution of cooling inside of freezer/refrigerator and keeps food fresher for longer. 2) High humidity for fresher food You can keep food, fruit and vegetables fresh for longer because your refrigerator supplies highly humidified cold air. 3) Door Alarm When the refrigerator door is left open for more than two minutes, a musical alarm is automatically triggered. This feature helps you save electricity and preserve stored foods. 6 3. INSTALLATION 1) To protect refrigerator in movement Use padded hand truck as shown. If entrance width is less than 30 , remove doors prior to installation and reattach doors according to procedure below. 2) Remove all protective tape and pad in refrigerators. Please adjust the clearance between the doors. 3) Set the temperature control to the temperature and wait for an hour. The refrigerator should get slightly chilled and the motor runs smoothly. 4) Once the refrigerator temperature is sufficiently cool You can store food in the refrigerator. After starting the refrigerator, it takes a few hours to reach the appropriate temperature. Disassemble the refrigerator 1) 2) 1) With the door closed, disassemble screw( ) by using (+) screw driver and then disassemble the upper hinge cover( ). 2) Disassemble bolts ( ) and screws ( ) to the counter-clockwise by using a tool, and take off the upper hinge ( ) along the arrow ( ). Take care when you disassemble the door to ensure that it does not fall on you. 3) Assemble the refrigerator 1) 2) 1) Insert the lower hinge ( ) in the bracket lower hinge ( ). 2) Assemble the door ( ) in the lower hinge ( ). 3) 4) 4) 3) Disassemble the door from the lower hinge ( ) by lifting the door ( ). 4) Disassemble the lower hinge ( ) from the bracket lower hinge ( ) by lifting the lower hinge ( ) in the direction of the arrow. 3) Insert the upper hinge shaft ( ) into the hole ( ). After leveling between the upper hinge hole ( ) and the hole of the refrigerator ( ), assemble bolts ( ) and screws ( ) to the clockwise by using a tool. 4) Put the front part of the upper hinge cover ( ) on the front part of the upper hinge ( ) and assemble, starting with the front part of the upper hinge cover. Assemble the screw to the clock wise by using a tool. 7 4. NOMENCLATURE R S 20 N C SW Color SW : Snow White SL : Stainless Looking Handle Type C ; Sky Bar Handle E ; Deluxe Bar Handle Option N : Nothing Capacity ; Cu. ft Door Type S - Side By Side Product ; R - Refrigerator Label Location 8 5. SPECIFICATIONS 5-1. Model Specification Volume capacity Items Specification Model Name RS20N*** Total Volume 496 l(17.5 cu.ft) Freezer Volume 188 l(6.6 cu.ft) Refrigerator Volume 308 l(10.9 cu.ft) Outer dimensions(width x depth x height) 850mm×724mm×1722mm Rated frequency Hz 60 60 50 50/60 50 Rated voltage V 110 115 127 220 220 230 Rated consumption of Comp. W 140 125 120 140 125 Rated consumption of Electric heater W 394 Refrigerator type Frost free Refrigerant HFC - 134a Refrigerant quantity 190gr Freezing Capacity Products weight 106kg 9 5-2. Electric Parts Specification Items Specification Model Name RS20N*** Performance of freezer Type 110V/60Hz 127V/60Hz 220V/50Hz 220V/50,60Hz 230V/50Hz MK183CL2U/EH1 MK183PL2U/EO1 DK190KT2U/EO1 SK190HL2U/E01 MK183QL2U/EO1 Freezing parts Compressor Freezer Refrigerator Defrostperiod Defrost sensor Inner Temperature detection parts R.S.C.R Sealing oils FREOL α- 15 (ESTER) Freezer SPLIT FIN TYPE Cooler Condensing method Force and natural convection method Drying agent MOLECULAR SIEVE XH-9 Capillary tube 0.82×3200, 5.5 kg/cm2 Refrigerant HFC-134a Types Parts related defrost Operation type Freezer temp. ON(℃) OFF(℃) Thermistor (F-sensor) 502AT Colder -24.0 -26.0 Normal -19.0 -21.0 Cold -15.0 -17.0 Types Refrigerator temp. ON(℃) OFF(℃) Colder 2.0 0.0 Normal 4.0 2.0 Cold 7.0 5.0 Thermistor (R-sensor) 502AT Period of initial defrost (F defrost) 4 hours ± 10 mins Defrost period of freezer 6~11 hours(Variable according to the use conditions)defrost Pause 7 ± 2 minutes F-defrost sensor Temperature fuse Types THERMISTOR (PX41C) Spec 5.0㏀ at 25 Rating AC 250V 10A 77 Operation temp. 10 +0 -5 ℃ Specification Items F-room defrost heater Conducting at F defrosting 200W F room heater sub Conducting at F defrosting 60W F room heater glass Conducting at F defrosting 130W R-room cover damper 3W R room electrically driven damper 1W Running Condenser for Comp.(monolithic) Start Electricparts - - - - - Type J531Q32E4R7M1802 J531Q32E4R7M1802 J531Q34E220M3502 J531Q34E220M3502 J531Q35E330M3852 Action Initial resistance: 68Ω±20% (Ambient temperature : 25℃) Type 4TM437RHBYY-53 4TM437RHBYY-53 4TM317SHBYY-53 4TM317SHBYY-53 4TM265RHBYY-53 ON temperature 130 ± 5℃ OFF temperature 69 ± 9℃ Start relay Overload relay 250VAC,12㎌ 250VAC,12㎌ 350VAC,5㎌ 350VAC,5㎌ 350VAC,5㎌ L.V.T(LOW VOLTAGE TRANSFORMER) 110 115V/60Hz 127V/60Hz 220V/50Hz 230 240V/50Hz F room cooling fan motor DC 12V DREP3030LA 0.3A Comp. Cooling fan motor DC 12V DRCP3030LA 0.24A Freezer interior light 30W (110 127V) 25W (220 230V) Refrigerator interior light 30W (110 127V) 25W (220 230V) Door switch AC 250V 0.5A 2EA Supply cord TO BE FOLLOWED LOCAL STANDARD Grounding screw BSBN (Bronze screw)×4EA 11 6. INTERIOR VIEWS AND DIMENSIONS 6-1. The Name of Each Part Freezer Refrigerator ① Interior light ⑦ Dairy compartment ② Ice tray ⑧ Interior light ③ Shelf ⑨ Shelf ④ Food Guard ⑩ Egg tray ⑤ Drawer ⑪ Fresh container(option) ⑥ Leg cover ⑫ Food Guard ⑬ Vegetable and fruit drawer 12 6-2. Dimensions of Unit 13 7. FREEZING CYCLE AND COOL AIR CIRCULATION ROUTE 7-1. Freezing Cycle Compressor Condenser Evaporator Accumulator Pipe cluster Pipe suction Pipe hot Dryer Compressor 14 Capillary tube 7-2. Cooling Air Circulation Refrigerator Freezer 15 8. MECHANICAL DISASSEMBLY 8-1. Accessories for storage and parts for lightening Door Gasket SHELVES The door gasket is set into groove on door liner. 1) Open the door. 2) Grasp the gasket and pull it out from the door liner. 1) Pull the shelf out as far as it goes. 2) Lift it up and pull it out from the unit. ICE TRAYS The ice tray is located at bottom of freezer shelfmid. 1) Pull the tray out by sliding. LIGHT SWITCHES The unit have two light switches on the side wall of freezer & refrigerator. 1) Use a small flat-blade screw driver to unlock the hook and pull the switch out until the wire connector is exposed. DRAWERS The drawers are located at bottom side of freezer and refrigerator. 1) Pull the drawer out as far as it goes. 2) Lift it up slightly and pull it out from the unit. LIGHTS The light of freezer & refrigerator are located at upper side of each compartment. 1) Remove the screws. 2) Remove the lamp cover by unlocking the hook. 16 TRAY-REF SHELF LOW REF. IN REFIGERATOR The tray-ref is located at bottom of shelf-ref in refrigerator compartment. 1) Pull the tray-ref out as far as it goes. 2) Lift it up slightly and pull it out from the shelf. The shelf low ref. in refrigerator can be removed as following sequence. 1) First, remove the drawer upp.. 2) Pull the shelf out as far as it goes. 3) Lift it up and pull it out from the unit. FOOD GUARDS 1) Lift the guard up and pull it out from door liner. 17 8-2. Cooling Unit COVER EVAP FRONT IN FREEZER COVER DUCT REAR IN FREEZER Before disassemble the cover, Should be removed all accessories in freezer. 1) Pull the screw cap out (4 EA). 2) Remove the screws (6 EA). 3) Grasp the bottom edge of the cover, and pull it out from the unit. Before disassemble the cover, Should be removed cover duct. front. 1) Remove the screws (3 EA). 2) Grasp the bottom edge of the cover, and pull it out from the unit. 3) Disconnect the wire connector and pull the cover out from the unt. COVER DUCT FRONT IN FREEZER Before disassemble the cover, should be cover evap. front. 1) Pull the screw cap out (1 EA). 2) Remove the screws (1 EA). 3) Grasp the bottom edge of the cover, and pull it out from the unit. 4) Disconnect the sensor wire connector and pull the cover out from the unt. FAN MOTOR 1) Remove the fan propeller (1 EA). 2) Disconnect the wire connector from body of the cover. 3) Remove the screws (3 EA) and separate the fan motor case. 4) Open the case and remove fan motor. 18 2) Cut the cable tie for securing the thermistor. 3) Separate the thermistor from the evaporator. Do not desolder evaporator to replace the thermistor only. EVAPORATOR IN FREEZER 1) Take off cover evap front, cover duct front and cover duct rear in sequence. 2) Disconnect all wire connectors. 3) Desolder the inlet and outlet tube. 4) Remove the evaporator. THERMISTOR IN FREEZER Before disassemble the thermistor, Should be removed cover duct. front. 1) Remove the sensor cover. 2) Separate thermistor. Thermistor-defrost Thermal Fuse Sensor AMBIENT THERMISTOR The thermistor is located at inside the upper hinge cover. It sends temperature signal to the micro-processor. THERMAL FUSE Thermal fuse is located at top of the evaporator. 1) Disconnect the wire connector of thermal fuse. 2) Cut the cable tie for securing the fuse. 3) Separate the fuse from the evaporator. Do not desolder evaporator to replace the fuse only. THERMISTOR DEFROST Thermal fuse is located on accumulator of evaporator. 1) Disconnect the wire connector of thermistordefrost. 19 ASS'Y DAMPER The Damper is for controlling cold air circulation. ●After disassemble cap screw(①) disassemble the screw(② ). ●Disassemble the connectors then, pull out the damper cover(③ ) from refrigerator. ●After disassembling the screw(④) from the damper cover(③), disassemble the temperature control part by pulling forward from the damper cover(③). ●Disassemble the screw(⑤) from the assembly part of temperature control part. And disassemble the PBA board. ●Assembly is reverse of disassembly. COVER MULTI IN REFRIGERATOR THERMISTOR IN REFIGERATOR Before disassemble the thermistor, Should be removed cover multi. 1) Peel off the tape on the back side cover assembly. 2) Separate insulation of cover multi from the cover. 3) Remove the sensor. Before disassemble the cover, Should be removed Ass'y damper. 1) Pull the screw cap out (1 EA). 2) Remove the screws (1 EA). 3) Disconnect the wire connector of thermistor. 4) Grasp the bottom edge of the cover, pull it down and remove it. 20 8-3. Machine compartment Condenser Fan Machine Compartment & Electric Box The condenser fan is located in the middle of machine compartment it cools down the subcondenser and compressor. 1) Disconnect the wire connector of Fan. 2) Remove the screws (1 EA) on the drain water tray. 3)Take out the condenser fan assembly. 1) Disconnect the compressor cover by releasing the screws(6EA). 2) Remove the screws which are securing the electric box. and press the tap in electric box coverto take outbyusing a flat-blade screw driver. Sub-condenser The sub-condenser is located in the machine compartment. 1) Desolder the compressor discharge & the outlet of sub-condensor. 2) Take out the sub condenser. (+)driver (-)driver Desoldering Point PCB-MAIN ASSY 21 9. FUNCTION AND OPERATION 9-1. Panel Display REF. TEMP. BUTTON To set the refrigerator temperature, push the button repeatedly to select a level between 1 level (cold) to 9 level (colder). FRE. TEMP. BUTTON To set the freezer temperature, push the button repeatedly to select a level between 1 level (cold) to 9 level (colder). • The higher level you set, the lower temperature inside the unit. NOTE 9-2. Temperature Control 1) Freezer • The freezer temperature can be set to a level between 1 level (cold) to 9 level (colder). • Push the FRE. TEMP. button repeatedly until the desired level is reached. - At each level, the LED lamps will turn on or off as shown on the table. Control table Temp. Fre -16℃ -18℃ (about) Ref 6℃ 4℃ Reference LED ⑤ condition ④ (on) ③ (off) ② ◐(blink) ● ○ 2) Refrigerator • The refrigerator temperature can be set to a level between 1 level (cold) to 9 level (colder). • Push the REF. TEMP. button repeatedly until the desired level is reached. - At each level, the LED lamps will turn on or off as shown on the table. NOTE cold ● level ⑤ ④ ③ ② ◐ 1 2 -20℃ 3℃ -22℃ 2℃ -25℃ 1℃ normal colder ● ④ ④ ④ ④ ● ◐ ● ③ ③ ● ◐ ● ● ● ● ◐ ●●●●● ●●●●●●● ⑤ ⑤ ⑤ ⑤ ⑤ ⑤ 3 4 5 6 7 8 9 After blinking (◐) for 3second, led turn on (●). • For your convenience, your freezer/refrigerator controls have been preset at the factory. The freezer/refrigerator control should both be set to normal (level 5) when you first install your freezer/refrigdfator. 22 9-3. Alarm ”) 1) Button touch sound (“DING-DONG” If the panel button is pressed, “DING-DONG” sound of input confirm is occurred. If the buttons are pressed at the same time or incorrectly, this sound is not occurred. 2) Alarm sound at the door opened ( “beep” ) If the door of refrigerator/freezer is opened and has passed 2 minutes, the alarm is occurred in 10 seconds. If the door is remained in open continuously, the alarm continues for 10 seconds 1 minute periodic. The alarm is sopped at once after closing the door of refrigerator/freezer. 3) Alarm sound at the forced start , defrost (“beep” ) If the forced start or defrost is selected , ( “beep” ) alarm sound occurred. If the forced start is selected, the alarm is continued to the auto release(after 24 hours operation in forced start) or the selection of release function. Also at the forced defrost, the alarm is continued to the completion(including the pause times) or the selection of release function. 9-4. Defrost 1) The freezer defrost is decided according to the integration time of Compressor ON. 2) At the initial power ON, freezer defrost is performed after 4 hours of integration time of Comp. ON. 3) After this, a defrost period is variable from 6 hours to 11 hours in accordance with the use condition and ambient environment. 4) The defrost period is decided by the outdoor temperature, number and time of the opening of refrigerator door. 9-5. Test function 1) Selection of test function Following two procedures are sequences for changing normal mode into test mode. Press both ‘R room key’ and ‘F room key’, and keeping pressing keys over 11 seconds. Note) 0 3 seconds : no phenomenon 3 7 seconds : panel display blinks of 0.5 sec interval 7 11 seconds : panel display blinks of 0.2 sec interval Press F room key after releasing two keys when 11 seconds passed. Then the mode is changed to the test mode. In the test mode, F room key is main key for changing status. Note) One times : forced running Two times : forced defrost (1) Three times : forced defrost (2) Four times : release function 23 2) The change of lamp displays test mode function(Pressing for 7 seconds) At the time of test mode selection : Lamp all OFF At the time of forced running selection : 8 lamps ON At the time of forced defrost(1) selection : 5 lamps of freezer control ON At the time of forced defrost(2) selection : 5 lamps of refrigerator control ON At the release of test function : Lamp all OFF 3) Forced running At the test mode, once more pressing the F room key selects forced running. At this time, buzzer performs alarm by beep. If the forced running is selected, compressor is in action immediately without 5 minutes delay action. If defrost is proceeded at this time, defrost stops immediately. If the forced running is selected, compressor and F-fan is operated on pull down for 24 hours, and R room is controlled by set temperature. The forced running is performed continuously until the completion(24 hours) or change to another mode, or release.. If the forced running is selected, freezer is selected to “ colder(-25 )” , and refrigerator “ middle colder(2 )” After the forced running is completed(24 hours), defrost is performed regardless of the former mode. If the forced running is released, Comp. on time during the forced running is reflected in a defrost period by addition. 24 4) Forced defrost When the test mode is selected, if F room key is pressed in twice, the forced defrost(1) is selected. If F room key is pressed in three times, the forced defrost(2) is selected. But the forced defrost(2) mode is not used. The beep sound continues, during the heating and resting period. Damper (cooling air interception) closes until the completion of defrost time. 9-6. Self Diagnosis 1) Self diagnosis in the initial power on When a power is ON, if internal MICOM will decide faulty in temperature within 1 second. If faulty sensor is found, the “related display LED” switches ON and OFF for 0.5 second intervals. At the LED situation is the faulty sensor display, self-test function key (F room key + R room key for 11seconds) is the control of normal temperature is delayed. Fixing default sensor when there is an error, or press F room key and R room key for 11 seconds, it automatically cancel self-test function and activate normally. 2) Self diagnostics in the normal operation If “ F-ROOM +R-ROOM” key is pressed for 3 seconds at the normal operation, temperature setting display proceeds ALL ON/OFF by 0.5 second intervals foe about 4 seconds. If “ F-ROOM +R-ROOM” key is pressed for 7 seconds including 4 seconds of ON/OFF, all displays proceed ALL ON/OFF by 0.2 second intervals for about 4 seconds. If “ F-ROOM +R-ROOM” key is pressed for total 11 seconds including 4 seconds of 0.2 second intervals ON/OFF, all displays becomes ALL ON and “ “ buzzer occurred, and then start a self diagnosis. Self diagnosis is performed from “ colder-colder” LED with being OFF in sequence at the state that freezer /refrigerator temperature setting displays are all ON. In case of detection inferior sensor, the corresponding display lamp keeps up ON. (Self diagnosis display table) No Items Symptorn Troubles Remarks Detaching the sensor Housing, fault of Connection, open or short of power cable, sensoritse lfinferiority, the others… Detaching the sensor Housing, fault of Outer Connection, open or short of power 2 Sensor cable, sensoritse lfinferiority, the others… Detaching the sensor Housing, fault of 3 F-Sensor Connection, open or short of power cable, sensoritse lfinferiority, the others… F-room defroster Detaching the sensor Housing, fault of Connection, open or short of power cable, 4 Sensor sensoritse lfinferiority, the others… Displayed inferiority When temperature detection of sensor is over 65 ℃or below -50℃. Displayed inferiority When temperature detection of sensor is over 65 ℃or below -50℃. Displayed inferiority When temperature detection of sensor is over 65 ℃or below -50℃. Displayed inferiority When temperature detection of sensor is over 65 ℃or below -50℃. Detaching of fan housing, fault of In case that BLDC fan motor feed back F Fan error open or short of power 5 (only stopping) Connection, cable,fan itself inferiority, constraint by signal is not detected ordetected the abnormal signal. fan wings freezing… Detaching of fan housing, fault of In case that BLDC fan motor feed back C Fan error open or short of 6 (only stopping) Connection, power cable, fan itself inferiority, signal is not detected ordetected the constraint by fan wings freezing… abnormal signal. 1 R-Sensor LED(cf. page23) R “Cold.Mid” R room LED No F “Cold” F room LED No F “Cold.Mid” F room LED No F “Mid” F room LED No F “Mid. Colder” F room LED No F “Colder” F room LED No ※ If you try to check the fan error condition, you should check the error at the forced running condition. 25 9-7. Display function of the presently operating parts 1) If you press ‘F room key’ and ‘R room key’ button together for 3 seconds during normal operation, LED display will show ON/OFF for 4 seconds at interval of 0.5 second. 2) At this moment, if you take off ‘F room key’ and ‘R room key’ button and press ‘R room key’ button, it change into the display of the presently operating parts. 3) This display condition is unrelated to actual operation and it is an reference of indication that MICOM commanded operating order. 4) After 30 seconds illumination of error signal, the system will return to the normal operation. (Display table of the presently operating parts) NO CONTENT 1 2 3 4 5 6 7 8 9 10 DAMPER At the normal times In the conditions of overload (over 30℃) C-FAN HIGH C-FAN LOW COMP F-FAN HIGH F room defrost heater F-FAN LOW In the conditions of low temperature DISPLAY LED R “ Cold ” R “ Cold. Middle ” R “ Middle ” R “ Middle. Colder ” R “ Colder ” F “ Cold ” F “ Cold. Middle” F “ Middle” F “ Middle. Colder ” F “ Colder ” R room LED No R room LED No R room LED No R room LED No R room LED No F room LED No F room LED No F room LED No F room LED No F room LED No 9-8. C-FAN(Comp-fan) Control In Accordance With Outdoor Temperature 1) According to the ambient temperature, the condenser fan located in the machine compartment is operated with different modes. Ranges of ambient temp. C-FAN Delay function Operation Above 18 ℃ C-FAN is ON as soon as the compressor ON. 13 17 ℃ C-FAN is ON with 5 minutes delay from the compressor ON. Below 12 ℃ C-FAN is OFF regardless of the compressor operation. 26 10. CIRCUIT DESCRIPTION 10-1. Power source part Power source Used circuit Vcc(DC 5V) Surrounding power of MICOM and sensor detection part +2V(DC 12V) Relay driving part, panel display part BLDC(DC 12V) OP AMP, TR constant voltage circuit use(BLDC fan motor drive) AC 220V input power is reduced by passing through LVT(DC-TRANS), this power is changed to DC voltage through rectification diode. After this, DC 12V leveled by 1000uF/35V capacitor and settled by regulator 7812 is output and in use for relay and panel PCB driving power, input power and refrigerator control. Another the second of LVT(DC-trans) is leveled by rectification diode and 1000uF/35V capacitor, and controlled to set voltage by OP amp, constant voltage TR circuit, and then supplies a settled voltage to BLDC motor. 10-2. Oscillation circuit part Terminal Oscillation frequency Xin(#30) 4MHz Xout(#31) 4MHz Oscillation circuit is for clock occurrence for synchronism to the information transmission/reception of MICOM internal elements and for time calculation. If the resonator spec is changed, normal function is not performed because of the changing of MICOM timing system. 10-3. Reset circuit part 27 Terminal Voltage Vcc DC 5V RESET DC 5V Reset circuit is that initializes many internal parts of the MICOM and makes the all programs to act in the initial state in case that power is impressed to MICOM by instantaneous interruption or power input. Reset terminal voltage becomes to scores of us “ LOW” compared to the MICOM Vcc((DC 5V) voltage on power impression, and keeps “ HIGH” (Vcc voltage) on the normal action. 10-4. Door S/W detection circuit Terminal Door state MICOM input CLOSE 0V (LOW) OPEN 5V (HIGH) CLOSE 0V (LOW) OPEN 5V (HIGH) F room R room CN30℃ is connected to GND and ② is supplied Vcc(DC 5V) by passing through Resistance R401 (10℃), and it detects F room door open/close by impressing to MICOM “ HIGH(5V)/LOW” . CN30 ℃ is connected to GND and ① is supplied Vcc(DC 5V) by passing through resistance R403(10℃), and it detects R room door open/close by impressing to MICOM “ HIGH(5V)/LOW” If there are some faults in door S/W at this time, the corresponding fan is not act or alarm occurs. Check the door S/W whether it has an abnormality. If the door is opened, the internal corresponding fan stops. This is occurred because MICOM stops the fan deciding door open although door is closed when being S/W contact point abnormality. 10-5. Temperature detection circuit MICOM terminal Voltage Outdoor temperature PIN #57 (F-DEF-SENSOR) MICOM terminal voltage is PIN #58 (R-SENSOR) changed by the PIN #59 (ATMOSPHERE SENSOR) temperature. PIN #56 (F-SENSOR) Sensor makes use of the character that resistance value becomes smaller when temperature is high, and bigger temperature is low by use of thermistor having a indeterminate resistance temperature coefficient. R302,4,6,8 and C301,2,3,5 have no concern with temperature detection because they are for noise protection parts. In case of F-sensor, if the voltage that input to MICOM is supposed to Vf, Vf= (Rth x Vcc)/(R301 + Rth).At this, Rth is a thermistor resistance value. Refer to attached appendix for MICOM terminal voltage corresponded to temperature and resistance/voltage conversion table of sensor. 28 10-6. Key scan and display circuit part 1) Description of key scan and display drive action As a following each part wave, “ HIGH” output is send out, by use of three terminals of MICOM No #5,6,7 by 6 msec intervals. This signal passes through input terminal of IC05 and is displayed to output terminal. At this time, the peak to peak voltage of rectangle wave is about 12V, the shape of output wave is like following. 2) KEY SCAN When GRID #3 wave is output, this signal is supplied to SW1 by passing through panel PCB R5 resistance 10℃. At this time, pressing SW1 makes a signal small by R508(6.8㏀) and R505(12㏀), and impress peak to peak 4.5V to MICOM. MICOM decides that GRID #3 wave is input and changes the function corresponding to SW1. Like this, each GRID wave is recognized. 29 10-7. BLDC MOTOR drive circuit ● Movement description When F-fan is driven to LOW RPM, Resetting the MICOM #40 pin with being set #39 always links the R705 and R707 in a parallel. At this time, the voltage is devided between a parallel resistance value and R706, impressed to OP-AMP. It makes Q1 turn ON, F-fan drive. If F-fan is in condition of OFF, MICOM #39 pin is reset and F-fan is stopped. In case of the Comp.-fan, it is controlled by the same method with F-fan. But its drive voltage is different with that because there is a difference in E1 voltage /E2 voltage due to the difference of RPM. ※ Fan motor protection When the fan is not run because of F-fan/C-fan freezing or power cord connection part inferiority, fan self-signal is not occurred. So MICOM decides fan abnormality. At this time, perform the fan three seconds ON, seven seconds OFF in five times. If there is no signal during the fan ON/OFF five times, after 10 minutes pausing repeat the three seconds ON, seven seconds OFF in five times. If the signal is occurred during the three seconds ON, seven seconds OFF, MICOM decides that operation is normal and releases all motor protect functions and performs a normal function. 30 10-8. Load drive part circuit ● Movement description When “ HIGH” signal is impressed to input terminal of IC04 at MICOM PIN NO #15, IC turns ON. At this time, V12(DC 12V) connected to one side end of Comp relay passes through output of IC04 to ground, and the core of relay causes a magnetic field and makes a contact point on. And AC input voltage(AC 220V) is impressed to the both side end of Comp. load, Comp. acts. In case of the MICOM PIN #15 signal is “ LOW” , IC04 turns off and the current is not flow to Comp. relay coil and makes a relay contact off. And Comp. stops. The load except the compressor equals or likes to the act principal of compressor. Refer to the above circuit diagram. 31 10-9. Damper motor drive part ● Movement description Damper is a 2 excitation type stepping motor used in controlling the refrigerator temperature. It is opened when the temperature is higher than the setting temperature of refrigerator sensor, and closed lower according to the refrigerator notch. It performs a open/close without regardless of refrigerator temperature at power ON, and then decides the state of open/close according to the temperature. Open/close action is controlled by MICOM #34, #35, #37 through damper motor(stepping-motor) exclusive control drive IC(IC8:TA7774P). Damper heater is supplied DC12V whenever voltage impresses to the refrigerator and the signal is occurred always in MICOM #24, DC 12V flows into the damper heater by IC3. ※ Note In case of the above damper heater, because the PCB cannot detect the open/close state, there is no self diagnosis function for deciding the abnormality. IN the above diagram, if a wire cut off linked 3,4,5 of CN7, motor is run as a normal, but refrigerator over cooling occurs by slightly open at the close of damper. So, check for deciding of abnormality of damper motor connection part like followings. 1) Check method : After separation of CN72 housing, measure the resistance value by use of multi tester and decide the abnormality. 2) Resistance value spec ①-② (black, brown) : 150Ω±15% ③-④ (white, blue) : 426Ω±15% ⑤-⑥ (yellow, red) : 426Ω±15% 32 10-10. Options ■ As like above circuit diagram, it makes change the items related to temperature and function by use of switching diode on the main PCB. ※ Note Because the option is set at shipment, hold free change except a special case. After change be sure to 10-11. Temperature related option ■Freezer temperature shift (unit: ) SHIFT D601 D602 D603 0 Standard 0 0 1 -0.5 0 0 0 -1.0 1 0 1 -2.0 1 0 0 -3.0 0 1 1 +1.0 0 1 0 +2.0 1 1 1 +3.0 1 1 ■Refrigerator temperature shift (unit: ) SHIFT D604 D605 D606 Standard 0 0 0 -0.5 1 0 0 -1.0 0 1 0 -2.0 1 1 0 -3.0 0 0 1 +1.0 1 0 1 +2.0 0 1 1 +3.0 1 1 1 ■Freezer hysteresis (unit: ) SHIFT D608 D609 Standard 0 0 1 0 0 1 1 1 ■Refrigerator hysteresis (unit: ) SHIFT D607 Basic type ±2.0 Standard 0 ±1.0 1 Basic type ±3.0 ±2.5 ±3.5 ±4.0 33 Appendix ■Sensor resistance value in accordance with temperature and MICOM ort voltage Temperature(℃) Resistance(Ω) Voltage(V) Temperature(℃) Resistance(Ω) Voltage(V) Temperature(℃) Resistance(Ω) Voltage(V) -42 98870 4.541 -11 21410 3.408 20 6013 1.878 -41 93700 4.518 -10 20480 3.36 21 5792 1.834 -40 88850 4.494 -9 19580 3.31 22 5581 1.791 -39 84150 4.469 -8 18730 3.26 23 5379 1.749 -38 79800 4.443 -7 17920 3.209 24 5185 1.707 -37 75670 4.416 -6 17160 3.159 25 5000 1.667 -36 71800 4.389 -5 16430 3.108 26 4821 1.626 -35 68150 4.36 -4 15740 3.057 27 4650 1.587 -34 64710 4.331 -3 15080 3.006 28 4487 1.549 -33 61480 4.301 -2 14450 2.955 29 4329 1.511 -32 58430 4.269 -1 13860 2.904 30 4179 1.474 -31 55550 4.237 0 13290 2.853 31 4033 1.437 -30 52840 4.204 1 12740 2.801 32 3894 1.401 -29 50230 4.17 2 12220 2.75 33 3760 1.366 -28 47770 4.134 3 11720 2.698 34 3631 1.332 -27 45450 4.098 4 11250 2.647 35 3508 1.298 -26 43260 4.061 5 10800 2.596 36 3390 1.266 -25 41190 4.023 6 10370 2.545 37 3276 1.234 -24 39240 3.985 7 9959 2.495 38 3167 1.203 -23 37390 3.945 8 9569 2.445 39 3062 1.172 -22 35650 3.905 9 9195 2.395 40 2962 1.143 -21 33990 3.863 10 8839 2.346 41 2864 1.113 -20 32430 3.822 11 8494 2.296 42 2770 1.085 -19 30920 3.778 12 8166 2.248 43 2680 1.057 -18 29500 3.734 13 7852 2.199 44 2593 1.03 -17 28140 3.689 14 7552 2.151 45 2510 1.003 -16 26870 3.644 15 7266 2.104 46 2429 0.977 -15 25650 3.597 16 6992 2.057 47 2352 0.952 -14 24510 3.551 17 6731 2.012 48 2278 0.928 -13 23420 3.504 18 6481 1.966 49 2206 0.904 -12 22390 3.456 19 6242 1.922 34 10-12. Electric Circuit Diagram BLU-BLUE BRN-BROWN E-EARTH GRY-GRAY ORG-ORANGE PNK-PINK PRP-PURPLE RED-RED S/BLU-SKY BLUE WHT-WHITE YEL-YELLOW BLK-BLACK W/BLK-WHITE/BLACK W/RED-WHITE/RED 35 11. DIAGNOSIS AND TROUBLESHOOTING 11-1. Power cut off Start Y Is the power cord or fuse break? N Fuse exchange N Is impressed the first power of DC trans? Power cord assembly connection check Y Y Is DC 12V, DC 5V on main PCB run? Y REG 7812, 7805 out end measurement Repair of power part on PCB N Is normal the power cord on panel PCB? Check the connection of housing of main PCB part and refrigerator panel connection part Y Panel PCB exchange N Is the reset IC (IC02) output terminal DC 5V? Y Exchange of the main PCB ASS’ Y 36 Exchange/repair of reset IC 11-2. Compressor trouble Pre-inspection 1. If compressor is off by refrigerator temperature, it is not run within five minutes minimum. 2. Compressor is not run during the defrost. 3. If the freezer sensor is not connected, compressor is not run due to low temperature detection. Start N Have passed 5 minutes after cut off? Y Check after 5 minutes Y Is compressor run at the forced start? Is occurred the forced start alarm? N Is the freezer/refrigerator temperature detection sensor normal? Y Is impressed DC 12V to the both side end of coil of compressor relay(RY72) on the main PCB? Check power cord connection Exchange the main PCB Y Is impressed between the gloomy line and red line of CN70 AC 220V? Exchange compressor relay on the PCB Y Check the connection of the lines of main PCB part and compressor surrounding OLP, relay PTC 37 N Exchange inferior sensor 11-3. Defrost failure Condition for decision 1. In case of the defrost inferior, it runs normally at the initial power on. But the freezing and cooling inferior occurs after some times and at the time of defrost. This is a abnormality of defrost system. Refer to the followings. Start Is the freezer defrost sensor normal by self diagnosis? N Y Corresponding sensor change/repair N Is the freezer defrost heater normal? Check the temperature fuse, heater self break, cord contact Y Is the temperature of defrost sensor below -5℃? N Y Forced start for a some times Perform the forced defrost N Is the defrost heater run? Y After heating some period check heater off. Is the cord connection terminal of main PCB part normal? Y Is the defrost relay normal? Y Exchange the main PCB 38 N Repair the connection terminal N Exchange/repair the defrost relay 11-4. Freezer fan abnormality(BLDC-FAN repair) Condition for decision 1) When the freezer fan is abnormal, freezer and refrigerator weak cooling occurs. This is a freezer fan system failure. Refer to the followings. Start N Is the compressor off? Y Is it DC 7V~DC 12V between main PCB part GND and CN73 1pin? Forced start Y F-fan normal Is it DC 0V between main PCB part CN30 1~2(freezer) and 5~6(refrigerator) pin? Y Measure in door closing -. F-DOOR OPEN : DC5V -. F-DOOR CLOSE : 0V Repair the door S/W connection part Impress the power after five minutes from the power off(Compressor O/L/protection) After impression of initial power compressor and fans run continuously. (It runs without regard to temperature) Is it repeated DC 7V~DC 12V and below 2V between main PCB part GND and CN73 1 pin? If the pulse signal of fan self occurring through CN73 3 is not detected to MICOM, fan protection function runs that performs 3 seconds ON 7 seconds OFF in five times. It occurs DC7~12V at the time of 3 seconds ON, it becomes below DC 2V at 7 seconds OFF. Y N Main PCB exchange/repair Check and repair the fan motor self inferior, contact inferior of cord connection part Reference 1) Refrigerator controls the refrigerator temperature by damper motor without fan motor. 2) Because the apparatus room fan motor is applied to the same BLDC fan with F-fan, Check it by reference to circuit diagram with the above method. 39 11-5. Refrigerator damper inferiority Condition for decision 1) When D/P motor in refrigerator is failed, weak cooling and over cooling can be occurred. 2) If the inferiority is occurred at the state of D/P motor open, refrigerator is over cooling. And at the state of close, refrigerator is over cooling. In this ases, it is the abnormality of refrigerator damper system. Refer to the followings. Start Disassemble refrigerator damper assembly. (Housing connection connectors keep up the assembly.) Power off and ON again. Y Is the D/P motor run for a time when power on? Decide that the abnormal or not after measurement of resistance value of damper connection part. N In case of power on, perform a time of open/close running to confirm that D/P motor run or not. Is there any abnormality of D/P motor part connection connector? N Y Is there any abnormality of main PCB CN72 connection connector? Y ▣ Measure after PBA main CN72 disassembly -. ①-② (black, brown):150Ω±15% -. ③-④ (white, blue):426Ω±15% -. ⑤-⑥ (yellow, red):426Ω±15% Repair the connection connector. N Repair the connection connector. Exchange the main PCB assembly or D/P motor assembly Reference 1) Refrigerator D/P motor is composed of stepping motor. 2) It has not self diagnosis function because MICOM cannot detect an abnormal running of D/P motor.3. Among the damper running, signal by step cannot be measured by the general tester. So, confirm by naked eye the running state at the time of power on with reference to the above method and circuit diagram. 40 11-6. Internal light not lit.(Freezer, Refrigerator) Start Y Is break off the internal filament? N Exchange/repair internal light N Is normal the door S/W contactor? Y Exchange/repair door S/W Confirm door S/W connection part and internal light socket and repair. 11-7. Circuit service materials list NO CODE-NO Name of goods Specification Q’ty 1 DA41-00113B PBA MAIN ASS’Y RS20N 1 2 DA41-00114A PBA PANEL ASS’Y DC12V 1 3 DA26-00009G DC-TRANS 110V∼115V/60Hz 1 DA26-00009F DC-TRANS 230V∼240V/50Hz 1 DA26-00009A DC-TRANS 220V/50Hz 1 DA26-00009H DC-TRANS 127V/60Hz 1 4 DA32-10105V R-ROOM SENSOR PX41C(Blue) 1 5 DA32-10109U F-ROOM SENSOR PX41C(Yellow) 1 6 DA32-00006B F-EVA SENSOR PX41C(Yellow) 1 7 DA32-10109T EXIT SENSOR PX41C(White) 1 41 Remarks 12. ILLSTRATED PARTS CATALOGUE 12-1. Parts of Freezer 42 ■ Parts list of Freezer NO CODE-NO 1 1-1 1-2 1-3 2 2-1 2-2 2-3 2-4 2-5 2-6 3 3-1 3-2 3-3 4 4-1 4-2 4-3 5 5-1 5-2 5-3 6 6-1 6-2 6-3 7 8 8-1 8-2 8-3 8-4 8-5 9 9-1 9-2 9-3 9-4 9-5 9-6 9-7 DA97-00124A DA64-00554A DA67-00644A DA64-00090A DA97-00125A DA64-00554B DA67-00645A DA61-00519A DA64-00090A DA63-01078A 6002-000224 DA67-00181B DA67-00177E DA67-00146A DA64-00090A DA67-00181A DA67-00177C DA67-00146A DA64-00090A DA67-00182A DA67-00150A DA63-00174A DA63-00170A DA67-00183A DA67-00151A DA63-00174A DA63-00170A DA67-30266D DA97-00128B DA63-01085A DA62-00169A DA32-10109U DA63-00798B DA63-00799A DA97-00153A DA63-01061A DA62-00164A DA61-00521A DA62-00259A DA61-00737A DA62-00182A DA62-00260A (http://www.e4buyer.com/refrigerator) Name of goods CSL ASSY-SHELF FRE UP GLASS-SHELF FRE,UP SHELF-FRE UP TRIM-SHELF ASSY-SHELF FRE MID GLASS-SHELF FRE,MID SHELF-FRE MID RAIL-TRAY ICE TRIM-SHELF TRAY ICE SCREW TAPPING ASSY SHELF FRE, LOW GLASS SHELF FRE, LOW SHELF-FRE, LOW TRIM-SHELF ASSY SHELF-FRE SHELF GLASS SHELF-FRE TRIM-SHELF CASE-BASKET ASSY,UP CASE-BASKET UP COVER-FRONT,B COVER-FRONT,A CASE-BASKET ASSY,LOW CASE-BASKET LOW COVER-FRONT,B COVER-FRONT,A CAP SCREW ASSY-COVER DUCT FRONT,FRE COVER-DUCT FRE DUCT FRONT,FRE SENSOR ASSY COVER-SENSOR,A COVER-SENSOR,B ASSY-COVER EVAP FRONT COVER-EVAP FRONT COVER EVAP FRONT PLATE-INS EVAP SEAL-INS EVAP FRONT, LOW PLATE COVER EVAP FRONT SEAL INS EVAP FRONT SEAL INS EVAP FRONT UP 43 RS20N*** CSW ESL ESW Specification ■ Parts list of Freezer NO CODE-NO 10 10-1 10-2 10-3 10-4 10-5 10-6 10-7 10-8 10-9 10-10 11 12 13 DA97-00129A DA63-01086A DA63-00713B DA31-00020M DA63-01146A DA39-00227A DA31-00052A DA61-20128A 6002-000480 DA62-00189A DA63-40167A DA63-01075A DA61-00518A 4713-001147 4713-001145 DA34-10120A DA96-00033B DA96-00033A DA97-00155A DA96-00033C DA47-10148M DA32-00006B DA60-00042A DA62-00184A 6002-000215 14 15 15-1 15-2 15-3 15-4 16 Name of goods CSL ASSY-COVER DUCT REAR, FRE COVER-DUCT REAR FRE COVER-MOTOR MOTOR BLDC GROMMET-MOTOR W/HARNESS SUB FAN PROPELLER SPRING ETC-FAN SCREW-TAPPING SEAL-DUCT REAR GROMMET-COVER CHIL COVER LAMP PLATE-REFLELTOR LAMP-INCANDESCENT RS20N*** CSW ESL ESW Specification DC 12V 110 127V, 25W 220 230V, 30W SWITCH DOOR ASSY-EVAP FRE 110V 230V 220V 127V ASSY-THERMO FUSE SENSOR TEMP SPACER EVAP FRE SEAL INS EVAP SCREW-TAPPING 250V, 10A, 77℃ 44 12-2. Parts of Refrigerator 45 ■ Parts list of Refrigerator NO CODE-NO 1 1-1 1-2 2 2-1 2-2 3 3-1 3-2 4 4-1 4-2 5 6 7 7-1 7-2 8 8-1 8-2 8-3 9 9-1 9-2 9-3 9-4 10 10-1 10-2 10-3 10-4 11 11-1 11-2 11-3 12 DA97-00126B DA64-00554C DA67-00646A DA97-00126B DA64-00554C DA67-00646A DA61-60183B DA61-60179A DA63-40256B DA61-60184B DA61-60180A DA63-40256B 6002-000215 DA63-01074B DA97-00126B DA64-00554C DA67-00646A DA97-00127B DA64-00554D DA67-00768A DA64-00647A DA97-00118A DA61-00507A DA63-01065A DA63-01064A DA64-00085A DA97-00117A DA61-00508A DA63-01065A DA63-01064A DA64-00085A DA97-00355C DA62-00166A DA31-00043B DA62-00167A DA97-00154C DA97-00154B DA97-00154A DA97-00154D DA63-01073A DA47-00106D DA47-00106B DA47-00106E DA47-00106C 12-1 12-2 (http://www.e4buyer.com/refrigerator) Name of goods CSL ASSY-SHELF REF, UP GLASS-SHELF REF,UP SHELF-REF UP ASSY-SHELF REFUP GLASS-SHELF REF,UP SHELF-REF UP RAIL-LOW L, ASSY RAIL-LOW L GROMMET-RAIL RAIL-LOW R, ASSY RAIL-LOW R GROMMET-RAIL SCREW-TAPPING TRAY-REF ASSY-SHELF REFUP GLASS-SHELF REF,UP SHELF-REF UP ASSY-SHELF REF, LOW GLASS-SHELF REF,LOW SHELF-REF LOW TRIM-SHELF REF,LOW ASSY-VEG UP CASE-VEG UP COVER-FRONT,B COVER-FRONT,A KNOB-MOIS CONT ASSY-CASE VEG LOW CASE-VEG LOW COVER-FRONT,B COVER-FRONT,A KNOB-MOIS CONT ASSY INS-DAMPER,REF INS-DAMPER UP MOTOR STEP-DAMPER INS-DAMPER LOW ASSY-COVER DAMPER RS20N*** CSW ESL ESW Specification 110V 230V 220V 127V COVER DAMPER HEATER-COVER DAMPER 110V/60Hz 230V/50Hz 220V/50Hz 127V/60Hz 46 ■ Parts list of Refrigerator NO CODE-NO 12-3 12-4 12-5 12-6 12-7 12-8 13 13-1 13-2 13-3 13-4 13-5 13-6 13-7 14 14-1 14-2 15 16 17 18 DA62-00227A DA41-00114A DA64-00557B 6002-000319 6002-000213 DA63-01076A DA97-00120B DA63-01087A DA62-00170A DA97-00589A DA97-00588A DA32-10105V DA63-00798B DA63-00799A DA97-00152A DA02-00057A DA63-01077A DA67-40250E DA63-01075A DA61-00518A 4713-001147 4713-001145 DA34-10110B DA67-30266D 6002-000215 DA63-01066A 19 20 21 22 Name of goods CSL INS-DAMPER REF.SUB PBA PANEL INLAY-PBA CONTROL SCREW-TAPPING SCREW-TAPPING COVER PBA CONTROL ASSY-COVER MULTI REF COVER-MULTI REF MULTI REF ASS’Y SEAL MULTI ASS’Y GUIDE MULTI SENSOR TEMP COVER-SENSOR,A COVER-SENSOR,B ASSY-COVER PURIFIER CATALYST-LTC COVER-PURIFIER TRAY-UTILITY COVER LAMP PLATE-REFLECTOR LAMP-INCANDESCENT RS20N*** CSW ESL ESW Specification 110 127V, 25W 220 230V, 30W SWITCH-DOOR CAP-SCREW SCREW-TAPPING COVER VEG LOW 47 12-3. Parts of Unit 48 ■ Parts list of unit NO CODE-NO 1 DA63-00201B DA63-00201L DA61-00058C DA61-00051D DA63-50192A DA60-10004A DA63-00200B DA63-00200L DA61-00058D DA61-00052F DA63-50192A DA61-00112F DA63-50207C DA61-00317A DA61-00111C DA63-50207C DA61-30102C DA61-00056A DA60-10122C 6009-001255 DA63-01062F DA61-00261A 2501-001045 2501-001045 2501-001091 2501-001091 DA41-00113A DA71-00155A DA26-00009G DA26-00009H DA26-00009A DA26-00009F DA63-00783A 2 2-1 2-2 3 4 5 5-1 5-2 6 6-1 7 8 8-1 9 10 11 12 13 14 15 16 17 18 19 20 21 22 22-1 22-2 23 24 25 26 DA97-00136A DA97-00359A DA62-20001R DA63-00951C DA63-40171B DA60-20008A MK183CL2U/EH1 DK182PL2U/E01 DK190KT2U/E01 MK183QL2U/E01 DA63-40004A (http://www.e4buyer.com/refrigerator) Name of goods CSL RS20N*** CSW ESL ESW Specification COVER HINGE-UP,L ASSY HINGE UP-L HINGE-UP, L SHIM-HINGE,UP SCREW TAP TITE COVER HINGE-UP,R ASSY HINGE UP-R HINGE-UP, R SHIM-HINGE,UP HINGE-LOW L,ASSY SHIM-HINGE,LOW BRACKET-HINGE,LOW HINGE-LOW R,ASSY SHIM-HINGE,LOW FOOT FRONT ASSY CASTER FRONT SCREW TAP TITE SCREW HEX COVER-LEG FRONT CASE PCB-PANEL C-OIL 110V/60Hz,250VAC,12uF 127V/60Hz,250VAC,12uF 220V/50Hz,350VAC,5uF 230V/50Hz,350VAC,5uF PBA MAIN FIXER-MAIN PCB TRANS POWER 110,115V/60Hz 127V/60Hz 220V/50Hz 230V/50Hz COVER PCB-PANEL CBF-POWER ASSY-COVER COMP ASSY TUBE-DRAIN TUBE PVC GROMMET-DRAIN HOSE GROMMET-SUCT PIPE BOLT-HEX COMPRESSOR 110V/60Hz 127V/60Hz 220V/50Hz 230V/50Hz GROMMET-COMP 49 ■ Parts list of unit NO CODE-NO 27 DA34-10003D DA34-10003D DA34-10003U DA34-10003V DA35-10013Q DA35-10013Q DA35-10013E DA35-10013B DA63-10352A DA39-00084B DA73-30102B 6002-000213 DA60-10124A DA60-10107A DA39-20389E DA97-00367C DA97-00259C DA63-00713A DA63-01146A DA31-00020H DA61-00415A DA66-00034A DA72-00176A 6002-000227 6002-000213 DA31-00010D DA31-00015C DA61-20128A DA97-00133B DA67-00642A 28 29 30 31 32 33 34 35 36 36-1 36-2 36-3 36-4 36-5 36-6 36-7 36-8 36-9 37 37-1 37-2 38 39 Name of goods CSL RELAY PROTECTOR O/L RS20N*** CSW ESL ESW Specification 110V/60Hz 127V/60Hz 220V/50Hz 230V/50Hz 110V/60Hz 127V/60Hz 220V/50Hz 230V/50Hz RELAY-PTC COVER-RELAY WIRE HARNESS,COMP DRYER-ASSY SCREW-TAPPING SCREW-TAP TITE SCREW-EARTH WIRE HARNESS-EARTH ASSY TRAY-DRAIN WATER ASSY PIPE-SPIRAL COND COVER-MOTOR GROMMET-MOTOR MOTOR DC-BLDC SENSOR SUPPORT-CIRCUITE MOTOR TRAY-DRAIN WATER SEAL-COND SCREW-TAPPING SCREW-TAPPING FAN-ASS’Y FAN-TURBO SPRING-ETC,FAN ASS’Y CHASSIS COMP DUCT-CABI, LOW DC12V 50 12-4. Parts of the freezer door 51 ■ Parts list of the freezer door NO CODE-NO 1 DA91-01516B DA91-01516G DA91-01516F DA91-01516N DA97-00178A DA63-00171A DA63-00171D DA63-00213A 6002-000468 6001-000716 DA61-00776A DA66-90112C 6001-000716 DA64-00110B DA64-00110C DA64-00096B DA64-00096C DA71-00077A 6002-000470 6002-000468 DA64-00097B DA64-00097C DA97-00654B DA97-00654C DA61-00511A 6002-000470 6002-000213 DA64-00209A DA64-00098H DA64-00098B DA64-00196A DA64-00196B DA64-00100L DA64-00100A DA64-00543B DA64-00543C DA64-00379B DA64-00379C DA64-00328B DA64-00328C DA71-00280A 6002-000213 DA64-00329B DA64-00329C DA64-00371B DA64-00371C 2 3 4 5 6 7 8 9 10 11 11-1 11-2 11-3 12 13 14 14-1 14-2 15 16 16-1 16-2 17 18 19 19-1 19-2 19-3 19-4 20 Name of goods (http://www.e4buyer.com/refrigerator) CSL RS20N*** CSW ESL ESW ASSY DOOR FOAM FRE Specification STS-LOOKING SNOW-WHITE STS-LOOKING SNOW-WHITE ASSY-GASKET DOOR,FRE GUARD-BOTTLE FRE,MID GUARD-BOTTLE FRE,LOW GUARD-FRE-UPP SCREW-TAPPING SCREW-MACHINE STOPPER DOOR CAM HINGE-RISER, LOW SCREW-MACHINE ASSY HANDLE MID SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE HANDLE BASE MID REINF HANDLE MID SCREW TAPPING SCREW TAPPING HANDLE BASE UPP SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE ASSY HANDLE LOW REINF HANDLE LOW SCREW TAPPING SCREW TAPPING ASSY TRIM HANDLE MID TRIM HANDLE MID SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE TRIM HANDLE CONNECT MID TRIM HANDLE UPP TRIM HANDLE LOW ASS'Y HANDLE HANDLE REAR REINF HANDLE SCREW TAPPING HANDLE FRONT - BASE HANDLE UPP 52 DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE ■ Parts list of the freezer door NO CODE-NO 21 DA64-00547B DA64-00547C 6002-001122 DA64-00326B DA64-00326C DA64-00544B DA64-00544C 6002-000468 DA64-00324B DA64-00324C 22 23 24 25 26 Name of goods CSL BASE HANDLE LOW RS20N*** CSW ESL ESW Specification DELUXE-BAR HANDLE DELUXE-BAR HANDLE SCREW TAPPING TRIM-HANDLE UPP DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE TRIM-HANDLE LOW SCREW TAPPING TRIM-HANDLE MID, A DELUXE-BAR HANDLE DELUXE-BAR HANDLE 53 12-5. Parts of the refrigerator door 54 ■ Parts list of the refrigerator door NO CODE-NO 1 DA91-01517B DA91-01517G DA91-01517F DA91-01517N DA97-00179A DA97-00732A DA63-01067B DA63-01068A DA63-01069A DA63-10170A 6002-000468 6001-000716 DA61-00776A DA66-90112C 6001-000716 DA64-00110B DA64-00110C DA64-00096B DA64-00096C DA71-00077A 6002-000470 6002-000468 DA64-00097B DA64-00097C DA97-00654B DA97-00654C DA61-00511A 6002-000470 6002-000213 DA64-00209A DA64-00098H DA64-00098B DA64-00196A DA64-00196B DA64-00100L DA64-00100A DA64-00543B DA64-00543C DA64-00379B DA64-00379C DA64-00328B DA64-00328C DA71-00280A 6002-000213 DA64-00329B DA64-00329C 2 3 4 5 6 7 8 9 10 11 12 13 13-1 13-2 13-3 14 15 16 16-1 16-2 17 18 18-1 18-2 19 20 21 21-1 21-2 21-3 21-4 Name of goods (http://www.e4buyer.com/refrigerator) CSL RS20N*** CSW ESL ESW ASSY DOOR FOAM REF Specification STS-LOOKING SNOW-WHITE STS-LOOKING SNOW-WHITE ASSY-GASKET DOOR, REF ASSY-GUARD,DAIRY COVER-GUARD,DAIRY GUARD-DAIRY GUARD-REF,UP GUARD-REF,LOW SCREW-TAPPING SCREW-MACHINE STOPPER DOOR CAM HINGE-RISER, LOW SCREW-MACHINE ASSY HANDLE MID SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE HANDLE BASE MID REINF HANDLE MID SCREW TAPPING SCREW TAPPING HANDLE BASE UPP SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE ASSY HANDLE LOW REINF HANDLE LOW SCREW TAPPING SCREW TAPPING ASSY TRIM HANDLE MID TRIM HANDLE MID SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE SKI-BAR HANDLE TRIM HANDLE CONNECT MID TRIM HANDLE UPP TRIM HANDLE LOW DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE ASS'Y HANDLE HANDLE REAR REINF HANDLE SCREW TAPPING HANDLE FRONT 55 DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE ■ Parts list of the refrigerator door NO CODE-NO 22 DA64-00371B DA64-00371C DA64-00547B DA64-00547C 6002-001122 DA64-00326B DA64-00326C DA64-00544B DA64-00544C 6002-000468 DA64-00324B DA64-00324C 23 24 25 26 27 28 Name of goods CSL BASE HANDLE UPP RS20N*** CSW ESL ESW Specification DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE BASE HANDLE LOW SCREW TAPPING TRIM-HANDLE UPP DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE DELUXE-BAR HANDLE TRIM-HANDLE LOW SCREW TAPPING TRIM-HANDLE MID, A DELUXE-BAR HANDLE DELUXE-BAR HANDLE 56 Appendix Ⅰ (RS20N for Circuit Diagram) 57 ELECTRONICS 272, Oseon-Dong, Kwangsan-Gu, Kwangju-City, Korea, 506-253 TEL : 82-62-950-6810, 6811 FAX : 82-62-950-6829 © Samsung Electronics Co., Ltd. Refrigerator Division 2002. 10 Printed in Korea Code : DA68-01197A