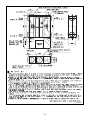

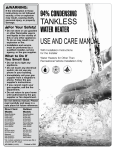

Download Mitsubishi Electric LGH-150RX5-E Specifications

Transcript