Download Allied GS660C Instruction manual

Transcript

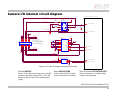

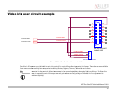

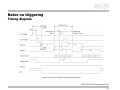

AVT Prosilica GS Technical Manual AVT GigE Vision Cameras V2.0.0 70-0066 14 July 2011 Allied Vision Technologies Canada Inc. 101-3750 North Fraser Way V5J 5E9, Burnaby, BC / Canada Legal notice For customers in the U.S.A. This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a residential environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. However there is no guarantee that interferences will not occur in a particular installation. If the equipment does cause harmful interference to radio or television reception, the user is encouraged to try to correct the interference by one or more of the following measures: • Reorient or relocate the receiving antenna. • Increase the distance between the equipment and the receiver. • Use a different line outlet for the receiver. • Consult a radio or TV technician for help. You are cautioned that any changes or modifications not expressly approved in this manual could void your authority to operate this equipment. The shielded interface cable recommended in this manual must be used with this equipment in order to comply with the limits for a computing device pursuant to Subpart A of Part 15 of FCC Rules. For customers in Canada This apparatus complies with the Class A limits for radio noise emissions set out in the Radio Interference Regulations. Pour utilisateurs au Canada Cet appareil est conforme aux normes classe A pour bruits radioélectriques, spécifiées dans le Règlement sur le brouillage radioélectrique. Life support applications These products are not designed for use in life support appliances, devices, or systems where malfunction of these products can reasonably be expected to result in personal injury. Allied Vision Technologies customers using or selling these products for use in such applications do so at their own risk and agree to fully indemnify Allied for any damages resulting from such improper use or sale. Trademarks Unless stated otherwise, all trademarks appearing in this document of Allied Vision Technologies are brands protected by law. Warranty The information provided by Allied Vision Technologies is supplied without any guarantees or warranty whatsoever, be it specific or implicit. Also excluded are all implicit warranties concerning the negotiability, the suitability for specific applications or the non-breaking of laws and patents. Even if we assume that the information supplied to us is accurate, errors and inaccuracy may still occur. Copyright All texts, pictures and graphics are protected by copyright and other laws protecting intellectual property. It is not permitted to copy or modify them for trade use or transfer, nor may they be used on web sites. Allied Vision Technologies Canada Inc. 7/2011 All rights reserved. Managing Director: Mr. Frank Grube TaxID: 889528709 Headquarters: 101-3750 North Fraser Way V5J 5E9, Burnaby, BC / Canada AVT Prosilica GS Technical Manual V2.0.0 2 Contents Contacting Allied Vision Technologies ............................................................. 5 Introduction .................................................................................................................. 6 Document history ...................................................................................................... 6 Symbols used in this manual ........................................................................................ 7 Warranty.................................................................................................................. 7 Precautions .............................................................................................................. 8 Cleaning the sensor ................................................................................................... 9 Conformity.................................................................................................................... 10 Specifications ............................................................................................................. 11 Prosilica GS650/650C ................................................................................................ 11 Prosilica GS660/660C ................................................................................................ 13 Prosilica GS1380/1380C ............................................................................................ 15 Prosilica GS2450/2450C ............................................................................................ 17 Camera attribute highlights ........................................................................................ 19 IR cut filter: spectral transmission .................................................................... 20 Camera dimensions.................................................................................................. 21 Mechanical drawings - Landscape sensor....................................................................... 22 Portrait sensor ......................................................................................................... 23 Adjustment of lens mount .......................................................................................... 24 Camera interfaces .................................................................................................... 25 Camera I/O connector pin assignment .......................................................................... 26 Gigabit Ethernet port ................................................................................................ 29 Camera I/O internal circuit diagram ............................................................................. 30 Camera I/O opto-isolated user circuit example ............................................................... 31 Camera I/O non-isolated user circuit example ................................................................ 32 Video iris user circuit example ..................................................................................... 33 Notes on triggering................................................................................................... 34 Timing diagram ........................................................................................................ 34 Signal definitions ..................................................................................................... 35 AVT Prosilica GS Technical Manual V2.0.0 3 Trigger rules ............................................................................................................ 36 Firmware update ....................................................................................................... 37 Resolution and ROI frame rates.......................................................................... 38 CAMERA: Prosilica GS650 ........................................................................................... 38 CAMERA: Prosilica GS660 ........................................................................................... 39 CAMERA: Prosilica GS1380 .......................................................................................... 39 CAMERA: Prosilica GS2450 .......................................................................................... 40 Prosilica GS family frame rate comparison ..................................................................... 40 Additional References ............................................................................................. 41 Prosilica GS webpage................................................................................................. 41 Prosilica GS documentation ........................................................................................ 41 GigE PvAPI SDK ........................................................................................................ 41 Knowledge base ....................................................................................................... 41 Case studies ............................................................................................................ 41 Prosilica GS firmware................................................................................................. 41 AVT Prosilica GS Technical Manual V2.0.0 4 Contacting Allied Vision Technologies • Technical information: http://www.alliedvisiontec.com • Support: [email protected] Allied Vision Technologies GmbH Taschenweg 2a 07646 Stadtroda, Germany Tel.: +49.36428.677-0 Fax.: +49.36428.677-28 e-mail: [email protected] Allied Vision Technologies Inc. 38 Washington Street Newburyport, MA 01950, USA Toll Free number +1-877-USA-1394 Tel.: +1 978-225-2030 Fax: +1 978-225-2029 e-mail: [email protected] Allied Vision Technologies Canada Inc. 101-3750 North Fraser Way Burnaby, BC, V5J 5E9, Canada Tel: +1 604-875-8855 Fax: +1 604-875-8856 e-mail: [email protected] Allied Vision Technologies Asia Pte. Ltd. 82 Playfair Road #07-02 D'Lithium Singapore 368001 Tel. +65 6634-9027 Fax:+65 6634-9029 e-mail: [email protected] AVT Prosilica GS Technical Manual V2.0.0 5 IIntrod ductiion This AV VT Prosilica GS G Technicall Manual desscribes in deppth the techn nical specificcations of this camera family including dimensions,, feature oveerview, I/O definition, trigger timing waveforms and a frame ratte performannce. For info ormation on software insstallation reaad the AVT GiigE Installattion Guide. For dettailed information on cam mera featuress and controols specific too the Prosilicca GX, GE, GS, GB and GC referr to the AVT Prosilica P GiggE Camera an nd Driver Atttributes doccument. AVVT Prosilica GS literature: htttp://www.alliedvisiontecc.com/us/suupport/down nloads/produuctliteerature/prossilica-GS.htm ml Pleease read thrrough this m anual carefuully. D Docum ment history h y Versio on Date Remarks V2.0.0 0 14.07.11 New Manuual – SERIAL Status Table 1: Doccument Histoory AVT Proosilica GS Tecchnical Manuual V2.0.0 6 S Symbo ols us sed in this manua m al Thiis symbol hig ghlights impportant inform mation ghlights impportant instruuctions. You must follow these Thiis symbol hig insstructions to avoid malfuunctions. ghlights URLLs for furtherr information n. The URL itsself is Thiis symbol hig sho own in blue. Exaample: htttp://www.alliedvisiontecc.com W Warra anty Alllied Vision Teechnologies Canada provvides a 2-yeaar warranty w which covvers the repllacement andd repair of alll AVT parts tthat are foun nd to be defective in thee normal usee of this prodduct. AVT willl not warran nty parts thaat have been n damaged thhrough the oobvious misuse of this prooduct. AVT Proosilica GS Tecchnical Manuual V2.0.0 7 P Precautions s DO O NOT OPEN THE T CAMERA A. WARRANTTY IS VOID IFF CAMERA IS OP PENED. Thiis camera contains sensittive components which ccan be damagged if handled incorrrectly. KEEEP SHIPPING MATERIALL. Poor packaging g of this prodduct can cause damage dduring shippiing. VERIFY ALL EXT XTERNAL CON NNECTIONS. Verify all external connectiions in termss of voltage llevels, power quirements, voltage polaarity, and siggnal integrityy prior to pow wering req thiis device. CLEANING. ning agents.. Avoid Thiis product caan be damag ed by some vvolatile clean cleeaning the im mage sensor unless absollutely necesssary. Please see insstructions on n sensor cleaaning in this document. DO O NOT EXCEED D ENVIRONM MENTAL SPECCIFICATIONSS. See environmeental specificcations limitss in the Speccifications seection of n a reasonable thiis document.. Special carre is requiredd to maintain operating temp perature. If the camera iis to be operated in a warrm environment, it is suggesteed that the camera be moounted on a heat sink succh as a metal bracket andd that there iis sufficient air flow. AVT Proosilica GS Tecchnical Manuual V2.0.0 8 Cleaning th he sensor DO O NOT CON NTACT CLEAN SENSSOR UNLEESS AB BSOLUTELLY NECESSARY Identiffying Debriss Debris on the image sensor or optical components w will appear as a darkened area or smudge on the image that doees not move as the t camera is moved. m Do not confuse this wiith a pixel defeect which will apppear as a distinct point. Locatin ng Debris Before attempting to clean the imagee sensor, it is im mportant to firsst determine that the problem m is due to debris on n the sensor wiindow. To do th his you, shouldd be viewing a uuniform image,, such as a piecee of paper, with the camera. Debriss will appear ass a dark spot orr dark region thhat does not moove as the cameera is moved. To determine that t the debris is not on the caamera lens, rottate the lens independent of tthe camera. If the spot mo oves as the lenss moves, then t he object is on the lens not on n the image sen nsor and therefore cleaning is no ot required. If the camera ha s an IR filter, t hen rotate the IR filter. If thee object moves, then t the particlle is on the IR filter f not the seensor. If this iss the case, remoove the IR filter carefully using a small s flat head screw driver. Clean both sidees of the IR filtter using the saame techniquess as explaineed below for thee sensor window. DO O NOT TOUCCH ANY OPT PTICS WITH FINGERS. OIL FROM M FINGERS CAN N DAMAGE FRAGILE O OPTICAL CO OATINGS. ng with Air Cleanin If it is deetermined that debris is on the sensor windoow, then removve the camera leens, and blow tthe sensor window directly with cllean compresseed air. If canneed air is used, ddo not shake or tilt the can priior to blowing the sensor. Vieew a live image with the cameera after blowinng. If the debris is still there, repeat this hat the process. Repeat the prrocess a number of times with increased inteensity until it is determined th particulaate cannot be dislodged. d If this is the case thhen proceed too the contact cleeaning techniqque. Contacct Cleaning Only usee this method as a last resort. Use 99% laborratory quality isopropyl alcoh hol and clean cootton swabs. Dampen D the sw wab in the alcoh hol and gently w wipe the sensor in a single strroke. Do not reeuse the same swab. Do not wip pe the sensor if the sensor andd swab are bothh dry. You mustt wipe the sensoor quickly mersion in the alcohol, or glue from the swaab will contaminnate the sensor window. Repeat this after imm process until the debriss is gone. If thiis process fails to remove the debris, then coontact AVT. AVT Proosilica GS Tecchnical Manuual V2.0.0 9 Conformity Allied Vision Technologies declares under its sole responsibility that all standard cameras of the AVT Prosilica GS family to which this declaration relates are in conformity with the following standard(s) or other normative document(s): • CE, following the provisions of 2004/108/EG directive • FCC Part 15 Class A • RoHS (2002/95/EC) We declare, under our sole responsibility, that the previously described AVT Prosilica GS cameras conform to the directives of the CE. Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. You are cautioned that any changes or modifications not expressly approved in this manual could void your authority to operate this equipment. AVT Prosilica GS Technical Manual V2.0.0 10 Specifications Prosilica GS 650/650C Resolution 659 x 493 Sensor Type Sensor size Sony ICX424 CCD Progressive Type 1/3 Cell size Lens mount Max frame rate at full resolution 7.4 μm C/CS 120 fps A/D 14 bit On-board FIFO Bit depth Mono formats 16 MB 8/12 Mono8, Mono16 (monochrome models only) Color formats Exposure control Bayer8, Bayer16, YUV411, YUV422, YUV444, RGS24, BGR24, RGSA24, BGRA24 10 μs to 60 seconds; 1 μs increments Gain control Horizontal binning Vertical binning TTL I/Os Opto-coupled I/Os 0 to 30 dB 0 to 8 pixels 1 to 14 rows 1 input, 1 output 1 input, 1 output RS-232 Power requirements 1 Power consumption 3W Mass Dimensions Sensor orientations Operating temperature 59g (without lens) 51 x 89 mm (Board Size - W x L) Landscape, Portrait 0 0C … +70 0C ambient temperature (without condensation) Connector orientations Storage temperature Inline, Vertical -10 0C … +70 0C ambient temperature (without condensation) Trigger latency Trigger jitter Tpd 1μs for non-isolated I/O, 9μs for isolated I/O ±20ns for non-isolated I/O, ±0.5μs for isolated I/O 10ns for non-isolated I/O, 1.3μs for isolated I/O Operating humidity Hardware interface standard 20 to 80% non-condensing IEEE 802.3 1000BASE-T, 100BASE-TX Software interface standard Regulatory GigE Vision Standard 1.0 CE, FCC Class A, RoHS (2002/95/EC) 5-16 VDC Æ Cameras SN: 02-22XXA 5-25 VDC Æ Cameras SN: 02-22XXB Table 2: Prosilica GS650 camera specification AVT Prosilica GS Technical Manual V2.0.0 11 60% 50% 40% Quantu um Efficien ncy 30% 20% 10% 0% 400 0 500 600 700 8800 m] Waavelength [nm 9000 1000 1100 Figure 1 – Prosilica GSS650 monochhrome spectrral response 40% 35% 30% 25% Quantu um Efficiency 20% 15% 10% 5% 0% 0 400 450 500 550 Red d 6600 Gree n 6500 700 750 Bluee Wavelength W [n nm] Figuree 2 – Prosilicaa GS650C collor spectral rresponse Thee design and d specificatioons for the prroducts desccribed above may chaange without notice. AVT Proosilica GS Tecchnical Manuual V2.0.0 12 Specifications Prosilica GS 660/660C Resolution Sensor Type Sensor size Cell size Lens mount Max frame rate at full resolution A/D On-board FIFO Bit depth Mono formats 659 x 493 Sony ICX618 CCD Progressive Type ¼ 5.6 μm C/CS 119 fps 14 bit 16 MB 8/12 Mono8, Mono16 (monochrome models only) Color formats Exposure control Bayer8, Bayer16, YUV411, YUV422, YUV444, RGS24, BGR24, RGSA24, BGRA24 10 μs to 60 seconds; 1 μs increments Gain control 0 to 30 dB Horizontal binning 0 to 8 pixels Vertical binning 1 to 16 rows TTL I/Os Opto-coupled I/Os RS-232 Power requirements 1 input, 1 output 1 input, 1 output 1 5-16 VDC Æ Cameras SN: 02-22XXA 5-25 VDC Æ Cameras SN: 02-22XXB 3W 59g (without lens) 51 x 89 mm (Board Size - W x L) Landscape 0 0C … +70 0C ambient temperature (without condensation) -10 0C … +70 0C ambient temperature (without condensation) 2 μs for non-isolated I/O, 10μs for isolated I/O ±20ns for non-isolated I/O, ±0.5μs for isolated I/O 10ns for non-isolated I/O, 1.3μs for isolated I/O 20 to 80% non-condensing IEEE 802.3 1000BASE-T, 100BASE-TX GigE Vision Standard 1.0 CE, FCC Class A, RoHS (2002/95/EC) Power consumption Mass Dimensions Sensor orientations Operating temperature Storage temperature Trigger latency Trigger jitter Tpd Operating humidity Hardware interface standard Software interface standard Regulatory Table 3: Prosilica GS660 camera specification AVT Prosilica GS Technical Manual V2.0.0 13 45% 40% 35% 30% 25% Quan ntum 20% Efficciency 15% 10% 5% 0% 00 40 500 600 700 800 Wavelength [[nm] 9900 10000 1100 Figure F 3 – Prosilica GS660 monochrom me spectral response 80% 70% 60% 50% 40% Quantu um Efficien ncy 30% 20% 10% 0% 400 0 450 500 550 Red 6600 6500 Green 700 750 Blue Wavelength W [[nm] Figure 4 – Prosilica GSS660C color spectral respponse Thee design and d specificatioons for the prroducts desccribed above may chaange without notice. AVT Proosilica GS Tecchnical Manuual V2.0.0 14 Specifications Prosilica GS 1380/1380C Resolution Sensor Type Sensor size Cell size Lens mount Max frame rate at full resolution A/D On-board FIFO Bit depth Mono formats 1360 x 1024 pixels Sony ICX285AL CCD (ICX285AQ for color) CCD Progressive Type 2/3 6.45μm C/CS 30 fps 14 bit 16 MB 8/12 Mono8, Mono16 (monochrome models only) Color formats Bayer8, Bayer16, YUV411, YUV422, YUV444, RGS24, BGR24, RGSA24, BGRA24 Exposure control 10 μs to 60 seconds; 1 μs increments Gain control 0 to 30 dB Horizontal binning 1 to 8 pixels Vertical binning TTL I/Os Opto-coupled I/Os RS-232 Power requirements Power consumption Mass Dimensions Sensor orientations 1 to 14 rows 1 input, 1 output 1 input, 1 output 1 5-16 VDC Æ Cameras SN: 02-22XXA 5-25 VDC Æ Cameras SN: 02-22XXB 3W 54g 51 x 89 (board size - W x L) Landscape, Portrait Operating temperature Storage temperature Trigger latency Trigger jitter Tpd Operating humidity Hardware interface standard Software interface standard Regulatory 0 0C … +70 0C ambient temperature (without condensation) -10 0C … +70 0C ambient temperature (without condensation) 1μs for non-isolated I/O, 9μs for isolated I/O ±20ns for non-isolated I/O, ±0.5μs for isolated I/O 10ns for non-isolated I/O, 1.3μs for isolated I/O 20 to 80% non-condensing IEEE 802.3 1000BASE-T, 100BASE-TX GigE Vision Standard 1.0 CE, FCC Class A, RoHS (2002/95/EC) Table 4: Prosilica GS1380 camera specification AVT Prosilica GS Technical Manual V2.0.0 15 60% 50% 40% Quan ntum Efficciency 30% 20% 10% 0% 400 4 500 600 700 800 Wavelength [[nm] 9900 10000 1100 Figure F 5 – Pro osilica GS138 80 monochroome spectrall response 50% 45% 40% 35% 30% 25% Quan ntum Efficciency 20% 15% 10% 5% 0% 400 450 500 Red 550 600 Green 650 7000 750 Blue Wavelength [nm] Figure 6 – Prosilica GSS1380C colorr spectral ressponse Thee design and d specificatioons for the prroducts desccribed above may chaange without notice. AVT Proosilica GS Tecchnical Manuual V2.0.0 16 Specifications Prosilica GS 2450/2450C Resolution Sensor Type Sensor size Cell size Lens mount Max frame rate at full resolution A/D On-board FIFO Bit depth Mono formats 2448 x 2050 Sony ICX625 CCD Progressive Type 2/3 3.45 μm C/CS 15 fps 14 bit 16 MB 8/12 Mono8, Mono16 (monochrome models only) Color formats Exposure control Bayer8, Bayer16, YUV411, YUV422, YUV444, RGS24, BGR24, RGSA24, BGRA24 10 μs to 60 seconds; 1 μs increments Gain control 0 to 30 dB Horizontal binning 1 to 8 pixels Vertical binning 1 to 14 rows TTL I/Os Opto-coupled I/Os RS-232 Power requirements 1 input, 1 output 1 input, 1 output 1 5-16 VDC Æ Cameras SN: 02-22XXA 5-25 VDC Æ Cameras SN: 02-22XXB 3W 54g 51 x 89 (board size - W x L) Landscape, Portrait 0 0C … +70 0C ambient temperature (without condensation) -10 0C … +70 0C ambient temperature (without condensation) 2μs for non-isolated I/O, 10μs for isolated I/O ±20ns for non-isolated I/O, ±0.5μs for isolated I/O 10ns for non-isolated I/O, 1.3μs for isolated I/O 20 to 80% non-condensing IEEE 802.3 1000BASE-T, 100BASE-TX GigE Vision Standard 1.0 CE, FCC Class A, RoHS (2002/95/EC) Power consumption Mass Dimensions Sensor orientations Operating temperature Storage temperature Trigger latency Trigger jitter Tpd Operating humidity Hardware interface standard Software interface standard Regulatory Table 5: Prosilica GS2450 camera specification AVT Prosilica GS Technical Manual V2.0.0 17 60% 50% 40% Quantu um 30% Efficiency 20% 10% 0% 400 500 600 700 8800 m] Waavelength [nm 900 1000 1100 Figure F 7 – Pro osilica GS245 50 monochroome spectrall response 45% 40% 35% 30% 25% 20% Quantu um 15% Efficiency 10% 5% 0% 400 450 500 Red 550 6600 Green 6500 700 750 Blue Wavelength W [nm m] Figure 8 – Prosilica GSS2450C colorr spectral ressponse Thee design and d specificatioons for the prroducts desccribed above may chaange without notice. AVT Proosilica GS Tecchnical Manuual V2.0.0 18 C Camera attrribute e highllights AVT cam meras support a number of standard aand extendeed features. TThe table beelow identifiies the most interesting capabilities c of this camera family. A complete lissting of cameraa controls, in ncluding conttrol definitioons can be foound in the A AVT Prosilicaa GigE Cameraa and Driverr Attributes document. AVVT Prosilica GigE Camera aand Driver Atttributes doccument onlin ne: http p://www.alliedvisio ontec.com/fileadm min/content/PDF/SSoftware/Prosilicaa_software/Prosilicca_firmware/ AVT_ _Camera_and_Drivver_Attributes.pdff Control Sp pecification Gain control c Manual M and auuto Exposure control Manual M and auuto Whitebalance Reed and blue channel; maanual and autto control Extern nal trigger evvent Riising edge, ffalling edge, any edge, leevel high, levvel low Extern nal trigger deelay 0 to 60 secondds; 1 us increements Fixed rate control 0.001 fps to m maximum frame rate Imaging modes Frree-running,, external trigger, fixed rrate, softwarre trigger Sync Out O modes Trrigger ready,, trigger inpuut, exposing, readout, im maging, sttrobe, GPO Region of Interestt (ROI) in ndependent x and y contrrol with 1 pixxel resolutioon Multiccast Sttreaming to multiple PC Event Channel In n-camera eveents includinng exposure start and triggger are assynchronoussly broadcastted to the hoost PC Tablle 6: Prosilicaa GS camera and driver atttribute high hlights AVT Proosilica GS Tecchnical Manuual V2.0.0 19 IR cu ut filte er: sp pectrral tra ansm missio on Alll Prosilica GSS color modeels are equipped with an infrared blocck filter (IR R filter). Thiss filter is empployed to stoop infrared w wavelength pphotons fro om passing to o the imagin g device. If the filter is rremoved, images will be dominated by b red and caannot be prooperly color bbalanced. Mo onochrome Prosilica P GS ccameras do nnot employ aan IR filter. Thee figure belo ow shows thee filter transm mission response for the IRC filter fam mily from Sun nex. Prosilicca GS cameraas utilize thee IRC30 filterr. Figure F 9: Sun nex IRC filterr transmissioon values AVT Proosilica GS Tecchnical Manuual V2.0.0 20 C Came era dimen d nsions The Pro osilica GS camera offers several s sensoor orientatioon options. TThe camera variatio ons are descrribed below and a detailedd dimension ddrawings aree provided in n Chapter Mechan nical drawin ngs on page 22. 2 Sensorr orientation n Modell Descriptiion Examplee Landscape GS Sensor m ounted in laandscape orientatioon GS1380 Portrait GS-P Sensor m ounted in poortrait orientatioon GS1380-P Tab ble 7: GS Sennsor orientattions d not suppoort a portrait sensor orien ntation, pleaase refer Some models do to Chapter Speecifications oon page 11. AVT Proosilica GS Tecchnical Manuual V2.0.0 21 Mechanical drawings - Landscape sensor 2.20 55.9 1.50 38 0.29 7.2 0.85 21.5 0.85 21.6 1.02 26 #1/4-20 2 PLCS TYP. 3.75 95.3 ITEM 3 PIXEL 1,1 1.02 26 2.90 73.7 1.02 26 M3 4MM DEEP 8 PLCS TYP. 0.62 15.7 0.37 9.4 2 MODEL: GS650/GS650C 1 OPTIONS: LANDSCAPE/RIGHT ANGLE CONNECTORS 1.00 25.4 1.50 38 * ITEM 1: 3M 10214-55G3PC ITEM 2: HALO HFJ11-1G16E-L12RL ITEM 3: SONY ICX424 INCHES[MILLIMETERS] *Nominal for C mount. Reduce by 5mm for CS mount. Add 0.3mm for color option. Figure 10: Prosilica GS650/GS650C mechanical drawing AVT Prosilica GS Technical Manual V2.0.0 22 Portrait sensor 2.20 55.9 1.50 38 0.29 7.2 0.85 21.5 0.85 21.6 1.02 26 #1/4-20 2 PLCS TYP. 3.75 95.3 ITEM 3 PIXEL 1,1 1.02 26 2.90 73.7 1.02 26 M3 4MM DEEP 8 PLCS TYP. 0.62 15.7 0.37 9.4 2 MODEL: GS650-P/GS650C-P 1 OPTIONS: PORTRAIT/RIGHT ANGLE CONNECTORS 1.00 25.4 1.50 38 * ITEM 1: 3M 10214-55G3PC ITEM 2: HALO HFJ11-1G16E-L12RL ITEM 3: SONY ICX424 INCHES[MILLIMETERS] *Nominal for C mount. Reduce by 5mm for CS mount. Add 0.3mm for color option. Figure 11: Prosilica GS650-P/GS650C-P mechanical drawing AVT Prosilica GS Technical Manual V2.0.0 23 Adjusttmentt of len ns mo ount Thee C-mount orr CS-mount i s adjusted att the factoryy and should not req quire adjusting. If for f some reasson, the lenss mount requuires adjustm ment, use thee folllowing meth hod. LO OCKING RING C-M MOUNT RING Figure 12: 1 Prosilica GS camera ffront view Looseen Locking Ring Use an adjustable wrench w to loo osen lockingg ring. Be carreful not to sscratch the ccamera. t locking riing is loose, unthread th e ring a few tturns from th he camera faace. When the A wrench w suitable for this pprocedure caan be provideed by AVT P/N: 02-5003A A Pro osilica GS cam meras can bee equipped w with a C-mount or a CS-mount depending on sensor s size aand camera oorder code Imagee to Infinitty Use a c-mount compatible lens that allows aan infinity foocus. Set thee lens to infinity and image a distant object. The disttance requir ed will depend on the len ns used but ttypically 30 to 50 feet should d suffice. Maake sure the lens is firmlyy threaded oonto the c-moount ring. Rotate R the len ns and c-mou unt ring untiil the image is focused. CCarefully tighten locking g ring. Recheeck focus. AVT Proosilica GS Tecchnical Manuual V2.0.0 24 C Came era in nterfa aces This chapter gives you y informattion on Gigabbit Ethernet port, inputs and outputss and trigger features. For accessoriess like cables ssee: htttp://www.alliedvisiontecc.com/emea//products/aaccessories/ggigeacccessories.htm ml Figure 13: Prosilica G GS connectioon diagram AVT Proosilica GS Tecchnical Manuual V2.0.0 25 C Camerra I/O connector pin as ssignm ment Pin Signal S Direction Level Description 1 --- Poweer Supply 2 External E Power P External E GND 3 Camera C In 1 In 4 Isolated I GND --- 5 Camera C Out1 Out Open emittter max. 20mA A 6 Video V Iris Out --- Grouund for isolateed outpputs (Isolated GND) Camera Output 1 optoo-isolated (GPO Out1) PWM M Signal for Iriis Control 7 Reserved R --- --- --- 8 --- 10 TxD T RS232 Out +5 V…+16 V DC (see note) GND for extt. power RS232 Poweer Supply 9 External E Power P External E GND 11 RxD R RS232 In RS232 Term minal Receive Data 12 Camera C In 2 In LVTTL max. 3.3 V 13 Camera C Out 2 Out LVTTL max. 3.3 V 14 Non-isolated N GND G --- --- Camera Input 2 non--isolated (GPIIn2) Camera Output 2 non--isolated (GPO Out2) Grouund for non-issolated outpputs and RS2332 --- --- +5 V…+12 V DC (see note) GND for power Uin(high) = 5 V...24 V Uin(low) = 0 V...0.8 V --- Exteernal Ground ffor exteernal power Camera Input 1 optoo-isolated (GPIIn1) Exteernal Ground ffor exteernal power Term minal Transmitt Data Table 8: Prosilica P GS I/ I/O connectoor definition The Gen neral Purposse I/O port usses a 3M 102214-55G3PC ((or 3M 102144-6212PC) connector on the camera side. The mating g cable conn ector is 3M 110114-3000PPE or a conneector with sh hielded housiing 3M 10314-3210-00X (X indicatess color preferrence). Thiis cable side Hirose connnector can bee purchased ffrom AVT. AVVT P/N: 02-70 003A AVT Proosilica GS Tecchnical Manuual V2.0.0 26 Extern nal Power The Pro osilica GS cam mera family has h recently been updateed to offer an n expanded iinput power voltage v rang ge. The cameera serial num mber is used to differentiiate between n cameraas that offer 5-16 5 VDC and d those that offer 5-25 VDC. SN: 02-22XXA, 5V - 16V. 122V Nominal. SN: 02-22XXB, 5V - 25V. 122V Nominal. 1 power ad daptor with ccamera connector can bee ordered from AVT: A 12V AVVT P/N: 02-80 007A North A America Suppply AVVT P/N: 02-80 008A Universsal Supply d Camera In n2 Camerra In 1 and These are a trigger lin nes which allow the cameera to be synnchronized too an external event. The cam mera can be programmed p d to trigger oon the rising edge, fallingg edge, both edges, or level of this signal. The cameera can also be programm med to captuure an imagee at some program mmable delaay time after the trigger eevent. GPIn1 is i isolated an nd should bee used in noissy environmeents to preveent false trigggering due to ground loop noise. GPIn n2 is non-isoolated and caan be used wh hen a faster trigger is requireed and when environmental noise is nnot a problem m. O NOT EXCEED D 5.5V ON SIIGNAL INPUTTS UNLESS O OTHERWISE DO INDICATED Pleease refer to Chapter Cam mera I/O optto-isolated u user circuit eexample on page 31. AVT Proosilica GS Tecchnical Manuual V2.0.0 27 Camera Out 1 and Camera Out 2 These signals (GPOut) only function as outputs and can be configured as follows: Exposing Corresponds to when camera is integrating light. Trigger Ready Indicates when the camera will accept a trigger signal. Trigger Input A relay of the trigger input signal used to “daisy chain” the trigger signal for multiple cameras. Readout Valid when camera is reading out data. Imaging Valid when camera is exposing or reading out. Strobe Programmable pulse based on one of the above events. GPO User programmable binary output. Any of the above signals can be set for active high or active low. GPOut 1 is isolated and should be used in noisy environments. GPOut2 is non-isolated and can be used when environmental noise is not a problem and when faster response is required. GPOut1 will require a pull up resistor of greater than 1Kohm to the user’s 5V logic supply. Review circuit diagrams for more information. RxD RS-232 and TxD RS-232 These signals are RS-232 compatible. These signals allow communication from the host system via the Ethernet port to a peripheral device connected to the camera. Note that these signals are not isolated and therefore careful attention should be used when designing cabling in noisy environments. Isolated Ground The isolated ground must be connected to the user’s external circuit ground if GPIn1 or GPOut1 is being used. Non-isolated Ground This ground connection must be connected to the user’s external circuit ground if GPIn2 or GPOut2 is to be used or if the RS-232 port is to be used. Note that non-isolated Ground is common with External (power) Ground however it is good practice to provide a separate ground connection for power and signaling when designing the cabling. AVT Prosilica GS Technical Manual V2.0.0 28 Video Iris A pulsee width modu ulated signall can be usedd to drive thee video inputt of a video irris lens. Please refer to Chap pter Video irris user circu uit example on page 33. Reservved These signals s are reeserved for fu uture use an d should be left disconneected. G Gigabit Ethe ernet port The Gig gabit Etherneet port confo orms to the IEEEE 802.3 10000BASE-T sttandard for G Gigabit Etherneet over copper. We recom mmend usingg Category 5ee or Categoryy 6 compatible cabling g and connecctors for bestt performancce. • Cable length hs up to 100 m are suppoorted. • The 8-pin RJJ-45 jack hass the pin assiignment acccording to the Ethernet staandard (IEEEE 802.3 10000BASE-T). • Cables with screw-lock cconnectors aare available from AVT: http://www w.alliedvisionntec.com/em mea/productss/accessoriees/gigeaccessories..html AVT Proosilica GS Tecchnical Manuual V2.0.0 29 Camera I/O internal circuit diagram CAMERA INTERNAL CIRCUIT SY NC OUTPUT 1 VDD-3.3 390R 1/8W SY NC INPUT 1 1 FAIRCHILD MOCD207M 8 2 7 3 6 SY NC OUTPUT 1 4 5 LOGIC SY NC INPUT 1 VDD-3.3 200R 2K ISOLATED GROUND LOGIC SY NC OUTPUT 1 DNC 12V POWER 1 2 3 4 AS SEEN FROM CAMERA REAR VIEW 1 0.1u 3M 10214-55G3PC (RIGHT ANGLE) 2 0.1u 3 4 5 8 0.1u 9 10 11 12 13 3M 10214-6212PC (VERTICAL) 14 VDD-3.3 MAXIM MAX3221CPWR 5 6 7 DNC GND POWER 6 12V POWER 0.1u GND POWER 7 8 EN FORCEOFF C1+ VCC V+ GND C1- DOUT C2+ FORCEON C2- DIN VRIN INVALID ROUT 16 15 14 13 12 11 LOGIC TXD 10 9 LOGIC RXD RS232-RXD RS232-TXD VDD-3.3 SY NC OUTPUT 2 SY NC INPUT 2 8 7 6 5 TEXAS INSTRUMENTS SN74LVC2G241DCU 1 VCC 1OE 2 2OE 1A 3 1Y 2Y 4 2A GND LOGIC SY NC OUTPUT 2 LOGIC SY NC INPUT 2 Figure 14: Prosilica GS camera internal circuit diagram Fairchild MOCD207 Consist of two silicon phototransistors optically coupled to two GaAs infrared LEDs. This is the input and output of the opto isolated camera trigger Maxim MAX3221CPWR Used to drive the RS232 signal logic via the external connector Texas Instruments SN74LVC2G241DCE Used to drive the non-isolated trigger signals from the camera. AVT Prosilica GS Technical Manual 2.0.0 30 Ca amera I//O opto o-isolate ed user circuit examp le CA ABLE SIDE USERS TRIGGER T CIRCUIT Externa al GND Externa al Power 7 1 6 1 GPOut1 5 1 Isolated GND 4 1 GPIn1 3 1 External GND 2 9 External Power 1 8 R1 GPIn1 3 3M 10114-3000PE USER POWER R2 GPOut1 US ER OWER PO RECOMMENDED VALUES R1 R2 5V 0 1K 1 2V 0.7K 2.7K 224V 1.8K 4.7K Figure 15:: Prosilica GS iso olated trigger usser circuit In nput: Incoming trigger must bee able to source 10mA. 1 *Camerass with SN: 02-XXXXXX-0XXXX, R1 necessary for > 5V 5 input, see table above. Camerras with SN: 02-XXXXXX-1XXXX, noo R1 necessary, 5-24V. Output: O User pow wer, with pull-up p resistor R2 is required. r Isolated output iss connected to th he open collecto or of Fairchild MO OCD207. The corrresponding tran nsistor emitter iss connected to olated ground. See S the Fairchild d MOCD207 datasheet for more detailed d informaation. iso AVT Prosilica GS Technicaal Manual 2.0.0 31 Ca amera I//O non--isolated d user circuit c e example e CABLE SID DE USERS U TRIGGER CIRCUIT C External GN ND External Power 7 14 4 6 13 3 5 12 2 4 11 1 3 10 0 Exxternal GND 2 9 Exxternal Power 1 8 3M 10114-3000 0PE G GPIn2 GPIn2 (3.3V DRIV VER) G GPOut2 GPOut2 (3.3V RE ECEIVER) Figure 16:: Prosilica GS no on-isolated triggger user circuit In nput: Incoming trigger must be able to source 10μA, 1 at 3.3V. Innput trigger volttage of > 5.5V wiill damage the camera. Output: O The maxiimum sync outpu ut current is 24m mA, at 3.3V. he non-isolated trigger t circuit iss connected to a Texas Instrumen nts SN74LVC2G2241 buffer/driveer inside the cam mera. See the Th Teexas Instrumentss SN74LVC2G241 1 for more detailed information.. AVT Prosilica GS Technicaal Manual 2.0.0 32 Vid deo iris s user circuit example e External GND External Power 7 14 6 13 5 12 4 11 3 10 External GND 2 9 External Powerr 1 8 3M 10 0114-3000PE CABL LE SIDE LEN NS POWER VID DEO SIGNAL LEN NS GROUND 1 2 3 4 JEITA CONNECTOR Figuree 17: Prosilica GSS video iris user circuit diagram meras provide bu uilt-in auto iris controls for controlling video-typpe auto-iris lensses. These lenses are available Prrosilica's GS cam fro om many populaar security lens companies c including Pentax, Fujjinon, Tamron, SSchneider and others. Remote R iris lens control c allows th he camera to be more adaptablee to changing ligght conditions. It allows the user u to manually control the exposure and gain values v and rely ssolely on the autto iris for adjusttment to ambient lighting. AVT Prosilica GS Technicaal Manual 2.0.0 33 Notes on triggering Timing diagram Figure 18: Prosilica GS internal signal timing waveforms AVT Prosilica GS Technical Manual 2.0.0 34 Signal definitions Term Definition User Trigger Trigger signal applied by the user (hardware trigger, software trigger) Logic Trigger Trigger signal seen by the camera internal logic (not visible to the user) Tpd Propagation delay between the User Trigger and the Logic Trigger Exposure ... is high when the camera image sensor is integrating light. Readout ... is high when the camera image sensor is reading out data. Trigger Latency Time delay between the User Trigger and the start of Exposure Trigger Jitter Error in the Trigger Latency Time Trigger Ready ... indicates to the user that the camera will accept the next trigger. Registered Exposure Time ... is the Exposure Time value currently stored in the camera memory. Exposure Start Delay ... is the Registered Exposure Time subtracted from the Readout time and indicates when the next Exposure cycle can begin such that the Exposure will end after the current Readout. Interline Time ... is the time between sensor row readout cycles. Imaging ... is high when the camera image sensor is either exposing and/or reading out data. Idle ... is high if the camera image sensor is not exposing and/or reading out data. Table 9: Explanation of signals in timing diagram AVT Prosilica GS Technical Manual V2.0.0 35 T Trigge er rule es Thee User Triggeer pulse widdth should bee at least thrree times thee width of thee Trigger Lattency as indiccated in Chappter Specificcations on page 11 • The end of Exposure E will always triggger the nextt Readout. • The end of Exposure E mu ust always ennd after the ccurrent Readdout. • The start off Exposure must m always ccorrespond w with the Inteerline Time iff Readout is true. • Expose Starrt Delay equals the Readdout time minnus the Regisstered Expossure Time. ng the Idlee State Triggeering durin For app plications req quiring the shortest s posssible Trigger Latency andd the smallesst possiblle Trigger Jittter the User Trigger sign al should bee applied wheen Imaging is false and Idlle is true. In this case, Trigger Latency and Trigger Jittter are as inddicated in the Specificatiions section n. Triggeering durin ng the Readout Statee For app plications req quiring the fastest f triggeering cycle time whereby the camera image sensor is exposing and a reading out simultanneously, then the User Trrigger signall should be applied as soon as a valid Triigger Ready iis detected. In this case, Trigger Latency and Trigger Jittter can be upp to 1 line tim me since Expposure must allways begin on o an Interliine boundaryy. AVT Proosilica GS Tecchnical Manuual V2.0.0 36 F Firmw ware upda ate Firmwaare updates are a carried ou ut via the Ethhernet conneection. AVT pprovides an applicaation for all Prosilica P GS cameras c whicch loads firm mware to the camera using a simple interface. uctions and product p imprrovements m motivate new w firmware releases. New feaature introdu All users are encouraged to use the newest ffirmware avaailable and ccomplete thee n firmware update if necessary. Do ownload the latest l GigE fiirmware loadder from the AVT website: htttp://www.alliedvisiontec.ccom/us/suppoort/downloads/firmware.httml To determine the current fi rmware verssion loaded oonto the cam mera, read thee camera’s Device Firmwaare attributee using GigE SSample View wer or thiird party app plications likee NI’s Measuurement and Acquisition asssistant. Figure 19: 1 Screenshot of AVT GiggE Sample Viiewer controls window AVT Proosilica GS Tecchnical Manuual V2.0.0 37 R Reso olution and d ROI fram me ra ates This secction aims to o provide useers with perfoormance infoormation which identifiees the impact of reducing the region of o interest onn the camera’s maximum frame rate. • The camera frame rate ccan be increaased by reduccing the camera's Height attribute, resultiing in a decreased region n of interest (ROI) or "window". • The camera frame rate ccan also be inncreased by iincreasing th he camera's BinningY attribbute, resulting in a vertically scaled iimage (less overall height withh same field oof view). f rate inncrease with reduced widdth • There is no frame • Frame rate data d was gennerated usingg StreamByteesPerSecondd equals 120 MB and an 8 bit pixeel format succh as Mono8 or Bayer8 C CAMER RA: Pros silica GS S650 600 500 400 Height H 300 (p pixels) 200 100 0 0 200 400 600 800 1000 Frame rate Fig gure 20: Maxiimum frame rate versus rregion height for GS650 AVT Proosilica GS Tecchnical Manuual V2.0.0 38 CAMERA: Prosilica GS660 600 500 400 Height 300 (pixels) 200 100 0 0 100 200 300 400 500 600 Frame rate Figure 21: Maximum frame rate versus region height for GS660 CAMERA: Prosilica GS1380 1200 1000 800 Height 600 (pixels) 400 200 0 0 50 100 150 200 250 Frame rate Figure 22: Maximum frame rate versus region height for GS1380 AVT Prosilica GS Technical Manual V2.0.0 39 CAMERA: Prosilica GS2450 2500 2000 Height (pixels) 1500 1000 500 0 0 10 20 30 40 50 60 70 80 90 Frame rate Figure 23: Maximum frame rate versus region height for GS2450 Prosilica GS family frame rate comparison 2500 2000 Height (pixels) 1500 GS650 GS660 1000 GS1380 GS2450 500 0 10 210 410 610 810 1010 Frame rate Figure 24: Maximum frame rate versus region height for all GS cameras AVT Prosilica GS Technical Manual V2.0.0 40 Additional References Prosilica GS webpage http://www.alliedvisiontec.com/us/products/cameras/gigabit-ethernet/prosilica-GS.html Prosilica GS documentation http://www.alliedvisiontec.com/us/support/downloads/product-literature/prosilica-GS.html GigE PvAPI SDK http://www.alliedvisiontec.com/us/products/software/avt-pvapi-sdk.html Knowledge base http://www.alliedvisiontec.com/us/support/knowledge-base.html Case studies http://www.alliedvisiontec.com/us/products/applications.html Prosilica GS firmware http://www.alliedvisiontec.com/us/support/downloads/firmware.html AVT Prosilica GS Technical Manual V2.0.0 41