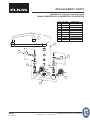

Download A.O. Smith DEL-15 Specifications

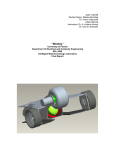

Transcript