Download 3. Disassembly and Reassembly

Transcript

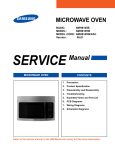

BASIC: SMH7185BG MODEL: SMH9207ST MODEL CODE: SMH9207ST/XAC 1. Precaution 2. Product Specification 3. Disassembly and Reassembly 4. Troubleshooting 5. Exploded Views and Part List 6. PCB Diagrams 7. Wiring Diagrams 8. Schematic Diagrams Refer to the service manual in the GSPN(see rear cover) for the more information. • Contents 1. Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1-1 Safety precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1-2 Special High Voltage Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2-2 Accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 2-3 Table of Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3. Disassembly and Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 3-1 Disassembly of Assembly Grille and Panel Outer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 3-2 Replacement of High Voltage Transformer and HVC and Base bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 3-3 Replacement of Magnetron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3-4 Replacement of Door Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 3-5 Replacement of Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 3-6 Replacement of Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 3-7 Replacement of stirrer motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 3-8 Removal of stirrer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 3-9-1 Replacement of Control Circuit Board (Power). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 3-9-2 Replacement of Control Circuit Board (Main). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 3-10 Replacement of Cooktop lamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 3-11 Replacement of Oven Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 4-1 Error Code Numbering Rule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 4-2 Error Code List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 4-3 Electrical Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 5. Exploded Views and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 5-1 Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 5-2 Main Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 5-3 Door Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 5-4 Control Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 5-5 Standard Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 6. PCB Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 6-1 PCB Diagrams (ML9M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 7. Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 7-1 Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 8. Schematic Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 8-1 Schematic Diagrams (ML9-Main). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 2 1. Precaution 3 1. Precaution Follow these special safety precautions. Although the microwave oven is completely safe during ordinary use, repair work can be extremely hazardous due to possible exposure to microwave radiation, as well as potentially lethal high voltages and currents. 1-1 Safety precautions ( ) 13. Design Alteration Warning: Use exact replacement parts only, i.e.,only those that are specified in thedrawings and parts lists of this manual. This is especially important for the Interlock switches, described above. Never alter or add to the mechanical or electrical design of the MWO. Any design changes or additions will void the manufacturer’s warranty. Always unplug the unit’s AC power cord from the AC power source before attempting to remove or reinstall any component or assembly. 14. Never defeat any of the B+ voltage interlocks. Do not apply AC power to the unit (or any of its assemblies) unless all solid-state heat sinks are correctly installed. 15. Some semiconductor (“solid state”) devices are easily damaged by static electricity. Such components are called Electrostatically Sensitive Devices (ESDs). Examples include integrated circuits and field-effect transistors. Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your body by touching a known earth ground. 16. Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the positive lead; always remove the instrument’s ground lead last. 17. When checking the continuity of the witches or transformer, always make sure that the power is OFF, and one of the lead wires is disconnected. 18. Components that are critical for safety are indicated in the circuit diagram by shading, or . 19. Use replacement components that have the same ratings, especially for flame resistance and dielectric strength specifications. A replacement part that does not have the same safety characteristics as the original might create shock, fire or other hazards. NOTE : Connect the oven to a 20A. When connecting the oven to a 15A,make sure that circuit breaker can operate. 1. All repairs should be done in accordance with the procedures described in this manual. This product complies with Federal Performance Standard 21 CFR 2. Microwave emission check should be performed to prior to servicing if the oven is operative. 3. If the oven operates with the door open :Instruct the user not to operate the oven and contact the manufacturer and the center for devices and radiological health immediately. 4. Notify the Central Service Center if the microwave leakage exceeds 5 mW/cm2. 5. Check all grounds. 6. Do not power the MWO from a “2-prong” AC cord. Be sure that all of the built-in protective devices are replaced. Restore any missing protective shields. 7. When reinstalling the chassis and its assemblies, be sure to restore all protective devices, including: nonmetallic control knobs and compartment covers. 8. Make sure that there are no cabinet openings through which people --particularly children--might insert objects and contact dangerous voltages. Examples: Lamp hole,ventilation slots. 9. Inform the manufacturer of any oven foundto have emission in excess of 5 mW/cm2 ,Make repairs to bring the unit into compliance at no cost to owner and try to determine cause. Instruct owner not to use oven until it has been brought into compliance. CENTRAL SERVICE CENTER 10. Service technicians should remove their watches while repairing an MWO. 11. To avoid any possible radiation hazard,replace parts in accordance with the wiring diagram. Also, use only the exact replacements for the following parts: Primary and secondary interlock switches, interlock monitor switch. 12. If the fuse is blown by the Interlock Monitor Switch: Replace all of the following at the same time: Primary, door sensing switch and power relay, as well as the Interlock Monitor Switch. The correct adjustment of these switches is described elsewhere in this manual. Make sure that the fuse has the correct rating for the particular model being repaired. 4 1. Precaution 1-2 Special High Voltage Precautions 1. High Voltage Warning Do not attempt to measure any of the high voltages --this includes the filament voltage of the magnetron. High voltage is present during any cook cycle. Before touching any components or wiring, always unplug the oven and discharge the high voltage capacitor (See Figure 1-1) 2. The high-voltage capacitor remains charged about 30 seconds after disconnection. Short the negative terminal of the high-voltage capacitor to to the oven chassis. (Use a screwdriver.) 3. High voltage is maintained within specified limits by closetolerance, safety-related components and adjustments. If the high voltage exceeds the specified limits, check each of the special components. H . V . Capacitor H . V . Diode Short PRECAUTION There exists HIGH VOLTAGE ELECTRICITY with high current capabilities in the circuits of the HIGH VOLTAGE TRANSFORMER secondary and filament terminals. It is extremely dangerous to work on or near these circuits with the oven energized. DO NOT measure the voltage in the high voltage circuit including filament voltage of magnetron. PRECAUTION Servicemen should remove their watches whenever working close to or replacing the magnetron. PRECAUTION Never touch any circuit wiring with your hand nor with uninsulated tool during operation. 5 2. Specifications 2-1 Features Product Features • Professional Design Samsung New OTR with Stainless Steel, it has professional look and the design matches great with other kitchen appliances, so that it provides harmonious kitchen interior and finally completes total kitchen solution. • Turbo vent With 400CFM ventilation power, New OTR can keep the comfortable cooking condition by absorbing smoke and odor from cook-top. Moreover, it provides the silent condition that is equivalent noise level to other OTR with lower ventilation power. The Strongest power without additional noise! That’s the benefit you can feel from New OTR! • Big Interior capacity for convenience With the 2.0 cu.ft capacity, it offers enough space to cook. The big capacity combined with 1,100 watts of output achieves superior cooking results. • Sensor cook Don’t worry about failure of your cooking! New OTR’s sensor technology offers the best dish. Only thing you need to do is just select the cooking menu, and then you will be satisfied with the cooking results by sensor cook. • VFD display With more informative VFD display, the OTR helps you use all the function it has with ease. 6 2. Specifications 2-2 Accessory Item Description Code No. Q’ty TRAY COOKING DE74-20002A 1 ASSY-GUIDE ROLLER DE97-00637A 1 ASSY-HOOD DAMPER DE92-90242D 1 ASSY-HARD WARE DE92-90505E 1 FILTER AIR DE63-30011A 2 FILTER CHARCOAL DE63-00367D 1 RACK-WIRE DE75-00036B 1 7 2. Specifications 2-3 Table of Specifications Items Oven Cavity Controls Timer Power Source Basic Model New Model SMH9207ST/XAA SMH9207ST/XAC 2.0 10 power levels, including defrost 2.0 10 power levels, including defrost 99 minutes, 99seconds 99 minutes, 99seconds 120VAC, 60Hz 120VAC, 60Hz 1650 Watts 1500 Watts Power consumption 1100 Watts Power Output Oven Cavity Outside Shipping Net/Gross Weight Export Zone 1/32 Dimensions (W x H x D inches) 22 7/8 x 10 1000 Watts 7/8 x 14 22 1/32 x 107/8 x 147/8 297/8 x 161/2 x 161/2 297/8 x 161/2 x 161/2 333/8 x 205/32 x 1913/32 333/8 x 205/32 x 1913/32 52.7lbs / 60.6lbs USA 52.7lbs / 60.6lbs Canada 8 3. Disassembly and Reassembly MAGNETRON, MOTOR ASSEMBLY, VENT BLOWER AND HIGH VOLTAGE TRANSFORMER Oven must be removed from wall. REMOVING OVEN FROM WALL (2 PEOPLE REQUIRED) Oven is hooked on metal tabs at bottom of wall mounting plate and to cabinet by (3) top cabinet bolts. 3-1 Disassembly of Assembly Grille and Panel Outer Parts Explaination Photo Explaination 1. Disconnect oven power. 2. Remove Grille. 1) Remove 2 screws 2) Slide the Grille to the left, then pull it straght out. Grille 1. Disconnect oven power. 2. Remove Grille. 3. Remove Screw.(7) Panel Outer 4. Remove Screw.(4) 9 3. Disassembly and Reassembly 3-1 Disassembly of Assembly Grille and Panel Outer Parts Explaination Photo Explaination 5. Remove Screw.(4) 6. Remove Screw.(2) Panel Outer 7. Remove Screw.(2) Explaination Photo Explaination 8. Remove Panel Outer. 10 3. Disassembly and Reassembly 3-2 Replacement of High Voltage Transformer and HVC and Base bottom Parts Explaination Photo Explaination 1. Disconnect Oven Power. 2. Remove Panel Outer. 3. Discharge The High Voltage Capacitor. ATTENTION : W hen discharge must become ground terminal of HVC and metal of around. High voltage capacitor 4. Remove screw.(1) 5. Disconnect the Lead Wire. Base Bottom 1. Remove Screw.(5) 2. Disconnect Lamp Housing. 3. Remove Base bottom. HV Trans 1. Disconnect Oven Power. 2. Remove the Base bottom and Panel Outer. 3. Disassembly the Bracket Duct upper after remove screw. 11 3. Disassembly and Reassembly 3-2 Replacement of High Voltage Transformer and HVC and Base bottom Parts Explaination Photo Explaination 4. Disconnect the Lead Wire. HV Trans 5. Remove screw.(4) 6. Take out the HV Trans. 12 3. Disassembly and Reassembly 3-3 Replacement of Magnetron Parts Explaination Photo Explaination Remove the magnetron including the shield case, permanent magnet, choke coils and capacitors (all of which are contained in one assembly). 1. Disconnect all lead wires from the magnetron. Magnetron 2. Remove nuts (4) securing the magnetron to the wave guide. 3. Take out the magnetron very carefully. NOTE1: W hen removing the magnetron, make sure that it antenna does not hit any adjacentparts, or it may be damaged. NOTE2: W hen replacing the magnetron, be sure to remount the magnetron gasket in the correct position and make sure the gasket is in good condition. PRECAUTION During replacement, be certain R.F. anode gasket is in place around anode stub. PERFORM MICROWAVE LEAKAGE TEST 13 3. Disassembly and Reassembly 3-4 Replacement of Door Assembly Parts Disassembly Photo Explaination Removal of Door Assembly 1. Disconnect the lead wire. 2. Open the Assembly Door by degree 90º 3. Seperate lifting Assembly Door from Set. Removal of Door C 4. Insert flat screwdriver into the gap between Door “A” and Door “C” to remove Door “C”. • Becareful when handling Door “C” because it is fragile. Removal of Key Door & Spring 5. Detach the spring and key door from Door. 14 3. Disassembly and Reassembly 3-4 Replacement of Door Assembly Removal of Handle 4. Remove 2 screws, then handle is detached from Door “A”. Removal of Door “E” 5. Following the procedure as shown in the figure, insert and bend a thin metal plate between Door “E” and Door “A” until you hear the ‘tick’ sound. • Insertion depth of the thin metal plate should be 0.5mm or less. 6. Remove 4 screw securing Door “E” to Door “A”. PRECAUTION PERFORM MICROWAVE LEAKAGE TEST 15 3. Disassembly and Reassembly 3-5 Replacement of Fuse Parts Explaination Photo Explaination The fuse is located on the noise filter. 1. Disconnect power and remove grilleand Assembly Control Box. 2. Replace the fuse. 3. When 20A fuse blows out by the operation of interlock monitor switch failure, replace the primary interlock switch, secondary interlock switch, door sensing switch, interlock monitor switch and power relay. 4. When the above four switches operate properly, check if any other part such as the control circuit board, blower motor or high voltage transformer is defective. Fuse Fuse Fuse 3-6 Replacement of Drive Motor Parts Explaination Photo Explaination 1. Disconnect power and remove Base bottom screws(5). 2. Remove Base bottom and disconnect the turntable motor drive. 3. Remove turntable motor screws(1) and pull the turntable motor out. 4. When replacing the drive motor, be sure to remount it in the correct position with the coupler. 5. Connect all the leads to the drive motor. Drive Motor 16 3. Disassembly and Reassembly 3-7 Replacement of stirrer motor Parts Explaination Photo Explaination 1. Disconnect power and remove Grille screws(3). 2. Remove the bracket duct upper. Stirrer Motor 3. Disconnect the stirrer motor wire. 4. Remove stirrer motor screws(1) and after turn to arrow direction pull the stirrer motor. 17 3. Disassembly and Reassembly 3-8 Removal of stirrer Parts Explaination Photo Explaination The stirrer is motor driver and located on the upper side of the cavity. The oven uses a top feed wave guide. The stirrer is located in the wave guide and the motor is located on the wave guide. 1. Disconnect power and open the door. Stirrer 2. Remove the clip and turn the stirrer cover left. 3. Remove stirrer cover and the stirrer will come with it. 18 3. Disassembly and Reassembly 3-9-1 Replacement of Control Circuit Board (Power) Parts Explaination Photo Explaination 1. Disconnect power and remove Grille. 2. Be sure to ground any static electric charge in your body and never touch the control circuit. Removal of Control Box Assembly 3. Remove a screw securing the control box assembly. 4. Disconnect the connectors from the control circuit board. 1. Pull the lever end of the plastic fastener and remove the Flexible Printed Circuit(FPC) of membrane panel. 2. Remove screws (3) securing the control circuit board. 3. Lift up the control circuit board from the Ass’y control box. 4. When reconnecting the FPC connector, make sure that the holes on the connector are properly engaged with the hooks on the Plastic Fastener. Removal of P.C.B Assembly(Sub) 3-9-2 Replacement of Control Circuit Board (Main) Parts Explaination Photo Explaination 1. Remove the Door-E(15Page) 2. Remove screws (3) securing the control circuit board. 3. Lift up the control circuit board from the Ass’y control box. 4. When reconnecting the FPC connector, make sure that the holes on the connector are properly engaged with the hooks on the Plastic Fastener. Removal of P.C.B Assembly(Main) 19 3. Disassembly and Reassembly 3-10 Replacement of Cooktop lamp When replacing the night light, make sure that you are wearing gloves to avoid injury from the heat of the bulb. Parts Explaination Photo Explaination 1. Unplug the oven or turn off the power at the main power. 2. Remove the bulb cover, and mounting screws. 3. Replace the bulb with a 40 watt appliance bulb. Cooktop Lamp 4. Replace the bulb cover and mounting screws. 5. Turn the power back on at the main power supply. 20 3. Disassembly and Reassembly 3-11 Replacement of Oven Light Parts Explaination Photo Explaination 1. Disconnect Oven power. 2. Remove the Grille Oven Light 3. Remove the bracket Duct upper by remove 1 screw. 4. Replace the bulb with a 40 watt appliance bulb. 21 4. Troubleshooting 4-1 Error Code Numbering Rule 1. ERROR CODE NUMBERING RULE is applied to a microwave oven and an oven.(CMO, OTR, Grill, Convection, Commercial etc.) 2. All sensors and devices have their own number. ex) Gas Sensor = 1, Temp. Sensor = 2, ... 3. Of each device, No.1 and No.2 refer to “Open Error” (not sensed) and “Short Error”, respectively. 4. This numbering rule has been applied to models to have been developed since January, 1, 2005. (But, GE or Customize model are excluded.) DEVICE ERROR CASE 0- Others 1- Open 1- Gas Sensor 2- Short 2- Temp. Sensor • 3- Weight Sensor • 4- Easy/PH Sensor • 5- EEPROM • • • 4-2 Error Code List Error Code -SE- Others (E-0X, Letter) Key Short Error (10 seconds) 22 Solution Page Turn off set and restart. 21 Page 4. Troubleshooting 4-2-1 Key Short Error “- SE -” is displayed. YES Is the key not recognized at all? NO YES Is the key recognized intermittently? NO Is a specific key not recognized? YES NO The membrane is defective. Replace the Control Panel. S/W Error After Power > On, does the symptom continue? NO YES Replace the PCB. Perform the operation again and check if it is working properly. 23 4. Troubleshooting PRECAUTION 1. 2. 3. 4. CHECK GROUNDING BEFORE CHECKING FOR TROUBLE. BE CAREFUL OF THE HIGH VOLTAGE CIRCUIT. DISCHARGE THE HIGH VOLTAGE CAPACITOR. WHEN CHECKING THE CONTINUITY OF THE SWITCHES OR TRANSFORMER, DISCONNECT ONE LEAD WIRE FROM THESE PARTS AND THEN CHECK CONTINUITY WITHOUT THE POWER SOURCE ON. TO DO OTHERWISE MAY RESULT IN A FALSE READING OR DAMAGE TO YOUR METER. 5. DO NOT TOUCH ANY PART OF THE CIRCUIT OR THE CONTROL CIRCUIT BOARD, SINCE STATIC DISCHARGE MAY DAMAGE IT. ALWAYS TOUCH GROUND WHILE WORKING ON IT TO DISCHARGE ANY STATIC CHARGE BUILT UP. 4-3 Electrical Malfunction Oven is dead. (No display and no operation at all.) Open or loose lead wire harness Fuse is OK Open thermal cutout (Magnetron) Check fan motor when thermal cutout is defective. Open low voltage transformer Check Ass’y PCB when L.V.T is defective. Defective Ass’y PCB Shorted lead wire harness Defective primary latch switch (NOTE (NOTE 1) 1) Defective monitor switch (NOTE (NOTE 1) 1) Check adjustment of primary, interlock monitor, power relay, door sensing switch. Shorted H.V.Capacitor Shorted H.V.Transformer (NOTE (NOTE 2) 2) NOTE 1: All of these switches must be replaced at the same time. (refer to adjustment instructions) Check continuity of power relay contacts and if it has continuity, replace power relay also. NOTE 2: When H.V.Transformer is replaced, check diode and magnetron also. Oven does not accept key input (Program) Oven does not accept key input Key input is not in-Sequence Refer to operation procedure. Open or loose connection of membrane key pad to Ass’y PCB Shorted or open membrane panel Timer starts countdown but no microwave Defective Ass’y PCB Replace PCB main. Off-alignment of latch switches 24 Adjust door and latch switches. Open or loose connection of high Check high voltage component according to Oven does not accept key input Open or loose connection of membrane key pad to Ass’y PCB 4. Troubleshooting Shorted or open membrane panel Defective Ass’y PCB Replace PCB main. Timer starts countdown but no microwave oscillation. (No heat while oven lamp and fan motor turn on.) Timer starts countdown but no microwave oscillation Off-alignment of latch switches Adjust door and latch switches. Open or loose connection of high voltage circuit especially magnetron filament circuit (NOTE) Check high voltage component according to component test procedure and replace if it is defective. Defective high voltage components H.V.Transformer H.V. Capacitor H.V.Diode, H.V.Fuse Magnetron Open or loose wiring of power relay Defective primary latch switch Defective power relay or Ass’y PCB Replace PCB main. NOTE: Large contact resistance will bring lower magnetron filament voltage and cause magnetron to lower output and/or intermittent oscillation. Oven can program but timer does not start. Oven can program but timer does not start Oven can program but timer does not start Oven can program but timer does Oven not canstart program but timer output does Microwave not start Microwave output is low is low. Microwave output is low Microwave output is low Microwave output is low Fan motor turns on when plugged in Open or loose wiring of secondary interlock switch Adjust door and interlock switches. Open or looseof wiring of secondary Off-alignment primary interlock interlock switch Adjust door and interlock switches. Open or loose wiring interlock of secondary Defective secondary S/W Off-alignment of primary interlock interlock switch Open or loose wiring of secondary interlock Off-alignment of primary interlock Defectiveswitch secondary interlock S/W Decrease power source voltage (Oven takesinlonger time to cook Off-alignment of primary interlock Defective secondary interlock S/W Open or loose wiring of magnetron Decrease in power source voltage filament Defectivecircuit. secondary interlock S/W (Intermittent oscillation) Open or loose wiring of magnetron Decrease in power source voltage filament Aging of circuit. magnetron (Intermittent Decrease in oscillation) power source voltage Open or loose wiring of magnetron filament circuit. Aging or of loose magnetron Open wiring of magnetron (Intermittent oscillation) filament circuit. (Intermittent oscillation) Aging magnetron Loose of wiring of door sensing switch Adjust door and interlock switches. Fan motor turns on when plugged in. Aging of magnetron Fan motor turns on when plugged in Fan motor turns on when plugged in Fan motor Oven doesturns not on when plugged operate and return in to the plugged Oven does not in mode operate and return to Oven does not operate the plugged Oven does not in mode operate and return to Oven does not the plugged operateinand return to mode Loud buzzing noise the plugged can be heard in mode Loud buzzing noise can be heard Loud buzzing noise can be heard Loud buzzing noise can be heard Turntable motor does not rotate. Adjust door and interlock switches. Consult electrician. food.) Consult electrician. Consult electrician. Consult electrician. Consult electrician. Loose wiring of door sensing switch Consult electrician. Loose wiring of door sensing switch Consult electrician. Loose wiring of door sensing switch Defective Ass’y PCB Consult electrician. Replace PCB main. Defective and return to Ass’y the PCB plugged in mode. Replace PCB main. Defective Ass’y PCB Loose fan and fan motor Defective Ass’y PCB Replace PCB main. Tighten screws of fan motor. Replace PCB main. Loose Loose screws fan and on fanH.V.Transformer motor Tighten screws screws of of fan H.V.Transformer. Tighten motor. Shorted H.V.Diode Loose screws fan and on fanH.V.Transformer motor Replace H.V.Diode. Tighten screws of fan motor. H.V.Transformer. Loose fan and fan motor Loose screws on H.V.Transformer Shorted H.V.Diode Tighten screws of fan motor. Tighten of H.V.Transformer. Replacescrews H.V.Diode. Loose screws H.V.Transformer Open or loose on wiring of Shorted H.V.Diode turntable motor. 25 Tighten of H.V.Transformer. Replacescrews turntable motor. Replace H.V.Diode. Shorted Open or H.V.Diode loose wiring of Defective turntable motor Replace H.V.Diode. Replace turntable motor. Loose wiring of door sensing switch (Intermittent oscillation) on when plugged in Aging of magnetron Fan motor turns Loose wiring of door sensing switch on when plugged in Aging of magnetron Fan motor turns Loose wiring of door sensing switch on when plugged in Oven does not Fan motor turns to operate and return Loose wiring of door Defective Ass’y PCB sensing switch onOven when plugged does not in the plugged Fan motor turns operateinand return to mode Loose wiring of door Defective Ass’y PCB sensing switch onOven when plugged does not in the plugged Loud buzzing noise operate return to can be heard. inand mode Defective Ass’y PCB Oven does not the plugged operateinand return to mode Defective Ass’y PCB the plugged Loose fan and fan motor Oven does not inand mode Loud buzzing noise operate return to Defective PCB Loose fan Ass’y and fan motor can be heard Oven does not the plugged Loose screws on H.V.Transformer Loud buzzing noise operate return to inand mode Defective Ass’y PCB Loose fan and fan motor can be heard the plugged Loose screws on H.V.Transformer Loud buzzing Shorted H.V.Diode in mode noise Loose fan and fan motor can be heard Loose screws on H.V.Transformer Loud buzzing noise Shorted H.V.Diode can be heard Loose screws fan and on fanH.V.Transformer motor Shorted H.V.Diode Turntable motor does not rotate. Loud buzzing noise Open or loose of Loose fan and wiring fan motor can be heard Loose screws on H.V.Transformer Shorted H.V.Diode turntable motor. Loud buzzing noise Turntable motor does Open or loose wiring of can heard notbe rotate. Loose screws on H.V.Transformer turntable motor. Defective turntable motor Shorted H.V.Diode Turntable motor does Open or loose wiring of not rotate. turntable motor. Defective turntable motor Shorted H.V.Diode Turntable motor does Open or loose wiring of not rotate. turntable motor. Defective turntable motor Turntable motor does Open wiring of not rotate. Open or or loose loose wiring of primary Defective turntable motor turntable motor. interlock switch Turntable motor does Oven stops operation during cooking. Oven stops operation Open or loose wiring Open or loose wiring of of primary not rotate. during cooking turntable motor. Defective turntable motor Turntable motor does interlock switch Operation of thermal cutout (Magnetron) Oven stops operation Open or loose wiring of primary not rotate. during cooking Defective turntable motor interlock switch Operation of thermal cutout (Magnetron) Oven stops operation Open or loose wiring of primary during cooking interlock switch Operation of thermal cutout (Magnetron) Oven stops operation Open or loose wiring of primary during cooking Metallic ware or cooking dishes Operation of thermal cutout (Magnetron) interlock switch Oven stops operation touching on thewiring oven of wall Open or loose primary Sparks Metallic ware or cooking dishes during cooking interlock switch Operation ofthe thermal (Magnetron) Sparks. Oven stops operation touching ware on oven cutout wall Ceramic trimmed with gold or Sparks Metallic ware or cooking during cooking silver powder also causesdishes sparks 4. Troubleshooting Sparks Sparks Uneven cooking Sparks Uneven cooking Sparks Uneven cooking Uneven cooking. Uneven cooking Uneven cooking Uneven cooking Noise from the turntable motor when Noiseto from the it starts operate. turntable motor when Noiseto from the it starts operate. turntable motor when Noiseto from the it starts operate. turntable motor Noise from thewhen turntable it starts operate. Noiseto from the turntable motor when Noiseto from the it starts operate. turntable motor when it starts to operate. Operation ofthe thermal (Magnetron) touching ware on oven cutout wall Ceramic trimmed with gold or Metallic ware or cooking silver powder also causesdishes sparks touching ware on thetrimmed oven wall Ceramic with gold or silver powder also causesdishes sparks Metallic ware or cooking Ceramic ware trimmed with golddue or Uneven intensity of microwave touching on the oven wall silver powder also causesdishes sparks Metallic ware or cooking to its characteristics Uneven intensity of microwave touching on thetrimmed oven wall Ceramic ware with golddue or to its characteristics silver powder also causes sparks Uneven intensity of microwave Ceramic ware trimmed with golddue or to its characteristics silver powder also causes sparks Uneven intensity of microwave due to its characteristics Uneven intensity of microwave due to its characteristics Uneven intensity of microwave due to its characteristics Noise may result from the motor Noise may result from the motor Noise may result from the motor Consult electrician. Consult electrician. Consult electrician. Consult Replaceelectrician. PCB main. Consult Replaceelectrician. PCB main. Replace PCB main. Replace PCB main. Tighten screws of fan motor. Replace PCB main. Tighten screws of fan motor. Tighten screws of H.V.Transformer. Replace PCB main. Tighten screws of fan motor. Tighten screws of H.V.Transformer. Replace H.V.Diode. Tighten screws of fan motor. Tighten screws of H.V.Transformer. Replace H.V.Diode. Tighten motor. Tighten screws screws of of fan H.V.Transformer. Replace H.V.Diode. Tighten of fan motor. Replacescrews turntable motor. Tighten of H.V.Transformer. Replacescrews H.V.Diode. Replace turntable motor. Tighten screws of H.V.Transformer. Replace H.V.Diode. Replace turntable motor. Replace H.V.Diode. Replace turntable motor. Replace turntable motor. Adjust door and latch switches. Replace turntable motor. Adjust door and latch switches. Adjust door and latch switches. Adjust door and latch switches. Adjust door and latch switches. Inform the customer: Do not use any type of cookware with trimming Adjust door andmetallic latch switches. Inform the customer: Do not use any type of cookware with metallic trimming Inform the customer: Do not use any type of cookware with metallic trimming Inform the customer: Do not use any type of cookware with metallic trimming Inform the customer: Do not use any type of Wrap thinner of the food with aluminum foil. cookware withparts metallic trimming Inform the customer: Do not use any type of Wrap thinner of the food with aluminum foil. cookware withparts metallic trimming se plastic wrap or cover with a lid. Wrap thinner parts of the food with aluminum foil. se plastic wrap or cover with a lid. Stir once or twice while cooking foods such as Wrap thinner parts of the food with aluminum foil. soup, cocoa, or or milk. se plastic wrap cover with a lid. Stir once or twice while cooking foods such as Wrap thinner parts of thewith fooda with soup, cocoa, or milk. se plastic wrap or cover lid. aluminum foil. Stir once or twice while cooking foods such as Wrap parts of the food with aluminum foil. soup, thinner cocoa, or milk. se wrap or while covercooking with a lid. Stirplastic once or twice foods such as soup, cocoa, or milk. Replace turntable motor. se plastic wrap or cover with a lid. Stir once or twice while cooking foods such as Replace turntable motor. soup, cocoa, or milk. Stir once or twice while cooking foods such as Replace turntable motor. soup, cocoa, or milk. may it result from the motorNoise when starts to motor operate. Replace turntable motor. Noise may result from the motor Replace turntable motor. Noise may result from the motor Replace turntable motor. 26 5. Exploded Views and Parts List 5-1 Exploded Views M060 P007 U008 P012 M061 G361 T001 P036 P039 P025 P124 M444 P105 P086 M015 M036 T030 M067 P024 P034 H093 M102 C309 P001 P226 M001 M024 M040 H024 M068 P106 M528 M039 M527 M017 M059 C144 M087 M034 H096 M059 W002 W004 M023 M049 M036 P059 M102 M102 M035 M443 P121 B022 B064 B048 M038 U060 M444 M453 U005 B047 B048 U057 U001 M048 27 M155 B013 P109 M021 5. Exploded Views and Parts List 5-2 Main Parts List (S.N.A : SERVICE NOT AVAILABLE) No. Code No. Description Specification Q’ty SA/SNA Remark B013 DE66-90106B LEVER SWITCH-LOWER OTR6,PP,T1.4,-,-,-,-, 1 SA - B022 DE96-00414A ASSY BODY LATCH RVM-1625BJ,- 1 SA - B047 3405-001033 SWITCH-MICRO 125/250VAC,16A,200gf,SPST-N 1 SA - B048 3405-001034 SWITCH-MICRO 125/250VAC,16A,200gf,SPST-N 2 SA - B064 DE66-00168A LATCH-BODY MODULAR-2,PP,-,-,-,-,- 1 SA - C144 DE66-20095B BUTTON-LOCKING -,-,OTR5,-,-,TB53) 1 SA C309 DE59-50002A C-FILM,LEAD-OTHER 10000nF,+10/-5%,220V,# 1 SA - G361 DE92-90508A ASSY HOLDER-NUT OTR6 1 SA - H024 DE60-30015A NUT-FLANGE -,MSWR10,P0.8,-,-,-,FEFZY,-,- 4 SA - H093 DE61-01181A BRACKET-CONNECTOR SMH9207,SECC,T0.5,-,-, 1 SNA - H096 DE31-90051A BLADE-FAN -,PP,-,D130,-,T,- 1 SA - M001 DE64-00754J PANEL-OUTER MAYTAG2.0,SECC,T0.4,BLACK 1 SA - M015 DE96-00218A ASSY POWER CORD UL,Straight,125V/15A,SJT 1 SC - M017 DE96-00400D ASSY NOISE FILTER -,SN-UF12D,250V/20A,SE 1 SA - M021 DE97-00365L ASSY COVER MOTOR W/POOL 2.0 GLIDE,-,-,PP 1 SNA - M023 DE31-00044B MOTOR FAN SMF-U4205A,120V/60Hz,2820rpm,A 1 SNA - M024 DE31-00029C MOTOR VENTILATION SMV-460UA1-AL,120V,60H 1 SNA - M034 DE67-00251A COUPLER SMH9207,SPS,-,-,-,- 1 SA - M035 OM75P(10)ESGN ASSY-MGT 1 SA - M036 4713-001013 LAMP-INCANDESCENT 130V,40W,ORG,25X73 1 SA - M036 4713-001013 LAMP-INCANDESCENT 130V,40W,ORG,25X73 2 SA - M038 DE26-00151A TRANS H.V SHV-U1850A,120V,60Hz,2310,2460 1 SA - M039 2501-001035 C-OIL 860nF,2100V,BK,35x54x75,20mm 1 SA - M040 DE61-00115A BRACKET-HVC SMH7175,SECC,T0.6,-,-,-,- 1 SA - M048 DE61-00905A BASE-PLATE MAYTAG2.0,SECC,T0.6 1 SA - M049 DE31-10172B MOTOR SYNCHRONOUS SM16FBY36P1AW3,OTR,FRE 1 SA - M059 DE61-00375A HOLDER-RACK OTR-1.5CUFT,PP,-,-,-,-,- 4 SA - M060 DE92-90505E ASSY HARD WARE SMH7175,-,- 1 SC - M061 DE63-00367D FILTER-CHARCOAL SMH7175,AL,CARBON,T9,W15 1 SC - M067 DE94-02100A ASSY GRILLE SMH9207,PC,STS 1 SA - M068 DE64-02216A GRILLE SMH9207,PC,-,-,-,-,BLK,- 1 SA - M087 DE71-60121A COVER-STIRRER -,PP,T2.0,W7,L198,-,-,85G, 1 SA - M102 DE47-00006A SOCKET-LAMP -,OTR7,-,250V,75W,-,250Vx187 2 SA - M102 DE47-00006A SOCKET-LAMP -,OTR7,-,250V,75W,-,250Vx187 1 SA - M155 DE97-00677B ASSY BASE PLATE MMV5207,-,T0.6,BASE-PLAT 1 SA - M443 DE47-20007A THERMOSTAT NT-101,250V 10A/125V 15A,150( 1 SA - M444 DE47-20059A THERMOSTAT -,NT-101,250V 10A/125V 15A,-, 1 SA - M444 DE47-20059A THERMOSTAT -,NT-101,250V 10A/125V 15A,-, 1 SA - M453 DE47-20034A THERMOSTAT -,NT-101,250V 10A/125V 15A,-, 1 SA - M527 DE59-00002A DIODE-H.V MWO ALL,2CL4512H,-,450mA 13KV, 1 SC - M528 DE91-70063D ASSY HVD MWO-GE,HV03-12,-,-,RED,- 1 SA - P001 DE94-02101A ASSY STIRRER SMH9207,ALP T0.5 1 SA - P007 DE70-00561A PLATE-MOUNTING GE 1.6 NEW APPEARANCE,GI, 1 SA - P012 DE92-90242D ASSY-HOOD DAMPER JVM-1870,-,JVM250BL OTR 1 SA - 28 5. Exploded Views and Parts List 5-2 Main Parts List (Continued) (S.N.A : SERVICE NOT AVAILABLE) No. Code No. Description Specification Q’ty SA/SNA Remark P024 DE32-60011A SENSOR GAS TGS-880,-,-,-,-,-,-,-,- 1 SC - P025 DE61-90111A HOLDER-SENSOR -,POM(DURACON-M90-02),-,-, 1 SA - P034 DE97-00366H ASSY DUCT UPPER SMH9207,FH44N,SENSOR 1 SA - P036 DE39-40678D WIRE HARNESS-S SMH7185WG/XAA,120V60HZ,86 1 SA - P039 DE67-00168B DUCT-UPPER SMH7175,PP,BLK,T2.0 1 SA - P059 DE63-00419A COVER-FRONT MAYTAG2.0,SECC,T0.6,MAYTAG 1 SA - P086 DE61-01008A BRACKET-BARRIER MHC4/5,SECC,0.5,-,-,-,- 1 SA - P105 DE61-00410A BRACKET-DUCT(U) SMH7175,SECC,T0.5,W200,L 1 SA - P106 DE63-00601A EARTH-GRILLE SMH9207,STS301,T0.15,-,-,-, 1 SA - P109 DE63-00141B COVER-MOTOR AMV5206BAB,PP(V0 ),MAYTAG 2. 1 SA - P121 DE61-00411B BRACKET-DUCT REAR NEW WAVE / MT 2.0,SECC 1 SA - P124 DE60-30063A NUT-MOUNTING -,S10C,M6.3,-,-,-,ZNC,-,- 2 SA - P226 DE64-02222A INLAY-GRILLE SMH9207,STS430,T0.4,-,-,-,- 1 SA - T001 DE74-20002A TRAY-COOKING -,GLASS,T6,NEG,PI360,1.2CUF 1 SC - T030 DE75-00036B RACK-WIRE SMH7175,SNCR,W315,D4 1 SA - U001 DE94-02136B ASSY BASE BOTTOM SMH9207ST/XAC,SECC,T0.4 1 SA - U005 DE67-40063A GLASS-COOK TOP LAMP -,GLASS,T3.2,W59,L15 1 SA - U008 DE63-30011A FILTER-AIR -,AL, 2 SA - U057 DE63-00100B COVER-COOKTOP LAMP OTR-9,SECC,T0.4,-,-,- 1 SC - U060 DE61-01179B BASE-BOTTOM SMH9207ST/XAA,SECC,T0.4,BLAC 1 SA - W002 DE96-00785B ASSY WIRE HARNESS-A SMH9207,120V/60Hz,MO 1 SNA - W004 DE96-00787A ASSY WIRE HARNESS-C SMH9207,120V/60Hz,MO 1 SA - 29 5. Exploded Views and Parts List 5-3 Door Parts List D049 D005 D004 D037 C003 D006 D011 C004 D184 C009 D007 D002 Z779 W005 D063 D077 D064 D003 D073 D195 (S.N.A : SERVICE NOT AVAILABLE) No. Code No. Description Specification Q’ty SA/SNA Remark C003 C004 DE92-02135A ASSY PCB-MAIN RAS-ML9M-00,SMH9207ST/XAA, 1 SA - DE34-00333A SWITCH MEMBRANE SMH9207ST/XAA,PC,BLACK 1 SA - C009 DE64-02268A WINDOW-DISPLAY SMH9207,SAN(CR-5381),BLUE 1 SA - D002 DE64-02217A DOOR-A SMH9207,PC,-,-,-,-,BLK,- 1 SA - D003 DE64-02226A SCREEN-DOOR SMH9207,REINFORCE GLASS,T3.2 1 SA - D004 DE94-01471B ASSY DOOR E MAYTAG2.0,-,-,COATING 1 SA - D005 DE01-00127A FILM-DOOR JVM-1860,POLYESTER,PET,L479,T0 1 SA - D006 DE64-00759A DOOR-C SMH7175,PP,T1.5,-,-,-,BLK,- 1 SA - D007 DE61-00048A SPRING-KEY -,HSWR,PI0.95,-,D8.75,L43,-,- 1 SA - D011 DE64-01308A DOOR-KEY MODULAR-2,POM,-,-,-,-,BLK,- 1 SA - D037 DE94-02096A ASSY DOOR A SMH9207,PC,STS 1 SA - D049 DE94-02095A ASSY DOOR SMH9207,PC,STS 1 SA - D063 DE64-02220A HANDLE-BASE UPPER SMH9207,PC,-,-,-,-,BLK 1 SA - D064 DE64-02243A HANDLE-BASE LOWER SMH9207,PC,-,-,-,-,BLK 1 SA - D073 DE63-00600A EARTH-DOOR SMH9207,STS301,T0.15,-,-,-,- 1 SA - D077 DE64-02224A HANDLE-TUBE SMH9187,Al 1 SA - D184 DE67-00250A CAP-DOOR A SMH9207,PC,-,-,-,BLK,- 1 SA - D195 DE63-00622A EARTH-DOOR(B) SMH9207,STS301,T0.15 1 SA - W005 DE96-00788A ASSY WIRE HARNESS-D SMH9207,120V/60Hz,MO 1 SA - Z779 DE64-02221A INLAY-DOOR SMH9207,STS430,T0.4,-,-,-,HAI 1 SA - 30 5. Exploded Views and Parts List 5-4 Control Parts List C082 P157 C301 C001 W038 C005 Z780 C302 C084 C010 C303 (S.N.A : SERVICE NOT AVAILABLE) No. Code No. Description Specification Q’ty SA/SNA Remark C001 DE94-02098A C005 DE64-02218A ASSY CONTROL PANEL SMH9207,STS,PC 1 SA - CONTROL-PANEL SMH9207,PC,-,-,-,-,BLK,- 1 SA - C010 DE64-02219A C082 DE94-02097A BUTTON-SELECT SMH9207,PC,-,-,BLK,- 1 SA - ASSY CONTROL BOX SMH9207,120V60HZ,STS,PC 1 SA - C084 DE96-00789A C301 DE92-02136A ASSY KEY MODULE SMH9207ST/XAA,DKM-ML9-00 1 SA - ASSY PCB-POWER RAS-ML9P-00,SMH9207ST/XAA 1 SA - C302 DE01-00259A FILM-KEY MODULE SMH9207,PET,T0.1 1 SA - C303 DE63-00603A EARTH-CONTROL SMH9207,STS301,T0.15,-,-,- 1 SA - P157 DE94-02099A ASSY BRACKET C/PANEL SMH9207,SECC,T0.4 1 SA - Z780 DE64-02223A INLAY-CONTROL PANEL SMH9207,STS430,T0.4, 1 SA - 31 5. Exploded Views and Parts List 5-5 Standard Parts List (S.N.A : SERVICE NOT AVAILABLE) No. Code No. Description Specification Q’ty SA/SNA Remark 1-1 6002-000643 SCREW-TAPPING TH,+,NO,2S,M4,L10,ZPC(WHT) 2 SNA - 1-1 6002-001173 SCREW-TAPPING FH,+,2S,M4,L12,ZPC(BLK),MS 8 SNA - 1-1 6003-001568 SCREW-TAPTYPE FH,TORX,B,M4,L16,NI PLT,SW 2 SNA - 1-1 6006-001170 SCREW-TAPPING TH,+,WT,TC,M4,L10,ZPC(WHT) 2 SA - 1-1 DE60-10045A SCREW-TAPPING PH,M3,FEFZY 2 SA - 1-1 DE60-10051A SCREW-TAPPING PH,+,M4,L6,NI PLT,SWRCH18A 2 SA - 1-1 DE60-10062A SCREW-TAPPING TH,M4,FEFZB 2 SNA - 1-1 DE60-10067A SCREW-TAPPING TH,2-SLOT,M4,2-SLOT,FEFZB 11 SA - 1-1 DE60-10080A SCREW-TAPPING PWH,+,-,2S,M5,L9,-,SWRCH18 4 SA - 1-1 DE60-10082I SCREW-A 2S-4X12,FEFZY 16 SA - 1-1 DE60-30015A NUT-FLANGE -,MSWR10,P0.8,-,-,-,FEFZY,-,- 4 SA - 1-1 DE92-90508A ASSY HOLDER-NUT OTR6 1 SA - 1-2 DE60-10111A SCREW-INCH MACH UNC1/4,L50,SWRCH18A 1 SNA - 1-2 DE60-20022A BOLT-TOGGLE -,-,-,W3/16X75,-,MSWR,-,-,- 3 SNA - 1-2 DE60-20066A BOLT-FLAT -,MSWR10,-,L110,-,UNF1/4,-,-,- 3 SNA - 1-2 DE60-30022A NUT-TOGGLE -,WHT,ZPC2,-,-,-,-,-,- 3 SNA - 1-2 6001-002033 SCREW-MACHINE TH,+,M4,L16,ZPC(BLK),SWRCH 2 SNA - 1-2 6002-000630 SCREW-TAPPING PH,+,-,2S,M3,L8,ZPC(WHT),S 2 SNA - 1-2 6006-001170 SCREW-TAPPING TH,+,WT,TC,M4,L10,ZPC(WHT) 4 SA - 1-2 DE60-10082I SCREW-A 2S-4X12,FEFZY 1 SA - 1-2 6002-000630 SCREW-TAPPING PH,+,-,2S,M3,L8,ZPC(WHT),S 3 SNA - 1-2 DE60-10082I SCREW-A 2S-4X12,FEFZY 1 SA - 1-2 DE60-10067A SCREW-TAPPING TH,2-SLOT,M4,2-SLOT,FEFZB 1 SA - 1-2 DE60-10082I SCREW-A 2S-4X12,FEFZY 2 SA - 1-2 6002-001004 SCREW-TAPPING TH,+,-,2,M4,L30,ZPC(WHT),S 2 SA - 1-2 DE60-10082I SCREW-A 2S-4X12,FEFZY 1 SA - 1-2 DE60-30063A NUT-MOUNTING -,S10C,M6.3,-,-,-,ZNC,-,- 2 SA - 1-2 DE60-10082I SCREW-A 2S-4X12,FEFZY 1 SA - 1-2 DE60-10045A SCREW-TAPPING PH,M3,FEFZY 1 SA - 1-3 DE60-10082I SCREW-A 2S-4X12,FEFZY 2 SA - 32 6. PCB Diagrams 6-1 PCB Diagrams (ML9M) (This Document can not be used without Samsung’s authorization) 3 Parts No. Part Name Number CN01 MAIN & POWER PBA Connector CN02 Membrane switch Connector_L CN03 Membrane switch Connector_R 1 2 3 Function and Rule Connect Main and Power PBA A Terminal for Connecting with Left Membrane Switch A Terminal for Connecting with Right Membrane Switch 2 1 33 6. PCB Diagrams 6-2 PCB Diagrams (ML9M) (This Document can not be used without Samsung’s authorization) C N 03 1) N O C O N N E C TIO N 2) K E Y IN -6 3) K E Y IN -5 4) K E Y IN -4 5) K E Y IN -3 6) K E Y IN -2 7) K E Y IN -1 8) K E Y O U T -9 9) K E Y O U T -8 10) K E Y O U T -7 11) K E Y O U T -6 12) K E Y O U T -5 13) K E Y O U T -4 14) K E Y O U T -3 15) K E Y O U T -2 16) K E Y O U T -1 C N 02 1) N O C O N N E C TIO N 2) K E Y IN -6 3) K E Y IN -5 4) K E Y IN -4 5) K E Y IN -3 6) K E Y IN -2 7) K E Y IN -1 8) K E Y O U T -9 9) K E Y O U T -8 10) K E Y O U T -7 11) K E Y O U T -6 12) K E Y O U T -5 13) K E Y O U T -4 14) K E Y O U T -3 15) K E Y O U T -2 16) K E Y O U T -1 C N 01 1) R Y -P O W E R -L 2) R Y -P O W E R -H 3) R Y -IN R U S H 4) G S 5) R Y -B R IG H T 6) K E Y 7-A D 7) R Y -S P A R E 8) V FD FILA M E N T 1 9) R Y -N IG H T 10) V FD FILA M E N T 2 11) R Y -V E N T -H 12) R Y -O P TIO N 13) R Y -V E N T -M 14) -34V 15) R Y -V _D O O R 16) G N D 17) B U ZZE R 18) G N D 19) R Y -V E N T -L 20) + 5V 21) R Y -TT 22) + 5V 23) IN T 24) TC O -S 25) R Y -M A IN 26) S TB 34 6. PCB Diagrams 6-1 PCB Diagrams (KEY-ML9) (This Document can not be used without Samsung’s authorization) Parts No. Part Name Number CN01 Power PBA Connector 1 Function and Rule A Terminal for Connecting with Power PBA 35 6. PCB Diagrams 6-2 PCB Diagrams (KEY-ML9) (This Document can not be used without Samsung’s authorization) C N 01 1) + 5V 2) K E Y 7-A D 3) G N D 36 6. PCB Diagrams 6-1 PCB Diagrams (ML9P) (This Document can not be used without Samsung’s authorization) Parts No. Number RY01 RY02 RY03 RY04 RY05 RY06 RY07 RY08 RY09 RY10 RY11 CN01 CN02 CN03 CN04 CN05 CN6 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 16 14 Part Name Main Relay Inrush Relay Power High Relay Power Low Relay Bright Relay Night Relay Spare Relay(for future use) Turn Table Relay Vent Low Relay Vent Mid Relay Vent High Relay Power & Relay Connector Power & Relay Connector Gas Sensor Connector Door switch Sensing Connector MAIN & POWER PBA Connector Dome Switch Connector 1 17 8 9 13 15 1 1 6 7 1 5 2 Function and Rule 4 3 Fan, Lamp, T/T Control Inrush Electric Current Decrease MW Power Control(High Power) MW Power Control(Low Power) Turn on High Light Turn on Low Light Spare Relay(for future use) Turn on Turn Table Turn on Low Ventilation Turn on Mid Ventilation Turn on High Ventilation Connect Power supply and Relay Contact(Inrush, Bright, Night, Spare) Connect Power supply and Relay Contact(Vent High/Mid/Low, Turn Table, Main) A Terminal for Connecting with Gas Sensor A Terminal for Connecting with Door Switch Connect Main and Power PBA A Terminal for Connecting with Dome Switch 37 6. PCB Diagrams 6-2 PCB Diagrams (ML9P) (This Document can not be used without Samsung’s authorization) C N 05 1) R Y -P O W E R -L 2) R Y -P O W E R -H 3) R Y -IN R U S H 4) G S 5) R Y -B R IG H T 6) K E Y 7-A D 7) R Y -S P A R E 8) V FD FILA M E N T 1 9) R Y -N IG H T 10) V FD FILA M E N T 2 11) R Y -V E N T -H 12) R Y -O P TIO N 13) R Y -V E N T -M 14) -34V 15) R Y -V _D O O R 16) G N D 17) B U ZZE R 18) G N D 19) R Y -V E N T -L 20) + 5V 21) R Y -TT 22) + 5V 23) IN T 24) TC O -S 25) R Y -M A IN 26) S TB C N 03 1) G A S 2) G A S 3) G A S 4) G A S S E N S O R (S 1) S E N S O R (S 2) S E N S O R (H 1) S E N S O R (H 2) CN6 1) + 5V 2) K E Y 7-A D 3) G N D C N 04 1) D O O R S W ITC H 2) G N D 3) D O O R S W ITC H 4) TC O 5) G N D C N 02 1) V E N T H IG H 2) N O P IN 3) V E N T M ID 4) N O P IN 5) V E N T LO W 6) N O P IN 7) TU R N TA B LE 8) N O P IN 9) M A IN C N 01 1) A C P O W E R (LIV E ) 2) N O P IN 3) IN R U S H 4) N O P IN 5) B R IG H T / N IG H T 6) N O P IN 7) S P A R E 38 R Y 03 1) P O W E R R E LA Y C O N TA C T 1(H V T P O W E R 1) A C P O W E R N E U TA L (A C 98V ~ 144V ) 2) P O W E R R E LA Y C O N TA C T 2(H V T P O W E R 2) R Y 04 1) P O W E R R E LA Y C O N TA C T 1(H V T P O W E R 1) A C P O W E R N E U TA L (A C 98V ~ 144V ) 2) P O W E R R E LA Y C O N TA C T 2(H V T P O W E R 3) 7. Wiring Diagrams 7-1 Wiring Diagrams (This Document can not be used without Samsung’s authorization) 39 7. Wiring Diagrams 7-2 Wiring Diagrams (This Document can not be used without Samsung’s authorization) 40 8. Schematic Diagrams 8-1 Schematic Diagrams (ML9-Main) (This Document can not be used without Samsung’s authorization) 5 4 3 2 1 KEY7-AD RY-BRIGHT GS RY-INRUSH RY-POWER-H RY-POWER-L TCO-S INT F1 F2 +5V -34V CONNECTING WITH SUB PBA 6 RY-SPARE RY-NIGHT 7 8 9 10 RY-VENT-H RY-OPTION 11 12 RY-VENT-M 23 RY-MAIN RY-TT RY-VENT-L BUZZER RY-V_DOOR 13 14 15 16 17 18 19 20 21 24 STB 22 25 +5V R01 2K C01 10uF IC02 ELM7533CBA-S C05 100nF IC03 24LC04B R02 47K C02 100nF +5V R03 4.7K RESET MICOM DISPLAY 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 4 VFD-2S VFD-3S VFD-4S VFD-5S VFD-6S VFD-7S VFD-8S VFD-9S VFD-10S VFD-11S VFD-12S VFD-13S VFD-14S VFD-15S VFD-16S VFD-17S NP2 NP1 VFD-7G VFD-6G VFD-5G VFD-4G VFD-3G VFD-2G VFD-1G VFD-1S VFD-2S VFD-3S VFD-4S VFD-5S VFD-6S VFD-7S VFD-8S VFD-9S VFD-10S VFD-11S VFD-12S VFD-13S VFD-14S VFD-15S VFD-16S VFD-17S 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 10G 9G 8G 7G 6G 5G 4G 3G 2G 1G P1 P2 P3 P4 P5 P6 P7 P8 P9 P10 P11 P12 P13 P14 P15 P16 F2 61 VFD-1S VFD-8G 14 15 12G 11G F1 60 VFD-1G VFD-9G 13 13G 42 43 44 F21 F22 F23 59 VFD-2G VFD-10G 12 14G 16 10 8 VFD-13G VFD-12G VFD-18G 5 6 NC 18G 9 47 VFD-14G STB 80 46 VFD-15G P17 58 VFD-3G VFD-11G 11 15G SDA 1 45 VFD-16G CN02 12516HS-16 1 CN03 12516HS-16 5 4 2 KO-4 6 KO-1 4 KO-5 7 1 KO-4 5 KO-6 8 KO-1 KO-4 KO-5 6 KO-7 9 KO-1 KO-5 KO-6 7 KO-8 10 3 KO-6 KO-7 8 KO-9 11 KO-2 KO-7 KO-8 9 KEY-1 12 KO-3 KO-8 KO-9 10 KEY-2 13 2 KO-9 KEY-1 11 KEY-3 14 3 KEY-1 KEY-2 12 KEY-4 15 KO-2 KEY-2 KEY-3 13 KEY-5 KO-3 KEY-3 KEY-4 14 KO-3 KEY-4 KEY-5 KEY-6 KO-2 1 2 3 F11 F12 F13 38 57 VFD-4G VFD-12G 10 16G +5V 13 56 VFD-5G VFD-13G 9 17G -34V 7 55 VFD-6G VFD-14G 8 IC01 TMP88PU74F 14 54 VFD-7G VFD-15G 7 78 12 53 VFD-8G VFD-16G 40 11 52 VFD-9G VFD-17G 39 19 51 VFD-10G C03 100nF 28 50 VFD-11G C04 100nF DOOR 21 49 OPTION-1 2 44 INT TCO 31 48 EMCR BZ 30 RESET SCL GAS-S C-S-I 79 OPTION-2 5 1N4148M VFD-17G 1N4148M 43 D01 1N4148M 42 D02 23 KEY1 VFD-18G D03 25 KEY2 VFD-17G RY-SPARE 37 KEY3 VFD-16G RY-INRUSH XTL1 12.5MHz SDA RY-VENT-H SCL KEY-CONTROL MEMBRANE C-S-O DOOR DOOR & TCO R04 4.7K 36 KEY4 VFD-18G 35 KEY5 1N4148M 41 17 34 D04 26 22 33 VFD-15G 1N4148M RY-POWER-L 77 KEY6 D05 27 20 32 VFD-14G 1N4148M 18 15 3 D06 1N4148M RY-VENT-L 24 VFD-13G D07 1N4148M RY-POWER-H RY-TT RY-NIGHT RY-VENT-M RY-OPTION RY-MAIN RY-BRIGHT KEY7-AD 29 VFD-12G D08 4.7K VFD-11G R11 4.7K KEY-5 15 16 KEY-6 16 KEY-6 41 26 YDAW200-26 CN01 +5V R05 4.7K BUZZER RY-V_DOOR TR101 KRC246 CN04 100nF R12 4.7K 1N4148M R13 4.7K D09 R14 VFD-10G KEY1 KEY2 KEY3 KEY4 47K 4.7K 47K R22 R15 47K R21 KEY5 47K R20 4.7K R19 R16 47K 47K DSP1 VFD33-1802F R17 R18 C06 100nF DGND OPTION SPARE KEY6 1nF R06 10K +5V OR02 2K 1nF C16 TCO +5V OR01 2K OPTION-1 OPTION-2 1nF 6 CLOCK SAVE D10 1N4148M C-S-I R10 47K C15 C07 100nF BUZZER BZ R09 47K DGND 1nF C14 RESET TR102 KRC246 R23 1M C10 10uF DGND 1nF C13 R07 4.7K GAS-S C09 10uF DGND 1nF C12 TCO-S R08 4.7K C08 100nF C-S-O DGND C11 GAS SENSOR GS 8. Schematic Diagrams 8-2 Schematic Diagrams (ML9-Sub) (This Document can not be used without Samsung’s authorization) PTC101 33ohm ZNR101 10D471 R01 51K R02 51K 1 2 PC01 PC817 SOURCE NEUTRAL 4 3 1N4007 1N4007 D101 D102 1N4007 RY02 G5T-1A-12VDC 4.7K R05 L101 1mH C101 22uF INRUSH INT INTERRUPT TR13 KRC246M R04 4.7K +5V 1N4007 D103 D104 +5V R03 10K C01 1nF PTC2 33ohm C102 22uF D02 1N4148M D03 R101 100K R102 100 D S5 S6 +12V C103 1nF 7 D10 1N4007 TR09 KRC246M TR08 KRC246M TR07 KRC246M TR06 KRC246M TR05 KRC246M ST101 ST-SM9GV 6 10 SENSOR OPTION SENSOR : JUMPER N/SENSOR : UF4007 D108 UF4007 R103 1K D110 UF4007 D109 UF4007 D107 UF4007 D106 SB140 POWER SUPPLY 2 9 8 1 7 11 4 3 C104 10uF RY-VENT-L RY-TT RY-SPARE RY-NIGHT RY-BRIGHT C03 10uF C02 100nF RY-MAIN RY-POWER-L RY-POWER-H RY-INRUSH RELAY CONTROL R14 4.7K R15 4.7K R16 4.7K +5V R17 100 TR12 KRA226-AT TR01 KRC246M TR04 KRC246M KRC246M TR03 TR02 KRC246M S7 2 B 1 IC101 TNY276P E 8 S8 D105 1N4007 4 5 6 1N4148M 1N4148M 1N4148M 1N4148M +12V C105 470uF C108 47uF PC101 PC817 C109 470uF 4 3 3 1 2 4 5 C106 470uF F1 TR103 KRC246M -34V R106 2K C107 220uF +5V ZD101 UZ5.1BSB +5V R07 19.1K R08 100K R12 470 +5V RY-V_DOOR R10 200K R09 26.1K L102 3.9uH +5V-1 F2 TR102 KRA226-AT 1 2 3 4 2 1 +12V DGND TCO-S RY-OPTION POWER RELAY OPTION R13 47K OR01 1. DEC : INSERT 2K 2. HKE : DELETE +5V DGND STB OJ101 TR101 KRA226-AT ZD102 MTZJ4.3B R06 100K +12V +5V +5V-1 STB GS KEY7-AD R11 1K GAS SENSOR R105 1K R919 220 +5V +12V VCC IC04 KIA75S358 VEE 1 2 3 DGND F1 +5V F2 -34V CN05 YDW200-26 RY-POWER-L 2 1 3 RY-POWER-H RY-INRUSH 4 6 5 GS KEY7-AD 7 RY-BRIGHT RY-SPARE 9 8 RY-NIGHT 10 12 11 13 RY-VENT-H RY-OPTION 16 15 14 RY-VENT-M RY-V_DOOR 17 18 19 BUZZER RY-VENT-L 21 20 RY-TT TCO-S INT 26 25 24 23 22 STB RY-MAIN 42 RY03 DU12D1-1P D08 D07 D06 D05 1N4148M D01 1N4148M 1N4148M D04 POWER-HIGH1N4148M RY04 DU12D1-1P MAIN POWER-LOW RY01 G5T-1A-12VDC RY05 G5T-1A-12VDC BRIGHT NIGHT SPARE T/T D09 RY-VENT-M RY-VENT-H CN03 SMW250-04V_RED L-IN LIVE D11 1N4007 RY06 G5T-1A-12VDC RY07 G5T-1A-12VDC RY08 G5T-1A-12VDC RY09 G5T-1A-12VDC VENT-LOW TR10 KRC246M TR11 KRC246M CN04 SMW250-05V(RED) LIVE 1 3 5 7 9 7 5 3 D10 1N4148M 1N4148M BUZZER RY-V_DOOR L-IN 1 RY10 G5T-1A-12VDC VENT-MID RY11 G5T-1A-12VDC D11 CN6 SMW250-03V_WHT SOURCE VENT-HIGH BZ01 CBE2220BA NEUTRAL CN01 SMW250-07AV_RED CN02 SMW250-09AV_RED GSPN (Global Service Partner Network) Contry Web Site North America service.samsungportal.com Latin America latin.samsungportal.com CIS cis.samsungportal.com Europe europe.samsungportal.com China china.samsungportal.com Asia asia.samsungportal.com Mideast & Africa mea.samsungportal.com ©Samsung Electronics Co., Ltd. March. 2010 Printed in Korea Code No. : DE68-05792A