Download Electrolux TM-75 Operating instructions

Transcript

OPERATING

INSTRUCTIONS

AND PARTSLIST

INSTRUCTIONS

D'UTILISATION

ET LISTEDE PIECES

INSTRUCCIONES

DE OPERACION

Y LISTADE PIEZAS

v

-

TM-75Tile Saw

FEL}<EFI.

174OOWest 119th Street

Olathe, Kansas 66061

CustomerSeruice......800-365-4003

Corp.Office

913-928-1000

Cust.ServiceFAX......800-825-0028

Corp.OfficeFAX .......91

3-438-7951

I

l+cIIAMANT

ElclaFrr

-f

I

v

0AF041

07

O C o p y r i g hA

t , u g u s t2 0 , 2 0 0 1 ,D i a m a nB

t o a r t ,I n c .

EVERY MACHINE IS THOROUGHLY TESTED BEFORE LEAVING THE FACTORY. EACH MACHINE IS

S UP P LI E DW IT H A C OP Y OF T H IS M A N U A L. OP E R A TOR SOF TH IS E QU IP ME N TMU S T R EAD AND BE

FAMILIARWITH THE SAFETY WARNINGS. FAILURE TO OBEY WARNINGS MAY RESULT IN INJURY OR

STRICTLYTO ENSURELONG SERVICEIN NORMALOPERATION.

DEATH. FOLLOWINSTRUCTIONS

CONTENTS

S y m b oD

l efinitions............

and Locations

DecalDescriptions

ReferencF

e igures

SafetyWarnings- DO's& DO NOT's.

Instructions

1. Features

2. Benefits

3 . M a c h i n eS e t - U p

4 . O p e r a t i n gP r o c e d u r e s . . . . . . . . . .

5 . A l i g n m e nPt r o c e d u r e s . .

6. Maintenance.........

7 . T r o u b l eS h o o t i n G

g uide.

8. Repairs

9 . S p a r eP a r t s

Diagramsand SparePafts

3-4

................5

. . . . . . . . . . . . .-.76

-9

...........8

............10

..............10

11- 12

12- 13

. . . . .1 3

............14

.....15

....15

...........15

16 - 17

AWARNING

HAZARD

HEARING

DURINGNORMALUSE OF THIS MACHINE,OPERATORMAY BE EXPOSEDTO A

NOISELEVELEQUALTO OR SUPERIORTO 85 dB (A)

AATTENZIONEIIIA

RISCHIO DE LESIONE ALL'APPARATO UDITIVO

NELLE NORMALI CONDIZIONI DI UTILIZZO,

MACCHINA

PUO

COMPORTARE PER L'OPERATORE ADDETTO UN ESPOSZIONE

QUESTA

ACUSTICA DI LIVELLO PARI O SUPERIOREA

8s dB (A)

A

AArENcroN

RIESGODE DANOAUDITIVO

E N C O N D I C I O N EN

S O R M A L E SD E U T I L I Z A C I O NE,L O P E R A D O RD E E S T AM A Q U I N AP U E D E

A 85 dB (A)

E S T A RE X P U E S T OA U N N T V E LD E R U T D OI G U A LO S U P E R I O R

SymbolsDefinitions

Symboles

DefinicionDe Simbolos

A

o

. Pleasereadthe instructions

for use priorto operatingthe machinefor the firsttime.

' Avanttoute mise en service,lireattentivement

la noticeet se familiariseravec la machine.

. Antesde la puestaen marcha,lea detenidamente

y familiaricese

las instrucciones

con la m6quina.

. Mandatory

. Obligatoire

. Obligatorio

o

. lndication

. Indicazione

e Indicacion

o

. Prohibition

. Interdiction

. Prohibicion

A

@

@

@

@

. WarningTriangle

. Triangled'advertissement

. TridngwuloDe Advertencia

. Wear Eye Protection

. Portobligatoiredes lunettesde protection

' Usar Gafas De Protecci6n

. Wear BreathingProtection

. Portobligatoired'un masquerespiratoire

protecteur

. Usar MdscaraDe Protecci6n

. The Use Of Ear Protectionls Mandatory

. Portobligatoireda casqueantibruit

. Es ObligatorioEl Uso De ProteccionAuditiva

. Wear SafetyShoes

. Portobligatoiredes chaussuresde s6curite

. UsarZapatosDe Seguridad

@

A

@

. Wear Appropriate

Clothing

. Portobligatoirede la tenueappropri6e

. Usar RopaAdecuada

. MachineryHazard,Keep HandsAnd Feet Clear

. Danger!Restera distancede la machine

. MdquinaPeligrosa- MantengaManosY PiesAlejadosDe La Mdquina

. No Non-Working

PersonnelIn Area

. Zone interditeau personnelnon-ouvrier

o ProhibidoParaPersonas

AjenasA La Obra

A

. Ke€pWork Area CleanAlVell

Lit, RemoveAll SafetyHazards

. La zone de travaildoittoujours6tre propre,bien eclaireeet ne pr6senteraucun risque

o MantengaLimpioEl SitioDe Trabajo/Bienlluminado,ElimineTodos Los RiesgosDe Seguridad

A

. DangerouslyHigh NoiseLevel

. Niveaude bruitdangereux

. NivelDe RuidoElevadamente

Peligroso

@

. RepairsAre To Be Done By An AuthorizedDealerOnly

. Les r6parationsne peuvent6tre ex6cut6esque par un distributeur

agr66

. Las ReparacionesDebenSer EfectuadasUnicamentePor Un Distribuidor

Autorizado

A

. AlwaysKeepthe BladeGuardsln Place

. Toujoursv6rifierque les protectionsde disquesont bien en place

. Mantengasiemprelas protecciones

de la hoja en su sitio

f\

. DiamondBlade

. Disquediamant6

. SierraDiamantada

A

o ElectricalShock Hazard

. Risquede secousses6lectriques

. Peligrode sacudidael6ctrica

t-t

DECAL DESCRIPTIONS

& LOCATION

AUTOCOLLANTS- DESCRIPTIONS

ET EMPLACEMENTS

DESCRIPTION

DE CALCAMONIASY UBICACIONES

P/N 185262

Location:Tray - Front

P/N 169866

Location:Rip Guide

P/N 185263

Location:MotorCover- Front

P/N 185264

Location:BladeGuard- Side

O U T L E TI S N O T F O R

G E N E R A LP U R P O S E

USE.

U S E O N L YF O RV E N D O R

A P P R O V E DW A T E RP U M P .

P/N 189247

Location:MotorCover- Rear

v

Read manual.

Lea el manml.

V e u r l l e zl i r e l e m a n u e . .

P/N 187043

Location:MotorCover- Top

FIGURES

REFERENCE

FrcuRES

DEnErEnENcE

F I G U R AD E R E F E R E N C I A

*4

tl

t

$tr';

F i g3

F i g5

F i g6

Fig 7

F i g8

F i g9

F i g1 0

F i g1 1

F i g4

%,'\

*.

Fig 12

REFERENCE

FIGURES

FrcuRES

DEnErEnENcE

FIGURADE REFERENCIA

F i g1 3

F i g1 a

F i g1 5

F i g1 6

F i g1 7

F i g1 8

F i g1 9

Fig 22

187076 90' AdjustableProtractor

F i g2 1

Fig 23

187077 Dual45'Angle Guide

Fig 24

187078 BullNoseMiterGuide

SAFETYFIRST!

WARNINGS

DO'sAND DO NOT's

TOCOMPLYWITHTHESEWARNINGSAND OPERATING

WARNING: FAILURE

INSTRUCTIONS

COULDRESULTIN DEATHOR SERIOUSBODILYINJURY.

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

DO

andcontrols.

all warnings,instructions,

readthisentireoperato/smanualbetoreoperatingthis machine.Understand

keepall guardsin placeand in goodcondition.

protection.

wearsafetyapprovedhearing,eye,headand respiratory

on the machine.

readand understand

all warningsand instructions

containedin this manual.

readand understand

the symboldefinitions

keepall partsof yourbodyawaylrom the blade.

knowhowto stopthe machinequicklyin caseof emergency.

turnthe "ON/OFF"switchto the "OFF"positionpriorto connectingtho machineto the powersource.

inspectthe blade,flangesandshattsfor damageor dirt beforeinstallingthe blade.

alwayskeepchildrenawaytromthis machine.

use onlybladesmarkedwitha maximumoperatingspeedgreaterthanthe bladeshaftspeed.

whenwetsawing.

alwaysusea groundfaull circuilinlerrupter

thataccompany

any bladeusedwiththismachine.

readall safetymaterialsand instructions

inspecteachbladecarefullybetoreusingit. lt thereare any signs ol damageor unusualwear,DO NOT USE THE

BLADE,

mountthe bladesolidlyandtirmly. Wrenchtightenthe arbornut.

il you do not knowil blade is

use lhe correctbladefor the type ot workbeingdone. Checkwith blademanufacturer

correcl.

operatethis machineonlyin wellventilaledareas.

establisha trainingprogramlor all operatorsot this machine.

people.Neverallowanyoneto standin lront of or behindthe bladewhilethe motor

clearthe workareaoI unnecessary

is running.

makesurethe bladeis notcontactinganylhingbetorestartingthe motor.

usecautionwhenlittingandlransporlingthismachine.

alwaystie downthe machinewhentransporting.

whensettingup the machine.

usecautionandfollowinstructions

haveall serviceperformedby competentservicepersonnel.

makesureelectricpoweredmachinesare pluggedintoa properlygroundedcircuii.

rnakesurepowercordsare the propersizeand in goodcondition.

maintaina securegripon the materialbeingcut.

verifythe bladearborholematchesthe machinespindlebetoremountingthe blade.

cleanthe machineattereachday'suse.

followall electricalcodesin yourarea.

considerworkareaenvironment.Don'texposepowertoolsto rain. Don'tuse powertoolsin wet locations.

use cautionto guard againslelectricshock. Preventbody contactwith groundedsurlaces(i.e., pipes, radiators,

ranges,relrigerators).

use correctvoltageand properextensioncords. Nevercarrytool by cord or yank it to disconnectit trom receptacle.

Keepcordawayfromheat,oil and sharpedges.

alwayscarrythe machinewiththe molorstoppedand powercord disconnected.

disconnect

toolsfrompowersourcewhennot in use,beforeservicingandwhenchangingaccessories.

for changingaccessories.Inspect

carefullymaintainand cleanlor betterand saferperformance.Followinstructions

and,if damaged,haverepairedby authorizedservicefacility.

tool cordsperiodically

onlycut in a straightline.

alwaysgivea copyol this manualto the equipmentuser. lf you needextracopies,callTOLLFREE 1-800-365-4003.

SAFETY FIRST!

WARNINGS

DO'SAND DO NOTS

WARNING: FAILURE

To COMPLYWITH THESEWARNINGSAND OPERATING

INSTRUCTIONS

COULDRESULTIN DEATHOR SERIOUSBODILYINJURY.

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

operatethis machine unless you have read and understoodthis operator'smanual.

operatethis machine withoutthe blade guard, or other protectiveguards in place.

stand behind or in front of the blade path while the motor is running.

leave this machine unattendedwhile the motor is running.

work on this machinewhile the motor is running.

operatethis machine when you are tired or fatigued.

use a wet blade without adequatewater supply to the blade.

exceed maximum blade speed shown for each blade size. Excessivespeed could result in blade breakage.

operatethe machine if you are uncertainof how to run the machine.

use damaged equipmentor blades.

touch or try to stop a moving blade with your hand.

cock, jam, wedge or twist the blade in a cut.

use a blade that has been droppedor damaged.

use carbidetipped blades.

use abrasiveblades.

touch a dry cutting diamond blade immediatelyafter use. These blades require several minutes to cool

after each cut.

use damaged or worn blade flanges.

allow other personsto be near the machinewhen startingor when the machine is in operation.

operatethis machine in an enclosedarea unless it is properlyvented.

operate this machine in the vicinity of anything that is flammable. Sparks could cause a fire or an

ex plos i o n .

allow blade exposurefrom the guard to be more than 180 degrees.

operatethis machine with the blade guard removed.

operatethis machine unless you are specificallytrainedto do so.

use a blade that has been over heated (Core has a bluish color).

jam materialinto the blade.

gr ind o n th e s i d e o f th e b l a d e .

lay power cords in or near the water.

replacethe motor with any motor that does not have a specialgroundingconnection.

s t and o r l e a n o n ma c h i n e .

start cuttingwith a saw until you have a clear work area and secure footing.

oper a teth i s m a c h i n ew h i l e u s i n gd rugs or al cohol .

This saw was designedfor certain applicationsonly. DO NOTmodity this saw or use lor any application

other than for which it was designed.lf you have any questions relativeto its application,DO NOTuse the

saw until you havewritten DiamantBoart, Inc. and we have advisedyou.

-

V

-

Diamant Boart, Inc.

17400West 119th Street

Olathe, Kansas 66061

1-800-365-4003

rruDrcAnotl

)ATORY

LJ:il5?IJH,8il

A

*ARNTNG

S

PRoHrBrroN

These signs will give

advise for vour

Before leaving our factory every machine

is thoroughly tested.

Follow our instructions strictly and your machine

will give you long service in normal operating

conditions.

1.

Features

Use:

Sawing of tile materials.

Tools: Diamondblades-(For information contact your FELKER@ supplie)

Bfade Capacity:A 8" (200 mm) - bore 5/8"

( 1 5 . 9m m ) .

(CCW).

Blade Rotation: Counter-Clockwise

Cutting Thickness (material): 1 518'(41.2mm)

Cutting Diagonal@ 10" (254mm)

Gutting Length: 14" (356mm)

Blade Cooling: Waterpump

Horsepower:

Voltage:

314

115 Volts,60 Hertz,1-Phase

4.2 amps

Amperage:

Blade Shaft RPM: (3300)

Weight lbs. (kg.): 36.5 (16.5)

Dimensions (L x W x H): 26" x16.5" x 14'

(660x 419 x 356mm)

Pan Holding Capacity: 9.3 quarts(8 liters)

Before starting up the machine, make sure

you read this entire manual and are familiar

with the operation of this machine.

The working area must be completely clear,

well lit and all safety hazards removed.

The operator must

wear protective

clothing appropriate

to the work he is

doing.

@@@

@e@

@

A

l0

Any persons not involved in the work

should leave the area.

Use only blades marked with a maximum

speed greater than the blade shaft

speed.

2.

Benefits

Your FELKER@tile saw is a ruggedlyconstructedunit

engineeredto give long, satisfactoryperformance.

Simple,daily maintenanceand care will add to the life

of your tile saw.

and productivity

.

and

Lightweightfor easy maneuverability

maintenance.

.

Has a durablepolymercuttingtable- able to

handlealmostany cuttingjob due to its reinforced

construction.

Cuttingtabledesignedto drainwater quicklyback

intothe watertrayfor efficientrecyclingof water.

Cast blade guard with hinge to allow easy

removalof cuttingblade.

Cutting table runs on nylon wheels for smooth

and accuratecuts and easy maintenance.

Water tray of durable polymer constructionto

resistrust and to drainwater and sedimentmuch

faster.

3.

MachineSet-Up

WATERPUMPSAFETYGUIDELINESAND

MAINTENANCE.

Follow all of the assembly and

i n s ta l l a ti o ni n s tru c ti o n sc o mpl etel y

before connecting this saw to a power

source.

UNPACKING

( F i g ' s1., 2 & 3 )

Carefully

openthe containerand removeall the saw

components

and packingmaterials.Be certainyou

havecheckedeach item with the checklistbelow

beforediscarding

the containeror the packing

materials.The contentsare as follows:

Always plug the saw power cord into a

GFCI outlet when using. lf a GFCI type

outlet is not available, use a plug-in type

GFCI plugged into a properly grounded

outlet. Do not use any temporary plug

adapters.

.

o

1. Operator'sManual

2. DurableWater Tray

3. Saw Framew/Cart

4. PowerHead

5. BladeGuard

6. CuttingGuides(4)

7. Water Pumpw/ Hose

8. Blade- B" [200mm]

9. Misc.Tools & Hardware

'

.

.

The waterpump is equippedwith a ground

electricalplug,to reducethe risk of possible

shock. Be sureto connectto a properlygrounded

type receptacle.

Neverpickthe waterpump up out of the water

when it is pluggedin.

DO NOT EVER use the water pump to pump

anythingbut water.

Neverseruicethe pumpwhen it is stillpluggedin.

Neverlet the pump operatedry. lt is self-cooled

by pumpingwater. Dry use willcausethe pumpto

fail.

Maintainregularlyand cleanout debrisfrom intake

screen.

Checkthe powercord for nicksor fraysand never

try to alterthe powercord in any way.

NOTE:lF ANYOFTHEPARTSAREMISSING

OR

DAMAGED

PLEASECONTACT

YOURFELKER

CUSTOMER

SERVICE

FORINSTRUCTIONS.

CALL1-800-365-4003

.

ASSEMBLY

. AssemblyTools required:

- fourwrenchessupplied(2 allentype)

.

Placesaw frame with cart intowatertray. (Fig4)

.

Feedthe powerheadassemblyonto the arm of the

saw framethroughthe openingin the backof the

powerhead.(Fig5)

.

Allignthe threeholesin the powerheadwiththe

threethreadedholesin the saw f ramearm and

installthe M5 x 1Ommcapscrewsand lock

washers.(Fig6)

.

LooselyInstallthe MGx 40mm capscrewand

washersat the rearof the saw frame. lnsertjust

enoughbrassspacersto fill any gap betweenthe

saw f rameand the powerhead,

and thenfully

tightenthe capscrew.Not usingspacerscan

adverselyaffectallignment.(Fig7)

o lnstallbladeguardontothe powerheadwith

s u p p l i e dk n o b . ( F i g8 )

FITTINGOR CHANGINGTHE BLADE

WATER PUMP INSTALLATION

.

Removethe waterpumpfrom its packagingand

checkit to be sure it is not crackedor damagedin

any way.

a

Routethe 8mm plastictubingas shown. (Figg)

o

Attachthe endsof the 8mm plastictubingto the

b l a d eg u a r da n d t o t h e w a t e rp u m p . ( F i g1 0 & 11 )

Placethe waterpump in the rearof the watertray

and set in placeusingthe mountingbracketas

s h o w n .( F i g1 2 )

Keepthe powercord out of the waterand pluginto

the motorpigtailthree-pronged

outlet. (Fig 16)

.

/\

ANDREMOVAL

r " 1 BLADEINSTALLATION

\r-Y

(Fig13_15)

o

o

o

Turn motorswitchoff.

Disconnectpowercord.

Carefullyraisethe bladeguardto its highest

positionand tightenthe adjustmentknob on the

rear support,so as to put firmlyin place.

Then removethe bladeshaft nut and the outer

f lange. (Fig13) Use the Smm allenwrenchto hold

the shaftand the box end wrenchto turn the nut

(Fig 15)

counter-clockwise.

Placebladeontothe shaft,pushingit up against

the innerflange. Makesurethe bladeis mounted

with the directionalarrowpointingcounterclockwise.(Fig1 )

Next replacethe outerflangeand shaft-nutand

tightendown. (Fig14, 15) Do not over-tighten.

Next lowerthe bladeguardback into positionand

tightenthe knob.

Pay attention to the direction of rotation

shown by the arrow on one side of the

Blade (rotation in the opposite direction

to the tightening of the nut). Blade should

rotate counter-clockwise when facing the

bladeshaftnut.

l1

Make sure that the supporting surfaces of

the Blade, the Flanges and the arbor are

clean.

ELECTRICALCONNECTIONS

.

Use a groundedcircuit.

.

Use a GFCIwhenwet sawing.

.

Usethe correctplugand outlet.

.

Check that the main voltageis identicalto that of

the machine.

.

Extensioncord: Use the correct size extension

cord. Be certainthat the cord is in good seruice

condition.

.

lf, on position1 (on),motordoes not run:

. check the electric power on the site (fuses,

cutouts,sockets,etc);

. check the extension being used (faulty

connection,wire break)

. check powercable,it's connection;

. checkthe operationof the on-offswitch.

Before any examination,

machines power cord.

4.

o

.

.

o

the

inq Procedures

.

.

.

unplug

Always be very careful.

Find a comfortable, well-balanced

position.

Always keep protective casing in

place while working.

Placethe machineon a dry sudace or the optional

stand.

Fill the holdingtank with clean water [holds 9.3

quarts(8 liters).

Plug the machine into the power outlet and turn

the motorswitchto the on position.

CUTTINGTABLE

THE CUTTINGTABLEIS MARKEDIN INCHESAND

M I L L I M E T E RTSO M A K EY O U RD I M E N S I O N A L

CUTSACCURATE.

GH E 9 0 D E G R E ER I P

S T E P SF O R P O S I T I O N I N T

.

guide

onto the tablebackstopfrom

Slidethe rip

one end. (Fig 17)

.

Set the rip guideby positioningit at the desired

pointon the front end of the cuttingtablef ront lip

and flippingdownthe thumblbck untilthe rip guide

is firmlylockedin place.(Fig 18) Notethat the

thumb lock will hold accessoryfirmlyin place

withoutusingthe full travelof the thumb lock.

t2

.

.

.

movementis designedfor any long

Additional

term wearingthat may be experienced.

Unnecessary

clampingwiththe thumblockcould

raisethe end of the accessoryup off the table

surface.

The rip guidecan be usedfor straight90" cuts

from boththe left and rightsides.

for the desiredcut,

Afterthe rip guideis positioned

placematerialflushagainstthe rip guideand the

measurement

rail.

Now you are readyto make your cut.

CUTTINGDEPTH

The 8" (2O0mm)bladecapacityyieldsa cuttingdepth

of 1 5/8"(41,2mm).

After completingany work, switch off the

machine.There is no point in leavingthe

motorrunningand the bladeturning.

QUICKTIPS FOR WATER PUMPOPERATION

lf you are havingtroublegettingwaterflow properly

throughthe waterpump,try this:

.

First,checkto see thatthe pump is fully

submergedin water.Fillthe watertray with clean

waterto completelycoverthe pump.

.

Second,checkto see if all tubingis connectedto

the pump correctlyand its feeds are properly

attached.

Sometimesthe tubingis not pushedfar enoughintoits

attachment,allowingwaterto escapeat the

attachmentpoint.Simplypushtubingfirmlyintofitting

untilit stopsand willnot pullbackout.

.

Third,if there is a problemgettingwaterto flow

out properly,checkthe watercontrolvalvesetting

on the front of the pump. lt can be adjustedf rom

"Min"to "Max"(Fig 19)

Oftentimesthe watercontrolvalveis set to "Min"and

is not capableof pumpingenoughwaterwhen first

turnedon. This is easilycorrectedby turningthe valve

to "Max"and then adjustingto the desiredwaterflow.

.

Fourth,if problemsstillpersist,there is also a

chancethatdebrisor sedimentis cloggingthe

waterpumpintakescreen,the pump impelleror

insidethe tubing.

- Clearingtheseareaswith f resh watercan

alleviatethe clogging.The buildup sediment

needsto be cleanedfrom the bottomof the

Water Tray and the intakescreencleaned.Fill

tray withf reshwater.

- With pump intakeremoved,look insidethe

area impellerand checkfor debris.Cleanas

neededwith freshwater.(Fig 20)

lf the tubingis clogged,removeendsfrom the

waterpumpand Bladeguardfitting.Flush

with freshwater untilall debrisis removedand

r e c o n n e ct u

t b i n g (. F i g1 0 & 1 1 )

WATER

(Fig's10,11)

TUBING

REMOVAL

Plastictubingconnectsthe waterpump to the blade

guard.The fittingsusedto connectthistubingsealand

gripthe outsidediameterof the tubing.Specialinternal

lockingfingersattachedto the flangedcolletholdthe

tubingfast.To cleanthe watertubingrequiresthe

tubingto be removedfrom the fittings.To releasethe

tubingform the fitting,fullydepressthe colletbefore

pullingthe tube out of the fitting.When you press

down on the colletyou are openingthe lockingfingers

and freeingthe tubingto be easilyremoved.

WATER TRAY REMOVALAND INSTALLATION

THE REMOVALAND INSTALLATION

OF THE

WATER TRAY IS EASY.

.

First turn off the saw and unplugthe power cord.

Do the same for the waterpump.

. Then removewaterpump from tray.

. Then take frame and motor assemblyout of the

water tray.

.

Take tray and drainwaterand contents(sediment)

. To installsimplyreversethis process.

NOTE: THERE ARE NO ADJUSTMENTS

TO WATER

TRAY

5.

Aliqnment Procedures

the fasteners.lt is recommendedthat the

ParallelAlignmentin step2 be checkedto

insurethe bestqualitycuts.

2. Checkthe ParallelAlignment

.

The conveyorcart shouldtravelparallelto the

planeof the blade.

.

Placea squarerule againstthe backstop,

lightlyin contactwiththe blade. The blade

surfaceshouldbe parallelto the square;e.9.,

no gap betweenthe bladeand the squareat

eitherthe frontor backedgeof the blade.

Next,holdingthe squarefirmlytraversethe cart

fore and aft. The bladeshouldremainparallel

to the square,stayingslightlyin contactwith it

throughoutits fulltravel. lf the bladedoes not

stay in contactwith the square,the Parallel

Alignmentmust be performed.

ParallelAlignment (See Parts List, Diagram 1 &

F i g2 1 )

.

Loosenthe fronttwo RollerGuidefasteners

(ltem6 & 8). Movethe RollerGuideBar (item

3) and Cart by the AdjustmentClamp(itema)

untilthe squareis flushwiththe blade.Tighten

the fastenersand recheckthe alignmentagain.

The cart shouldnow travelparallelto the blade

and the bladeshouldbe centeredin the slot.

Your TM-75tile saw is factoryassembledand

alignedpriorto shipmentto ensureaccuratecuts

when your saw is delivered.However,since FELKER

@cannotcontrolroughhandlingduringshipping,it is

suggestedthat the alignmentbe checked. lf the saw

is found in need of adjustment,referto the appropriate

section(s)below.

There are two basic TM-75alignmentchecks. Any

adjustmentsmade mustfollowthese proceduresto

ensurethat the unitfunctionsfreely.

Adjustmenttools required:Carpenter'sSquareand

the smallopen-endwrenchprovidedwith your new

saw. (Fig 3)

1. Check the Blade in Slot Alignment

.

The bladeshouldbe centeredin the conveyor

cart slot.

.

Set-upyour saw as describedabove,move the

conveyorcaft back and forthform the f rontto

the rear of the pan. lf the bladecontactseither

side of the slot,the Cart Slot Location

Adjustmentmustbe performed.

Cart Slot Location Adjustment (See Parts List,

Diagram1)

.

Movethe ConveyorCart so the Bladeis

approximately

midwaybetweenthe front and

backof Cart.Loosenthe three(3) RollerGuide

fasteners(ltems6 & 8) withthe supplied

wrench. Movethe AdjustmentClamp(item4),

RollerGuideBar (item3) and Carttogether

untilthe bladeis centeredin the slot.Tighten

l3

Before performing any maintenance'

ALWAYd Place the machine on a level

surface with the motor OFF and

disconnect the electrical current' Let

the machinecool down!!

FOR LONGESTLIFEAND BESTPERFORMANCE

.

Alwayscleanthe saw aftereveryuse'

. wipe all of the exteriorsediment or dirt off the

the

motor. Never spray water directly onto

motor!

. Wipe all exterior surfaces and keep the cutting

tablecleanand free of all debris'

. Wipe the rollerguidebar on the f rame'

r Always check lhe blade for cracks or signs of

damage.

OPTIONALACCESSORIES

FoldingStand:

- #187073Standwith wheels

Store in a safe Place, out of reach of

children.

Maintain atl tools carefullY'

WJ

'"-J

t4

7.

The manufacturer accepts no

responsibility caused by unsuitable use

or modifications. At the workstation, the

sound pressure level may exceed 85 dB

(A). ln this case hearing protection must

be worn.

T r o u b l eS h o o t i n gG u i d e

SAW WON'T START,SAW IS TOO SLOW TO

S T A R T ,S A W M O T O RM A K E SH U M M I N GN O I S E

.

Makesure plugis in liveelectrical

circuit.

.

Voltagefrom sourcemay be too low.

SAW SHUTSOFF ABRUPTLY

.

Poweris interrupted,

checkpowersourceand

restartthe saw.

r Voltagefrom sourcemay be too low. Checkfor

low voltage.

WATER PUMPSYSTEMWON'T STARTOR STOPS

ABRUPTLY

.

Checkto see that pump is pluggedin and is

connectedto plastictubing.

.

Checkto see if pumpis completelysubmerged.

.

Checkto see if the waterpump is cleanand f ree

o f a n yc h i p s ,d e b r i sc, l o g g i n ge, t c .

SAW WON'T CUT STRAIGHT

.

Checkto see if saw f rameor rollingguidebar is

bent.

.

Checkto see if the supportfor the cuttingtableis

bent.

.

Checkfor possibledefectiveblade.

.

Materialsmay havebeenpushedor forced

throughthe cut. Let bladepullmaterialfor a clean

cut.

.

Checkcarttrackingadjustment.

S A W B L A D ED O E S N ' TC U T W E L L

.

Bladeneedsto be dressed.

.

Blademay be mountedon saw backwards.

.

Blademay be wornor damaged.

.

Bladeslifemay be usedup (oldblade)

8.

Repairs

Entrust all repairs to your authorized

dealeronly.

We carry out all repairsin the shoftestpossibletime

and at the most economicalprices. (See front page

for our'addressand phone numbers) Contactyour

authorizedFELKER@dealerconcerningmaintenance

and repairs.

9.

SpareParts

For quick supplyof spare pafis and to avoid any lost

time, it is essential to quote the data on the

platefixedto the side of the motorand

manufacturer's

the part number(s)and description

to be replacedwith

everyorder.

The instructions for use and spare parts found in this

document are for informationonly and are not binding.

As part of our product quality improvementpolicy, we

reserue the right to make any and all technical

modifications without prior notice.

The manufacturer accepts no responsibility caused by unsuitabte use or modifications.

l5

\,

\1

l6

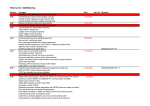

DIAGRAM1 ..- TM.75 PARTS LIST

Loc

1

2

3

4

5

6

7

8

9

10

11

12

13

't4

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

P/N

185108 Frame Assy (incl. 2-8)

185106 Frame

185107 Bar. RollerGuide

18 5 15 9 Clamp,RollerBar Adj.

17301I Lockwasher,ExternalTooth, M8

167478 Capscrew,Hex Hd M8 x 1.25x 25mm

139746 Washer, Flat M6

185255 Screw,Mach Pan Hd M6 x 1.0 x 1Omm

1 8 5 1 1 1Water Tray

1 8 5 1 3 0 &"y, Cutting Table (incl. 11-24)

185136 CuttingTable

185125 Bracket.U Roller

185126 Stud,UpperU Roller

185127 Stud, LowerU Roller

185137 Roller,U ShapedNylon

139745 Locknut,FiberM6 x 1.0

't39737 Capscrew,Hex Hd M8 x '1.25

x 20mm

185129 Bracket,SingleRoller

172027 N u t .H e xH d M 8 x 1 . 2 5

185138 Roller,RightSide Nylon

18 5 13 1 Stud,SingleRoller

17301I Lockwasher,ExternalTooth, M8

173059 Washer,Flat M8

139738 Locknut,FiberM8 x 1.25

185245 tusy, Power Head w/ Guard (incl. 26-53)

185235 Bracket.Motor Base Wldmnt

18s260 Plate,Spacer

185221 Motor k"y, 3l4HP 4.2A115V (incl. 29-35)

185216 SpacerSleeve

185215 Seal, Shaft

18 5 2 1I Flange,Inner

18 5 2 1I Outer Flange

185220 Nut,ArborM12

185248 Cover,Fan

185274 Slinger,Shaft

185239 Cover.Motor- Machined

185238 Bushing,StrainRelief

185214 Capacitor

185246 Cord, 16/3 SJTW w/ Male Plug

185247 Cord, 16/3 SJTW w/ FemalePlug

020762 Washer.Flat .250 SAE

163689 Lockwasher,Split M6

185252 Capscrew,Soc Bt Hd M6 x 1.0 x 16mm SS

185253 Switch,Toggle3/4hp

090552 Plate,Switch

032503 S h i m ,B r a s s . 0 2 0

173059 Washer,Flat M8

185258 Capscrew,Soc Bt Hd M6 x 1.0 x 40mm SS

020782 Lockwasher,

Split#10

185259 Capscrew,Soc Bt Hd M5 x 0.8 x 16mm SS

17201',| Nut, Hex Hd M5 x 0.80

174432 Capscrew,Soc Hd M5 x 0.8 x 1Omm

Loc

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

P/N

185243

185241

18 5 15 0

't85257

Descri

kty, Blade Guard (incl. 54-61)

Guard.Blade8in - Machined

Adaptor-YWaterTube

Tube.Water6x4x280mm

185140 Knob,M8 x 45

18 5 14 1 Screw,M4 x 20mm

185244 Flap,Splash

020762 Washer.Flat.250SAE

185251 Capscrew,Soc Bt Hd M6 x 1.0 x 1OmmSS

185237 Blade,Sin (200mm)Cont Rim

185160 Bracket,Pump Mounting

1 8 5 1 3 2 Assy, Water Pump (incl. 65-66)

185146 Water Pump 115V/60H2

185158 Adaptor,90'Tube - Water Pump

185201 T u b e . W a t e r B x 6 x 6 0 0 m m

169887 Guide,Rip - Plain

-

lls6e Not Shown -

P/N

169866

185262

185263

185264

187043

189247

Decal,FelkerRip Guide

Decal,TM-75 Pan

Decal.TM-75 MotorCover

Decal,FelkerB" [200mm]Guard

Decal,Warning

Decal,Water Pump Outlet

192001

185233

18 5 1 4 5

185272

Wrench,Allen4mm

Wrench.Allen5mm

W r e n c h ,O p e n[ 1 7x 1 3 ]

Wrench,Bo></Open

[18 x 10]

187076 90' AdjustableProtractor

187077 D u a l 4 5 ' A n g l eG u i d e

187078 Bull Nose MiterGuide

2

'l

'l

1

4

5

4

1

1

5

1

1

7

4

4

3

t7

ffi ffiHmcfrmlus(

Electrolux

Construction

Products

INSTRUCTION

SHEET

P/N 542195411 Mist Flap Installation

Installthe RubberMist Flap

(P/N 542195411) as shown in the

pictureon the left.

Installation:

1) Use the hardwarethat

mountsthe headto the

frame,and

2) the hardwarethat mounts

the motorcoverto the motor

base. The cover hardware

must be removed& reinstalledwith the Mist Flap

underthe FlatWasher.

3) Tightenthe hardware

securelywith the M4 hex

wrenchthat is provided.

Save this sheetwith the operation

manualfor futurereferenceand for

orderingof seruiceparts.

- P/N 5422010-65INSTRUCTION

Rev.0 - 05-17-2005

SHEET

Felker's New Equipment Warranty

Except as noted below. Felker warrants that its new equipment will be free from manufacturing defectsfor a

period of two (2) yearsfrom date of purchase b1'the original consumerpurchaser.

-

The abovewarrantyis subjectto the following new equipmentexceptions:

l. The warrantytime period for the following new equipmentis limited as follows:

T M-7 5 rM,F T S-1 5 0 F

, R S -3 0,FR S -38,FR S -51--- One (l ) year

FIS-7OrM,Little Jack,JackJuniorand SlammerJacktools--- Six (6) months

FIS-5OrM--- Ninety (90) days

2. To the extentthe following componentsare part of any the new equipment,Felker's warrantyon the

componentpartsis limited to the manufacturer'swarrantyperiod set out below:

Manufacturer.....WarrantyPeriod

GAS and DIESEL ENGINES

Manufacturer.....WarrantyPeriod

ELECTRIC MOTORS

Manufacturer.....WarrantyPeriod

TRANSMISSIONS

B r ig g s& S tra tto n .

.Z y e a rs

K ole rGa s ...........

....2y e a rs

Rob i nGa s ................2

y rs ./2 ,0 0h0rs .

HondaGas...........

.2 years

W is c i n s iG

n a s ..........

I y e a rl 2 ,0 0h0rs .

H a t zD i e s e l . . . . . . . . . . . . . . . . 1 y e a r

v

B al dor.......

I year E aton........

........ . .year

. 3 s*

Leeson......

yrs./1, 000

I year S unstrand................3

hr s. *

(* fromdateof m anuf act ur e)

B osch........

.........6

months

Milwaukee

..........Lifetime

HYDRAULIC PUMPS

B l ack& D ecker..

....1year Fenner-S tone............. . I year

D M1 0 0 . . . . .

. . . . . . . .m

. 6o n t h s J o h nS .B a r n eCs o . . . . . . . . . . . . . . y. .e. .a. r. 1

AIR MOTORS and VAC. PUMPS

WATER PUMPS

Gast..........

I year Jasbsco.....

I year

Beckett......

I year

3. Felker'sobligationunderthis warrantyis expresslylimited to the replacementor repair at Felker,Olathe,

KS 66061,or at a servicefacility designated

by Felker,of suchpartsas inspectionshalldiscloseto have been

defective.This warrantydoes not cover labor, exceptfor gas poweredQuickie Super sawsand does not cover

maintenance

items suchas belts,air filters,bearingsand wheels.Purchaserwill be responsibilefor payingfor

shippingcoststo and from the locationwherethe equipmentis to be repairedor replaced.Motors and engines

are to be servicedby the nearestfactory authorizedsericecenter.Theseservicecentersare designatedby the

manufacturerof the engine/motor.Under no circumstances will Felker be responsible for incidental or

consequentialdamages.

1. Felker'swarrantydoes not apply to defectscausedby damage,abuse,modifications,low voltage,actsof

God, unreasonbleuse, faulty repairs made by others or defects caused by failure to plrovide reasonable

maintenance.

All warrantiesare void if the equipmentor any of its componentsare alteredor modified by the

purchaser,

or of the productis usedin a manneror with a bladenot recommended

by the manufacturer.

-s. The forgoingexpresswarrantiesare in lieu of all otherwarranties.FELKER EXPRESSLY DISCLAIMS

ALL

OTHER WARRANTIES, INCLUDING, WITHOUT

LIMITATION,

THE IMPLIED

\\"{RRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Plc'ascrecord the Date of Purchaseand the Serial Number of your saw in the spacebelow. (The serial number

is locatedon the sideof the motor.)When orderingserviceitems,pleasehavethis informationavailable.

S er ia lN u m b e r:

Date of Purchase:

lvlodcl Number:

Where Purchased:

For any missing,damagedor serviceitems needed,DO NOT return to original storeof purchase,

insteadcontact:

FELKER CUSTOMER SERVICE

Cust.ServicePhone.....

I -800-365-4003

Cust.ServiceFAX.......1-800-825-0028

-

l9