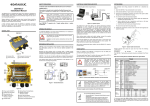

Download SenseLink QM MVA for Injection Molding User Manual

Transcript