Download Series 611T/612T

Transcript

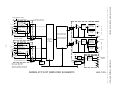

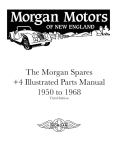

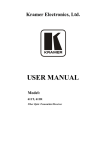

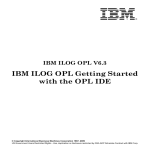

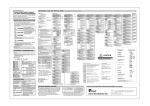

Series 611T/612T Single/Dual Channel Isolators Universal Process Current/Voltage Input USER’S MANUAL ACROMAG INCORPORATED 30765 South Wixom Road P.O. BOX 437 Wixom, MI 48393-7037 U.S.A. Tel: (248) 624-1541 Fax: (248) 624-9234 Copyright 1999, Acromag, Inc., Printed in the USA. Data and specifications are subject to change without notice. 8500-602-G06G002 Series 611T/612T Isolator User’s Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ 1.0 INTRODUCTION Safety Summary - Symbols on equipment: ! These instructions cover hardware functionality of the transmitter models listed in Table 1. Supplementary sheets are attached for units with special options or features. Means “Caution, refer to this manual for additional information”. The information contained in this manual is subject to change without notice. Acromag, Inc., makes no warranty of any kind with regard to this material, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose. Further, Acromag, Inc., assumes no responsibility for any errors that may appear in this manual and makes no commitment to update, or keep current, the information contained in this manual. No part of this manual may be copied or reproduced in any form, without the prior written consent of Acromag, Inc. Table of Contents 1.0 INTRODUCTION ………………………………..…….. DESCRIPTION ………………………………………… Key 61xT Isolator Features………..……………..… ACCESSORY ITEM….………………………………… AC Current Sensor (Model 5020-350)…………….. 2.0 PREPARATION FOR USE ….……………………….. UNPACKING AND INSPECTION …………………… INSTALLATION ……………………………………….. Jumper Installation (Current Input)……..…………. Mounting ……………………………………………… Electrical Connections ……………………………… 3.0 MODULE CONFIGURATION………………………… CONFIGURATION PROCEDURE…………………… 4.0 THEORY OF OPERATION ………………………….. 5.0 SERVICE AND REPAIR ……………………………… SERVICE AND REPAIR ASSISTANCE ……………. PRELIMINARY SERVICE PROCEDURE ..…………. 6.0 SPECIFICATIONS ……………………………………. MODEL NUMBER DEFINITION……………………… INPUT SPECIFICATIONS ……………………………. OUTPUT SPECIFICATIONS …………..…………….. ENCLOSURE/PHYSICAL SPECIFICATIONS..…….. APPROVALS ………………………………………….. ENVIRONMENTAL SPECIFICATIONS …………….. CONFIGURATION CONTROLS & INDICATORS….. List of Drawings Simplified Schematic (4501-731)…….………………….… Electrical Connections (4501-732).……………….…..…... AC Sensor Connections (4501-734)..………………..…… Enclosure Dimensions (4501-733)….………………..…… Page 2 2 3 3 3 4 4 4 4 4 4 5 5 7 7 7 7 7 8 8 8 9 9 9 10 Table 1: Models Covered in This Manual -Factory Series/ -Options/Output/ Input/Type Enclosure/Approvals1 Configuration2 611T3 -0500 -C 612T3 -0500 -C Notes (Table 1): 1. Approvals: CE marked, UL and cUL listed. (See specifications). 2. Include the “-C” suffix to specify factory configuration option. Otherwise, no suffix is required for standard configuration. 3. Model 611T-0500 units have one input/output channel, while 612T-0500 units have two input/output channels. DESCRIPTION Series 61xT Isolators are members of Acromag’s vast line of isolators, alarms, and transmitters. These models will accept one channel (611T), or two channels (612T), of DC current or voltage input, and provide a corresponding isolated process current or voltage output. Universal inputs and outputs support process current or voltage over a wide range. Units are easily calibrated via push-buttons and status LED’s on the front of the module. These isolators contain an advanced technology microcontroller with integrated flash memory for non-volatile configuration and calibration parameter data storage. Modules may be field connected for process current or DC voltage, input or output signals. Input and output ranges are user-configured. The 611T model provides a single isolated current or voltage input and output, while the 612T combines two isolated current or voltage inputs, with two isolated current or voltage outputs (outputs share common). Inputs may be configured for any range from 0-100mA DC (4mA minimum span), -100V to +100V DC (1.0V minimum span), or -1V to +1V (40mV minimum span). Outputs may be configured for any range from 0-20mA DC, or 0 to 10V DC. The minimum possible output span is limited to a reasonable effective resolution, as resolution will be diminished proportionally as the calibrated output span is reduced from nominal. Each channel includes a yellow LED on the front-panel to provide visual indication of an over-range input signal and configuration status. Additionally, a green “Run” LED indicates power and operation status. Page 11 12 13 14 IMPORTANT SAFETY CONSIDERATIONS The module uses a high resolution, low noise, Sigma-Delta, Analog to Digital Converter (Σ-∆ ADC) to accurately convert the input signals into digitized values. A microcontroller drives an optically-isolated analog output used to generate a corresponding process current or voltage. Units are DIN-rail mounted and removable terminal blocks facilitate ease of installation and replacement, without having to remove wiring. Transmitter power and output wiring are inserted at one side of the unit, while input wiring is inserted at the other side. Connectors are an industry standard screw clamp type and accept a wide range of wire sizes. It is very important for the user to consider the possible adverse effects of power, wiring, component, sensor, or software failures in designing any type of control or monitoring system. This is especially important where economic property loss or human life is involved. It is important that the user employ satisfactory overall system design. It is agreed between the Buyer and Acromag, that this is the Buyer's responsibility. -2- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ An optional AC current sensor (Acromag Model 5020-350) may be used in conjunction with the DC current input circuit of this device to implement an AC current transmitter for inputs up to 20A rms. The optional AC current sensor is itself an isolated, accurate, toroidal instrument transformer, that outputs a safe, low-level DC milliampere signal to the input of the transmitter. As an isolated device, it adds an extra level of input isolation and protection. See “AC Current Sensor” section for more information. Key 61xT Features…continued • • • All 61xT isolator modules are designed to withstand harsh industrial environments. They feature RFI, EMI, ESD, EFT, and surge protection, plus low temperature drift, wide ambient temperature operation, and isolation from input to output and channel to channel. They also have low radiated emissions per CE requirements. The safe, compact, rugged, and reliable design of these isolators makes them an ideal choice for control room or field applications. • ACCESSORY ITEM The following accessory is available from Acromag which allows AC currents to be input to this module, and other modules that support DC current inputs. Acromag offers a full line of other standard and custom transmitter, isolator, and alarm types to serve a wide range of applications (please consult the factory). Key 61xT Features • • • • • • • • • • Hardened For Harsh Environments - The unit will operate reliably in harsh industrial environments and includes protection from RFI, EMI, ESD, EFT, and surges, plus low radiated emissions per CE requirements. Convenient Mounting, Removal, & Replacement - The DIN-rail mount and plug-in type terminal blocks make module removal and replacement easy. High-Resolution Precise A/D Conversion - Includes a high-resolution, low noise, Sigma-Delta, Analog-to-Digital Converter (Σ-∆ ADC), for high accuracy and reliability. LED Indicators - Used to indicate power, operation, configuration, under/over-range, and channel status. Wide-Range Universal Input & Output Ranges - Supports process current or voltage in user-configured ranges. The unit may be calibrated for input ranges from 0-100mA DC (4mA DC minimum input span), and input voltage ranges from -100VDC to +100VDC (0.1V DC minimum input span), or optionally –1V to +1V (40mV min input span). The output supports current ranges from 0 to 20mA DC, and voltage ranges from 0 to 10VDC. The minimum possible output span is limited to a reasonable effective resolution, as resolution will be diminished proportionally as the calibrated output span is reduced from nominal. The current output may drive up to 550Ω, typical. The voltage output includes short circuit protection. Optional AC Current Input - An optional AC current sensor can be purchased separately to support AC current inputs. Wide-Range DC-Powered - This device receives power over a wide DC supply range and the power terminal is diode-coupled. This makes the product useful for systems with redundant supplies and/or battery back-up. Over/Under-Range Indication - LED’s for each channel indicate when the I/O signal is outside of the ±12.5% of over/under-range automatically built into calibrated ranges. Normal Or Reverse Acting Output - The output of this transmitter may be calibrated for a normal (ascending), or reverse acting (descending) response. Easy Push-Button Configuration - Units are easily configured and calibrated via push-buttons and status indicators at the front of the module. Configuration Lockout - To help prevent tampering or inadvertent reconfiguration in the field, the calibration pushbuttons may be selectively locked out of reconfiguration mode. Fully Isolated - Input(s), output(s), and power are isolated from each other for safety and increased noise immunity. Inputs are isolated from each other, while outputs share common and are not isolated from output-to-output. Nonvolatile Reprogrammable Memory - This module has an advanced technology microcontroller with integrated, non-volatile, flash memory and EEPROM. This allows the functionality of this device to be reliably reprogrammed thousands of times. Wide Ambient Operation - The unit is designed for reliable operation over a wide ambient temperature range. AC Current Sensor (Model 5020-350) This optional sensor is an accurate toroidal instrument transformer used to convert a sinusoidal 50-60Hz AC current signal into a low level DC milliampere signal of 0 to 11.17mA. The input AC current range is a simple function of the number of turns placed through the toroid as shown in Table 2. This sensor is isolated and requires no calibration or adjustment. A sensor used with the 611T/612T provides redundant input isolation. Table 2: AC Current Sensor Turns & Range AC Current Primary Sensor Output Input Range Turns (Red/Black Wires) 0 to 20A AC 1 0 to 11.17mA DC 0 to 10A AC 2 “ 0 to 5A AC 4 “ 0 to 2A AC 10 “ 0 to 1A AC 20 “ The output wires of this sensor are polarized: Red is (+) plus and Black is (-) minus. Normally these output wires are attached to one end of a user supplied cable, and the other end of the cable connects to the 611T/612T Transmitter’s process current input terminals. Input Burden: A function of the wire gauge resistance used for the primary turns (current-carrying wire being monitored). Input Overload: The AC current sensor will withstand overload conditions as follows: • 20 times full scale for 0.01 seconds. • 10 times full scale for 0.1 seconds. • 5 times full scale for 1.0 second. AC Current Sensor to Transmitter Wiring Distance: 400 feet maximum for 18 gauge wire. Other wire gauges can be used as long as the resistance of both wires is less than 5Ω. -3- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ 2.0 PREPARATION FOR USE Jumper Installation (Current Input Only) UNPACKING AND INSPECTION For process current input ranges, a short jumper wire must be installed between the input “JMP” terminals. This jumper is not included from the factory. Remove this jumper for voltage input applications. Refer to Electrical Connections Drawing 4501-732 for example connections. Upon receipt of this product, inspect the shipping carton for evidence of mishandling during transit. If the shipping carton is badly damaged or water stained, request that the carrier's agent be present when the carton is opened. If the carrier's agent is absent when the carton is opened and the contents of the carton are damaged, keep the carton and packing material for the agent's inspection. For repairs to a product damaged in shipment, refer to the Acromag Service Policy to obtain return instructions. It is suggested that salvageable shipping cartons and packing material be saved for future use in the event the product must be shipped. Mounting: Refer to Enclosure Dimensions Drawing 4501-733 for mounting and clearance dimensions. DIN Rail Mounting: This module can be mounted on "T" type DIN rails. Use suitable fastening hardware to secure the DIN rail to the mounting surface. Units may be mounted side-by-side on 1-inch centers for limited space applications. "T" Rail (35mm), Type EN50022: To attach a module to this style of DIN rail, angle the top of the unit towards the rail and locate the top groove of the adapter over the upper lip of the rail. Firmly push the unit towards the rail until it snaps solidly into place. To remove a module, first separate the input terminal block(s) from the bottom side of the module to create a clearance to the DIN mounting area. Next, insert a screwdriver into the lower arm of the DIN rail connector and use it as a lever to force the connector down until the unit disengages from the rail. This module is physically protected with packing material and electrically protected with an anti-static bag during shipment. However, it is recommended that the module be visually inspected for evidence of mishandling prior to applying power. This circuit utilizes static sensitive components and should only be handled at a static-safe workstation. Electrical Connections Terminals can accommodate wire from 12-24 AWG, stranded or solid. Strip back wire insulation 1/4-inch on each lead before installing into the terminal block. Input wiring should be shielded twisted-pair. Since common mode voltages can exist on signal wiring, adequate wire insulation should be used and proper wiring practices followed. It is recommended that transmitter output and power wiring be separated from the input signal wiring for safety, as well as for low noise pickup. Note that input, power, and output terminal blocks are a plug-in type and can be easily removed to facilitate module removal or replacement, without removing individual wires. If your input is process current, you must also install a short jumper wire between the input “JMP” terminals. Be sure to remove power and/or disable the load before unplugging the terminals to uninstall the module, installing or removing jumpers, or before attempting service. All connections must be made with power removed. INSTALLATION This transmitter module is packaged in a general purpose plastic enclosure. Use an auxiliary enclosure to protect the unit in unfavorable environments or vulnerable locations, or to maintain conformance to applicable safety standards. Stay within the specified operating temperature range. As shipped from the factory, the unit is factory calibrated for the input & output ranges shown in Table 3 below. WARNING: Applicable IEC Safety Standards may require that this device be mounted within an approved metal enclosure or sub-system, particularly for applications with voltages greater than or equal to 75VDC or 50VAC. CAUTION: Risk of Electric Shock - More than one disconnect switch may be required to de-energize the equipment before servicing. Table 3: 611T/612T Default Factory I/O Configuration PARAMETER CONFIGURATION/CALIBRATION Input 1 Range1 0 to 10V DC1 or 0 to 99mV DC2 Output 1 Range 4 to 20mA DC Input 2 Range1 (612T) 0 to 10V DC1 or 0 to 99mV DC2 Output 2 Range (612T) 4 to 20mA DC * Shaded entries apply to dual channel Model 612T units only. Notes (Table 3): 1. For current input ranges, a short jumper wire must be inserted between the input “JMP” terminals (not included). This jumper must be removed for voltage input ranges. 2. The optional low voltage range signal is input at the JMP terminal adjacent to the V+ input with jumper removed. 1. Power: Refer to Electrical Connections Drawing 4501-732. Variation in power supply voltage within rated limits has negligible effect on module accuracy. For supply connections, use No. 14 AWG wires rated for at least 75°C. The power terminal is diode-coupled for reverse polarity protection. 2. DC Voltage/Current Inputs (Without AC Current Sensor): Connect input(s) per Drawing 4501-732. Observe proper polarity (see label for input type). For current inputs, the input “JMP” terminals must be jumpered together. Place a short jumper wire between these terminals to complete the input circuit for current inputs only. Otherwise, voltage is delivered to the “V+” input directly with this jumper removed (for ranges greater than ±1V), or optionally to the JMP terminal adjacent to V+ (for ranges below ±1V, with 1K input impedance). Your application may differ from the default configuration and will require that the transmitter’s input & output ranges be reconfigured to suit your needs. Refer to the Configuration & Calibration section for additional instructions. -4- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ 3. AC Current Input (Optional): Refer to Drawing 4501-734 to connect the optional AC current sensor. The sensor is typically mounted near the AC current being measured and will transmit a low level DC milliampere signal to the module. This allows the module to be mounted remote from the AC signal and sensor and connected using small gauge wire. The sensor output (Red/Black) wires can be shorted, opencircuited, or removed from the transmitter input terminals, without hazard to personnel or to the sensor. Be sure to also install a jumper between the input “JMP” terminals for current input ranges. Configuration of I/O zero & full-scale is accomplished via the transmitter module’s “SET”, “MODE”, “UP”, and “DOWN” push buttons, and the module’s status LED’s (see Drawing 4501-733) as described in the following paragraphs. Equipment Required • • AC Current Sensor: Per Table 2 on Page 3, loop the required number of turns through the toroid for the full-scale current range required by your application. Use the cable tie provided with the sensor to mechanically secure it. An accurate input source (voltage or current) adjustable over the configured input range. This source must be accurate beyond the module specifications for best results. For voltage inputs, use a voltage source with an output impedance of 100Ω or less. An accurate current or voltage meter is also required to monitor the output level. This meter must be accurate beyond the module specifications for best results. IMPORTANT: Input levels outside of the module’s input and output ranges are not acceptable for zero, or full-scale calibration. Likewise, the absolute value of the input used for full-scale calibration must be greater than the absolute value of the input used for zero calibration. For nonsymmetric bipolar input ranges (-5V to +1V for example), if the absolute magnitude of the lower endpoint of your range is greater than the absolute magnitude of the higher endpoint of your range, you will have to use the lower range endpoint as your “full-scale” input signal level, the higher range endpoint as your “zero” input signal, and perform a reverse acting output calibraton (see Note 4 of the Configuration Procedure). Since I/O levels cannot be validated during field programming, entering incorrect signals can produce an undesired output response. Be sure to install a jumper between the input “JMP” terminals for current input ranges and remove this jumper for voltage input ranges. DANGER: If the AC current sensor is used with an AC Current Transformer (C.T.), disconnect power from the C.T., or short the output of the C.T., before removing the wire going through the AC current sensor. If this is not done, an open circuited C.T. will generate hazardous high voltages and possible C.T. damage. 4. Analog Output Connections: Wire output(s) as shown in Electrical Connections Drawing 4501-732. Separate output terminals are provided for voltage or current. Voltage and current is output simultaneously for a channel, but the channel can only be calibrated to one output range at a time. Dual channel outputs share common and are not isolated from output-to-output. Note: For sensitive applications or high-speed sampling, high frequency noise may be reduced at the load by placing a 0.1uF capacitor directly across the load. CONFIGURATION PROCEDURE 5. Grounding: See Electrical Connections Drawing 4501-732. The module housing is plastic and does not require an earth ground connection. If the “RUN” and “ST” LED’s are both ON, then the configuration mode is locked-out and must be unlocked prior to configuration by pressing the MODE and DOWN buttons at the same time until the “ST” LED turns OFF. This allows the pushbuttons to be used to reconfigure the module as illustrated below. WARNING: For compliance to applicable safety and performance standards, the use of shielded cable is recommended as shown in Drawing 4501-732. Further, the application of earth ground must be in place as shown in Drawing 4501-732. Failure to adhere to sound wiring and grounding practices may compromise safety & performance. The following procedure uses the corresponding channel outof-range LED’s (labeled “CH1” or “CH2”) to indicate which parameter, zero or full-scale, is being programmed. In configuration mode, the green power LED is turned OFF, and the yellow “ST” LED is OFF. The yellow channel LED flashes, or is constant ON, if full-scale or zero is being configured for a channel. Refer to Table 4. 3.0 MODULE CONFIGURATION The I/O ranges of this transmitter need to be configured and calibrated for your application. Inputs may be configured for any range from 0-100mA DC (4mA minimum span), -100V to +100V DC (1.0V minimum span), or optionally –1V to +1V (40mV min input span). Outputs may be configured for any range from 020mA DC, or 0 to 10V DC. The minimum possible output span is limited to a reasonable effective resolution, as resolution will be diminished proportionally as the calibrated output span is reduced from nominal (see Output Resolution). Table 4: LED Indication In Configuration Mode CH1 CH2 CONFIG MODE RUN1 ST Set CH1 Full-Scale OFF1 OFF2 Flashing OFF Set CH1 Zero OFF1 OFF2 ON OFF Set CH2 Full-Scale OFF1 OFF2 OFF Flashing Set CH2 Zero OFF1 OFF2 OFF ON Notes (Table 4): 1. The green “Run” LED is turned OFF in configuration mode. 2. The yellow “ST” LED will flash one time each time SET is pressed to capture a full-scale or zero I/O setting in configuration mode. Note that a normal acting (ascending), or reverse acting (descending) output response may be configured by swapping the full-scale & zero output levels during configuration. -5- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ CAUTION: Do not insert sharp or oversized objects into the push-button switch openings as this may damage the unit. When depressing the push-buttons, use a blunt tipped object and apply pressure gradually until you feel or hear the tactile response. For a reverse acting output, you would adjust the output level to a higher level in response to the zero input here, and a lower level in response to a full-scale input in Step 6. See Note 4. 11. Press the “SET” push-button to accept the zero I/O value. Note that every time the “SET” button is pressed, the yellow “ST” LED will flash once and the zero I/O point will be captured. 12. Press the “MODE” push button a third time and the program sequence for channel 1 will be completed. 1. Connect a voltage or current source to the input, as required (refer to Electrical Connections Drawing 4501-732). 2. Apply power and the module’s green “Run” LED will light. 3. If the yellow “ST” LED is also ON, then the reconfiguration push-buttons must first be unlocked by simultaneously pressing the “MODE” and “DOWN” button for one second. The yellow “ST” LED should turn OFF (See Table 6). The push-buttons may now be used to reconfigure the module. 4. Press and hold the “MODE” push button until the green “RUN” LED turns OFF and the yellow “CH1” LED flashes. In this mode, the unit is ready to accept a full-scale input signal for transmitter input channel 1. If you do not wish to change the full-scale parameter, skip to step 8. 5. Adjust the input source to the “full-scale” input signal level according to your input range. The full-scale input signal must be within the input range limits of the module. The absolute value of this level must be greater than the absolute value of the opposite endpoint—otherwise, see Note 4. 6. Press the “UP” or “DOWN” push-button one time to cause the module to auto-adjust the corresponding output level to full-scale. If the output is not exactly at the desired full-scale level, then each successive depression of the “UP” or “DOWN” switch will increment or decrement the output signal by a small amount. Holding the switch depressed will increase the amount of increment or decrement. Note that a reverse acting output response can be easily obtained by using the push-buttons to adjust the output level accordingly. For a reverse acting output, you would adjust the output level to a lower level here in response to the full-scale input, and a higher level in response to a zero input in Step 10. See Note 4. 7. Press the “SET” push-button to accept the full-scale I/O value. Note that every time the “SET” button is pressed, the yellow “ST” LED will flash once and the full-scale I/O point will be captured. 8. Press the “MODE” push button one more time. The green “RUN” LED will still be OFF and the yellow “CH1” LED will be ON, indicating that the unit is ready to accept the zero value for input channel 1. If you do not wish to change the channel 1 zero parameter, skip to step 12. 9. Adjust the input source to the “zero” input signal according to your input range. The “zero” input signal must be within the input range limits for the module. The module uses the full-scale and zero levels to set the input span (span = fullscale - zero). The absolute value of this level must be less than the absolute value of the opposite endpoint— otherwise, see Note 4. 10. Press the “UP” or “DOWN” push-button one time to cause the module to auto-adjust its output level to a zero output level. If the output is not exactly at the desired zero level, then each successive depression of the “UP” or “DOWN” switch will increment or decrement the output signal by a small amount. Holding the switch depressed will increase the amount of increment or decrement. Note that a reverse acting output response can be easily obtained by using the push-buttons to adjust the output level accordingly. Model 611T units will return to run mode at this point and calibration is complete (the green “RUN” LED will turn ON). You may skip ahead to step 14 to optionally lock-out reconfiguration mode. On 612T models, the green “RUN” LED will still be OFF, the yellow “CH1” LED will turn OFF, and the yellow “CH2” LED will flash. In this mode, the unit is ready to accept a fullscale input signal for transmitter input channel 2. To calibrate the second I/O channel, repeat steps 4-11 substituting channel 2 for channel 1. If you do not wish to program channel 2, skip to step 13. 13. Press the “MODE” push button a fourth time on 612T units and the module will return to run mode. The green “RUN” LED will turn ON, the status LED is OFF, and the channel LED’s will now reflect over/under range status. Calibration is complete at this point. Note that during configuration, until “SET” is pressed, pushing “MODE” will only toggle between the full-scale & zero I/O sequence, without affecting their values. Further, if no push-buttons are depressed within 2 minutes, then the module will automatically revert to run mode (green “Run” LED will light) and no changes will be made to the original zero or full-scale I/O settings. 14. OPTIONAL CONFIGURATION LOCK-OUT - At any time, you may optionally lock-out the push-buttons to prevent inadvertent reconfiguration or tampering in the field. The unit may be locked out of configuration mode by pressing the MODE and UP push-buttons simultaneously for 1 second. The status LED will turn ON to indicate that the lock feature is enabled. You may unlock the configuration mode by pressing the MODE and DOWN buttons simultaneously for one second. The status LED will be turned OFF to indicate the lock is disabled. Notes (Configuration Procedure): 1. In configuration mode, the module’s LED’s are used to indicate the program sequence as illustrated in Table 5: Table 5: Configuration Mode LED Indication LED LED INDICATOR LED ON LED OFF FLASHING Green “RUN” Run Mode Config Mode NA Yellow “CH1” Calibrate Calibrate Cal CH1 CH1 Zero CH2 Full-Scale Yellow “CH2” Calibrate Calibrate Cal CH2 CH2 Zero CH1 Full-Scale Yellow “ST” NA NA One Flash as SET pressed 2. The reconfiguration push-buttons may be alternately locked out, or unlocked as illustrated in Table 6: -6- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ 5.0 SERVICE AND REPAIR Notes (Configuration Procedure)…continued: Table 6: Configuration Mode Lock ACTION Status LED PUSH-BUTTONS Lock-out ON Press “MODE” + “UP Configuration (Locked) ARROW” Together To Lock Unlock OFF Press “MODE” + “DOWN Configuration (Unlocked) ARROW” Together To Unlock CAUTION: Risk of Electric Shock - More than one disconnect switch may be required to de-energize the equipment before servicing. SERVICE AND REPAIR ASSISTANCE This module contains solid-state components and requires no maintenance, except for periodic cleaning and transmitter configuration parameter (zero, full-scale) verification. Since Surface Mounted Technology (SMT) boards are generally difficult to repair, it is highly recommended that a non-functioning module be returned to Acromag for repair. The board can be damaged unless special SMT repair and service tools are used. Further, Acromag has automated test equipment that thoroughly checks and calibrates the performance of each module. Please refer to Acromag’s Service Policy Bulletin or contact Acromag for complete details on how to obtain service parts and repair. 3. If the module is in field configuration mode and no push buttons are pressed after 2 minutes, then the module will return to the run mode, the green “Run” LED will light, and no changes to any program parameters will be made. 4. If you want to calibrate a bipolar range that is non-symmetric around 0 and where the absolute value of the low-endpoint of the input range is greater than the absolute value of the high endpoint of the range (for example: -5V to +1V), then you must use the low endpoint of your range as your “full-scale” input signal (Step 5), the high endpoint of your range as the “zero” input signal (Step 9), and perform a reverse acting output calibration (Steps 6 & 10). For example, to calibrate -5V to +1V at the input for 4mA to 20mA at the output, in Step 5 of the Configuration Procedure you would use -5V as your “full-scale” input signal. In step 6, you would adjust the output to 4mA for the full-scale output (reverse acting). Later in step 9, you would use +1V as your “zero” input signal. Then in step 10, you adjust the output to 20mA for the zero output level (reverse acting). PRELIMINARY SERVICE PROCEDURE Before beginning repair, be sure that all installation and configuration procedures have been followed. The unit routinely performs internal diagnostics following power-up or reset. During this period, all LED’s will turn ON momentarily, and the green “Run” LED flashes. If the diagnostics complete successfully, the “Run” LED will stop flashing after approximately one second and remain ON. This indicates that the unit is operating normally. If the “Run” LED continues to flash, then this is indicative of a problem with the unit. In this case, you should try to reconfigure the module and this may cure the problem. If the diagnostics continue to indicate a problem (a continuously flashing green LED), or if other evidence points to a problem with the unit, an effective and convenient fault diagnosis method is to exchange the questionable module with a known good unit. 4.0 THEORY OF OPERATION Refer to Simplified Schematic 4501-731 to gain a better understanding of the circuit. Note that this transmitter will prefilter a signal and convert the signal to a scaled voltage--either through a voltage divider circuit (voltage input), or a current sink resistor (current input). An A/D converter stage then applies appropriate gain to the signal, performs analog-to-digital conversion, and digitally filters the signal. The digitized signal is then transmitted serially to a microcontroller. The microcontroller drives an optical isolator and filter circuit. A corresponding analog output voltage is generated and used to drive a voltage to current converter (current output), and an amplifier (voltage output), in tandem. I/O range configuration and calibration parameters are stored in non-volatile memory. A wide input range switching regulator provides separately isolated power to the input and output circuits. Acromag Application Engineers can provide further technical assistance if required. When needed, complete repair services are available from Acromag. 6.0 SPECIFICATIONS 611T-0500-C, One I/V Input, Single Process I/V Output 612T-0500-C, Two I/V Inputs, Dual Process I/V Outputs General: The 611T/612T Transmitters are DC powered isolators for one or two channels of process current or voltage. Isolation is supplied between the inputs, output, and power. Inputs are isolated channel-to-channel. Output channels share common and are not isolated from each other. This transmitter is DIN-rail mounted. The unit is configured and calibrated via front panel pushbuttons and status LED’s. Refer to Module Configuration. All calibration and configuration information is stored in nonvolatile reprogrammable memory in the module. -7- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ MODEL NUMBER DEFINITION Input Bias Current: ±100nA maximum, excluding excitation current of process current inputs. Input Filter: Normal mode filtering, plus digital filtering, optimized and fixed per input range within the Σ-∆ ADC. Bandwidth: -3dB @ 1Hz typical. Noise Rejection (Normal Mode): Better than 60dB @ 60Hz, typical with 100Ω input unbalance (10.0Ω for process currents). Noise Rejection (Common Mode): Better than 100dB @ 60Hz, typical with 100Ω input unbalance (10.0Ω for process currents). Analog to Digital Converter (A/D): 16-bit Σ-∆ converter. Input Conversion Rate: 4.6 conversions per channel, per second (612T). 20 conversions per second (611T). Transmitters are color coded with a white label. The prefix “6” denotes the Series 600, while the “T” suffix specifies that this device is primarily a process transmitter. 61xT: A DC powered, field-programmable module that provides isolation for one channel (611T), or two channels (612T), of process current or voltage input and output signals in user-defined ranges. -0500: The four digits of this model suffix represent the following options, respectively: 0 = Option Specifier - No Option; 5 = Output: Transmitter Voltage or Current; 0 = Enclosure: DIN rail mount; 0 = Approvals: CE marked UL listed (UL3121) cUL listed (Canada Standard C22.2, 1010.1-92) OUTPUT SPECIFICATIONS These units utilize an optically isolated output voltage that drives a process current and output voltage circuit in tandem. The output current or voltage can be set to any value within nominal output range limits. Although output voltage and current is simultaneous at different terminals, calibration may only occur with respect to one of the outputs at a time. Further, outputs share common and are not isolated output-to-output. A reverse acting output response can be easily obtained by adjusting the output minimum and maximum levels accordingly during zero and full-scale reconfiguration. INPUT SPECIFICATIONS Unit must be wired and configured for the intended input type and range (see Installation Section for details). Input ranges are userconfigured within the limits of the input given below. The following paragraphs summarize this model’s input types, ranges, and applicable specifications. Voltage Output Specifications: Output Range: Output range is user-configured and based on a nominal output range of 0-10VDC (approximately -1 to +11V including over-range). Approximately ±12.5% of over-range is already built into calibrated output ranges. For rated performance, output spans from 5V minimum to 10V maximum are recommended. See Table 7. Output Resolution: Varies with calibrated output range. Nominal output resolution is 1 part in 6644 (12.7 bits) and based on a 0-10V, or 0-20mA, nominal calibrated output range. The minimum possible output span is limited to a reasonable effective resolution, as resolution will be diminished proportionally as the calibrated output span is reduced from nominal. Over-range of approximately ±12.5% is already built into a calibrated range and will not degrade the nominal effective resolution. See Table 7. Output Load Current: 0-10mA DC maximum. Output Impedance: 1Ω, Typical. Output Short Circuit Protection: Included DC (Process) Current: Any user-configured input range within nominal range limits of 0-100mA, 4mA minimum input span. Over/under-range of ±12.5% is automatically built into calibrated spans. A precision 10.0Ω current sink resistor is placed in the “I+” input lead and converts the input current to a voltage that is processed by the A/D converter. The input “JMP” terminals must be jumpered together to utilize current input. Current Input Reference Test Conditions: Input = 4-20mA; Ambient Temperature = 25°C; Power Supply = 24VDC; Output = 4-20mA. Input Overvoltage Protection: Bipolar Transient Voltage Suppressers (TVS), 8V clamp level typical. Input Resistance (Current): 10.0Ω. DC Voltage: A user-configured input range within limits of -100V to +100V DC, 1.0V minimum input span, for inputs at V+ (101KΩ input impedance here). Optionally, small voltage signals within limits of –1V to +1V with a 40mV minimum input span can be connected to the JMP terminal adjacent to V+ (1KΩ input impedance). Voltage Input Reference Test Conditions: 0 to 10V DC input; Ambient Temperature = 25°C; Power Supply = 24V DC; Output = 4-20mA. Input Resistance (Voltage): 101KΩ at V+ (±100V input); 1KΩ at JMP terminal adjacent to V+ input (±1V input). Input Overvoltage Protection: Bipolar Transient Voltage Suppressers (TVS), 135V clamp level typical. Current Output Specifications: Output Ranges: Output range is user-configured and must reside within the nominal range limits of 0 to 20mA DC (0-22mA including over-range). Approximately ±12.5% of over/under-range is already built into calibrated ranges. Output spans from 10mA minimum to 20mA maximum are recommended for rated performance. General Input Specifications Accuracy: See General Output Specifications. Resolution: 1 part in 6644 or 12.7 bits effective. Input resolution is actually 16 bits internally, but limited by the output resolution of 12.7 bits. See Output Resolution below. -8- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ ENVIRONMENTAL SPECIFICATIONS Output Resolution: Varies with calibrated output range. Nominal resolution is 1 part in 6644 (12.7 bits) and based on a 0-20mA, or 0-10V, nominally calibrated output range. The minimum possible output span is limited to a reasonable effective resolution, as resolution will be diminished proportionally as the calibrated output span is reduced from nominal. Over-range of ±12.5% is already built into a calibrated range and will not affect effective resolution calculations. See Table 7. Output Maximum Current: 21.8mA DC, Typical. Output Compliance: 10.9V DC, Typical. Output Load Resistance Range: 0 to 550Ω, Typical. Operating Temperature: -25°C to +70°C (-13°F to +158°F). Storage Temperature: -40°C to +85°C (-40°F to +185°F). Relative Humidity: 5 to 95%, non-condensing. Power Requirements: +10V Minimum to +36V DC Maximum. Current draw is a function of supply voltage (see Table 8). Current shown in Table 8 assumes that each output is delivering full-scale current (20mA). An internal diode provides reverse polarity protection. CAUTION: Do not exceed 36VDC peak, to avoid damage to the module. Table 7: Output Range Effective Resolution Output Range Effective Resolution 0 to 20mA DC 1 part in 6644 4 to 20mA DC 1 part in 5315 0 to 11.17mA DC 1 part in 3711 0 to 10mA DC 1 part in 3322 0 to 10V DC 1 part in 6644 0 to 5V DC 1 part in 3322 Table 8: 611T/612T Power Supply Current Supply Model Model Voltage 611T-0500 612T-0500 10V 110mA 180mA 12V 95mA 150mA 15V 80mA 115mA 24V 55mA 75mA 36V 35mA 65mA General Output Specifications Accuracy: Better than ±0.1% of output span typical for nominal output ranges of 0-10V or 0-20mA. This includes the effects of repeatability, but not sensor error. Actual accuracy will vary with effective I/O resolution according to the calibrated I/O range. Accuracy Versus Temperature: Better than ±0.010% (±100ppm) of output span per °C for nominal calibrated output ranges of 0-10V, or 0-20mA. Output Response Time: 800ms typical, 1000ms maximum, to 98% of output transition for a step change in the input. Power Supply Effect: DC Volts: Less than ±0.001% of output span change per volt DC for rated power supply variations. 60/120 Hz Ripple: Less than 0.01% of output span per volt peak-to-peak of power supply ripple. Isolation: Inputs, output, & power circuits are isolated from each other for common-mode voltages up to 250VAC, or 354V DC off DC power ground, on a continuous basis (will withstand 1500VAC dielectric strength test for one minute without breakdown). This complies with test requirements outlined in ANSI/ISA-82.01-1988 for the voltage rating specified. Isolation rating applies input-to-output, power-to-input, and power-to-output. Outputs share common and are not isolated from each other. Input-to-Input: Inputs are isolated from each other for voltages up to 200V AC or DC peak. Installation Category: Designed to operate in an Installation Category (Overvoltage Category) II environment per IEC 1010-1 (1990). Radiated Field Immunity (RFI): Designed to comply with IEC1000-4-3 Level 3 (10V/M, 80 to 1000MHz AM & 900MHz keyed) and European Norm EN50082-1. Electromagnetic Interference Immunity (EMI): No output shift will occur beyond ±0.25% of span, under influence of EMI from switching solenoids, commutator motors, & drill motors. Electrical Fast Transient Immunity (EFT): Complies with IEC1000-4-4 Level 3 (2KV power; 1KV signal lines) and European Norm EN50082-1. Electrostatic Discharge (ESD) Immunity: Complies with IEC1000-4-2 Level 3 (8KV/4KV air/direct discharge) to the enclosure port and European Norm EN50082-1. Surge Immunity: Complies with IEC1000-4-5 Level 3 (2.0KV) and European Norm EN50082-1. Radiated Emissions: Meets or exceeds European Norm EN50081-1 for Class A equipment. ENCLOSURE/PHYSICAL SPECIFICATIONS Unit is packaged in a general purpose plastic enclosure that is DIN rail mountable for flexible, high density (approximately 1” wide per unit) mounting. See Enclosure Dimensions Drawing 4501-733 for details. Dimensions: Width = 1.05 inches, Height = 4.68 inches, Depth = 4.35 inches (see Drawing 4501-733). DIN Rail Mounting (-xx0x): DIN rail mount, Type EN50022; “T” rail (35mm). Connectors: Removable plug-in type terminal blocks; Current/Voltage Ratings: 15A/300V; Wire Range: AWG #24 to 12, solid or stranded; separate terminal blocks are provided for input 1, input 2, power, and outputs. Case Material: Self-extinguishing NYLON type 6.6 polyamide thermoplastic, UL94 V-2, color beige; general purpose NEMA Type 1 enclosure. Printed Circuit Boards: Military grade FR-4 epoxy glass. Shipping Weight: 1 pound (0.45 Kg) packed. APPROVALS (-xxx0) 0: CE, UL, & cUL approvals. All units comply with European Community “CE” marking, plus applicable CSA, UL, and FM standards. Consult the factory for current available agency approvals (e.g. CSA, FM, UL, etc.). -9- Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ CONFIGURATION CONTROLS & INDICATORS Notes: Units are configurable via push-buttons and status indicators on the front panel of the module. These controls and indicators operate as follows: Module Push Buttons (See Dwg 4501-733 for Location): Mode - Used to change between Run and Configuration Modes. Set - Used to capture I/O settings during configuration. Up - Used to increment output level during configuration. Down - Used to decrement output level during configuration. Mode + Up - Press together to lock out Configuration Mode and help prevent inadvertent field reconfiguration (Status LED turns ON). Mode + Down - Press together to unlock Configuration Mode and allow reconfiguration (Status LED turns OFF). LED Indicators (See Dwg 4501-733 for Location): Operating (Run) Mode Run (Green) - Constant ON indicates power is applied and unit is operating normally. Flashing ON/OFF indicates that unit is performing diagnostics (first second following powerup), or has failed diagnostics (after a few seconds). Module Status STAT (Yellow) - ON if push-buttons are locked out to prevent inadvertent field reconfiguration. OFF if Configuration Mode is unlocked to allow reconfiguration. See Table 6. Channel 1 Status CH1 (Yellow) - ON if input 1 out of range. Approximately ±12.5% of over-range is built into the calibrated range and this LED turns ON if the signal goes beyond this over-range limit. Channel 2 Status CH2 (Yellow) - ON if input 2 out of range. Approximately ±12.5% of over-range is built into the calibrated range and this LED turns ON if the signal goes beyond this over-range limit. Configuration Mode (Also See Table 5) Run (Green) - Turned OFF in this mode. Status (Yellow) - Turned OFF, but blinks each time the “SET” button is pressed to capture an I/O signal in configuration mode. Channel 1 Status CH1 (Yellow) - ON if CH1 zero is being configured. Flashes if CH1 full-scale is being configured. Channel 2 Status CH2 (Yellow) - ON if CH2 zero is being configured. Flashes if CH2 full-scale is being configured. Input Type Jumper (See Drawing 4501-732): A short jumper wire must be installed between the input “JMP” terminals to utilize current input ranges. Remove input “JMP” jumper for voltage input. Normal/Reverse Acting Output Selection: A normal or reverse acting output signal is selected by exchanging the maximum and minimum output adjustment levels as required during full-scale and zero calibration. - 10 - INPUT CONDITIONING NC I N P U T 1 11 12 V1+ JMP 13 14 15 ISOLATED OUTPUTS SSR's -1.0V to +1.0V (40mV MIN SPAN) OPTIONAL LOW-V INPUT (JUMPER REMOVED) JMP I1+ CH1 Switches Are Shorts For Single Channel Version (611T) -100V to +100V (1V MIN SPAN) 100K 0-100mA (4mA MIN SPAN) 10.0 FILTER INPUT CONDITIONING - 11 - I N P U T 2 V2+ JMP 23 24 -100V to +100V 100K (1V MIN SPAN) I2+ 25 0-100mA (4mA MIN SPAN) 10.0 42 V1+ 41 INTEGRATED EEPROM AND FLASH MEMORY FILTER AMPLIFIER FILTER 46 O U T P U T 1 612T ONLY I2+ 45 V2+ 44 1K O U T P U T 2 RTN JUMPER (CURRENT INPUT ONLY) 26 RTN2 +16V OUTPUT CIRCUIT POWER ISOLATED CHANNEL 2 (612T ONLY) BIAS INSTALL I+ TO JMP JUMPER FOR CURRENT INPUT ONLY VOLTAGE TO CURRENT CONVERTER SSR's -1.0V to +1.0V (40mV MIN SPAN) OPTIONAL LOW-V INPUT (JUMPER REMOVED) JMP I1+ RTN 16 BIT A/D CONVERTER AND MULTIPLEXER 612T ONLY 22 AMPLIFIER FILTER MICROCONTROLLER AND SUPPORT LOGIC ISOLATED CHANNEL 1 21 43 1K JUMPER (CURRENT INPUT ONLY) 16 RTN1 NC VOLTAGE TO CURRENT CONVERTER +5V INPUT CIRCUIT POWER ADDITIONAL TRANSIENT PROTECTION AND FILTER CIRCUITRY NOT SHOWN SERIES 611T/612T SIMPLIFIED SCHEMATIC POWER ISOLATION 31 DC+ 10-36 VDC POWER SWITCHER 32 10-36VDC DC33 NC 34 NC 35 NC 36 NC 4501-731D Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ SCREW TERMINAL NUMBER ANALOG OUTPUT MODEL 61xT INPUT CONNECTIONS AT TB1/TB2 PLACE A JUMPER WIRE BETWEEN JMP TERMINALS FOR CURRENT INPUT SIGNALS NC NC 11 12 V + 13 JMP + 2-WIRE XMTR TB1 TB1 14 JMP 15 I + - 16 RTN DC PWR NC PLACE A JUMPER WIRE BETWEEN JMP TERMINALS NC FOR CURRENT INPUT SIGNALS DC CURRENT (mA) 11 VOLTAGE OUT LOAD OR CURRENT OUT LOAD I + + - DC POWER RL 10 TO 36V DC + 12 V + 13 JMP 14 JMP 15 I + + SHIELDED CABLE EARTH GROUND 16 RTN OUTPUTS SHARE COMMON AND ARE NOT ISOLATED OUTPUT-TO-OUTPUT TB4 NOTE 1 OUTPUT 2 (612T ONLY) TB3 TB4 EARTH GROUND NOTE 1 TWO-WIRE TRANSMITTER DOWN SWITCH 16 RTN NOTE 1 MODEL 611T-0500 MODEL 612T-0500 INPUT 1 MODEL 612T-0500 INPUT 2 I+ RTN JMP V+ 11 12 13 14 15 16 R JMP TB2 I+ RTN JMP V+ AC CURRENT SENSOR INPUT JMP +/-40mV to +/-1V DC RANGES (V-IN AT JMP TERMINAL) 1K INPUT IMPEDANCE + SET SWITCH TB1 DC VOLTAGE INPUT (UNIPOLAR OR BIPOLAR) PWR MODEL 612T-0500 UP SWITCH 14 JMP 15 I + SET NOTE 1 OUTPUT 2 OUTPUT 1 DC+ CHANNEL 1 LED (YELLOW) MODE SWITCH DC- 12 V + 13 JMP 36 35 34 33 32 31 TB3 MODE 2 11 46 45 44 43 42 41 RTN CHANNEL 2 LED (YELLOW) I+ - 16 RTN - LOW VOLTAGE SOURCE + CH V+ 14 JMP 15 I + 1 RUN/PWR LED (GREEN) STATUS LED (YELLOW) V+ - 12 - NC NC NC VOLTAGE SOURCE ST RTN 11 12 V + 13 JMP RUN I+ TB1 NC PLACE A JUMPER WIRE BETWEEN JMP TERMINALS FOR CURRENT INPUT SIGNALS TB1 NC AC CURRENT SENSOR RED WIRE (+) NC 5020-350 BLACK WIRE (-) Acromag TB4 +/-1V to +/-100V DC RANGES 101K INPUT IMPEDANCE + DC CURRENT INPUT (mA) 21 22 23 24 25 26 TB1 NC NC NC NC - 11 12 V + 13 JMP 14 JMP 15 I + 16 RTN NOTE 1 LOW DC VOLTAGE INPUT (UNIPOLAR OR BIPOLAR) NOTE 1: THIS GROUND CONNECTION IS RECOMMENDED FOR BEST RESULTS. IF SENSORS ARE INHERENTLY CONNECTED TO GROUND, USE CAUTION AND AVOID MAKING ADDITIONAL GROUND CONNECTIONS WHICH COULD GENERATE GROUND LOOPS AND MEASUREMENT ERROR. TB1 TB1 REMOVABLE (PLUG-IN TYPE) TERMINAL BLOCKS WARNING: FOR COMPLIANCE TO APPLICABLE SAFETY AND PERFORMANCE STANDARDS, THE USE OF SHIELDED CABLE IS RECOMMENDED AS SHOWN. ADDITIONALLY, THE APPLICATION OF EARTH GROUND MUST BE IN PLACE AS SHOWN IN THIS DRAWING. FAILURE TO ADHERE TO SOUND WIRING AND GROUNDING PRACTICES MAY COMPROMISE SAFETY AND PERFORMANCE. SAFETY GUIDELINES MAY REQUIRE THAT THIS DEVICE BE HOUSED IN AN APPROVED METAL ENCLOSURE OR SUB-SYSTEM, PARTICULARLY FOR APPLICATIONS WITH VOLTAGES GREATER THAN OR EQUAL TO 75VDC/50VAC. TB2 TB2 (612T ONLY) CURRENT INPUT JUMPER INPUT CONNECTIONS (SEE INPUT CONNECTIONS AT LEFT) 4501-732B Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ ELECTRICAL CONNECTIONS APPLICATION EXAMPLE A: AC CURRENT TRANSFORMER (C.T.) 611T/612T INPUT CONNECTIONS WIRE NUT FIGURE 1 NC NOTE: DESIGN ALLOWS INADVERTANT OPENS OR SHORTS. LEADS 12 INCHES NOMINAL RED AC CURRENT SENSOR NC + V+ JMP JMP MOUNTED IN POWER AREA EARTH GROUND 400 FEET 18 GA. WIRE (5 OHMS) INSULATED WIRE 12 IN. FIGURE 2 RED USER SUPPLIED AC CURRENT TRANSFORMER. (C.T.) + BLACK - NOTE 1: THIS GROUND CONNECTION IS RECOMMENDED. IF UNIT HAS TWO INPUTS, GROUND ONLY ONE INPUT, DO NOT CONNECT THE SECOND INPUT TO GROUND AS THIS WOULD PRODUCE A GROUND LOOP. - 13 - AC CURRENT SENSOR MOUNTED IN POWER AREA WIRE NUT NOTE: DESIGN ALLOWS INADVERTANT OPENS OR SHORTS. 1.05 0.375 (MIN.) I+ RTN SEE NOTE 1 DANGER: AC CURRENT TRANSFORMER (C.T.) CONNECTIONS: DISCONNECT POWER TO C.T. OR SHORT OUTPUT OF C.T. BEFORE REMOVING INPUT CONNECTIONS TO AC CURRENT SENSOR. IF THIS PROCEDURE IS NOT FOLLOWED, AN OPEN CIRCUIT C.T. WILL GENERATE HIGH VOLTAGES AND POSSIBLE C.T. DAMAGE WILL RESULT. FIGURE 3 RED + 611T/612T INPUT CONNECTIONS CAUTION: CONNECT MODULE TO AC CURRENT SENSOR ONLY. DO NOT CONNECT AC CURRENT DIRECTLY TO MODULE INPUT TERMINALS. APPLICATION EXAMPLE B: 115V/230VAC ELECTRICAL CIRCUIT INPUT RANGE SELECTION BLACK - V+ JMP JMP AC CURRENT SENSOR TABLE 1: TURNS CHART 1.35 NC BLACK TURN COUNT: NUMBER OF WIRES PASSING THROUGH CENTER HOLE (SEE INPUT RANGE SELECTION TABLE). AC CURRENT SENSOR NC RED + I+ RTN BLACK - AC CURRENT 5 AMPS FULL SCALE (4 TURNS) AC CURRENT 5 AMPS FULL SCALE (4 TURNS) INPUT RANGE (RMS) TURNS 0 TO 20A 0 TO 10A 0 TO 5A 0 TO 2A 0 TO 1A 1 2 4 10 20 AC LOAD AC SOURCE 611T/612T INPUT CONNECTIONS MOUNTED IN POWER AREA LEADS 12 INCHES NOMINAL RED NC WIRE NUT NOTE: DESIGN ALLOWS INADVERTANT OPENS OR SHORTS. + DANGER: HIGH VOLTAGE EARTH GROUND AC CURRENT 20 AMPS FULL-SCALE (1-TURN) V+ JMP JMP I+ RTN BLACK - AC CURRENT SENSOR ACROMAG MODEL 5020-350 NC SEE NOTE 1 CAUTION: CONNECT MODULE TO AC CURRENT SENSOR ONLY. DO NOT CONNECT AC CURRENT DIRECTLY TO INPUT TERMINALS. AC CURRENT SENSOR CONNECTIONS 4501-734A Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ CAUTION: DO NOT CONNECT AC CURRENT DIRECTLY TO MODULE INPUT TERMINALS. RUN ST "T" RAIL DIN MOUNTING DIN EN 50022, 35mm (118.9) 4.68 CH 1 2 MODE (95.3) 3.75 CL SET (59.4) 2.34 - 14 - SCREWDRIVER SLOT FOR REMOVAL FROM "T" RAIL R 1.05 (26.7) 3.90 (99.1) 4.35 (110.5) NOTE: ALL DIMENSION ARE IN INCHES (MILLIMETERS) SERIES 611T/612T TRANSMITTER ENCLOSURE DIMENSIONS 4501-733A Series 611T/612T Isolator User's Manual Universal DC Voltage/Current Input ___________________________________________________________________________________________ Acromag