Download HU UGH HEY & P PHIL LLI IPS, LLC C.

Transcript

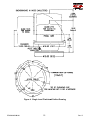

HU UGH HEY & PHIL P LLIIPS, LLC C. Ins stallatiion and Operation Guide e FL LASHG GUARD 2000B FL LASHG GUARD 3000B 12 20/240//480, 50 0/60HZ MED DIUM INTE ENSITY WHITE, W R RED AND DUAL LIIGHTING SYSTEM MS E EPM-00 000000 02-001 Re evision D Hughey y & Phillips, LLC. L 136 Ea ast Court Stre eet Urban na, OH 4307 78 Telephon ne (937) 652--3500 Fax (9 937) 652-350 08 www.o oblighting.co om PROPR RIETARY NOTIC CE THIS DOCUM MENT AND THE E INFORMATION N DISCLOSED HEREIN H ARE PR ROPRIETARY DA ATA OF HUGHEY & PHILLIPS INC. NEITHER THIS S DOCUMENT NOR N THE INFOR RMATION CONT TAINED LL BE REPROD DUCED, USED, OR O DISCLOSED D TO OTHERS WITHOUT W THE WRITTEN W HEREIN SHAL AUT THORIZATION OF O HUGHEY & PHILLIPS P INC. NOTICE FREE EDOM OF INFOR RMATION ACT (5 USC 552) AND D DISCLOSU URE OF CONFID DENCE INFORM MATION GENER RALLY (18 USC 1905) THIS DO OCUMENT IS BE EING FURNISHE ED IN CONFIDEN NCE BY HUGHE EY & PHILLIPS INC. THE INFORMA ATION DISCLOSED HEREIN FAL LLS WITHIN EXE EMPTION (b) (4) OF 5 USC 552 AND THE PROHIBITIO ONS OF 18 USC C 1905. Copyright 2010 2 Honeyw well Inc. All Rig ghts Reserve ed EPM-00000002-001 Rev. D REV VISIONS S REV DATE ECO COMMEN NT A 4/21/04 3871 Initial Issu ue B 5/14/04 4242 Add spare e Flashhead o-rings to o spare parts list, page e 48. C 9/17/08 Updated document d f formatting, table of con ntent, list off figures, Figure 3, Fig gure 6, Add ded Figure 9 -13, Updated Section S 7.0 0 Part List, GPS G system m installatio on D 4/1/10 Companyy Name Cha ange TABLE OF FLA ASH GUA ARD ST TANDAR RD SYST TEMS FG2000B B SYSTEMS ARE A SINGLE E RED NIGHT T ONLY OR WHITE W DAY/N NIGHT FG3000B B SYSTEMS ARE DUAL NIGHT N AND DAY MODEL R NUMBER IN NPUT VOL LTAGE Hz. PO OWER SUP PPLY P/N F FG2000B-00 04 120/240VAC 60 40000681-023 *277-5047 7W (white) F FG2001B-00 04 240/4 480VAC 50 40000681-021 *277-5047 7W (white) F FG2002B-00 04 240/4 480VAC 60 40000681-024 *277-5047 7W (white) F FG2006B-00 04 240/4 480VAC 50 40000681-021 *277-5047 7R (red) F FG2007B-00 04 240/4 480VAC 60 40000681-024 *277-5047 7R (red) F FG2009B-00 04 120/240VAC 60 40000681-027 *277-5047 7R (red) F FG3000B-00 04 120/240VAC 60 40000681-033 *277-5004 4RW (red and a white) F FG3001B-00 04 240/4 480VAC 50 40000681-031 *277-5004 4RW (red and a white) F FG3002B-00 04 240/4 480VAC 60 40000681-034 *277-5004 4RW (red and a white) F FG3004B-00 04 240/4 480VAC 60 40000681-035 *277-5004 4RW (red and a white) F FG3005B-00 04 240/4 480VAC 50 40000681-032 *277-5004 4RW (red and a white) FLA ASH HEAD P/N This manuall covers the T e above listed systemss. Manual(ss) for otherss custom syystems are available upon request. EPM00000002 2-001 i Rev. D TABLE OF CONTENTS T C S 1.0 SAFE ETY AND GENERAL G INFORMAT TION ............................................................... 4 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 Equipm ment Descripttion ....................................................................................................................................... 4 Flashh heads ........................................................................................................................................................ 4 Powerr Supply ..................................................................................................................................................... 4 Safetyy Notice ...................................................................................................................................................... 8 Safetyy Summary ................................................................................................................................................ 9 Electro ostatic Discha arge ...................................................................................................................................... 9 Powerr Tools and Hand Tools .......................................................................................................................... 10 Mainte enance Philos sophy .................................................................................................................................. 10 Refere ence Data ................................................................................................................................................ 12 2.1 2.2 2.3 2.4 2.5 2.6 Unpaccking ........................................................................................................................................................ 14 Mounting and Prepa aration................................................................................................................................ 14 Installa ation Wiring............................................................................................................................................. 19 GPS Sync S Wiring (O OPTIONAL) ....................................................................................................................... 20 GPS Sync S Installation (OPTIONA AL) ................................................................................................................ 20 Final Check C ...................................................................................................................................................... 27 2.0 3.0 INSTA ALLATION ...................................................................................................... 14 OPER RATION ........................................................................................................... 28 3.1 Generral ............................................................................................................................................................ 28 3.2 Operating Procedurres ...................................................................................................................................... 28 3.3 Statuss Indicators .............................................................................................................................................. 28 4.0 FUNC CTIONAL DESCRIPTI D ION................................................................................ 30 4.1 4.2 4.3 4.4 4.5 Generral ............................................................................................................................................................ 30 Major Assemblies A ............................................................................................................................................. 30 Functio onal Descripttion of Subsysstems............................................................................................................. 30 GPS SYNC S ...................................................................................................................................................... 37 System m Failure (Ala arms) .................................................................................................................................. 37 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 5.10 Generral ............................................................................................................................................................ 39 Tools Required ................................................................................................................................................. 39 Troubleshooting Pro ocedures and d Tables ......................................................................................................... 39 ............................................................................ 40 Flashh head (Strobe)) Problems Lo ogic Diagram..................... . Multiplle Strobe Problems Logic Diagram D ........................................................................................................ 45 Side Light L Problems s Logic Diagrram ................................................................................................................ 47 Flashh head Isolation n Test .................................................................................................................................. 48 Powerr Supply Isola ation Test ............................................................................................................................ 49 Flashh head Maintenance................................................................................................................................... 50 Pow wer Supply an nd Light Senssor Maintenan nce ........................................................................................... 52 5.0 6.0 TROU UBLESHOO OTING AND D CORREC CTIVE MAINTENANCE ................................ 39 PART TS LISTING G ..................................................................................................... 53 EPM00000002 2-001 ii Rev. D LIST OF O FIGUR RES FIGURE 1. SINGLE LE F EVEL FLAS SHHEAD ......................................................................... 6 F FIGURE 2. DUAL LEV VEL FLASH HHEAD ............................................................................. 7 F FIGURE 3. LIGHTING G SYSTEM POWER SUPPLY ........................................................... 8 F FIGURE 4. SINGLE LE EVEL FLAS SHHEAD OUTLINE O DRAWING ..................................... 16 F FIGURE 5. DUAL LEV VEL FLASH HHEAD OUT TLINE DRA AWING ........................................ 17 F FIGURE 6. LIGHTING G SYSTEM POWER SUPPLY OU UTLINE DRAWING ...................... 18 F FIGURE 7. SYSTEM S WIRING W DIA AGRAM ......................................................................... 22 F FIGURE 8. SYSTEM WIRING W DIA AGRAM FO OR MASTE ER / SLAVE E UNITS ...................... 23 F FIGURE 9. SYSTEM S WIRING W DIA AGRAM FO OR UNIT WITH W GPS ..................................... 23 F FIGURE 10.. INTERNA AL WIRING DIAGRAM FOR UNIT T WITH GPS ................................ 24 F FIGURE 11.. GPS FLAS SH RATE DIP D SWITC CH POSITIO ONS ............................................. 25 F FIGURE 12.. GPS POLE MOUNT (OPTIONA AL) ................................................................ 26 F FIGURE 13.. GPS UNIT T (OPTIONAL) ............................................................................... 27 F FIGURE 14.. FG3000B LIGHTING G SYSTEM SCHEMAT TIC DIAGRA AM.............................. 32 F FIGURE 15.. FG2000B LIGHTING G SYSTEM SCHEMAT TIC DIAGRA AM.............................. 33 F FIGURE 16.. FG3000B TRIGGER CONTROL L SWITCH SETTINGS S ................................. 35 F FIGURE 17.. FG2000B TRIGGER CONTROL L SWITCH SETTINGS S ................................. 35 F FIGURE 18.. FG2009B TRIGGER CONTROL L SWITCH SETTINGS S ................................. 35 F FIGURE 19.. SYNC/MO ONITOR SW WITCH SET TTINGS ........................................................ 36 F FIGURE 20.. FG3000B SYNC/MO ONITOR SW WITCH SET TTINGS ........................................ 37 F FIGURE 21.. FG2000B SYNC/MO ONITOR SW WITCH SET TTINGS ........................................ 37 F FIGURE 22.. FG2009B SYNC/MO ONITOR SW WITCH SET TTINGS ........................................ 37 F FIGURE 23.. GPS SYNC SWITCH H SETTING GS .................................................................. 38 F FIGURE 24.. FLASHTU UBE ASSEM MBLY WITH H FERRITE E BEADS ..................................... 52 F FIGURE 25.. ATTACHM MENT OF FERRITE F B BEADS WIT TH QUICK--ON CONN NECTIONS . 52 F FIGURE 26.. FLASHTU UBE INSER RTION............................................................................ 53 LIST OF O TABL LES TABLE 1. T T TABLE 2. T TABLE 3. T TABLE 4. T TABLE 5. T TABLE 6. T TABLE 7. T TABLE 8. LIMITATION L NS OF MAINTENANC CE .................................................................. 11 M MAINTENAN NCE WORK REQUIR REMENTS ..................................................... 11 E EQUIPMEN T SPECIFICATIONS ..................................................................... 12 L LED STATU US INDICAT TORS ............................................................................ 29 S SIDE LIGHT T ALARM MODULE M FA AULT INDICATORS..................................... 38 F FLASHHEA AD (STROBE) PROBLEMS CORR RECTIVE MAINTENA M ANCE.......... 41 M MULTIPLE STROBE S P PROBLEMS S CORREC CTIVE MAIN NTENANCE E ................ 46 S SIDE LIGHT T PROBLEM MS CORRE ECTIVE MA AINTENANCE ............................. 47 EPM00000002 2-001 iii Rev. D 1.0 SAFETY AND D GENERA AL INFOR RMATION N 1.1 Equipment Des scription pacitor disccharge, xen non flash strobe light system s The liighting systtem is a cap manu ufactured to o comply with Federal Aviation Ad dministratio on (FAA) Ad dvisory Circcular 150/5 5345-43E. Each E system m consists of an omni-directionall flashhead, associated power supply with integ grated controls, ambie ent light sen nsor (photoccell), and an interconn necting cable e. System componentss are shown n in Figuress 1, 2 and 3. 3 Modificatiions may be made to suit different applications a s. 1.2 Flash hheads 1.2.1 Single Le evel (Red orr Clear) The flashhead, Figure 1, consissts of one acrylic a lens assembly (red ( or clea ar) d base. Included within n the flashh head is the flashtube attached to a hinged y, an interlock switch, trigger t transsformer and the termin nal block where w the assembly interconnecting cable terminate es. el (Red and d Clear) 1.2.2 Dual Leve The flashhead, Figure 2, consissts of two acrylic a lens assembliess (red and clear) c attached to a hinged d base. Included within n the flashh head are the e two flashttube assemblie es (one for the red and d one for th he white), an interlock switch, two o trigger transform mer and the terminal block where the interconnecting ca able termina ates. er Supply 1.3 Powe The power p supp ply contains power con ntrol circuitss (relays, fu uses, switch hes) for both strobe and auxiliary a sid de lights, a high-voltag h e circuit (po ower transfformer, recttifiers, enerrgy storag ge capacito ors, discharrge circuits)), flash interval and tim ming circuitss, dual mon nitor circuits, intensity y selection controls, an nd a triggerr generator. Also attacched to (or remotely r locate ed from) the e power supply is the ambient light sensor (photocell). Optio onal items may m include e a Power Line L Filter and/or a alarm m lockout module m (K6-K7) depen nding on re equired systtem. Modifications ma ay be made to suit diffe erent appliccations. EPM00000002 2-001 4 Rev. D Figure 1. Single Level Flashhead EPM00000002 2-001 5 Rev. D Fig gure 2. Du ual Level Flashhead EPM00000002 2-001 6 Rev. D Figure 3. Lighting System Power Sup pply (su upplied powerr supply may be b different) EPM00000002 2-001 7 Rev. D 1.4 Safety Notice 1.4.1 Voltages The Indiv vidual contro ol cabinet contains c voltages of 1,000 VDC and a constitu utes a personne el safety hazzard. Perso onnel must observe sa afety regula ations at all times. 1.4.2 Interlocks s The Indiv vidual Contrrol Cabinet contains in nterlocks forr your prote ection. To ensure e safety, alw ways removve power frrom the equ uipment prior to opening any acccess panel or door. d Do no ot depend on o the interllocks or door switchess for person nnel protection n when worrking with th he equipme ent. Do not short-circuit or tamper with any acces ss gate, door, or otherr safety inte erlock switcch. Ground capacitors with a grounding g rod prior to t touching any compo onent. Whe en it is abso olutely mandatory that an interlock be bypassed b in n order to trace a faultt or correct a malfunction authorized maintena ance person nnel may pe erform the bypass for the specificc test to be perform med. 1.4.3 Keep Awa ay From Livve Circuits Operating g and mainttenance pe ersonnel mu ust observe e all safety regulations r at all times. Do o not change “Plug-In” componen nts or make adjustmen nts inside th he equipmen nt with the high h voltage e power control circuitts in the ON N position. Under U certain co onditions, dangerous voltage v pote entials mayy exist in cirrcuits with the Power Co ontrols in th he OFF possition due to o the charge es retained d by the flassh capacitors s. To avoid d casualtiess, always re emove the power, p wait one (1) minute, and then discharge the t flash ca apacitors, C1, C C2, and d C3, by tou uching a gro ounding rod to the e capacitor terminals, t p prior to toucching any component. c . 1.4.4 Resuscita ation Maintenance person nnel shall fa amiliarize th hemselves with w the tecchnique for o First Aid Instruction ns. resuscitattion found in manual on onary Notice e for Semicconductor and a Integratted Circuitss 1.4.5 Precautio This equipment conttains semicconductor devices / inttegrated circuits. Take e the necessary y ESD preccautions priior to attem mpting any service s work. EPM00000002 2-001 8 Rev. D 1.5 Safety Summarry The following f is s a summarry of warnin ngs containe ed within th his technica al manual: W WARNING! ! Thiis system us ses lethal volltages in botth the powerr supply and d the flashhe ead. Do not attempt a to se ervice or adju ust the equ uipment with h line power applied. Inte erlock switch hes are prov vided in both h the flashhea ad and pow wer supply enclosures e to o interrupt main m power to o the pow wer supply. These switch hes are activ vated when the t power sup pply door orr flashhead le ens assemblly is opened in a con nventional manner. m No in nterlock is prrovided whe en other me eans of acces ss are used. Never tampe er with (remo ove, short circ cuit) the inte erlocks in any y way. W WARNING Lin ne voltage is still presentt when interlo ocks are acttivated. Dis sconnect pow wer before in nspecting orr servicing W WARNING Ens sure that the e power is OF FF and the capacitor c ban nk has bee en discharge ed before op pening the fla ashhead. W WARNING Ins stalling contrrol boards th hat are incorrrectly config gured may cau use damage and system failure. W WARNING Letthal voltages s are presentt in the cond ductors betw ween the pow wer supply and a flashhea ad. There sho ould be one continuous c run n of cable fro om flashhead d to power su upply. Underr no circ cumstance should s these e conductors s be spliced. 1.6 Electtrostatic Dis scharge The componentts inside yo our system are a extremely sensitivve to static electricity, e a also know wn as electrrostatic disccharge (ES SD). Static electricity e ca an cause irrreparable damage d to yo our system; however, if you follow w these prevventative measures m and precautiions, you shou uld prevent such dama age. a) Static Ele ectricity Prevention: EPM00000002 2-001 9 Rev. D b) 1. We ear a groun nding wrist strap s (available at mosst electronic stores). 2. Turn off the system pow wer. 3. Un nplug all corrds from the e wall outle et. 4. Re emove the case c cover.. Static Ele ectricity Precautions: 1. If you're y repla acing or add ding parts, remove the e parts from m their antisstatic bags only when you are ready to usse them. Do not lay pa arts on the outside of antistatic bags since only o the insside provide es antistaticc protection. 2. Av void static-ccausing surffaces, such h as plastic and Styroffoam in you ur work are ea. 3. Alw ways hold cards c by the eir edges and a their me etal mountin ng bracket. Avoid tou uching com mponents on n the cards and the ed dge connectors that co onnect to expansion slo ots. 4. Ne ever slide ca ards or othe er parts ove er any surfa ace. 1.7 Powe er Tools an nd Hand To ools Prop per safety procedures shall s be observed whe en using po ower tools or o hand tools. 1.8 Main ntenance Ph hilosophy Docu umentation reflects ma aintenance philosophyy and suppo orts equipm ment to this extent. Funcctional theo ory of opera ation and flo ow-charts fo or field troubleshooting g support field main ntenance. Parts P listing reflect onlyy items thatt can be rem moved or re eplaced by field main ntenance pe ersonnel. Parts P and co omponents that are no ot suited forr field repairr or repla acement are e not includ ded in the te echnical ma anual. Refe er to Table 1 for a desccription of th he limitation n of mainte enance. Refe er to Table 2 for mainte enance worrk requirem ments and established e limitations for field and supplier. s EPM00000002 2-001 10 Rev. D Table e 1. Limita ations of Maintenanc M ce Field • Periodic check ks of equipme ent Performance. • V Visual inspections • C Cleaning of system elements • Servicing of sp pecified itemss • Assembly/suba A assembly rem moval and re eplacement. • Scheduled maintenance req quiring eq quipment disa assembly and d assembly (liimited to majo or assembliess and su ubassemblies s). S Supplier Comple ete overhaul, rebuilding, an nd perform mance testing of assemblie es, subassemblies, and component replacement. r Note:: Field maintenance is limited to removal r and replacement r of the followin ng items: M assembllies • Major • Predetermined d subassembllies d circuit card assemblies a • Predetermined • Fuses nterconnecting g cables • In • Bulbs ens covers • Le Table 2.. Maintena ance Work Requirem ments Crite eria Field Maintenance Supplier Main ntenance Done e where? At the operational siite or where ever the prime e equipmen nt is located d. Specialized re epair activity or manufactur m rer’s plant. Done e by whom m? System/e equipment operating o personne el. Supplier facilitty personne el or manufactur m rer’s pro oduction personnel. On whose w equip pment? Using org ganization’ss system. Equivalent Ho oneywell sysstem. Type e of work Visual insspection acco omplished? Operation nal checkou ut Minor serrvicing External adjustment a ts Removal and replaccement of some s compone ents. EPM00000002 2-001 11 Complicated factory f adjjustments. Complex equiipment rep pair and mo odifications.. Ovverhaul and rebuild Detailed calibration ntenance Sofftware main (de etailed modifications). Supply suppo ort Rev. D 1.9 Refe erence Data a Referr to Table 3 for a listing g of the equ uipment spe ecificationss. Table 3. Equip pment Spe ecifications s Item Specifica ation Light Outtput Day Intensity 20,0 000 ±25% effe ective candela as, single flassh Nightt Intensity 2,00 00 ±25% effecctive candelass, burst of flasshes Beam m Pattern 360ºº horizontally; 3º min. verticcally; Maximu um intensity of o 3% of peak @ –10° Flash h Rate Da ay 40 flashes per minute (FPM) - single white flash f Nig ght 20–4 40 FPM red flash burst Maste er/Slave Operation Up to o 4 slave unitts may share a common syync and photo ocell circuit Side Lights 1 to 4 type L-810 lights steadyy burn night on nly Electrical Input I Powe er Supply 120, 240, 480 VA AC 50 or 60 Hz Side Lights 1 to 4 type L-810,, 120V LED or o 116 W, 120 0 V incandesccent Me echanical Prroperties Flash hhead We eight 34 pounds p Dim mensions (inc ches) 16.5 5 wide X 23 hiigh Su urface area 1.98 8 ft/2 Wind Load 105 pounds @ 15 50 mph Powe er Supply We eight 65 pounds p Dim mensions (inc ches) 21 wide w X 16.5 hiigh 10.5 deep p Op perating Environment Temp perature –55ººC to +55ºC Humiidity 95% % relative Status Indic cators Neon n Lamps Pow wer line and hiigh voltage indicators LED Sync//Monitor PCB B Syncc out, master (red); fault re elay (green) Trigger Control PC CB Syncc line active (g green); red LED on (red) Fault Strrobe Rela ay closure, co ontact ratings 3 A @ 120 VAC V Inccandescent/LED Rela ay closure(s), contact rating gs 3 A @ 120 0 VAC EPM00000002 2-001 12 Rev. D Item Specificattion Electrical input GPS Inp put Power Fla ash Rate Settings Day Nite Nite Enable Input I Ca able Length (fe eet) 100–132 VAC/ 50 or 60 Hz, 10 watts Max F 40 FPM 24, 30, 40, 60 FP PM 100–132 VAC/ 50-60 Hz 25, 50, 100, 150,, 350 available Mec chanical Pro operties We eight Dim mensions (inc ches) 3.6 pounds 7.37 74 wide X 6.2 25 high Ope erating Environment Tem mperature Humidity –40ºC to +55ºC 95% % relative S Status Indica ators LED G Green Y Yellow R (Flashing Red g) EPM00000002 2-001 wer On Pow GPS S Lock Syn nc 13 Rev. D 2 2.0 INST TALLATIO ON 2.1 Unpa acking Care efully unpac ck each item m and remo ove any inte ernal packin ng material from the power supp ply and flash hhead. Exa amine each item for ob bvious physsical damag ge. Report any a claim ms to the ca arrier immed diately. Perrtinent data such as installation drawings, sche ematics, inte erconnectio on drawingss, and operration manu uals are included in the e power supp ply carton. The T flashtub be is packa aged inside the flashhe ead. 2.2 Moun nting and Preparation P 2.2.1 General Th his section contains c de etailed draw wings for mo ounting the flashhead and power supplyy. See Figurres 4, 5 and d 6. S Flasshhead 2.2.2 Lighting System No ormally the flashhead is i mounted at the uppermost poin nt on the sttructure. It must m be mo ounted leve el to assure proper ligh ht output. 2.2 2.2.1 Insta allation Reccommendations for AM M Towers Fo or AM towerrs, an isolattion device must be ussed for the tower lighting sys stem. There e are three options avvailable: Iso olation transsformer, tow wer ligh hting choke es, and cusstom isolatio on inductors. Fo or mechaniccal incandescent red lighting conttrols, isolatiion transforrmers and tower ligh hting choke es provide a reliable means m of supplying AC C power wers, an isolation transsformer to the tower liighting conttrol. For some AM tow ay be the be etter choice e as they prrovide high RF impeda ance betwe een ma tow wer and gro ound. With either of the ese devices, the tower lighting co ontrol is mo ounted to th he tower. If possible, th he lighting control sho ould not be located at a high RF current c poin nt. Isolation n transforme ers and tow wer lighting chokes are e not recom mmended fo or solid-statte red lighting controlss or for strob be ligh hting system ms. Cu ustom isolattion inducto ors are the preferred choice c for so olid-state re ed ligh hting contro ols and stro obe lighting systems. Custom C isolation inducctors pro ovide isolattion betwee en the tower lighting co ontrol/powe er supply an nd the tow wer lighting fixtures. The conducttors betwee en the tower lighting fixxtures and the lightin ng controls are would through a copper c indu uctor, allowing the ligh hting contro ol/power su upply to be mounted att ground po otential. Use e of the Cu ustom Isolattion Inducto or provides several ad dvantages: The lighting g controls or strrobe powerr supplies are a kept outt of the RF field, f and can c be orked on witthout shuttiing down th he transmittter. Also, th he lighting alarm a wo contacts are easily e available for rem mote monito oring. EPM00000002 2-001 14 Rev. D Figure 4. Single Leve el Flashhea ad Outline Drawing EPM00000002 2-001 15 Rev. D Figure 5. Dual Level Flashhead d Outline Drawing EPM00000002 2-001 16 Rev. D HUGHEY & PHILLIPS Figurre 6. Lighting System m Power Supply Outlline Drawin ng EPM00000002 2-001 17 Rev. D Fo or any lightin ng system on o AM towe ers, the ligh hting condu uctors or ca ables sho ould be installed in ga alvanized stteel conduitt. The cond duit system should be bonded to each towe er section with w a bondin ng strap. If the tower is painted, the paint p should d be scrape ed off before e installing the bonding kits. Aftter pulling the wires through the conduit c system, an inssulation testt using a me egger should be performed betwe een every conductor-t c o-conducto or, and between everry conducto or-to-conduit system. Installation Recommen ndations forr FM towerss: ARNING WA Lethal volttages are pre esent in the conductors c b between the power supply and flashhead. f Th here should be one contiinuous run of o cable from m flashhead to t power supply y. Under no circumstance c e should the ese conducto ors be spliced. Fo or strobe lighting systems on FM towers, t carre should be e taken nott to expose strobe e cable to high h FM RF F fields. Gen nerally this is done by running e strobe cab ble in conduit through the aperture of the FM M antenna. Conduit the sho ould be installed from 15 feet bellow the botttom bay of the FM anttenna to 15 feet above e the top ba ay. The conduit should d be bonded d to the tow wer using a bonding b kit every 5 fee et. If the tow wer is painted, the pain nt should be scrraped off be efore installing the bon nding kit. 2.2.3 Lighting System S Pow wer Supply Th he power su upply is con nnected to its flashhea ad via the ca able provided by Ho oneywell. Th he length of o this cable e determine es how far frrom the flasshhead the e power sup pply can be e mounted. Th he user should determine that the e power line e voltage se elector, loca ated on the e transformer board inside the po ower supplyy enclosure is set to th he main voltage being g used. L Senso or 2.2.4 Ambient Light Th he ambient light sensor, when sup pplied with the system m, should be e mo ounted upright, away from f artificia al light (e.g., floodlightts), and in a loc cation that will w enable its sensor window w to have h an uno obstructed view of the e polar sky (e.g., pointted north in the Northe ern Hemisphere). Typ pical ins stallation is done by ussing ½” rigid d conduit and #14-AW WG wire to remotely r mo ount the photocell. EPM00000002 2-001 18 Rev. D 2.3 Insta allation Wiring Perfo orm the following proccedures for installing in nterconnectting wiring (see ( Figure e 7 for stand d-alone installation and Figure 8 for master//slave insta allation): a) Conne ect all wiring between the flashhe ead and the e power sup pply using Honey ywell suppliied cable P/N P *77-4017-4. The wires w in this cable are color c coded d and conne ect to the numbered te erminals of flashhead TB1 T corressponding numbe ered termin nals of the power p supp ply TB2. b) Conne ect all wiring that intercconnects between the e steady burning red side lights and po ower supplyy using the e Honeywell supplied cable c WC23 3012CL0T or WC23 3012DL0T or o equivalen nt #12 AWG G cord (colo or coding may m be diffe erent than liisted below w). The wire es in this cable are con nnected to the t numberred termin nals of TB1 as follows:: 1. Black Wire e of Cable to t TB1-11, 120VAC Liine out to Sidelight S Level 1 2. Orange Wire W of Cable to TB1-12 2, 120VAC Line out to o Sidelight Level L 2 3. Red Wire of Cable to o TB1-10, Neutral N return from Sid delight Leve el(s) 4. Blue Wire of Cable to o TB1-Grou und Lug c) Conne ect wiring between b the e external photocell p an nd the powe er supply ussing #12 AWG wire. The wires w in thiss cable are connected from TB1, as follows: 1. Black wire e of the pho otocell to TB B1-2 2. Red wire of o the photo ocell to TB1 1-1 3. White wire e of the pho otocell to TB B1-Ground lug he wiring be etween the master d) For structures with 2 or morre systems,, connect th powerr supply and d slave pow wer supply using Hone eywell cable e *77-4231. This cable has a total of 10 cond ductors and can be use ed to distrib bute power and timing g pulses and d consolida ates alarm functions f to o and from slave s powe er supplies. For dettails consultt Honeywelll Tech Sup pport at 805 5-581-5593. EPM00000002 2-001 19 Rev. D 2.4 GPS S Sync Wirin ng (OPTION NAL) Perfo orm the following proccedures for installing in nterconnectting wiring (see ( Figure e 9 for Syste em installattion and Fig gure 10 for Power Sup pply interna al GPS wirin ng installation): a) Conne ect all wiring between the flashhe ead and the e power sup pply using Honey ywell suppliied cable P/N P *77-4017-4. The wires w in this cable are color c coded d and conne ect to the numbered te erminals of flashhead TB1 T corressponding numbe ered termin nals of the power p supp ply TB2. b) Conne ect all wiring that intercconnects between the e steady burning red side lights and po ower supplyy using the e Honeywell supplied cable c WC23 3012CL0T or WC23 3012DL0T or o equivalen nt #12 AWG G cord (colo or coding may m be diffe erent than liisted below w). The wire es in this cable are con nnected to the t numberred termin nals of TB1 as follows:: 1. Black Wire e of Cable to t TB1-11, 120VAC Liine out to Sidelight S Level 1 2. Orange Wire W of Cable to TB1-12 2, 120VAC Line out to o Sidelight Level L 2 3. Red Wire of Cable to o TB1-10, Neutral N return from Sid delight Leve el(s) 4. Blue Wire of Cable to o TB1-Grou und Lug c) Conne ect all wiring between the GPS Sync S and the e power supply using Honey ywell suppliied cable P/N P 4000207 74-( ) for GPS G connecctor location n (see Figure e 6). 2.5 GPS S Sync Insta allation (OP PTIONAL) The GPS (part number 400 002075) un nit should be mounted outdoors with w a clear view of the South S sky. A 25 to 350 0-feet GPS cable can be b ordered as needed d. Nearby obstrructions to the South should s be avoided. a Th he unit shou uld be moun nted on a flat verticcal surface or a pole (ssee Figure 12). h S1-4 on th he Sync/Mo onitor Boarrd should be e in the ON N (slave) po osition for a) Switch all GP PS-controlle ed units. b) Typica ally requiress one of the e following photocells (sold separrately). Imp portant: If photoc cell is not re equired, so ocket cover must be left in place to t prevent water w entry into i GPS unit. 1. Photocell 77-3258-00 01 (for Red Beacons, 35–58 fc) 2. Photocell 77-3759-00 01 (for Whitte or Dual Beacons, B 1–3 fc) EPM00000002 2-001 20 Rev. D W WARNING Lethal high h voltages are present in the e conducto ors betwee en the pow wer supply y and the fllashhead. There should be one e continuo ous run of cable from m flashhea ad to power supply. Under U no circumstan c nces shoulld these co onductors be spliced d. Fig gure 7. Sys stem Wiring g Diagram EPM00000002 2-001 21 Rev. D W WARNING Lethal high h voltages are present in the e conducto ors betwee en the pow wer supply y and the fllashhead. There should be one e continuo ous run of cable from m flashhea ad to power supply. Under U no circumstan c nces shoulld these co onductors be spliced d. Figurre 8. Syste em Wiring Diagram fo or Master / Slave Uniits EPM00000002 2-001 22 Rev. D Fig gure 9. Sys stem Wirin ng Diagram m for Units with GPS EPM00000002 2-001 23 Rev. D Fig gure 10. In nternal Wiriing Diagra am for Unit with GPS EPM00000002 2-001 24 Rev. D Figure 11. GPS Flash h Rate Dip p Switch Po ositions EPM00000002 2-001 25 Rev. D Figure e 12. GPS Pole Mount (Optional) EPM00000002 2-001 26 Rev. D Figure 13. GPS G Unit (O Optional) 2.6 Finall Check Before applying g power to the t equipment, check all relays and a printed circuit boarrds (PCB Bs) to ensure that theyy are properly seated in i their sockets. Checkk to ensure e that any user--installed wiring w does not interferre with relayy operation when cove ers are clossed. EPM00000002 2-001 27 Rev. D 3 3.0 OPE ERATION 3.1 Gene eral This section pro ovides inforrmation for operating the lighting system durring normall operating conditions. 3.2 Operrating Proce edures Afterr the system m has been wired acco ording to the instructio ons in Sectio on 3, it is re eady for norm mal operatio on. The flasshhead asse embly shou uld be close ed and secu ured. When n the cove er of the pow wer supply is closed so that the in nterlock sw witch is enga aged and power p is appliied, the sys stem will be egin to operrate. If there e is sufficient light and d the ambient light senssor is mounted correctly, the syste em will auto omatically switch s to the correct mode m after a 1 to 2 minute delay. The delayy protects against a unw warranted sw witching du ue to mom mentary cha anges in the e light reach hing the sen nsor. If a GPS G sync un nit is used the t GPS syncc indicator should s begin flashing at a power-up p, but allow 20 minutess for full syn nc operation. The built-in ante enna requirres clear vie ew of the so outh horizo on (in the no orthern p to 5 degre ees elevatio on (position the antenn na straight up). u hemiisphere) up 3.3 Statu us Indicatorrs Refe er to Table 4 LED statu us indicatorrs. EPM00000002 2-001 28 Rev. D Ta able 4. LED D Status In ndicators Indic cator D Description n C Control pow wer ON Located on the contrrol panel (top p center), this indicator is illuminate ed wheneverr input powe er is present and a the power supply intterlock switcch is engaged. H High Voltage e Neon Lam mp Located on the high voltage circu uit (top) board, this lamp indiicates that th he high volta age circuits are a active. ould be used if the neon lamp is Extreme caution sho on. F Flashhead A Alarm Status s LED Located on the sync//monitor (middle) board,, this LED will be green wh hen the flash hhead is ope erating correctly. If the LED D is off, the system is in alarm mode e. S Sync Out LE ED Located on the sync//monitor (middle) board,, this LED blinkks red to ind dicate that a sync signal has been gen nerated. In a multiple flashhea ad system, only o the sync/mon nitor board that is set ass the master will blink this LED S Sync In LED D Located on the trigge er/control (bo ottom) board d, this LED blinkks green to indicate thatt a sync sign nal has been recceived from the t sync/monitor board. F Flashtube Status LED Located on the trigge er/control (bo ottom) board d, this LED is re ed if the red flashtubes are a in operattion. If the whiite flashtube es are being used, the LE ED is off. S Side light Fa ailure LED(s) Located on the alarm m card (AC) inside the lid d of power su upply, these LEDs turn red to indicatte a side light lamp p failure. This LED D is green wh hen the side elights are op perating properly. LED2 will be b lit RED du uring night operation ght level is in use. when onlly one sidelig Located on the botto om of the GP PS sync unit (Refer to Figure e 13), this LE ED will turn green g when power is on. om of the GP PS sync unit (Refer Located on the botto e 13), this LE ED will turn yellow y when unit has to Figure locked on nto a satellitte signal. Located on the botto om of the GP PS sync unit (Refer e 13), This LE ED will flash h red with ea ach sync to Figure pulse. G GPS SYNC Green LED G GPS SYNC Yellow LED D G GPS SYNC Red LED EPM00000002 2-001 29 Rev. D 4 4.0 FUNCTIONAL L DESCR RIPTION 4.1 Gene eral The purpose p of Section S 5 iss to provide e a general overall desscription of how the eq quipment comp ponents function with relation r to each e other (equipment ( t as a whole e) and funcctional descrription of ho ow individua al units or subassemb s blies of the equipment e function. 4.2 Majo or Assemblies The AC A main po ower input to the powe er supply is converted to approxim mately 1,00 00 VDC to bia as the flashttubes in the e flashhead d and to cha arge the en nergy storag ge capacito ors. The ambie ent light sen nsor sends correct control signals to the pow wer supply to automattically chang ge the inten nsity of the flashhead and a controll the red inccandescentt side lightss. The main m powerr to the pow wer supply is applied to o the contro ol and logicc circuitry, th hereby activa ating relays s that determ mine the inttensity of th he flashhea ad. Logic cirrcuits in the e power supply generate a timing signal that co ontrols the rate of flash. The GPS S sync sign nal disab bles the inte ernal clock circuit. c The flash occurs at the sa ame time ass the sync signal. s Test switch s located on the switch pane el allows th he system to o operate in n either dayy or night mode. This s switch sho ould be leftt in the AUT TO position for photocell operatio on. 4.3 Funcctional Desc cription of Subsystems S s 4.3.1 Lighting System S Flasshhead and d Power Su upply Th he main AC input powe er is transfo ormed to hig gh voltage DC and sto ored in capacitors. Th he trigger circuit c fires the t flashtub be, in paralllel with the capacitors. Th his discharg ges the cap pacitors, pro oducing a flash f of light. Ch hanging the e capacity fo or energy stored s between flashess varies the e intensity of the light. The e flashtube extinguishe es when cu urrent from the t t low to support s the arc. The power supplly short circcuit capacitors is too ube currentt to preventt continuouss current is set below the minimum tu T capacito ors then reccharge for the t next fla ash. conduction. The put power iss applied to o the primarry of the ferrroresonantt power tran nsformer Inp (T1 1) when the e flashhead d and coverr interlocks are closed. The high voltage v output of T1 is rectified and a charges the energ gy storage capacitors. c In the day mo ode, normall operation has the interlock relayy (K1) enerrgized hile the day//night relayy K2 is de-e energized. Capacitors C C2 and C3 in the wh hig gh voltage circuit c are kept k charge ed. With thiss amount off capacitance in the circuit and DC C voltage provided, su ufficient ene ergy is disch harged thro ough shtube to produce p an effective in ntensity of 20,000 2 cand delas ( ±25%). flas In the night mode m (low in ntensity), 12 20 VAC is supplied s fro om the phottocell o the power supply (on n TB1-1) an nd to the da ay/night rela ay (K2). and applied to Wh hen K2 is energized, e itts contacts will remove e C2 from the t high-energy circuit and disscharge it th hrough R2 and R4. No ow only C3, with R3 in n series, EPM00000002 2-001 30 Rev. D is in i the tube circuit. Thiss provides the t energy required to o produce th he efffective inten nsity of app proximately 2000 cand delas. Conccurrently, 12 20 VAC Figurre 14. FG30 000B Lightting System m Schema atic Diagram EPM00000002 2-001 31 Rev. D Figurre 15. FG20 000B Lightting System m Schema atic Diagram EPM00000002 2-001 32 Rev. D is applied a to pin p 8 of the trigger con ntrol PCB, switching s lo ogic from sin ngle sho ot to burst mode. m The AC voltage e is also ap pplied to pin n 32 of the syn nc/monitor PCB, estab blishing the e number off red FPM. 4.3.2 Side Ligh hts Th he AC night control voltage at TB1 1-1 operate es a red ligh ht control module m consisting of a SPDT rellay and an alarm card. These com mponents power p and monitor any a red obsstruction lights used in conjunction with the lighting sys stem, indica ating the lo oss of any in ncandescen nt bulb or LED L fixture. The mo odule will co ontrol up to o two levels of four 120 0 V steady burning sid delights. 4.3.3 High Voltage PCB Th he high volta age PCB co onsists of a three-diod de-per-leg bridge b and two t 3dio ode circuits. High volta age AC from m the powe er transform mer is provid ded to the e HV PCB connector. c This high AC A voltage is full wave e bridge recctified by the e bridge. Ne eon lamp, LP1, L lights whenever w h high voltage e is present. 4.3.4 Trigger Control C PCB B Th he function of o the Trigg ger Control PCB is to provide p a syynchronized trigger pulse to the primary p of a trigger tran nsformer lo ocated in the flashhead d. A sin ngle pulse in n the day mode m and a burst in the night mod de. DIP switches sett the burst flashes f individually forr red, SW1,, and white operation, SW2. EPM00000002 2-001 33 Rev. D SW W1 1 2 3 4 5 OFF 0 0 0 0 0 ON 1 2 4 8 16 SW W2 1 2 3 4 5 6 0 32 6 OF FF ON 0 1 0 2 0 4 0 8 able E Enable Disa Day Mode M Da ay Mode Not Use ed - settingss per shaded areas a Fig gure 16. FG G3000B Trigger Conttrol Switch h Settings W1 SW 1 2 3 4 5 OFF 0 0 0 0 0 ON 1 2 4 8 16 SW W2 1 2 3 4 5 6 0 32 6 OF FF ON 0 1 0 2 0 4 0 8 able E Enable Disa Day Mode M Da ay Mode Not Use ed - settingss per shaded areas a Fig gure 17. FG G2000B Trigger Conttrol Switch h Settings SW W1 1 2 3 4 5 OFF 0 0 0 0 0 ON 1 2 4 8 16 SW W2 1 2 3 4 5 6 0 32 6 OF FF ON 0 1 0 2 0 4 0 8 Disa able E Enable Day Mode M Da ay Mode Not Use ed - settingss per shaded areas a Fig gure 18. FG G2009B Trigger Conttrol Switch h Settings EPM00000002 2-001 34 Rev. D 4.3.5 Sync/Mon nitor PCB The functtion of the Sync/Monito S or Board is to generate a sync pu ulse for the trigger control bo oard; to sele ect AC 50 or o 60 Hz orr DC input power, p masster or slave e operation n; and to detect faulty operation o o the lightin of ng system such s as misssing or out of syn nc flashes. The Day Mode flash h rate is set at 40 FPM per FAA re equirementts and cann not be changed. The Nite Mode flash h rate can be b adjusted between 20–40 FPM per FAA requireme ents. Switch h S2 allowss for field ad djustment of o the nite fllash rate. See S Figure 19 9 for switch settings. Field adju ustment can n also be made m at Swiitch S1 for the t followin ng: • AC or DC voltage • 50 Hz or 60 6 Hz • Night Ligh ht (White orr Red) • Master or Slave hes per min nute (FPM)) for the re ed night sysstem can be b field adjusted by The flash setting S2 2 to equal the numberr in the FPM M table: Flashes Per Minutte F FPM Power Line Freq q. Hz DC 50 60 20 125 125 150 30 100 100 120 40 4 7 75 7 75 9 90 Figure 19. Sync/M Monitor Sw witch Settin ngs The switc ch settings shown in Figures F 20,, 21, and 22 2 represen nt the units with the following characterisstics Inp put Phase – AC A Inp put Frequencyy – 60 Hz Sta and-alone (i.e. Master) Same uniits may havve different settings. If the your model m does not match the t units shown he ere, please contact Ho oneywell Te echnical Support at 805-581-5591 1 for specific switch settin ngs. EPM00000002 2-001 35 Rev. D S1 1 2 3 4 OF FF AC C 50 Hz H White Light @ Night Master Syync Card ON O D DC 60 0 Hz Red Ligh ht @ Night Slave Sync Card S2 OFF ON 0 1 1 0 2 2 0 4 3 0 8 4 0 16 5 0 32 6 0 64 7 0 128 8 - settingss per shaded areas a Figure 20. FG3000B F S Sync/Monit tor Switch Settings S1 1 2 3 4 OF FF AC C 50 Hz H White Light @ Night Master Syync Card ON O D DC 60 0 Hz Red Ligh ht @ Night Slave Sync Card S2 OFF ON 0 1 1 0 2 2 0 4 3 0 8 4 0 16 5 0 32 6 0 64 7 0 128 8 - settingss per shaded areas a F S Sync/Monit tor Switch Settings Figure 21. FG2000B S1 1 2 3 4 OF FF AC C 50 Hz H White Light @ Night Master Syync Card S2 1 2 3 4 5 6 7 8 OFF 0 0 0 0 0 0 0 0 ON O D DC 60 0 Hz Red Ligh ht @ Night Slave Sync Card ON 1 2 4 8 16 32 64 128 - settingss per shaded areas a Figure 22. FG2009B F S Sync/Monit tor Switch Settings EPM00000002 2-001 36 Rev. D 4.4 GPS S SYNC The function f of the GPS syync is to ge enerate a syync pulse fo or the trigge er control board. b The Day Mode flash rate iss set at 40 FPM per FA AA requirements and cannot be chan nged. The Nite Mode flash rate can c be set for f 24, 30, 40 4 or 60 FP PM. Switch S1 on the GPS G unit allow ws for field adjustment a of the nigh ht flash rate. See Figurre 11 for sw witch positio ons and Figurre 23 for the flash rate e settings. GPS UN NIT S1 0 = Open 1 = Closed FPM 0 0 24 0 1 30 1 0 40 1 1 60 Figurre 23. GPS Sync Swittch Setting gs • h S1-4 on th he Sync/Mo onitor Boarrd should be e in the ON N (slave) po osition for Switch all GP PS-controlle ed units. 4.5 Syste em Failure (Alarms) 4.5.1 Strobe Fa ailure Fail detec ction during g the day op peration causes fault relay r K1 on the Sync/M Monitor board to open o 10 seconds afterr the last no ormal flash. Occasiona al missed fllashes will go un ndetected. The T fault relay closes whenever w n normal operation is resstored (a go condition). ction during g night operration in add dition to op pening the fault f relay (ffail Fail detec condition)), establishes operatin ng condition ns for white/night flash htube opera ation. White/nig ght operation only occu urs whenevver red operration fails, and beginss 10 seconds after a the lasst flash of the red lamp p. The presset white/nig ght flashing g conditions s are: 40 FPM giving an a equivale ent light outtput of 2,000 candelass. Operation n in this mo ode continue es until dayy mode is called c for, orr power is interrupte ed. When da ay operatio on is called for by the photocell, p th he fail detecction system ve erifies proper day operation, clossing the fail relay K1. A test buttton switch is located on o the top edge e of the PCB. Thiss switch gro ounds out the flash signal when n held close ed, thus sim mulating fla ash failure. To T operate, hold ed for longe er than 10 seconds. the test button close ole double-tthrow relay contacts are available e (12E0004 45-002) for Single-po closed whiile TB1-6 monitoring. Continuity between n TB1-7 and d TB1-8 is maintained m o as a go g condition n. Continuityy between TB1-6 and 8 represen nts a and 8 is open fault cond dition, while e TB1-7 and d 8 is open.. EPM00000002 2-001 37 Rev. D 4.5.2 Alarm Ca ard (AC) The side light alarm provides fa ault indicato ors when on ne or more incandesce ent lamps or LED fixture es fail. Whe en a lamp fa ails, a decre ease in currrent is senssed and m card transfers to the alarm mode e. This is re eflected in two t ways. The T red the alarm LED lights s and the re elay transfe ers to provid de an open n circuit betw ween the common c (wiper) an nd the norm mally closed d contacts and a a close ed circuit be etween the wiper and the normally n ope en contact. Replacement of a failed lamp re esets the ala arm output an nd extinguisshes the LE ED. During the t day mode when th he red lightss are not on, the module m doess not report an alarm. STATUS ODE MO DAY D NIGHT O OK AL LARM RELAY1 C C1-NC1 C1 1-NO1 LED D1 G GREEN RE ED RELAY2 C C1-NC1 C1 1-NO1 LED D2 G GREEN RE ED RE ELAY1 C C1-NC1 C1 1-NO1 LED D1 G GREEN RE ED RE ELAY2 C C1-NC1 C1 1-NO1 LED D2 G GREEN RE ED ( (RED IF UNUSED D) Ta able 5. Sid de Light Allarm Modu ule Fault In ndicators EPM00000002 2-001 38 Rev. D 5 5.0 TRO OUBLESH HOOTING AND CO ORRECTIV VE MAINT TENANCE E 5.1 Gene eral The purpose p of Section S 6 iss to provide e procedure es that enab ble the trou ubleshooterr to isolate and corre ect the causses of malfunctions. Such S correcctive action may be in the t form of an immediate fix of a pro oblem or ma ay direct the troublesh hooter to a corrective c mainttenance pro ocedure forr adjustmen nt or repair. 5.2 Toolss Required • Flat head d screwdrivver • 5/16 nut driver to op pen flashhe ead • oves to use e when changing flash htubes Clean glo • Digital multimeter m w Ohm read w/ ding and 50 00 VDC cap pacity • NE2 neo on light, HO ONEYWELL L part numb ber *77-2342 • Short pie ece of wire for jumper (Approx. #1 12 wire gau uge) g Procedure es and Tab bles 5.3 Troubleshooting Logicc diagrams direct main ntenance personnel to o associated d tables listting the malfu unction, tes st, and corre ective main ntenance acction to perrform. EPM00000002 2-001 39 Rev. D 5.4 Flash hhead (Stro obe) Proble ems Logic Diagram D Utilizze the follow wing logic diagram d to determine d t most co the orrect coursse of mainte enance actio on to perform m to trouble eshoot the flashhead when w strobe problemss occur. Utillize Table e 6 in conju unction with h the logic diagram. d EPM00000002 2-001 40 Rev. D Table 6. Flashhea ad (Strobe)) Problems s Correctiv ve Maintenance Malfunction T Test Corrective Action S Section 1 Flashhead does d not operate o in any a mode, no LEDs on. o In nput power incorrect. Me easure inpu ut power – it sh hould be witth ±10% of req quired volta age. Sup pply correct input pow wer. Power supply interlock P sw witch not engaged. Prress the pow wer supply intterlock switch and hold d it do own. Clo ose the unit – the syste em sho ould operate e properly. Blown F1 (6 Amp) fuse B e, or trransformer (630mA) fu use. Re emove all th hree PCBs and ch heck for dam mage. Rem move the e photocell wiring from m TB B1-1 and TB B1-2. Perfo orm fla ashhead iso olation test and ch heck for imp proper ressistances. Leave L the fla ashhead cable dissconnected d, replace th he fusse and app ply power. Re eplace the strobe s cable, the e photocell wiring, and d the PC CBs one byy one to de etermine wh hich one will blo ow the fuse e. Rep place the defective com mponent. Section 2 S Flashhea ad does no ot operate in any mod de, controll power ind dicator on,, high-voltage neon lam mp off. Flashhead in F nterlock sw witch not engaged d. Re emove the flashhead f w wires TB B2-5 and TB B2-6 (gray and wh hite), and measure m ressistance be etween them m - it sh hould be lesss than 5Ω. Re--seat the fla ashhead co over, making sure th he interlockk swiitch engage es when the e covver is closed d. If the sysstem stilll does not have h continuity bettween TB2--5 and TB2--6, rep place the fla ashhead inte erlock switcch and inspe ect the strobe cab ble for dama age. R Relay K1 no ot energizing. When the inte erlock switcches are e engaged,, the K1 rela ay sh hould energize. If not, me easure for 120 1 VAC accross the e relay coil.. Alternative ely, rem move the connectors c a and ch heck resista ance acrosss the K1 1 coil – it sh hould be 30 00Ω. Rep place the K1 K relay. EPM00000002 2-001 41 Rev. D F Faulty high-vvoltage PCB. Vissually checck the traces on the e high-volta age PCB. Check C forr any shorte ed diodes. Use dio ode check function f on mu ultimeter if available. place the high-voltage e Rep PCB. Section 3 S Flashhea ad does no ot operate in any mod de, controll power ind dicator on,, high-voltage neon lam mp on. Trigger control PCB T defective or incorrect DIP D sw witch settin ng. Pe erform flash hhead isolation tesst and powe er supply iso olation test.. Compare trig gger PCB DIP D switch se ettings with default setttings in technical manual. m Sett DIP switch hes according to specificatio s ns. If no trig gger is observed o when perform ming Trig gger Test, replace r the trigger control PCB. In nsufficient trigger t volta age to th he flashhea ad. If tower t heigh ht is greaterr than Lea ave the con nnector at E14. E 34 40 feet, rem move the co onnector at terminal E1 13 on the e motherbo oard, and co onnect it to E14. This will w bo oost the volttage to the fla ashhead by approxima ately 10 0%. Section 4 S Flashhea ad operates s properly y in day mo ode, but at night goes s into whitte b backup night mode an nd trips the strobe alarm. Red flashtub R be/ red trigg ger trransformer faulty. Sw wap the wirres between n TB B2-3 and TB B2-4. Put th he un nit in night mode. m Affter this testt return the wires to their original ositions. po If system flash hes red nigh ht mode through the white h the strobe e flasshtube, with alarm off, replace the red d flasshtube and//or red trigg ger tran nsformer. Green G LED on Syn nc Board = ON T Trigger control PCB fau ulty. Pe erform powe er supply iso olation test to check fo or trig gger pulsess. Rep place the trrigger contrrol PCB. D Diode PCB DB1 D faulty. Re emove the two t mounting sccrews on the e control pa anel. Disconnect DB1, D and me easure resistance both h wa ays across each diode e. Ma ake sure no o diodes ha ave sh horts. If shorted, DB1 iss fau ulty. Note: The diode PCB DB B1 is locate ed under the e co ontrol panel where the test sw witches are.. place DB1. Rep Section 5 S Flashhea ad operates s properly y in night mode, m strob be alarm is s off. No fla ash in n day mode e, strobe alarm a is on n. EPM00000002 2-001 42 Rev. D Day Enable switch SW D W2-5 on Se et SW2-5 on the trigge er th he trigger co ontrol PCB set to co ontrol PCB to t ON, then n test O OFF. the e unit in day mode. ave SW2-5 ON. Lea White flashtu W ube and/or white trrigger transformer faulty. Sw wap the wirres on TB2--3 an nd TB2-4 Pu ut the unit in day mo ode. Affter perform ming this tesst retturn the wirres to their oriiginal positiion. hes day mo ode If system flash ough the re ed flashtube e, thro with h the strobe e alarm off, rep place the wh hite flashtub be and d / or white trigger tran nsformer. Green G LED on Syn nc Board = ON. T Trigger control PCB fau ulty. Pe erform powe er supply iso olation test to check fo or trig gger pulsess. place the trrigger contrrol Rep PCB if test faills. D Diode PCB DB1 D faulty. Re emove the two t mounting sccrews on the e control pa anel. Disconnect DB1, D and me easure resistance acro oss ea ach diode. Replace R DB B1 if an ny diodes ha ave shorted d. No ote: The dio ode PCB DB1 is loccated under the contro ol pa anel where the test sw witches are.. place DB1. Rep S Section 6 System S willl not switch h between day and night n mode es correctly y. Mode switch M hes in wrong position. EPM00000002 2-001 Pu ut rocker sw witch (S2) in n Au uto position. Illuminate e the ph hotocell for a minute orr so to approxima ate daytime onditions. The system co sh hould go into o day mode e. Co over the photocell with ha thiick, dark, opaque mate erial, to approxima ate nighttime e co onditions. Wait W for a minute or so. The syystem shoulld go intto night mode. If the syystem does not respon nd co orrectly to th he photocelll, try ch hanging modes by usin ng the e rocker sw witch on the e co ontrol panel. 43 If th he system responds r to o the swiitch change es, but not to t the photocell, replace the e pho otocell. Rev. D K2 mode relay K ng. m malfunctioni Se et the day mode m switch h to Re emote, nigh ht mode to Test. T Th he K2 relay should en nergize. If not, measurre for 12 20 VAC acro oss the rela ay co oil. Alternatively, removve the e connectors and checck ressistance accross the K2 2 coil – iti should be e at 300Ω. Rep place the K2 K relay. Section 7 S System operates o properly in day mode, but at nig ght goes in nto white b backup night mode, no n strobe alarm. a Sync PCB switch S1-3 set to S w white night mode m – OFF position. Se et S1-3 to re ed night mo ode – ON position. p Section 8. Flashhead S d flashing slow s (<20 FPM), F in ba ackup mod de at night, and strob be alarm on. Not configurred or defec N ctive syync monitor PCB. En nsure the DIP D switchess on the e sync mon nitor PCB are se et correctly per the manual. Vissually verifyy that the re ed LE ED on the sync s monito or PC CB is pulsin ng at 40 FP PM. If th he DIP swittch settingss are corrrect, and th he red LED is nott pulsing at 40 FPM, rep place the syync monitorr PCB. Current sensse transform C mer w wires are cro ossed, or current se ense transfformer is defective. Th he brown wire should co onnect to the capacitorr side of the currentt sense tra ansformer, the t purple wire w tow wards TB2.. he transform mer wires are a If th corrrect, replacce the curre ent sen nse transforrmer. D Defective GP PS Sync un nit Sw wap with a known good unit Rep place the GPS G sync unit. S Section 9 Night N mode e very brigh ht, red, no alarms. R Relay K2 op pen. EPM00000002 2-001 Pu ut the syste em in night mo ode. Checkk for 120 VA AC accross the co oil of the K2 2 rellay. Alterna atively, remo ove the e connectors and checck ressistance accross the K2 2 coil – iti should be e @ 300Ω. 44 Rep place the K2 K relay. Rev. D 5.5 Multiiple Strobe Problems Logic L Diagrram Utilize e the follow wing logic diiagram to determine d th he most corrrect course e of mainte enance action n to perform m and to tro oubleshoot the flashhe ead when multiple m stro obe problem ms occur. Utilize e Table 7 and a the secttion listed in n the logic diagram. d EPM00000002 2-001 45 Rev. D Table 7. Multiple Strobe Problems P C Corrective Maintenan nce Malfunction T Test Corrective Action Section 1 S Flashhea ads are ope erating, bu ut out of sy ync. At nig ght, slave units u in white b backup night mode in nstead of normal n red. Sync monito S or PCB on the t m master powe er supply no ot co onfigured as a master. DIP switch S1-4 in the master m unit should be set s to OFF.. In nterconnectting wire between ma aster and slave power supplies missing g. Insspect wiring g between po ower supplie es. TB1 possition ed 3 should s be daisy-chain d be etween each power supply, pe er the installation wiring g dia agram. Insttall intercon nnecting wiring. Sync/Monito S or S1-4 is OFF, O G GPS Sync Unit U Defectiv ve or In ncorrectly wired. w Ch heck S1-4 position. p Insspect wiring. Swap the GPS Sync S nit with know wn good un nit. Un Turrn ON S1-4 4. Correct wiriing. Replacce the GPS S Syn nc Unit. Section 2 All S A lights arre in sync, but there is a double e-flash, or flashing fa aster than 40 F FPM. More than one sync mo M onitor P PCB is set as a master. Insspect the DIP D switchess on ea ach sync mo onitor PCB. In the e master po ower supplyy, DIP switch S1-4 should be se et to OFF, which w is the ma aster positio on. In all th he oth her power supplies, s th his sw witch 4 shou uld be set to o ON N, which is the slave po osition Recconfigure sync s monito or PCBs. Refer to the manu ual for correct possitions. Section 3 Master S M unit switches to t night mode at night, but slav ve units re emain in da ay m mode. In nterconnectting wire between ma aster and slave power supplies missing g. EPM00000002 2-001 g between Insspect wiring po ower supplie es. TB1 possition ed 1 should s be daisy-chain d be etween each power supply, pe er the installation wiring g dia agram for multiple m unitts. 46 Insttall intercon nnecting wiring. Rev. D 5.6 Side Light Problems Logicc Diagram Utilize e the follow wing logic diiagram to determine d th he most corrrect course e of mainte enance action n to perform m and to tro oubleshoot the flashhe ead when siide light pro oblems occcur. Utilize e Table 8 and a the secttion listed in n the logic diagram. d Tab ble 8. Side e Light Problems Corrrective Ma aintenance e Malfunction T Test Corrective Action S Section 1 Side S lights not operatting at nigh ht. Verify correcct wiring pe V er installatio on diagram. On system ms with morre than one e power sup pply, note that eacch side ligh ht module should s run two levels of o side lightss F fuse open. F3 Re emove the F3 fuse. Ch heck forr continuity. Resseat / Repla ace. Power supply rocker sw P witch iss in the wrong position n. Ma ake sure ro ocker switch h is in the Auto A position, and that the ph hotocell is not n illuminatted (if necessary, temp porarily covver it to simulate nighttime). S Section 2 Side S lights in alarm S Side light lam mp burned out. On n the alarm card (AC1) set Rep place burne ed out side the e DIP switcches to mon nitor ligh ht. 1 (one) ( less side s light th han the e current nu umber (re eference sw witch setting g po ositions in manual). m Altternatively, measure the cu urrent going g out to your side lights though the wire on n TB B1-11 or TB B1-12. Com mpare yo our current reading r to the t no ominal (expected) currrent levvel to see how h many side s lights you havve operatin ng. Wrong DIP switch W s setting on th he side light alarm module. atch DIP sw witch setting g on AC1 at a switch(ess) SW1 or SW2 S Ma witth the actua al number of o side lightts to monito or. Low input vo oltage. Ch heck input voltage v – it sh hould with ±10% ± of req quired vo oltage. EPM00000002 2-001 47 Increase inputt voltage. Rev. D 5.7 Flash hhead Isola ation Test Turn off the inpu ut voltage at a the circuiit breaker to o the power supply. Disconnect the t seve en conducto or cable from m power su upply at term minal blockk TB2. Using an Ohmm meter, checck the resisttance betwe een the con nductors off the discon nnected flasshhead cab ble, and comp pare to the expected values: v 5.7.1 FG200B Single S Flasshhead Rea adings (cab ble disconne ected from power supp ply) • #1 Red: Open O to all conductors c • #2 Brown:: Open to all a conducto ors • #3 Black: < 5Ω to blu ue, open to all others • #4 Blue: < 5Ω to blacck, open to all others • #5 White: < 5Ω to gra ay, open to all others • #6 Gray: < 5Ω to white, open to all others • #7 ground d: Open to all a conducto ors 5.7.2 FG3000B B Dual Flash hhead Rea adings (cablle disconne ected from power p supp ply) • #1 Red: Open O to all conductors c • #2 Brown:: < 5Ω to blue & black,, open to alll others • #3 Black: < 5Ω to bro own & blue,, open to alll others • wn & black,, open to alll others #4 Blue: < 5Ω to brow • #5 White: < 5Ω to gra ay, open to all others • #6 Gray: < 5Ω to white, open to all others • #7 ground d: Open to all a conducto ors Flashhead Test Ressults orrect readin ngs do not ensure tha at the flashh head and ca able are go ood, but a) Co this s is a quickk check for obvious pro oblems. b) If the t readings above are e correct, proceed p to the t Power Supply S Isola ation Te est. c) If the t resistan nce between #5 (gray) and #6 (wh hite) is grea ater than 5Ω Ω, or is open, suspecct that the flashhead in nterlock switch is not depressed. d EPM00000002 2-001 48 Rev. D d) Fo or other inco onsistencies with the above a chartt, the proba able causess are inc correct wirin ng, or conductors shorrted and/or opened. If possible, dis sconnect the flashhead d cable at both b ends and a perform m a Meggerr test witth a Megoh hm Meter. 5.8 Powe er Supply Is solation Te est Leavve the seven conducto or strobe ca able disconn nected from m the powerr supply at terminal blockk TB2. Insta all a jumperr wire betwe een termina als 5 and 6 to simulate e the interlo ock switcch being de epressed. In nstall a neo on lamp (HO ONEYWELL L Part # 77-2342) acro oss the trigge er output. For F the Dayy Mode, insttall the neo on lamp in te erminals 2 and 4 on TB2. T For the Night N Mode, install the neon lamp p in termina als 2 and 3 on o TB2. Ap pply power to t the syste em and insu ure the follo owing: 5.8.1 Voltage Measureme M ents Using a voltmeter, v m measure the e voltages of o the conductors to grround terminal 7. Check the e measurem ments in bo oth day and d night modes, and com mpare to th he expected values: upply Measurements Power Su #1, Red: +500 VDC to ground # Blue: –5 #4, 500 VDC to ground #2, Brown n: –500 VD DC to ground # Gray: 12 #5, 20 VAC to ground g #3 See Below # White: 120 VAC to ground #6, If either th he red or th he brown co onductor do oes not havve +500 VD DC or –500 VDC V respective ely, there iss most likelyy a problem m in the T1 transforme er, the high voltage board, or a capacitor has failed d. Check the e input and output volttage of the transform mer. Check the t high vo oltage board d for bad dio odes. Checck each cap pacitor for the pro oper value.. If your me eter will not measure capacitance (Farads) th hen check the e capacitorss for opens or shorts. mp Flash Rate R 5.8.2 Neon Lam With the power p supp ply in day mode, m you should s see one o quick flash f at a fla ash rate of 40 FPM M. When the system iss put into niight mode, you should d see a long g burst of flashes fo or a few secconds. Then the lamp should beg gin flashing short burstts of flashes. This T happen ns because e the powerr supply can n tell that th he red flash htubes are not op perating, so o it tries to go g into backup white night n mode. If the neo on tube will never flash h, you mostt likely have e a problem m with the trrigger board. Ch heck the DIP switch se ettings with those in th he manual, and replace e the board if necessary. n If the neo on tube flash hes slowly, you most likely l have a problem with the sync board. Ch heck the DIP switch se ettings with those in th he manual, and replace e the board if necessary. n EPM00000002 2-001 49 Rev. D If the neo on lamp is fllashing corrrectly, and the voltage es are corre ect, the pow wer supply is probably working, w and d the proble em is likely in the flash hhead or the e strobe cable. n lamp & jumper frrom TB2 be efore recon nnecting the e flashhead. Remove neon 5.9 Flash hhead Main ntenance No special or prreventive maintenance m e is required for the fla ashhead, bu ut only thatt which can be b performe ed on an ass-needed basis. b Should it becom me necessarry to replacce the flash htubes, the following in nstructions must be ad dhered to: W WARNING Ensure that th he power is s OFF and the capacitor bank has h been discharged d d before open ning the fla ashhead. a) Lo oosen the eight e (8) bollts securing g the globe only enoug gh to turn th he black rettainers. Th he bolts will fall out if they are loo osened exce essively. b) Affter turning the black retainer’s 90 0 degrees, lift the glob be approxim mately twelvve incches. When n the top exxtent is reached, rotate e the globe e slightly (co ounterclockkwise) to move the lift guide into its i support position. EPM00000002 2-001 50 Rev. D c) Th he two strin ngs of three e flashtubess are attach hed at both ends to socckets with co onnectors. See S Figure 24. Discon nnect both ends e of the flashtube assembly a to o be re eplaced. F A Assembly Fiigure 24. Flashtube with Ferritte Beads d) Ge ently remov ve each flasshtube from m its supports, being careful c not to t break it. See S Figure 25. Diisconnect fe errite supprressors from m quick-on fasteners. Figure 25 5. Attachm ment of Ferrrite Beads s with Quic ck-On Fastteners EPM00000002 2-001 51 Rev. D CA AUTION Us se a clean pair of glo oves to han ndle the fla ashtubes. Fingerprin nts or conttamination n on the gla ass will advers sely affect reliability of o flashtub bes. e) Re emove the new flashtu ubes from their t contain ner and con nnect the re ed-marked lead to the red socke et. See Figu ure 26. Carrefully conn nect ferrite suppressor s rs to their quick-on fastener grou unding lugss. Working counterclockwiise from the e red socke et, insert ea ach flashtub be into its pair of f) W su upports. Apply equal pressure p TO O THE MET TAL END CAPS C ONLY Y (as shown n in the illu ustration be elow) so tha at the ends of each fla ashtube are e simultaneo ously snapp ped into pla ace. THE FLASHTUB F BE ASSEMB BLY IS EXT TREMELY FRAGILE, especially at a the junction betw ween glass and metal. Handle the e flashtubess in a mann ner that avo oids s critical sea al. stressing this Fiigure 26. Flashtube F Insertion g) Co onnect the black-markked lead to the black socket. s h) Ro otate the gllobe slightlyy (clockwise e) to realign n the lift guide in its ve ertical trave el slot. Pu ush down on o the globe e to re-seatt it on the gasket. i) Tu urn each black retaine er back 90 degrees d and d tighten th he bolts. 5.10 Power Su upply and Light L Senso or Maintenance The power p supp ply and amb bient light se ensor require no speccial mainten nance. The light senso or should be checked and cleane ed periodica ally because too much h dirt on the e window can cause c it to malfunction m . EPM00000002 2-001 52 Rev. D 6 6.0 PAR RTS LISTING The purpose T e of Section n 7 is to pro ovide parts information n for the dissassembly, repair, re eplacementt, and reass sembly of th he equipme ent reflectin ng the main ntenance ph hilosophy. Not N all possible spa are parts arre listed for all variation ns of the FllashGuard series unitss. Descriptiion Part Numb ber Ref. Designator D r Fllashhead Flashtu ube Assemb bly 12S00602 2 FT T1, FT2 Holder, Flashtube 77-4026 6 Switch, FH Interloc ck 77-2644 4 S1 Transfo ormer, Trigg ger, White 77-4040W W T1 Transfo ormer, Trigg ger, Red 77-4040R R T2 O-Ring, Upper AS568A-383 N/A O-Ring, Lower AS568A-380 N/A Pow wer Supply y Capacittor, 70μF C CA706A441 1EK C C2A-F Capacittor, 4μF 77-3911 C3 Capacittor, 7μF CA505B661C CDG C1 Fuse, 6A 6 (120VAC C) 77-1167 7 F1 Fuse, 4A 4 (220VAC C, 50/60 Hz)) DP-1020 0 F F2 F1, Fuse, 2A 2 (480VAC,, 50/60 Hz ) DP-1021 1 F F2 F1, Fuse, 6A 6 (Sideligh ht Fuse) 77-1167 7 F3 Fuse, 630mA 6 SB DP-1019 9 T T1-F1 PCB, Diode D 277-3939 9 ----- PCB, High H Voltage e 277-3937 7 ----- PCB, Sync/ S Monito or 277-4163 3 ----- PCB, Trigger/ T Con ntrol 2 277-5014-0 003 ----- PCB, Motherboard M d 2 277-5016-0 001 ----- 77-2013 3 K K2 K1, Relay, Mother M Boa ard KA A025DC10 0S2N K3 Relay, Sidelight S Po ower K KA121AV05 522C K4 Relay EPM00000002 2-001 53 Rev. D Power Supply S (con nt’d.) Sidelight Level(s) L Ala arm Card (Incandesscent Lamps s only) B7C23P PAA AC Sidelight Level(s) L Ala arm Card (LED Fixtures only) B7C23LA AA-001 AC XZLM1 111 AC-U1 XZ14011 1BCL AC-U4 XZ14049UBAL AC-U5 77-2759 R R3, R4 R2, Resistor, 1.5kΩ, 50W W 40000683 3-001 R5 Resistor, 50kΩ, 50W W RW50RB0 0502GF R6, R7 Resistor, 50Ω, 55W RW50RB0 0500GF R1 Transform mer, 120/24 40V, 60Hz 77-5002 T1 Transform mer, 240/48 80V, 60Hz 77-5066 T1 Transform mer, 240/48 80V, 50Hz 77-5067 T1 Transform mer, Curren nt Sensing 40000679 9-001 T2 Interlock Switch S Ass sembly 40000676 6-001 ----- 77-4017-4 ----- 12E00045-002 ----- IC, Voltag ge Compara ator IC, Quad NAND Gate e IC, Inverte er Buffer Resistor, 20Ω, 40W Cable, Intterconnect Single-po ole double-tthrow relay GPS S GPS Sync Unit 40002075 5-001 ----- GPS Sync Unit Cablle, 25 ft 40002074 4-001 ----- GPS Sync Unit Cablle, 50 ft 40002074 4-002 ----- GPS Sync Unit Cablle, 100 ft 40002074 4-003 ----- GPS Sync Unit Cablle, 150 ft 40002074 4-004 ----- GPS Sync Unit Cablle, 350 ft 40002074 4-005 ----- Bracket, Pole-Mount P t 40002082 2-001 GPS Con nnector Ass sembly (Internal to t Power Supply) SMISC230 ----- Photoc cell Photocell (Red Night Only) 77-3258 8-001 ----- Photocell (White or Dual D Lightin ng Systems)) 77-3259 9-001 ----- EPM00000002 2-001 54 Rev. D