Download Installation Manual -YM11512 4x12 Pergola Room Kit

Transcript

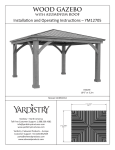

Installation Manual -YM11512 4x12 Pergola Room Kit (0.51m) (1.99m) (0.51m) Yardistry Ltd. Mount Forest, ON Canada N0G 2L1 (1.00m) Toll Free Customer Support: 1.888.509.4382 (1.18m) [email protected] www.yardistrystructures.com (3.37m) Revised 02/08/2011 1 !Important Safety Notice! • Yardistry components are intended for privacy, decorative and ornamental use only. Product is NOT INTENDED for the following: - A safety barrier to prevent unsupervised access to pools, hot tubs, spas, or ponds. - Safety railings for elevated platforms or decks. - As load bearing support for a building, structure, heavy objects or swings. - Used in structures that trap wind, rain or snow that would create extra load on the product. • Permanent structures may require a building permit. As the purchaser and or installer of this product you are advised to consult local planning, zoning, and building inspection departments for guidance on applicable building codes and or zoning requirements. • Wood is NOT flame retardant and will burn. Grills, fire pits and chimneys are a fire hazard if placed too close to a Yardistry structure. Consult user’s manual of the grill, fire pit or chimney for safe distances from combustible materials. • During installation, follow all safety warnings provided with your tools and use OHSA approved safety glasses. • Some structures may require two or more people to install safely. Check for underground utilities before digging or driving stakes into the ground! General Information: Wood components are manufactured with Cedar (C. Lanceolata) which is protected with factory applied water-based stain. Knots, small checks (cracks) and weathering are naturally occurring and do not affect the strength of the product. Annual application of a water-based water repellent sealant or stain will help reduce weathering and checks. Keys to Assembly Success Tools Required Warranty: Yardistry Limited products are backed by a 5 year limited lifetime warranty from the date of original retail purchase and if installed as• Open per manufacturer’s installation • Tape Measure for manufacturing • #1, defects #2 & #3 Phillips End Wrench • 3/16”instructions. Hex Key • Carpenters Level • Carpenters Square • Claw Hammer • Standard or Cordless Drill • Tape Measure or Robertson Bits (7/16”, 1/2” & 9/16”) Patents Pending or Screwdriver • Adjustable Wrench • Ratchet with extension Tools Required • 1/8” & 3/16” Drill Bits (1/2” & 9/16” sockets) • Pencil • #2 Phillips or Robertson Bits or Screwdriver • 8’ Step Ladder • Safety Glasses • Adult Helpers • 8’ Step Ladder • Adjustable Wrench Part Identification Key • Carpenters Level • 1/8” Drill Bit On each page, you will find the parts and 2X A1 Post 2 x 4 x83” • Ratchet with extension • Carpenters Square • Pencil quantities required to complete the assembly (7/16” sockets) step illustrated on that page. Here is a sample. • Safety Glasses • Adult Helpers • Standard or Cordless Drill Symbols • 1/4” Drill Bit Key Number Part Description, Part Size • Open End WrenchQuantity • 3/16” Hex Key (7/16”) Throughout these instructions symbols are provided as important reminders for proper and safe assembly. Keys To Assemble Success This identifies information that requires special attention. Improper assembly could lead to an unsafe or dangerous condition. Use Help Measure Distance Use Help Check that set or assembly is properly level before proceeding. Pre-drill 1/8” & 3/16” Bit Where this is shown, 2 or 3 people are required to safely complete the step. To avoid injury or damage to the assembly make sure to get help! Check that assembly is square before tightening bolts. Pre-drill a pilot hole before fastening screw or lag to prevent splitting of wood. Square Assembly Tighten Bolts This indicates time to tighten bolts, but not too tight! Do not crush the wood. This may create splinters and cause structural damage. Use a measuring tape to assure proper location. No CAUTION – Protrusion Hazard Use Level 2 Yes If Bolt protrudes beyond T-Nut Material List (1) 2 x 6 x 80 1/8" Y50100-024 A B C D E F (2) 2 x 6 x 71 5/8" Y50100-023 (9) 5/4 x 4 x 59¾" Y50100-025 (4) 2 x 2 x 40" Y50100-026 (2) 2 x 6 x 21 5/8" Y50100-022 Nominal 1x6 5/4 x 4 2x2 2x6 4x4 (1) 1 x 6 x 11" Y50100-019 Y YARDISTRY (2) 2 x 6 x 16¾" Y50100-021 Actual 5/8 x 5 3/8" 1 x 3 1/2" 1 1/2 x 1 1/2" 1 1/2 x 5 1/2" 3 1/2 x 3 1/2" Post Heights - Altura de los postes - Hauteur des poteau H (4) 2 x 6 x 13½" Y50100-020 (2) 2 x 6 x 66 5/8" Y50100-027 To determine post length requirements, use this formula: Z C Post must be securely installed to support structure. Consult local building codes and ground conditions for required footing design. (4) 1/4 x 1¼" (9277211) B > 24" Pour déterminer la longueur des poteaux, utilisez cette formule: El poste debe instalarse firmemente para sostener la estructura. Consulte los códigos o leyes de construcción locales y las condiciones del suelo para el diseño del cimiento requerido. Les poteau doivent être installés solidement pour soutenir la structure. Consultez les codes du bâtiment locaux et les conditions du sol pour concevoir adéquatement la semelle. A = B+C A (90"- 96") H0 Para determinar los requerimientos de longitud de los postes, utilice la siguiente fórmula: (4) 1/4" (9285200) - Corte - Couper (4) 1/4"Cut (9253200) ! Check for underground utilities before digging or driving stakes into the ground! (12) 1/4" (9251200) S1 ¡Verifique la ubicación de las tuberías subterráneas antes de excavar o de clavar estacas en el suelo! 2½ (4) #8 x 1½" (9290512) (90"- 96") Vérifiez la présence d'installations de services publics souterraines avant de creuser ou d'enfoncer des piquet dans le sol! S2 (18) #8 x 3" (9290530) (8) 1/4 x 2½" (9272222) S3 4 x 4 Posts and Post Top Connectors (sold separately) 4 x 4 Postes y el conector superior de poste (se vende por separado) 4 x 4 Poteau en le connecteur de bout de poteau (vendu séparément) (16) #12 x 3" (9260630) (6)(sold Postseparately) Top Connector With 4 x 4 Posts and Post Top Connectors 7/16” Bolt 4 x 4 Postes y el conector superiorWH de poste (seHex vende porAssembly separado) 4 x 4 Post Top Connector 4 x 4 Posteaux en le connecteur de 4 x 4 conector superior de poste 4 x 4 de connecteur de (vendu bout de poteau bout poteau séparément) 4 x 4 Post (30) Panel Clips 4 x 4 Postes 4 x 4 Poteau 4 2 3 Material List PX1 PA1 (2) One High X Topper (8) One High X Topper PL3 PX3 P S4 S4 S7 S7 (6) Three High Lattice Panel (4) Three High X Panel S5 R #10 x 1” Pan Head Screw S4 (10) Top and Bottom Rail (Lengths Vary) S6 S6 S6 #10 x 1 1/2” Pan Head Screw S4 S4 #8 x 2 1/4” Wood Screw S7 S5 S5 (6) 4x4 Post 4 S7 S7 #8 x 1 1/2” Wood Screw Step 1- Assemble Screens for Main Wall 1. Remove the metal connectors on both sides of PL3 - Three High Lattice Panel. Reattach the metal connectors to PL3 by securing the bottom two holes of the metal connectors to the top two holes on PL3 so that the metal connectors stick out from the top. Slide PX1 – One High X Topper between the two protruding metal connectors on the top of PL3. Attach the metal connectors to the factory drilled holes in PX1. (Fig. 1A) *Ensure Panels are right side up! (Fig. 1B) 2. Secure panels with a S4 - 2 1/4” Wood Screw the location indicated by the large arrow in the direction of the arrow. Note PX1 orientation of keyhole. 3.Repeat until 4 panel assemblies are created. d reattach using n panel. Tenga en cuenta la orientación del agujero de la cerradura. y vuelva a eros Notez l'orientation de l'encoche en trou deserrure. accordement et n des deux trous été percés à Fig. 1B - Filler Strips on Bottom of Panel! x4 Fig. 1A Do not remove Small Connector PL3 No retire los conectores Ne retirez pas les petites pièces d raccordement. 4x PX1 One High X Topper 4x PL2 Two High Lattice Panel 4x 5 S4 #8- 2 1/4” Wood Screws Step 2- Assemble main Wall Fig. 1 1. Assemble panels together in configuration shown. (Fig.1) Insert male connector into female. Slide down until flush with adjacent Pautas básicas para Instruc pour l' el ensamblado de Basic Guidelines panel as shown. (Fig. 1A) Instructions de base Cut and attach des paT 1 Assemble Toppers to Panels. los paneles for Panel Assembly 3 Pautas básicas para Les assem Las ilustraciones muestran l'assemblage pour Shown here are configurations using 2. S ecure Panels with S4 2 1/4” pièces supé el ensamblado de configuraciones con topes. También a Topper. 2 and 3 High Panels can Corte y fijeégalement los r des panneaux se pueden conectar 2 y 3 paneles also be connected together as screws provided in pre-drilled los paneles à deux ou à altos a medida que se adquieran. purchased. Instale los topes en los paneles. Assemblez les pièces supérieures et les panneaux. Basic Guidelines for Panel Assembly Les assemblages illustrés comportent des *Use tornillos de acero inoxidable holes as indicated bylos arrows, *Use 2 1/4" stainless steel screws Taillezinet fixez l de 2 1/4" que se incluyen en el juego *Utilisez les Shown here are configurations using Las ilustraciones muestran included in the Panel Clip set to pièces supérieures. Il est possible 2-1/4 po fou de arrow. sujetadores de (Fig.1) paneles para the direction of the configuraciones con topes. También secure and strengthen the assembly. Panels side by side. (Maximum 3 wide x 3 high) B. Assembledes fixations po a Topper. 2 and 3 High Panels can reforzar el ensamblado. également d'assembler panneaux One Wide Anch de renforce se pueden conectar 2 y 3 paneles Conecte los paneles lado a lado. also be connected together as à deux ou à trois carreaux de hauteur 20" altos a medida que se adquieran. Assemble purchased. Assemblez à côte.Panels side by side. 2 les panneaux côte (vendus séparément). *Use los tornillos de acero inoxidable Conecte Fig. 1Alos paneles lado a lado. *Use 2 1/4" stainless steel Remove screws *Utilisez les vis en acier inoxydable de Assemblez les panneaux côte à côte. Large Connectors and reattach using top two de 2 1/4" que se incluyen en el juego factory drilled holes on panel. included in the Panel Clip set to 2-1/4 po fournies dans le nécessaire de Two Wide Anc de sujetadores de paneles para los conectores grandes y vuelva a instalarlos secure and strengthen theRetire assembly. usando los dos agujeros pretaladrados del panel. Instructions de base Cut and attach fixations pour panneaux afin de fixer et 3 Pautas básicas para reforzar el ensamblado. Retirez les grandes pièces de raccordement et fixez-les depour renforcer l'assemblage. Note Tenga en cuenta Notezl'assemblage l'orientation + (vendus sé = eldeuxensamblado de de nouveau au moyen des trous Basic Guidelines orientation supérieurs du panneau qui ont été percés of keyhole. los paneles for Panel Assembly à l'usine. Assemble Panels side by side. 2Shown here are configurations using 3 des panneaux la orientación del de l'encoche en trou de serrure. agujero de la cerradura. Corte y fije los Three Wide Anc Les assemblages illustrés comportent des Taillez et fixez Las ilustraciones muestran Conecte configuraciones los panelescon lado a También lado. pièces supérieures. Il est possible topes. a Topper. 2 and 3 High Panels can également d'assembler des panneaux One Wide An se pueden conectar 2 y 3côte paneles Insert male into female. Slide down until flush with adjacent panel also be connected togetherAssemblez as les panneaux à côte. à deux ou à trois carreaux de hauteur 20" altos a medida que se adquieran. Introduzca el extremo macho en el extremo hembra. Deslícelo ha 3. Connect last asse Four Wide Anc purchased. abajo hasta que quede al ras del panel adyacente. *Use los tornillos de acero inoxidable (vendus séparément). *Use 2 1/4" stainless steel screws en acier inoxydable de down male into Slide until with Insérez les female. pièces de raccordement mâles dansflush les pièces de 2 1/4" que se incluyen en el juego *Utilisez les visInsert adjacent included in the Panel Clip set to depanel. raccordement femelles. de Faites glisser le panneau 2-1/4 po fournies dans le nécessaire Two Wide An vers le bas jusqu'à ce qu'il soit au même niveau que secure and strengthen the assembly. de sujetadores de paneles para Fig. 2 Introduzca elafin extremo macho en el extremo hembra. fixations pour panneaux de fixer et le panneau adjacent. reforzar el ensamblado. Deslícelo hacia abajo hasta que quede al ras del ez l'orientation panel adyacente. deremove renforcer l'assemblage. Do not Small Connectors. 3. Secure R-Top and encoche en R No retire los conectores Insérez les pièces de raccordement mâles dans les de serrure. Bottom Rails to Panel pequeños. pièces de raccordement femelles. Faites glisser le Assemble Panels side by side. Ne retirez pas les petites pièces panneau vers le bas jusqu'à ce qu'il soit au mêmeThree Wide Note wood piece at bottom prevents Assembly with S4 - 2 1/4” niveau que le panneau adjacent. de raccordement. collection of water. Wood Screws locations Note que Conecte los paneles lado a lado. la pieza de madera inferior evita la acumulación de agua. indicated by arrows in PrenezAssemblez note que la pièce en bois les panneaux côte à côte. située au bas de chaque élément the direction of the arrow. de l'assemblage empêche Four Wide l'accumulation d'eau. (Fig. 2) 2 An An Insert male into female. Slide down until flush with adjacent panel. Secure with Screws*. Use factory drilled holes. *R- Top and Bottom Rails Los torn ensamblado usando tornillos*. Use los agujeros pretaladrados. Introduzca el extremo machoAsegure en elel extremo hembra. Deslícelo hacia 3. Connect last assembled panels to make a fence section. y se incluyen Fixez l'assemblage au moyen de vis.* Servez-vous des trous prépercés à l'usine. will overhang 1/4” on otez l'orientation abajo hasta que quede al ras del panel adyacente. *Les vis sont celles de 2-1/4 po en acier inoxydable qui sont fournies dans le l'encoche en either side of panel. u de serrure. Insérez les pièces de raccordement mâles dans les pièces *R- Top Bottom RailsFaites glisser le panneau deand raccordement femelles. mayvers need tojusqu'à be cut to soit au même niveau que le bas ce qu'il le 6’panneau 6 1/2”adjacent. (2m) panel_cap_labels_19x9.5.indd 7 male Top and Bottom Railconnector will the male connectors from the outside 1/4"on of the either side. overhang C. Remove conector panel assembly. masculino Attach Top with Screws* (It is recommended to all Connectors. Quite los conectores masculinos delthrough exterior de la factory drilledconnecte holes. asamblea de panel. use a Mitre Box or MitreInsert male into female. Slide down until flush with adjacent panel. mâle On Bottom, space Screws* tores Enlever les connecteurs mâles de l'extérieur 4" from de edges of panels. Saw) l'assemblée de panneau. short male Introduzca el extremo macho en el extremo hembra. Deslícelo hacia 3. Connect last assembled panels to make a fence section. connector petites pièces abajo hasta que quede al ras del panel adyacente. Insérez les pièces de raccordement mâles dans les pièces de raccordement femelles. Faites glisser le panneau vers le bas jusqu'à ce qu'il soit au même niveau que le panneau adjacent. mall Connectors. ectores conector masculino corto 2x R le connect mâle court Top & Bottom Rail at 6’ 6 1/2” (2m) 24x S4 #8- 2 1/4” Wood Screws Screws* are 2 1/4" stainless steel included in Panel Clip set. y drilled holes. spretaladrados. petites pièces . ercés à l'usine. Los tornillos* son de acero inoxidable de 2 1/4" y se incluyen en el juego de sujetadores de paneles. *Les vis sont celles de 2-1/4 po en acier inoxydable qui sont fournies dans le nécessaire de fixations pour panneaux. 6 1/4" Top and R Bottom Rail will overhang 1/4"on either side. Attach Top with Screws* through factory drilled holes. 1/4" On Bottom, space Screws* 4" from edges of panels. 2 Assemble Panels side by side. Three Wide Ancho trip Four Wide Ancho cu ConecteSingle los paneles lado a lado. Step 3- Assemble Screens Assemblez les panneaux côte à côte. 1. Remove the metal connectors on both sides of PL3 - Two High Lattice Panel. Reattach the metal connectors to PL3 by securing the bottom two holes of the metal connectors to the top two holes on PL3 so that the metal connectors stick out from the top. Slide PX1 – One High X Topper between the two protruding metal entation connectors on the top of PL3. Attach the metal connectors to the factory drilled holes in PX1. (Fig. 1A) *Ensure he en rrure. Panels are right side up! (Fig. 1B) R 2. Secure R-Top and Bottom Rails to Panel Assembly with S4 - 2 1/4” Wood Screws locations indicated by arrows and in the direction of the arrow. *R- Top and Insert male into1/4” female. Bottom Rails will overhang onSlide down until flush with adjacent panel. Note PX1 orientation of keyhole. either side of panel. Introduzca el extremo macho en el extremo hembra. Deslícelo hacia 3. Connect last assembled panels to make a fence section. hastamay que quede ras del panel adyacente. and *reattach usingabajo R- Top and Bottom Rails needal to Tenga en cuenta la orientación del agujero de la cerradura. on panel. bepièces cut de toraccordement 20” (50.8cm) Insérez les mâles dans les pièces Instructions de base 3 Cut and attach Top a Pautas de raccordement femelles. Faites glisser le panneaubásicas para pour l'assemblage Notez l'orientation Corte de l'encoche fijewill los rieles des panneaux Los r Top and Bottomy Rail en trou deserrure. (It is recommended to use a Mitre Box elniveau ensamblado de Basic Guidelines vers le bas ce qu'il soit au même que es y vuelva ajusqu'à or Mitre Saw) los paneles for Panel Assembly le panneau adjacent. gujeros Las ilustraciones 3. Repeat until two panel assemblies are muestran here are configurations using nnectors. Shown aassembled. Topper. 2 and 3 High Panels can also be connected together as purchased. e raccordement et *Use 2 1/4" stainless steel screws pièces des yen deux trous included in the Panel Clip set to ont été percés à the assembly. secure and strengthen 2 Ancho dob 39½" 1/4" Three Wide Ancho trip Four Wide Ancho cuá 1/4" Screws* are 2 1/4" stainless steel included in Panel Clip set. Los tornillos* son de acero inoxidable de 2 1/4" y se incluyen en el juego de sujetadores de paneles. *Les vis sont celles de 2-1/4 po en acier inoxydable qui sont fournies dans le nécessaire de fixations pour panneaux. ntation e en rure. Fig. 1B - Filler Strips on Bottom of Panel! Fig. 1A Insert male into female. Slide down until flush with adjacent panel. x2 Do not remove Small Connec PL3 No Introduzca el extremo macho en el extremo hembra. Deslícelo hacia 3. Connect last assembled panels to make a fenceretire section. abajo hasta que quede al ras del panel adyacente. 2x PX1 One High X Topper 2x PL2 Two High Lattice Panel 4x R los conectores Ne retirez pas les petites pièce raccordement. R Insérez les pièces de raccordement mâles dans les pièces de raccordement femelles. Faites glisser le panneau vers le bas jusqu'à ce qu'il soit au même niveau que le panneau adjacent. nectors. pièces Two Wide Assemble Panels side by side. Conecte los paneles lado a lado. Assemblez les panneaux côte à côte. ed holes. adrados. à l'usine. overhang 1/4"on either side. a cad et fixez la en ma lo AttachTaillez Top with Screws* through factory drilled holes. infer One Wide Anchotorni sen On Bottom, space Screws* 4" from edges of panels. 20" Les assemblages illustrés comportent des configuraciones con topes. También pièces supérieures. Il est possible également d'assembler des panneaux se pueden conectar 2 y 3 paneles à deux ou à trois carreaux de hauteur altos a medida que se adquieran. *Use los tornillos de acero inoxidable (vendus séparément). de 2 1/4" que se incluyen en el juego *Utilisez les vis en acier inoxydable de 2-1/4 po fournies dans le nécessaire de de sujetadores de paneles para fixations pour panneaux afin de fixer et reforzar el ensamblado. de renforcer l'assemblage. 6x S4 #8- 2 1/4” Wood Screws Top and Bottom Rail will overhang 1/4"on either side. Attach Top with Screws* through factory drilled holes. On Bottom, space Screws* 4" from edges of panels. Top & Bottom Rail At 20” (50.8cm) 7 1/4" Los rie a cada en los inferio tornillo Step 4A- Assemble Wings 1. Remove the metal connectors on both sides of PX3 - Two High X Panel. Reattach the metal connectors to PX3 by securing the bottom two holes of the metal connectors to the top two holes on PX3 so that the metal connectors stick out from the top. Slide PA1 – Arch Topper between the two protruding metal connectors on the top of PX3. Attach the metal connectors to the factory drilled holes in PA1. (Fig. 1A) *Ensure Panels are right side up! (Fig. 1B) 2. Secure panels with a S4 - 2 1/4” Wood Screw the location indicated by the large arrow in the direction of the arrow. 3.Repeat until two panel assemblies are assembled. Note orientation of keyhole. and reattach using on panel. Tenga en cuenta la orientación del agujero de la cerradura. PA1 Notez l'orientation de l'encoche en trou deserrure. es y vuelva a gujeros e raccordement et yen des deux trous ont été percés à Fig. 1B - Filler Strips on Bottom of Panel! Fig. 1A Do not remove Small Connec x2 2x PA1 Arch Topper 2x PX2 Two High X Panel PX3 No retire los conectores Ne retirez pas les petites pièce raccordement. 2x 8 S4 #8- 2 1/4” Wood Screws Step 4B- Assemble Wings Continued 4. Remove the metal connectors on both sides of PX3 - Two High X Panel. Reattach the metal connectors to PX3 by securing the bottom two holes of the metal connectors to the top two holes on PX3 so that the metal connectors stick out from the top. Slide PA1 – Arch Topper between the two protruding metal connectors on the top of PX3. Attach the metal connectors to the factory drilled holes in PA1. (Fig. 4A) *Ensure Panels are right side up! (Fig. 4B) 5. Secure panels with a S4 - 2 1/4” Wood Screw the location indicated by the large arrow in the direction of the arrow. 6.Repeat until two panel assemblies are created. Note orientation of keyhole. and reattach using on panel. Tenga en cuenta la orientación del agujero PX1 de la cerradura. Notez l'orientation de l'encoche en trou deserrure. es y vuelva a gujeros e raccordement et yen des deux trous ont été percés à Fig. 4B - Filler Strips on Bottom of Panel! Fig. 4A Do not remove Small Connec x2 2x PA1 Arch Topper 2x PX2 Two High X Panel PX3 No retire los conectores Ne retirez pas les petites pièce raccordement. 2x 9 S4 #8- 2 1/4” Wood Screws Step 5- Assemble Side Wall Fig. 1 1. Assemble panels together in configuration shown. (Fig.1) Insert male connector into female. Slide down until flush with adjacent Pautas básicas para Instruc pour l' el ensamblado Basic Guidelines panel as shown. (Fig. 1A)and de Cut and attach Top Bottom des R pa 1 Assemble Toppers to Panels. c Guidelines anel Assembly 3for Panel Assembly Instale los topes en los paneles. Instructions de base Pautas básicas para Assemblez les pièces supérieures et les panneaux. pour l'assemblage el ensamblado de des panneaux los paneles los paneles Les assem Las ilustraciones muestran here are configurations 2.SShown ecure Panelsusing with S4 - 2con1/4” configuraciones topes. También pièces supé a Topper.Corte 2 and 3 High Panels can los y fije rieles superior e inf également conectar 2 y 3 paneles also be connected together as screws provided insealtospueden pre-drilled à deux ou à a medida que se adquieran. purchased. (vendus sé Les assemblages illustrés comportent des *Use tornillos de acero inoxidable holes as indicated byloslaarrows, in *Use 2 1/4" stainless steel screws Taillez et fixez main courante a de 2 1/4" que se incluyen en el juego *Utilisez les included in the Panel Clip set to pièces supérieures. Il est possible 2-1/4 po fou de arrow. sujetadores de (Fig.1) paneles para the direction of the secure and strengthen the assembly. B. Assemble Panels side by side. (Maximum 3 wide x 3 high) fixations po Las ilustraciones muestran configuraciones con topes. También reforzar el ensamblado. également d'assembler des panneaux One Wide Ancho sencillo Une de pièce renforce se pueden conectar 2 y 3 paneles Conecte los paneles lado a lado. à deux ou à trois carreaux de hauteur 20" 20" altos a medida que se adquieran. Assemble Panels side by side. Assemblez 2 les panneaux côte à côte. *Use los tornillos de acero inoxidable (vendus séparément). Conecte Fig. 1Alos paneles lado a lado. *Utilisez de Remove Large Connectors and reattach using topInstructions two les vis en acier inoxydable de base Cut and attach Top and Assemblez les panneaux côte àBottom côte. de 2Pautas 1/4" quefactory se incluyen enpanel. el juego drilled holes on básicas para2-1/4 po fournies dans le nécessaire de Two Wide Ancho doble Deux pièce l'assemblage pour de sujetadores de paneles para Retire los conectores grandes y vuelva a instalarlos el ensamblado de del panel. usando los dos agujeros pretaladrados fixations panneaux afin de fixer et Corte y fije los 39½"rieles superior e ensamblado. despour panneaux losel paneles Panel Assembly reforzar Retirez les grandes pièces de raccordementde et fixez-les renforcer l'assemblage. Note Tenga en cuenta Notez l'orientation de nouveau au moyen des deux trous Les assemblages comportent en orientationillustrés la orientación del de l'encochedes Taillez et fixez la main courante supérieurs dumuestran panneau qui ont été percés trou de serrure. of keyhole. agujero de la wn here are configurations using Las ilustraciones pièces supérieures. Il est possible à l'usine. cerradura. Three Wide Ancho triple Trois pièces de configuraciones con topes. También Assemble Panels side by side. pper. 2 and 3 High Panels can également d'assembler des panneaux One Wide Ancho sencillo Une piè se pueden conectar 2 y 3 paneles 59" be connected together as à deux ou à trois carreaux de hauteur Conecte los paneles lado a lado. 20" 20" altos a medida que se adquieran. hased. (vendus séparément). *Use tornillos de acero inoxidable Insert male into female. Slide down until flush with adjacent panel Assemblez leslospanneaux côte à côte.*Utilisez les vis en acier inoxydable de 2 1/4" stainless steel screws Introduzca elAncho extremo macho en el extremo hembra. Deslícelo ha 3. Connect last asse de 2 1/4" que se incluyen en el juego Four Wide cuádruple Quatre ded in the Panel Clip set to hasta que quede al ras del doble panel adyacente. Deux pi 2-1/4 po fournies dans le nécessaire de Twoabajo Wide Ancho de sujetadores de paneles para 78½" re and strengthen the assembly. into Slide down until with Insérez les female. pièces de raccordement mâles dansflush les pièces fixations pour panneaux afin de fixer etInsert male 39½" reforzar el ensamblado. adjacent depanel. raccordement femelles. Faites glisser le panneau de renforcer l'assemblage. vers le bas jusqu'à ce qu'il soit au même niveau que ere are configurations using r. 2 and 3 High Panels can connected together as ed. /4" stainless steel screws in the Panel Clip set to sic Guidelines nd strengthen the assembly. + = x2 3 Introduzca el extremo le panneau adjacent. macho en el extremo hembra. Deslícelo hacia abajo hasta que quede al ras del panel adyacente. Do not remove Small Connectors. Fig. 2 Assemble Panels side by side. Conecte los paneles lado a lado. R Three Wide Ancho triple No retire los conectores Insérez les pièces de raccordement mâles dans les pequeños. pièces de raccordement femelles. Faites glisser le Trois pièce 59" panneau vers le bas jusqu'à ce qu'il soit au même Note wood piece at bottom prevents collection of water. Ne retirez pas les petites pièces niveau que le panneau adjacent. de raccordement. de agua. Panel Assembly with S4evita- la2acumulación 1/4” Wood Prenez note que la pièce en bois située auby bas de chaque élémentin Screws locations indicated arrows de l'assemblage empêche l'accumulation d'eau. the direction of the arrow. (Fig. 2) Four Wide Assemblez les Note panneaux 3. Secure R-Top and Bottom Rails to côte à côte. que la pieza de madera inferior Ancho cuádruple Qua 78½ Insert male into female. Slide down until flush with adjacent panel. Secure with Screws*. Use factory drilled holes. *R- Top and Bottom Rails will overhang Asegure el ensamblado tornillos*. Use los agujeros pretaladrados. Introduzca el extremo macho en el extremo hembra. Deslícelo hacia usando 3. Connect last assembled panels to make a fence section. Fixez l'assemblage au moyen de vis.* Servez-vous des trous prépercés à l'usine. 1/4” on either side of panel. abajo hasta que quede al ras del panel adyacente. x2 Los torn y se incluyen *Les vis sont celles de 2-1/4 po en acier inoxydable qui sont fournies dans le *R- Top and Bottom Rails may need to les pièces de raccordement mâles dans les pièces be cutFaites to size ordement femelles. glisserindicated le panneau in material list below. bas jusqu'à ce qu'il soit au même niveau que panel_cap_labels_19x9.5.indd 7 male connector Los rieles superior e inferio Top and Bottom Rail will the male connectors the outside the Fije el tope in (It is recommended to use a Mitre Box a cadaoflado. overhang 1/4"on eitherfrom side. C. Remove conector panel assembly. masculino en los agujeros pretaladra Attach Top with Screws* Insert male into female. Slide down until flush with adjacent panel. or Mitre Saw) Quitethrough los conectores del exterior de ladeje un espacio de inferior, factorymasculinos drilled holes. connecte asamblea de panel. mâle de lo tornillos* y los bordes On Bottom, space Screws* el extremo macho en el extremo hembra. Deslícelo hacia 3. Connect last assembled panels to make a fence section. 4. RepeatIntroduzca to create two walls. Enlever les connecteurs mâles de l'extérieur de 4" from edges of panels. abajo hasta que quede al ras del panel adyacente. l'assemblée de panneau. eau adjacent. short male connector érez les pièces de raccordement mâles dans les pièces accordement femelles. Faites glisser le panneau s le bas jusqu'à ce qu'il soit au même niveau que anneau adjacent. Top and R Bottom Rail will overhang 1/4"on either side. 1/4" Attach Top with Screws* through factory drilled holes. On Bottom, space Screws* 4" from edges of panels. #8- 2 1/4” Wood Screws 1/4" 2x R Top & Bottom Rail at 3’ 3 1/2” (1m) 20x 2x R Top & Bottom Rail at 2’ 1/4” (0.62m) Screws* are 2 1/4" stainless steel included in Panel Clip set. S4 conector masculino corto Los rieles superior e in le connect a cada lado. mâle Fije elcourt top en los agujeros pretala inferior, deje un espac tornillos* y los bordes d Los tornillos* son de acero inoxidable de 2 1/4" y se incluyen en el juego de sujetadores de paneles. 10 1/4" } *Les vis sont celles de 2-1/4 po en acier inoxydable qui sont fournies dans le nécessaire de fixations pour panneaux. 4" Step 6- Attach Panel Clips Back posts 1. On a flat surface place P- 4x4 Post on its side and position Panel Clips in locations indicated in Figures 1 and 1A. Ensure Panel Clips are oriented as shown in Diagrams! Fig. 2 2. Panel Clips should be placed in the centre of the post or the leading edge of the clip should be 1” or 2.54cm away from the side of the post as shown in Fig. 2. 3. With Panel Clips in place, mark screw holes with a pencil and pre-drill holes with a 1/8” drill bit. (Not provided) 1” (2.54cm) Pre-drill holes and secure with S7- #8 x 1 1/2” Wood Screws 4. Secure Panel Clips in locations indicated in figure 1 and 1A with S7- #8 x 1 1/2” wood screws. Top View A C B Front View (1.88m) (1.03m) (0.25m) 4x P 4x4 Post 21x - Panel Clips 42x S7 #8 x 1 1/2” Wood Screw 11 D Step 7- Attach Panel Clips to Side Posts 1. On a flat surface place P- 4x4 Post on its side and position Panel Clips in locations indicated in Figures 1 and 1A. Ensure Panel Clips are oriented as shown in Diagrams! Use posts A and D from previous step. Fig. 2 2. Panel Clips should be placed in the centre of the post or the leading edge of the clip should be 1” or 2.54cm away from the side of the post as shown in Fig. 2. 3. With Panel Clips in place, mark screw holes with a pencil and pre-drill holes with a 1/8” drill bit. (Not provided) 1” (2.54cm) Pre-drill holes and secure with S7- #8 x 1 1/2” Wood Screws 4. Secure Panel Clips in locations indicated in figure 1 and 1A with S7- #8 x 1 1/2” wood screws. 5. Repeat for each post configuration. Top View Top View F E A Left Side View D RIght Side View Use posts A and D from previous step! (1.88m) (1.88m) (1.6m) (1.03m) (0.25m) 2x P 4x4 Posts (1.6m) (1.03m) (1.03m) (0.25m) (0.25m) 12x - Panel Clips 24x S7 #8 x 1 1/2” Wood Screw 12 (1.03m) (0.25m) This identifies information that requires special Check that set or assembly is properly level before proceeding. Step 9- Attach to attention. Panels Improper assembly couldPosts lead to an unsafe or dangerous condition. Use Use Pre-drill 1/8” & 3/16” Bit Where this is shown, 2 or 3 1. Place panel assembliesHelp on posts as post and the hole Helpshown (Fig.1) allowing a 4” gap between the bottom of the Pre-drill a pilot people are required to safely bottom edge of the bottom rail on the panelcomplete assembly. Note: This is best achieved by laying a 4x4 post on the screw before fastening the step. To avoid ground. Position panel assembly correctly in place. Once attached, stand the post and attach assembly with or lag to preventthe injury or damage to the completed posts and panel assembly pieces. splitting of wood. assembly make sure to get help! 2. With a 1/8” drill bit, predrill holes as shown in figure 2. Measure Check that assembly is square Square Tigh Bo 3. Fasten the panel assembles post and Panel S5- 1” Pan Head Screw provided in location of Distance to the Assembly before tightening bolts.Clips with a This indicates time to tighten bolts, but circles. (Fig. 1) not too tight! Do not crush the wood. This may create splinters and cause structural damage. Use a measuringFig. tape1 to assure Back View proper location. No Ye If Bolt protrudes beyond T-Nut CAUTION – Protrusion Hazard Once the assembly is tightened, watch for exposed threads. If a thread protrudes from the T-Nut, remove the bolt and add washers to eliminate this condition. Extra washers have been provided for this purpose. Use an extra Flat Washer Lag Assembly Proper Hardware Assembly Lag screws require drilling pilot holes to avoid splitting wood. Only a flat washer is required. For ease of installation liquid soap can be used on all lag-type screws. Lag Screw For bolts, tap T-Nut into hole with hammer. Insert the hex bolt through 4” (10.2cm) lock washer first then flat washer then hole. Because the assemblies need to Left Side View be squared do not completely tighten until instructed. Pay close attention to diameter of the bolts. 5/16” is slightly larger than 1/4”. Note: Wafer head bolts with blue lock tight or a bolt with a Ny-Lok nut do NOT require a lock washer. Before mounting use factory drilled guides to drill 1/8 Flat Washer Bolt Assembly Right Side View Hex Bolt Lock Washer Flat Washer 6 Fig. 2. Predrill Holes and Fasten with S5- 1” Pan Head Screw 12x P 4x4 Post 30x S5 #10 x 1” Pan Screws 13 T-Nut (Hammer Do not cr This identifies information that requires special Check that set or assembly is properl 78½" attention. Improper assembly could lead to an before proceeding. 20" 20" unsafe or dangerous condition. Installer le Poteau 4 x 4 po et le Connector de Poteau 4 x 4 po. L’espace 4 x 4 po et la direction de Poteau Use entre Poteau Use Pre-drill 1/8” & 3/16” Bit Where this is shown, 2 or 3 connecteur et critical. Help Help Pre-drill a pilo people are required to safely before fasteni complete the step. To avoid or lag to prev injury or damage to the splitting of wo assembly make sure to get help! 20" Step 10- Layout Posts and 20" Connectors 1. Layout pergola bases in configuration shown in figure 1. *Pergola bases must be installed Measure on a flat and level surface. It is recommended the is structure secured to existing stone, Check that assembly square beSquare Distance Assembly concrete or deck with the Yardistry Post Base (YM21016) or equivalent hardware. before tightening bolts. This indicates time to tighten bolts, b " Head " 177Screws 2. Install Post Top Connectors with S6- 1177 1/2” Pan provided. (Fig. 2)not Ensure theDo not crush the wood. too tight! Use a measuring tape to assure direction of the Post Top Connector is the same direction as indicated by the arrows in figure 1. This may create splinters and cause proper location. structural damage. 78½" No 78½" If Bolt protrude beyond T-Nut CAUTION – Protrusion Hazard Once the assembly is tightened, watch for exposed threads. If a thread protrudes from the T-Nut, remove the bolt and add washers to eliminate this condition. Extra washers have been provided for this purpose. 20" 132½" Proper Hardware Assembly Lag screws require drilling pilot holes to avoid splitting wood. Only a flat washer is required. For ease of installation liquid soap can be Fig.used 1 on all lag-type screws. Install on a flat andhole level surface! For 20" bolts, tap T-Nut into with hammer. Insert the hex bolt through lock washer first then flat washer then 78½" hole. Because the assemblies need to be squared do not completely tighten until instructed. Pay close attention to diameter of the bolts. 5/16” is slightly larger than 1/4”. Note: Wafer head bolts with blue lock tight or a bolt with a Ny-Lok nut do NOT require a lock washer. Use an extra Flat Washer Lag Assembly Lag Screw 20" 20" Flat Washer Bolt Assembly Hex Bolt Lock Washer Flat Washer 6 Fig. 2 - Attach Post Top Connectors 5 Head Screws. with S6- 1 1/2” Pan 24x S6 1 1/2” Pan head Screws 6x - Post Top Connector 14 Be use gu Step 11- Assemble Front and Back Beams 1. Secure two Z-2 x 6 x 66 5/8” Beams together with H0-1/4" x 1 1/4" Wafter Bolts as shown in Figure 1. Note: Wafer Bolt assembly in diagram below. 2. Attach Y-1 x 6 x 11" Plaque with S1- #8 - 1 1/2" Wood Screws as shown in Fig. 1. 3. Complete Z- Front Beam by securing two Z-2 x 6 x 66 5/8” Beams and two D-2 x 2 x 40” Brace with 1/4 x 2½” Hex Lag Bolt and S3- #12 x 3” Wood Screws as shown in Figure 1. Note: Hex Lag Bolt assembly in diagram below. 4. Assemble A- Back Beam by attaching one A-2 x 6 x 80 1/8” Beam and two D-2 x 2 x 40” Brace with 1/4 x 2½” Hex Lag Bolt and S3- #12 x 3” Wood Screws as shown. Note: Hex Lag Bolt assembly in diagram below. 1 (1.11m) Fig. 1- Laminate Front Beam Z S1 5 43 8 " H0 x4 x4 D 2½ Z Z Y Wafer Bolt Assembly Fig. 2 - Front Beam 2 Wa fer Bolt Drill 1/8" holes Flat Washer Taledre agujeros piloto de 1/8" S3 Pre-drill all holes using Percez avante-trous a 1/8” drill bit before deinstalling 1/8 po (3.2mm) screws. x16 A Fig. 3 - Back Beam 2½ 1 20 8 " (0.51m) 3 Predrill Pilot Holes for Hex Lag He x Bolt Z D 2½ Predrill 1/8” pilot hole 6 Posts, do not cut! Use factory drilled Flat Washer 6 Postes, no corte! hole as a guide 68x Poteaux, ne coupez pas! 4x1/4" x 1 1/4” Wafer Bolt 1/4 x 2 1/2” Hex Lag Bolt w/ 2½ 16x S3 H0 washers S1 assembly #12- 3” Wood Screw 2x 4x T- Nut Z 2 x 6 x 66 5/8” Beam #8- 1 1/2” Wood Screw Cut - Corte - 15 Taillez 1x A 2 x 6 x 80 1/8” Beam 4x D 2 x 2 x 40” Brace 1x Y 1 x 6 x 11” Plaque A B B B Step 12- Mounting Beams to Connectors 1 6 Posts 6 Postes 6 Poteaux B F B 4 Posts 4 Postes 4 Poteaux 1. Attach two B- 2 x 6 x671Posts 5/8" Beams to Postes Post Top Connectors6with WH-7/16" Hex Bolt as shown in Fig.61 Poteaux and 1A. 1 1 1F FB Fig. 1 B 2 B 2 Fig. 1A G A E B 2. Attach two F-F2 x 6 x 16 3/4" Beams Ends to Post Top Connectors with WH7/16" Hex Bolt as shown in Fig. 1 and 1A. G E B 3. Attach one A-BBack Beam and one ZFront Beam to Post Top Connectors with WH-7/16" Hex Bolt as shown in Fig. 2 and 2A. 4. Attach four H- 2 x 6 x 13 1/2" Beam Ends to Post Top ConnectorsAwith WH-7/16" Hex Bolt as shown in Fig. 2 and 2A. Z 2 2 5. Attach Z1two E- 2 x 6 x 21 5/8" Beams to Post Top Connectors with WH-7/16" Hex GBolt as shown in Fig. 2 and 2A. G G 2A E Z G E 2 Fig. 2 H G A A Drill 1/4” holes forE bolts E G using holes in Post Top Connector as guides Z G G Z1 Taladreagujerosde1/4" para los pernos usando los agujeros delconector superior de poste como guía Percez des trous de 1/4 po (6,35 mm) pour les boulons en utilisant les trous des connecteurs de bout de poteau comme guides H G Fig. 2A Drill 1/4” holes for bolts using holes in Post Top Connector as guides 7 2x B 2 x 6 x 71 5/8” Beams 2x 2x F 2 x 6 x 16 3/4” Beam Ends 48x WH 7/16" Hex Bolt w/ Nut 4x H 2 x 6 x 13 1/2” Beam Ends 16 E 2 x 6 x 21 5/8” Beams Taladreagujerosde1/4" para los pernos usando los agujeros delconector superior de poste como guía Percez des trous de 1/4 po (6,35 mm) pour les boulons en utilisant les trous des connecteurs de bout de poteau comme guides 12 3 4" S2 Step 13- Installing Pergola Roof x18 6 Posts 6 Postes 6 Poteaux C x9(32cm) 12 3 4" Fig. 2 6 Posts 6 Postes 6 Poteaux S2 Fig. 1 S2 x18 12 3 4" S2 Fig. 1A x14 2. Allow for a 12 3/4” or 32cm gap between each Trellis. (outside face to outside face) 3. Fasten Trellis roof to beams with S2- #8 x 3” Wood Screws. Fig. 1 &1A S2 12 3 4" 1. Layout nine C-5/4 x 4 x 59 3/4" Trellis on the beams, centering the middle beam as shown in figure 1. C x7 12 3 4" S2 x14 C x7 S2 9x C 5/4 x 4 x 59 3/4" Trellis 18x S2 #8 x 3” Wood Screws 8 4 Posts 4 Postes 4 Poteaux 17 1 3 S2 C x9 S2 x18 C x9