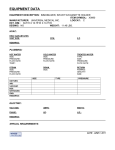

Download Calibration & Clinical Measurements in Computed Tomography

Transcript