Download Senior Design II Report - University of Central Florida

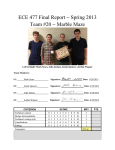

Transcript