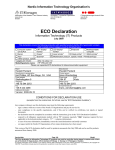

Download Draft for Certification Criteria of Eco Mark Product Category

Transcript