Download DOC-APEXMAN16 Rev10.indd - Mass Flow & Pressure Measurement

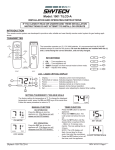

Transcript