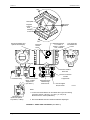

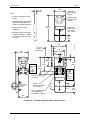

Download USER`S MANUAL XTC Critical Pressure Transmitters Model 345

Transcript